| Pages:

1

2

3

4 |

joseph6355

Hazard to Others

Posts: 144

Registered: 23-8-2017

Member Is Offline

Mood: Nitrated

|

|

Quote: Originally posted by Bert  |

| Quote: |

I'm trying to find a thinner that contains n-heptane but so far no luck.

|

| Quote: |

I can't find PIB neither any product that contains it and allows its extraction.

|

You live in a country without gasoline, Colman camping fuel or any glue board type sticky traps.

Sounds like a nice place, no air pollution or vermin.

[Edited on 5-10-2018 by Bert] |

I didn't say anything about the solvent, but since you mentioned it, does it have to be pure heptane or I can use the purest gasoline I can find? I

also don't own a distilling apparatus.

Any rat trap will yield PIB?

I found a fly trap. The description says that it is a layer of plastic with PIB to make it sticky.

PIB should be dissolved in something. It must be mineral oil or some other type of oil, I just don't know what it is.

Quote: Originally posted by Fulmen  | | Nonsense, I'm sure you can find PIB somewhere. Self-vulcanizing tape should be available, I got a very nice product from it. I don't remember which

solvent I used, but I'm fairly sure it was an aromatic. Xylene should work. Just don't shake or stir the tape too much, the PIB will leech out of the

tape leaving a soft, black rubbery mass. Breaking it up only causes it to disperse in the thick PIB-solution, and it's not something you can filter

easily. So just let it stand for a few days and decant, the PIB can be precipitated out by adding acetone. |

I have found plenty of self-vulcanizing tapes, but they are all EPR based. I haven't found a single one that contains PIB.

At least the solvent issue is "solved".

Oh, hello!  |

|

|

Bert

Super Administrator

Posts: 2821

Registered: 12-3-2004

Member Is Offline

Mood: " I think we are all going to die. I think that love is an illusion. We are flawed, my darling".

|

|

Perhaps your best course of action is to read a lot more. Search on GOOGLE with sciencemadness.org and your topic of interest, rather than the site

search engine.

Look up SDS or MSDS for an over the counter product to find out what the ingredients are.

The answers to every question you have asked are here already, take the time and make the effort to look for them. Then ask questions- in the future,

please give links or describe your starting sources when asking. Because it looks like you are not trying otherwise.

Rapopart’s Rules for critical commentary:

1. Attempt to re-express your target’s position so clearly, vividly and fairly that your target says: “Thanks, I wish I’d thought of putting it

that way.”

2. List any points of agreement (especially if they are not matters of general or widespread agreement).

3. Mention anything you have learned from your target.

4. Only then are you permitted to say so much as a word of rebuttal or criticism.

Anatol Rapoport was a Russian-born American mathematical psychologist (1911-2007).

|

|

|

joseph6355

Hazard to Others

Posts: 144

Registered: 23-8-2017

Member Is Offline

Mood: Nitrated

|

|

Quote: Originally posted by Bert  | Perhaps your best course of action is to read a lot more. Search on GOOGLE with sciencemadness.org and your topic of interest, rather than the site

search engine.

Look up SDS or MSDS for an over the counter product to find out what the ingredients are.

The answers to every question you have asked are here already, take the time and make the effort to look for them. Then ask questions- in the future,

please give links or describe your starting sources when asking. Because it looks like you are not trying otherwise.

|

Thanks, Bert.

I'm afraid of openly disclosing my location. People have stopped helping me when I did that.

The fact that I'm very amateur also doesn't help. I feel like people are afraid of teaching me anything.

My material sources, as I said, are caulk and a fly trap, which I'm uncertain if I can separate PIB from. I provided the chemicals are the

concentrations for the caulk. I didn't upload the datasheet because its not in english, I figured that people wouldn't understand it since its an

english-speaking forum.

I'm trying to get in contact with a manufactures to see if he is willing to sell me PIB in small quantities, but so far I haven't heard of them.

I have been trying hard to stay away from TNP because its very toxic.

I'm getting kind of insecure to post here, its like I'm doing something wrong, I don't know.

Oh, hello!  |

|

|

greenlight

National Hazard

Posts: 763

Registered: 3-11-2014

Member Is Offline

Mood: Energetic

|

|

You can also use polybutene bird repellent as binder with motor oil or methyl ricinoleate as plasticizer and roll to incorporate. I have PE with

density 1.45 from this method.

Here is the self amalgamating tape for LL's method which also work well. It is not as high density but much softer and doesn't fall apart anywhere

near as easy as the PB plastic. I just put a metre of it in some white spirits and store it like that and pour and evap solvent when using. Link

here:

https://m.ebay.com.au/itm/Polyisobutylene-Self-Amalgamating-...

Don't try to cast the ETN for safety reasons IMO.

Your not doing anything wrong but this has been discussed so just search something like "plastic explosive sciencemadness.com" and it will come up

with existing threads or use the search engine on the actual site here.

|

|

|

Bert

Super Administrator

Posts: 2821

Registered: 12-3-2004

Member Is Offline

Mood: " I think we are all going to die. I think that love is an illusion. We are flawed, my darling".

|

|

Anyone tried this variety?

Intertape 5517, on Amazon less than $3.00/.75"X22' roll

Rapopart’s Rules for critical commentary:

1. Attempt to re-express your target’s position so clearly, vividly and fairly that your target says: “Thanks, I wish I’d thought of putting it

that way.”

2. List any points of agreement (especially if they are not matters of general or widespread agreement).

3. Mention anything you have learned from your target.

4. Only then are you permitted to say so much as a word of rebuttal or criticism.

Anatol Rapoport was a Russian-born American mathematical psychologist (1911-2007).

|

|

|

roXefeller

Hazard to Others

Posts: 463

Registered: 9-9-2013

Location: 13 Colonies

Member Is Offline

Mood: 220 221 whatever it takes

|

|

Never seen it before. Seems worth a look. Anyone have personal experience with rubber cement. Dr Liptakov's videos look like a jar of cement when

he's done.

|

|

|

joseph6355

Hazard to Others

Posts: 144

Registered: 23-8-2017

Member Is Offline

Mood: Nitrated

|

|

Quote: Originally posted by greenlight  | You can also use polybutene bird repellent as binder with motor oil or methyl ricinoleate as plasticizer and roll to incorporate. I have PE with

density 1.45 from this method.

Here is the self amalgamating tape for LL's method which also work well. It is not as high density but much softer and doesn't fall apart anywhere

near as easy as the PB plastic. I just put a metre of it in some white spirits and store it like that and pour and evap solvent when using. Link

here:

https://m.ebay.com.au/itm/Polyisobutylene-Self-Amalgamating-...

Don't try to cast the ETN for safety reasons IMO.

Your not doing anything wrong but this has been discussed so just search something like "plastic explosive sciencemadness.com" and it will come up

with existing threads or use the search engine on the actual site here. |

Thanks!

I found a product for sealing headlamps in cars.. It is "butyl-rubber" based.

From the pictures I can see that they separate the layers to prevent the rubber from fusing with itself.

Do you guys think its worth a try?

How long should I leave it in heptane before using? Can I speed things up by applying heat?

I'm looking for a density of at least 1.6 g/cm³ so I can obtain a high VoD (+7800 m/s)

Attachment: butse.webp (17kB)

This file has been downloaded 930 times

Attachment: butse2.webp (49kB)

This file has been downloaded 781 times

[Edited on 11/5/18 by joseph6355]

Oh, hello!  |

|

|

Bert

Super Administrator

Posts: 2821

Registered: 12-3-2004

Member Is Offline

Mood: " I think we are all going to die. I think that love is an illusion. We are flawed, my darling".

|

|

Rubber cement is natural latex from rubber trees, dissolved in a suitably fast evaporaring solvent in my experience. Certainly it COULD be used as a

binder for a plastic explosive, and at times it certainly has been so used.

One should look at the parameters which caused military and industrial plastic explosives manufacturers to make the choices they did.

Personally, I use rubber cement by the gallon can on movie and video sets as an accelerant for fire effects. Heptane is reasonably low in volatility,

allowing a bit of time from rigging the effect to lighting it, yet volatile and low enough flashpoint that it is responsive and reliable enough

regarding ignition for our uses.

Rapopart’s Rules for critical commentary:

1. Attempt to re-express your target’s position so clearly, vividly and fairly that your target says: “Thanks, I wish I’d thought of putting it

that way.”

2. List any points of agreement (especially if they are not matters of general or widespread agreement).

3. Mention anything you have learned from your target.

4. Only then are you permitted to say so much as a word of rebuttal or criticism.

Anatol Rapoport was a Russian-born American mathematical psychologist (1911-2007).

|

|

|

joseph6355

Hazard to Others

Posts: 144

Registered: 23-8-2017

Member Is Offline

Mood: Nitrated

|

|

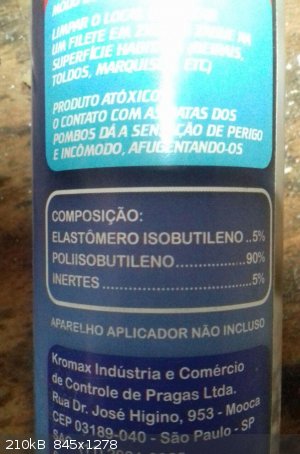

I deeply thank you guys. I found a rat trap that is composed by 90% PIB, 5% Isobutylene elastomer and 5% unknown inert materials.

Two questions.

1. Is the Isobutylene elastomer a concern?

2. PIB is soluble in many solvents, I'd like to know what solvents it isn't soluble in.

The plan is to wash the PIB with this solvent to try and remove the 5% unknown inert chemicals, and hope that it removes it.

I basically found concentrated PIB for sale as an OTC product. Most of rat traps contain smaller concentrations of PIB.

The product is manufactured locally by a small company that is based close to where I live.

Oh, is there a significant difference in performance between using Dibutyl phthalate or mineral/vegetable oil as the plasticizer?

Can I also phlegmatize ETN and also plasticize it at the same time? Will it make a difference? I was thinking about adding 1% petroleum jelly along

with the binder and plasticizer.

Edit: I found another one that is made from polybutene and an unknown "inert polymer".

[Edited on 11/5/18 by joseph6355]

Oh, hello!  |

|

|

Bert

Super Administrator

Posts: 2821

Registered: 12-3-2004

Member Is Offline

Mood: " I think we are all going to die. I think that love is an illusion. We are flawed, my darling".

|

|

No additional phlegmatizer is needed.

Rapopart’s Rules for critical commentary:

1. Attempt to re-express your target’s position so clearly, vividly and fairly that your target says: “Thanks, I wish I’d thought of putting it

that way.”

2. List any points of agreement (especially if they are not matters of general or widespread agreement).

3. Mention anything you have learned from your target.

4. Only then are you permitted to say so much as a word of rebuttal or criticism.

Anatol Rapoport was a Russian-born American mathematical psychologist (1911-2007).

|

|

|

joseph6355

Hazard to Others

Posts: 144

Registered: 23-8-2017

Member Is Offline

Mood: Nitrated

|

|

Quote: Originally posted by greenlight  | You can also use polybutene bird repellent as binder with motor oil or methyl ricinoleate as plasticizer and roll to incorporate. I have PE with

density 1.45 from this method.

Here is the self amalgamating tape for LL's method which also work well. It is not as high density but much softer and doesn't fall apart anywhere

near as easy as the PB plastic. I just put a metre of it in some white spirits and store it like that and pour and evap solvent when using. Link

here:

https://m.ebay.com.au/itm/Polyisobutylene-Self-Amalgamating-...

Don't try to cast the ETN for safety reasons IMO.

Your not doing anything wrong but this has been discussed so just search something like "plastic explosive sciencemadness.com" and it will come up

with existing threads or use the search engine on the actual site here. |

The MSDS from the bird repellent that I found says that it is composed by 80% polybutene and 20% of inert materials. It is gummy, transparent and

whitish in appearance.

If it only contains 20% by weight of oil, it should be a good plasticizing mix, right? By the looks of it, there isn't any dye or other solids in the

mixture.

Should I add 25-30% of extra methylricinoleate to the mixture?

This is looking good so far.

What velocities would I be getting at 1.45ish g/cm³, 7500 m/s?

Would dissolving the binder/oil in solvent and then adding the EM and mixing it until the solvent evaporates result in a better mixture instead of

just adding the EM to the gummy mass?

[Edited on 13/5/18 by joseph6355]

Oh, hello!  |

|

|

Rocinante

Hazard to Others

Posts: 121

Registered: 13-11-2017

Member Is Offline

Mood: No Mood

|

|

You need to roll that plastic on a suitable surface with some protective gear - crystal shaving inside that plastic is going to increase the density.

Also, our guys from Explosia have some success with re-crystalizing PETN from solutions that contain 1 % of stearic acid - they can make PETN crystlas

that are completely comparable to RDX. It might work for ETN, too.

|

|

|

joseph6355

Hazard to Others

Posts: 144

Registered: 23-8-2017

Member Is Offline

Mood: Nitrated

|

|

Quote: Originally posted by Rocinante  | You need to roll that plastic on a suitable surface with some protective gear - crystal shaving inside that plastic is going to increase the density.

Also, our guys from Explosia have some success with re-crystalizing PETN from solutions that contain 1 % of stearic acid - they can make PETN crystlas

that are completely comparable to RDX. It might work for ETN, too. |

"Shaving ETN" sounds dangerous. LOL.

What do you mean by "comparable to RDX"? You mean they are smaller?

Oh, hello!  |

|

|

Rocinante

Hazard to Others

Posts: 121

Registered: 13-11-2017

Member Is Offline

Mood: No Mood

|

|

Comparable in friction and impact sensitivity to RDX.

Shaving referes to the plastic itself, you take 1 g piece of your plastic and you roll it with a wooden cylinder on a smooth surface. I've never hear

of an accidental detonation doing that but be sure to wear earpro, gloves and body protection (leather, kevlar...) - one pair of polycarbonae glasses

isn't enough, face shield + glasses should do the trick

|

|

|

joseph6355

Hazard to Others

Posts: 144

Registered: 23-8-2017

Member Is Offline

Mood: Nitrated

|

|

Quote: Originally posted by Rocinante  | Comparable in friction and impact sensitivity to RDX.

Shaving referes to the plastic itself, you take 1 g piece of your plastic and you roll it with a wooden cylinder on a smooth surface. I've never hear

of an accidental detonation doing that but be sure to wear earpro, gloves and body protection (leather, kevlar...) - one pair of polycarbonae glasses

isn't enough, face shield + glasses should do the trick |

But the ETN crystals will scratch against each other inside the putty mass, right?

Wouldn't pressing the putty be safer than rolling?

The putty will be homogeneous anyway, because I'll dissolve the plasticizing mixture in a solvent and add the EM bit by bit while mixing.

I was also thinking about adding a dye to mimic Semtex, just for the looks.

Oh, hello!  |

|

|

Rocinante

Hazard to Others

Posts: 121

Registered: 13-11-2017

Member Is Offline

Mood: No Mood

|

|

I don't think that pressing would increase the density like rolling. Ys, the crystals are going to scratch against each other. Yes, dye is OK.

You can easily reach 1.5 and 7500 m/s+ with ~ 225 kbar. Most Semtex formulatios are near 1.45 and 180 - 220 kbar. There is a blakc one, PlNp 10 - 85 %

PETN, Red and Yellow - 80 % RDX/PETN mix. Your plastic is likely to be slightly more powerful - but you're not likely to get to 1.5 without rolling.

Using 2 crystals sizes prior to plastification is a good practice, too - higher density, you may use 20 % large crystlas and 80 % of fine crystals.

|

|

|

joseph6355

Hazard to Others

Posts: 144

Registered: 23-8-2017

Member Is Offline

Mood: Nitrated

|

|

Quote: Originally posted by Rocinante  | I don't think that pressing would increase the density like rolling. Ys, the crystals are going to scratch against each other. Yes, dye is OK.

You can easily reach 1.5 and 7500 m/s+ with ~ 225 kbar. Most Semtex formulatios are near 1.45 and 180 - 220 kbar. There is a blakc one, PlNp 10 - 85 %

PETN, Red and Yellow - 80 % RDX/PETN mix. Your plastic is likely to be slightly more powerful - but you're not likely to get to 1.5 without rolling.

Using 2 crystals sizes prior to plastification is a good practice, too - higher density, you may use 20 % large crystlas and 80 % of fine crystals.

|

Man, that sucks. :\

Its like there isn't a "safe" way to achieve high densities.

I'll use 10% binder + 90% ETN recrystallized from Ethanol.

Btw, can gasoline or any other solvent attack ETN or decompose it in any way?

Is it okay to leave plasticized ETN in contact with metals like steel or copper?

[Edited on 14/5/18 by joseph6355]

Oh, hello!  |

|

|

Rocinante

Hazard to Others

Posts: 121

Registered: 13-11-2017

Member Is Offline

Mood: No Mood

|

|

Yes, recrystalized or double-recrystalized ETN plastic that is free of acid is quite safe. You can roll small bits and you can use a very thick wooden

cylinder - very little risk even in case of detonation (+ body protection). Gasoline is unlikely to decompose ETN.

|

|

|

joseph6355

Hazard to Others

Posts: 144

Registered: 23-8-2017

Member Is Offline

Mood: Nitrated

|

|

Quote: Originally posted by Rocinante  | | Yes, recrystalized or double-recrystalized ETN plastic that is free of acid is quite safe. You can roll small bits and you can use a very thick wooden

cylinder - very little risk even in case of detonation (+ body protection). Gasoline is unlikely to decompose ETN. |

Sorry I didn't report back, I was waiting for the bird repellent to arrive.

As you can see, it is 90% polyisobutylene, 5% isobutylene elastomer (aka rubber) and 5% inert materials.

The consistence of the repellent is of a very thick and viscous paste. It is opaque and milky in color.

I prepared 1.1g of the repellent and 1g of mineral oil + 20g of dough. I dissolved everything in gasoline and it is drying now.

At first I thought that the mineral oil wasn't thick enough to make it like a putty, but now it is starting to look and feel like a plasticized solid.

I can't wait to see how it is going to turn out when I make ethanol free gasoline and use a proper plasticizer.

The repellent weighs 265 g of net product per canister and it costs about 4.55 usd.

Do you guys think that it is a better alternative to the SCAPA tape? If there is any oil in it, it is limited to the 5% inert materials, and it is

very cheap for the amount of PIB that it contains.

Oh, hello!  |

|

|

roXefeller

Hazard to Others

Posts: 463

Registered: 9-9-2013

Location: 13 Colonies

Member Is Offline

Mood: 220 221 whatever it takes

|

|

Quote: Originally posted by roXefeller  | | It might extract it if you find a suitable solvent. But will the molecular weight of the extracted PIB be what you are hoping for? Dr Liptakov did a

couple videos comparing PIB from different sources and showed the European tape SCAPA to perform better, I presume it had a higher molecular weight.

|

To follow up on this statement with some references, I'm attaching two patents. The first is the old patent for RDX PBX compositions. It states

that the preferential PIB polymer molecular weight is between 100,000 and 140,000. The second patent in the background of prior art details the

physical properties of various PIB polymer molecular weights. The cold flowing and tacky polymer is in the range of 40,000 and 100,000. The low tack

rubbery polymer without cold flow is in the higher range. This is the sample that Dr Liptakov has identified. I suspect the formulators chose this

because it had some tack for adhesion, but lacked the cold flow which is essentially fluid strain velocity at moderate shear stress. While rubber

that doesn't cold flow will exhibit a solid strain field without velocity under shear stress.

This isn't to say that other polymers couldn't replace PIB. I've seen numerous reports from Lawrence Livermore that propose new compositions.

Bert, the tape that you asked about above, I tested some of it. It swells in the heptane much like the silicone based tape. It doesn't dissolve like

the SCAPA tape.

Attachment: US3321341.pdf (166kB)

This file has been downloaded 500 times

Attachment: US3050497.pdf (533kB)

This file has been downloaded 470 times

|

|

|

joseph6355

Hazard to Others

Posts: 144

Registered: 23-8-2017

Member Is Offline

Mood: Nitrated

|

|

Quote: Originally posted by roXefeller  | Quote: Originally posted by roXefeller  | | It might extract it if you find a suitable solvent. But will the molecular weight of the extracted PIB be what you are hoping for? Dr Liptakov did a

couple videos comparing PIB from different sources and showed the European tape SCAPA to perform better, I presume it had a higher molecular weight.

|

To follow up on this statement with some references, I'm attaching two patents. The first is the old patent for RDX PBX compositions. It states

that the preferential PIB polymer molecular weight is between 100,000 and 140,000. The second patent in the background of prior art details the

physical properties of various PIB polymer molecular weights. The cold flowing and tacky polymer is in the range of 40,000 and 100,000. The low tack

rubbery polymer without cold flow is in the higher range. This is the sample that Dr Liptakov has identified. I suspect the formulators chose this

because it had some tack for adhesion, but lacked the cold flow which is essentially fluid strain velocity at moderate shear stress. While rubber

that doesn't cold flow will exhibit a solid strain field without velocity under shear stress.

This isn't to say that other polymers couldn't replace PIB. I've seen numerous reports from Lawrence Livermore that propose new compositions.

Bert, the tape that you asked about above, I tested some of it. It swells in the heptane much like the silicone based tape. It doesn't dissolve like

the SCAPA tape.

|

Is it possible to measure the molecular weight of the PIB that I have available?

[Edited on 24/5/18 by joseph6355]

Sorry, I hadn't seen the attached files.

"Polyisobutylene with a molecular weight of from about

1,000 to 5,000 is an oil. The polyisobutylene with a molecular weight of from about 5,000 to 18,000 is of a consistency similar to chewing gum and the

polyisobutylene of molecular weight of about 18,000 to 40,000 is a semi-solid, tacky, plastic mass. The polyisobutylene with a molecular weight of

from about 40,000 to 100,000 is a tacky elastic solid that has cold flow properties. The polyisobutylene of about 100,000 to 300,000 molecular weight

is a rubber-like, strong elastic polymer of low tacki

ness, with no cold flow properties at room temperature."

It appears that my PIB ranges from 18000 to 100000. Maybe I could upload a video and ask for opinions on it.

[Edited on 24/5/18 by joseph6355]

Oh, hello!  |

|

|

joseph6355

Hazard to Others

Posts: 144

Registered: 23-8-2017

Member Is Offline

Mood: Nitrated

|

|

Ok, it appears that I have found a good source of PIB.

Here is a video of 8.7 % PIB and 91.3 % flour.

https://vimeo.com/276031986

The password is the name of this forum without spaces or capital letters.

The product is a tire repair patch.

https://i.imgur.com/EKNnYLq.jpg

https://i.imgur.com/zIM5JTk.jpg

The extracted PIB is a very dark brownish red, it doesn't stick as rat trap glue does, but it still does to a certain degree. The PIB alone smells

like rubber, and you can stretch it like bubble gum to a certain point, then it breaks. It is not malleable, it is more like a chunk of rubber that

needs strong pressure to conform or stretch.

The data sheet says it contains PIB, butyl rubber, oil and fibers.

I dissolved 60 patches in about a liter of Hexane. The PIB dissolves, but the fibers stay as a solid, which can be easily picked out by hand and

squeezed.

One problem that I have encountered is that the putty isn't a solid like modeling clay. It feels kind of porous after you break it in half or play

with it.

https://i.imgur.com/GjRrNsE.jpg

But you can make it more solid by compacting it with your hands. Maybe thats because the flour is rather powderish, more than fine sand.

It does not fall apart by itself and feels very solid after compacted.

https://i.imgur.com/DZQrc9g.jpg

https://i.imgur.com/v5Fpw1E.jpg

Would adding methylricinoleate help to improve it somehow?

The amount of PIB added is rather low. Increasing it to 15 % would help to make it more solid, I believe. And using actual crystals instead of very

fine grains would require less inerts.

Regarding methylricinoleate, can I use Ethanol instead of Methanol?

[Edited on 20/6/18 by joseph6355]

[Edited on 20/6/18 by joseph6355]

Oh, hello!  |

|

|

roXefeller

Hazard to Others

Posts: 463

Registered: 9-9-2013

Location: 13 Colonies

Member Is Offline

Mood: 220 221 whatever it takes

|

|

That sounds promising for the PIB you extracted. For the USA, I'll continue to source mine from tape I found on eBay.

| Quote: |

Regarding methylricinoleate, can I use Ethanol instead of Methanol?

|

Do you mean will ethylricinoleate work as a plasticizer? I don't know.

Or, Will ethanol produce methylricinoleate? No, it is a different functional you are estering with.

|

|

|

joseph6355

Hazard to Others

Posts: 144

Registered: 23-8-2017

Member Is Offline

Mood: Nitrated

|

|

Quote: Originally posted by roXefeller  | That sounds promising for the PIB you extracted. For the USA, I'll continue to source mine from tape I found on eBay.

| Quote: |

Regarding methylricinoleate, can I use Ethanol instead of Methanol?

|

Do you mean will ethylricinoleate work as a plasticizer? I don't know.

Or, Will ethanol produce methylricinoleate? No, it is a different functional you are estering with. |

How didn't I think about it? LOL.

I'll make sure to use Methanol instead. Thanks.

Oh, hello!  |

|

|

markx

National Hazard

Posts: 650

Registered: 7-8-2003

Location: Northern kingdom

Member Is Offline

Mood: Very Jolly

|

|

Quote: Originally posted by joseph6355  | Quote: Originally posted by roXefeller  | That sounds promising for the PIB you extracted. For the USA, I'll continue to source mine from tape I found on eBay.

| Quote: |

Regarding methylricinoleate, can I use Ethanol instead of Methanol?

|

Do you mean will ethylricinoleate work as a plasticizer? I don't know.

Or, Will ethanol produce methylricinoleate? No, it is a different functional you are estering with. |

How didn't I think about it? LOL.

I'll make sure to use Methanol instead. Thanks.

|

Actually regular motor oil also works very good as a plasticizer in combination with the high molecular weight PIB from tape. Just in case you are not

inclined to synthesize the ricinoleate esters, but it is an educational excercise on it's own to go through with it.

Use a 50/50 mix by weight of PIB/oil as a solution of known concentration and add in about 10% content to the material that you want to bind.

Exact science is a figment of imagination.......

|

|

|

| Pages:

1

2

3

4 |