DubaiAmateurRocketry

National Hazard

Posts: 841

Registered: 10-5-2013

Location: LA, CA, USA

Member Is Offline

Mood: In research

|

|

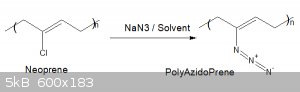

Poly-Azido-Prene from Neoprene

So similar to the synthesis of:

Glycidyl chloride polymer > GAP

and PVC to PVazide.

What about Polychloroprene to polyazidoprene?

Here is a possible route? any thoughts?

|

|

|

roXefeller

Hazard to Others

Posts: 463

Registered: 9-9-2013

Location: 13 Colonies

Member Is Offline

Mood: 220 221 whatever it takes

|

|

It would make sense seeing the chlorine as a leaving group. But does neoprene typically exhibit a reactivity to alkali salts? Does that chlorine

remain during crosslinking? I tried to briefly answer these myself, but I couldn't find anything obvious.

|

|

|

DubaiAmateurRocketry

National Hazard

Posts: 841

Registered: 10-5-2013

Location: LA, CA, USA

Member Is Offline

Mood: In research

|

|

Quote: Originally posted by roXefeller  | | It would make sense seeing the chlorine as a leaving group. But does neoprene typically exhibit a reactivity to alkali salts? Does that chlorine

remain during crosslinking? I tried to briefly answer these myself, but I couldn't find anything obvious. |

Thank you for your input. Hmmm, what do you mean by crosslinking? like after curing? Why would the chlorine not remain? thank you !

|

|

|

Bert

Super Administrator

Posts: 2821

Registered: 12-3-2004

Member Is Offline

Mood: " I think we are all going to die. I think that love is an illusion. We are flawed, my darling".

|

|

Crosslinking = vulcanization, adding other monomers is copolymerization.

Sulfur and heat is the classic crosslinking technology, developed by Goodyear and others back in the 1800s.

Crosslinking with thiocarbamide is a bit more modern, peroxides may be used as well. Ethylene thioureas are effective for crosslinking chloroprene

rubber.

You are interested in this for a composite rocket binder/fuel? With lighter elements than Sulfur for crosslinking, perhaps increasing isp? There is

also UV radiation based crosslinking, tough to do if you've doped the fuel grain with Carbon black to prevent IR penetrating the fuel grain and

accelerating the burn...

[Edited on 5-30-2018 by Bert]

Rapopart’s Rules for critical commentary:

1. Attempt to re-express your target’s position so clearly, vividly and fairly that your target says: “Thanks, I wish I’d thought of putting it

that way.”

2. List any points of agreement (especially if they are not matters of general or widespread agreement).

3. Mention anything you have learned from your target.

4. Only then are you permitted to say so much as a word of rebuttal or criticism.

Anatol Rapoport was a Russian-born American mathematical psychologist (1911-2007).

|

|

|

roXefeller

Hazard to Others

Posts: 463

Registered: 9-9-2013

Location: 13 Colonies

Member Is Offline

Mood: 220 221 whatever it takes

|

|

I'm not able to get smart about the specifics of neoprene at the moment, but my question was this: what is the process used to vulcanize or crosslink

the base polymer (not the monomer). Other polymer systems use a reactive element of the base polymer to initiate the crosslinking, such as double

bonds. After that is done the base polymer is less reactive and effectively a massive molecule(s). I suppose the author may be considering sourcing

the uncured polymer but will curing still require the chlorine or does it use the double bond?

[Edited on 30-5-2018 by roXefeller]

|

|

|

DubaiAmateurRocketry

National Hazard

Posts: 841

Registered: 10-5-2013

Location: LA, CA, USA

Member Is Offline

Mood: In research

|

|

Quote: Originally posted by Bert  |

Crosslinking = vulcanization, adding other monomers is copolymerization.

Sulfur and heat is the classic crosslinking technology, developed by Goodyear and others back in the 1800s.

Crosslinking with thiocarbamide is a bit more modern, peroxides may be used as well. Ethylene thioureas are effective for crosslinking chloroprene

rubber.

You are interested in this for a composite rocket binder/fuel? With lighter elements than Sulfur for crosslinking, perhaps increasing isp? There is

also UV radiation based crosslinking, tough to do if you've doped the fuel grain with Carbon black to prevent IR penetrating the fuel grain and

accelerating the burn...

[Edited on 5-30-2018 by Bert] |

we can hydroxylterminate the polychloroprene to form HTPCP, now if we add azide groups, it'd be HTPAP. Then it could be cured with isocyanates.

However, straight up polyazidoprene does not need crosslink to cure. cyanide groups can cure it, for example a small amount of polynitrile will cure

with the azide groups. the CN N3 forms a tetrazole ring.

[Edited on 30-5-2018 by DubaiAmateurRocketry]

|

|

|

DubaiAmateurRocketry

National Hazard

Posts: 841

Registered: 10-5-2013

Location: LA, CA, USA

Member Is Offline

Mood: In research

|

|

so, any other input if this reaction might work ?

|

|

|

UC235

National Hazard

Posts: 565

Registered: 28-12-2014

Member Is Offline

Mood: No Mood

|

|

It will not work. Vinylic halides are unreactive in SN1/SN2 type reactions which is what is being proposed here.

|

|

|

DubaiAmateurRocketry

National Hazard

Posts: 841

Registered: 10-5-2013

Location: LA, CA, USA

Member Is Offline

Mood: In research

|

|

Quote: Originally posted by UC235  | | It will not work. Vinylic halides are unreactive in SN1/SN2 type reactions which is what is being proposed here. |

How come PVC works? Thanks!

|

|

|

UC235

National Hazard

Posts: 565

Registered: 28-12-2014

Member Is Offline

Mood: No Mood

|

|

Despite the name, the chlorine atoms on PVC are not vinylic halides, but alkyl halides, which are quite reactive.

|

|

|