| Pages:

1

2 |

Bert

Super Administrator

Posts: 2821

Registered: 12-3-2004

Member Is Offline

Mood: " I think we are all going to die. I think that love is an illusion. We are flawed, my darling".

|

|

Electric matches, uniform resistance of bridge wires and reliability in series firing

I have been having a series of email communications with my main supplier of electric matches.

Apparently, the way many ematch manufacturers have dealt with the difficulty of providing a reliable product when series fired in fair numbers at

typical voltages (low voltage, less than 50 V DC in USA) has not been to focus on producing an electrically uniform product as far as resistance of

the bridge wire element- And a resulting uniform heating rate of the "first fire" composition, leading to all match head bridge wires imparting

sufficient energy to ensure function of the first fire BEFORE the first bridgewire wire opens due to electrical heating or heating from the match head

igniting and so opening the circuit, or the output from the firing set ends.

Rather, they have tweaked the first fire compositions to ensure sufficient sensitivity to thermal input that the match heads will function on the

ammount of current received, nearly regardless of how out of spec any individual resistance element may have been, leading to an early circuit

disconnection- Or to a large extent, the durarion of the applied firing pulse.

This equals a disturbingly frequent choice of what I would characterise as use of FUCKING INSANELY SENSITIVE FIRST FIRE COMPOSITIONS to compensate

for resistance of bridge wires being allowed to vary between .8 and 1.2 ohms. Yes, 20% higher or lower than the nominal spec of 1 ohm.

There is generally a relationship between thermal sensitivity and sensitivity to SHOCK/FRICTION/ELECTROSTATIC DISHARGE. The big three of accidental

ignition stimuli.

The upshot of this all being that the first fire of the variety of ematch we order for our larger series fired effects is different from the rest of

our inventory- And quite a bit more sensitive to accidental firing.

I am trying to convince the supplier to solve the series reliability problem through electrical and mechanical engineering along with production

rarionalization/materials science rather than chemical engineering aimed at senstizing the pyrogen.

|

|

|

Twospoons

International Hazard

Posts: 1327

Registered: 26-7-2004

Location: Middle Earth

Member Is Offline

Mood: A trace of hope...

|

|

You would have thought the simplest method would be resistance binning i.e. grading into 2% bin steps. Measuring and sorting is a pretty easy thing to

automate. Its done in the electronics component industry all the time. I would imagine the positive temperature coefficient of the bridge wire would

make the mismatch problem worse ( the hottest wire will have the highest resistance and therefore suck out more voltage from the string, and heat even

faster!)

Why do you series fire? Is it a question of practicality, in terms of connecting a bunch of e-matches together?

Helicopter: "helico" -> spiral, "pter" -> with wings

|

|

|

Sulaiman

International Hazard

Posts: 3727

Registered: 8-2-2015

Location: 3rd rock from the sun

Member Is Offline

|

|

As an electronic engineer, it seems stange to me;

electric matches and explosives = OK

>50 V = dangerous

CAUTION : Hobby Chemist, not Professional or even Amateur

|

|

|

Bert

Super Administrator

Posts: 2821

Registered: 12-3-2004

Member Is Offline

Mood: " I think we are all going to die. I think that love is an illusion. We are flawed, my darling".

|

|

The igniters have a nominal 1 ohm resistance and are specified to all fire from a minimum 1 amp current, produced by a minimum of 1V across them.

Some reasons for shooting in series-

1: The firing systems are current limited. If the system were NOT current limited, you could destroy it by firing into a dead short, welding contacts

of mechanical switches or overheating semiconductor switching-

You can't fire as many igniters in parallel as you can in series, you run out of current to divide among parallel igniters rather faster than you go

below 1 V across each igniter in a series . Additionally, the resistance of a group of igniters paralleled may go below that of the firing lines- Then

you are making more heat in your firing line than in your igniters... In a series, for a given firing line length, the more igniters you use the lower

the ratio of line to load resistance becomes, you are heating what you WANT to heat, not the supply line.

2: All the bridge wires will have the same current through them in a series circuit. Power in watts = I2R, the difference in heating due to

a maximum .4 ohm variation in resistance will be minor compared to the variations in current of these same somewhat varying resistance bridge wires in

parallel-

3: The system does a continuity check on each connected hit. A single BAD connection will keep a whole series from testing good, alerting the crew to

go back and locate/fix the problem. A single GOOD connection will cause a parallel to test as good.

|

|

|

Bert

Super Administrator

Posts: 2821

Registered: 12-3-2004

Member Is Offline

Mood: " I think we are all going to die. I think that love is an illusion. We are flawed, my darling".

|

|

I'm not worried about the voltages used endangering my crew!

I just want 100% of the igniters to fire.

Most systems for display fire works output 12 or 24V. The arbitrary distinction between low and high voltage in US electrical codes and the resulting

assumptions of know nothing authorities having jurisdiction DOES keep some idiots from trying to apply non pertinent regulations to my field setups-

I have had a fire inspector who thought he knew how to inspect my setup freak out at seeing western union splices with a piece of masking tape applied

to the bare wire junctions just laying on the ground- And he calmed down when I said it was 24V, low voltage DC. I guess he thought we would get

electrocuted if it rained?! He had no clue.

That system outputs a current limited 100ms pulse at 24V, our scab wires are not continuously energised like power transmission lines. Only reason we

bother to insulate the junctions with a bit of tape is to prevent shorting if the splices touch or are laying on a metal deck.

We DO use firing systems that run at higher voltages- One of our firing systems is a capacitor discharge type, it outputs around 250V for shooting

100+ igniters in series. THAT one could give you a noticable jolt, but why would one ever be in a position to?

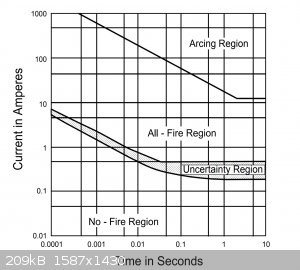

Our ematches have a maximum voltage rating as well as a minimum all fire spec, which is counterintuitive- You can cause an arc and blow the match head

apart without reliably igniting it too, see the attached graph.

[Edited on 5-3-2018 by Bert]

Attachment: Kosanke-ematch physical parameters.pdf (513kB)

This file has been downloaded 522 times

Attachment: Kos-614-633.pdf (935kB)

This file has been downloaded 988 times

[Edited on 5-3-2018 by Bert]

|

|

|

aga

Forum Drunkard

Posts: 7030

Registered: 25-3-2014

Member Is Offline

|

|

How many do you need to fire at the same time ?

Presumably this match thing sets off the device that shoots a rocket up, produces sparks etc.

|

|

|

Twospoons

International Hazard

Posts: 1327

Registered: 26-7-2004

Location: Middle Earth

Member Is Offline

Mood: A trace of hope...

|

|

Thanks for the explanation Bert. Those reasons all make perfect sense.

I can see another way to handle the issue, but it might need a little modification of the firing system.

If the firing system is set up to deliver a fixed current ( eg always 1A no matter what resistance it was working into) then it would be possible to

bridge each 1 ohm e-match with, say, 5 ohms externally. That way if the bridge burns out early, the 5 ohm external bridge can still pass current down

the string - provided the current driver of the firing system has enough voltage overhead to compensate for the increase in resistance. It could

probably be done with diodes too, but that would cost more, and you'd have the issue of making sure the polarity was correct on every e-match.

You would lose 1/6 of your current in the external 5 ohm bridge, but that could be compensated with a 17% increase in firing current, well within the

50:1 ratio of acceptable current shown in your graph.

Second idea: bridge each e-match with a capacitor. The capacitors would need to be sized to hold enough energy to guarantee firing. The fire control

would probably have to be a capacitive discharge type, with the stored energy tailored to the number of capacitors in the string (easy to do). The

string would charge instantly (or as near instant as makes no difference) with a high current pulse, with each string capacitor then dumping energy

into its own e-match. Since each match has its own energy store a premature break in the string wont matter.

[Edited on 5-3-2018 by Twospoons]

Helicopter: "helico" -> spiral, "pter" -> with wings

|

|

|

dave321

Harmless

Posts: 45

Registered: 22-11-2012

Member Is Offline

Mood: No Mood

|

|

bert,

some of the issues you mention are discussed in "high explosives and propellants" by Fordham

......"For any single fusehead, of course, the excitation time cannot exceed the lag time. If a number of fuseheads in series is to be fired

successfully, the shortest lag time of the fuseheads involved, which determines the application time, must exceed the longest excitation time present

in the circuit......"

pages 112 to 122

|

|

|

aga

Forum Drunkard

Posts: 7030

Registered: 25-3-2014

Member Is Offline

|

|

Adding a capacitor would introduce a store of energy.

Same as putting a battery in there of indeterminate charge.

The idea (presumably) is to be able to set up the firing mechanisms with as much Safety as possible.

If the capacitor happened to be charged at the time, the consequences might not be inconsequential, seeing as it could detonate what is basically an

explosive.

|

|

|

Twospoons

International Hazard

Posts: 1327

Registered: 26-7-2004

Location: Middle Earth

Member Is Offline

Mood: A trace of hope...

|

|

Adding a shorting link to a capacitor is a simple matter. Simpler than handling ematches made from really sensitive materials, which was Berts primary

objection. In fact it could actually add safety - if the entire system is wired with the shorting links in place surely that would reduce the risk of

accidental ignition.

It does require discipline - though I doubt there is any lack of discipline among pyrotechnicians (among old ones at least).

I keep thinking of better ideas after I hit [Post].

Each capacitor could have a bleed resistor permanently attached. Given the nominal 1 ohm of the ematch, the bleed could be just a few tens of ohms.

That would guarantee the capacitors were discharged when not in use, and not mess up a continuity check.

[Edited on 5-3-2018 by Twospoons]

[Edited on 5-3-2018 by Twospoons]

Helicopter: "helico" -> spiral, "pter" -> with wings

|

|

|

roXefeller

Hazard to Others

Posts: 463

Registered: 9-9-2013

Location: 13 Colonies

Member Is Offline

Mood: 220 221 whatever it takes

|

|

Bert, did you get any details about what pyrogen they were moving to toward that end? Or what ignition temperature they targeted for the pyrogen?

Aga, distal capacitor systems start with a discharged capacitor that is shunted until a power supply holds it high long enough to be fully charged.

I suspect they need to use sensitive fuse heads for that as well else they use massive capacitors in the blasting cap.

|

|

|

aga

Forum Drunkard

Posts: 7030

Registered: 25-3-2014

Member Is Offline

|

|

The problem with 'good ideas' where explosives are concerned is that anything unexpected tends to seriously damage or kill someone.

New ideas tend to come with baggage that the inventor never imagined could happen.

This universe is like that.

|

|

|

Twospoons

International Hazard

Posts: 1327

Registered: 26-7-2004

Location: Middle Earth

Member Is Offline

Mood: A trace of hope...

|

|

Well, we always start with a 'good idea', then comes a lot of rigorous testing to ensure it really is a 'good idea'. Thats how engineering is meant to

be done. And not just for explosives.

Though sometimes it can be hard to convince Management of that ...

Thats why seasoned engineers never tell the Sales department what they're working on.

Sorry, getting off topic Bert.

[Edited on 5-3-2018 by Twospoons]

Helicopter: "helico" -> spiral, "pter" -> with wings

|

|

|

sodium_stearate

Hazard to Others

Posts: 255

Registered: 22-4-2011

Location: guard duty at the checkpoint

Member Is Offline

Mood: No mask.

|

|

Speaking of "good ideas" and pyrotechnics, I am

again reminded of NASA's space shuttle program.

As many of you may recall, those vehicles used 2

solid-fueled reusable booster rockets.

Being reusable, those boosters had field joints where the

sections were assembled each time they were sent

back to Morton Thiokol for refueling.

Those field joints were poorly designed. They flexed

while the booster was in use, and on a bad day, the

internal fire could leak past the joint when the o-ring

would fail. After the Challenger disaster, a 2nd o-ring

was added to improve the seal.

The engineers at Thiokol had specifically warned everyone

involved against launching on that very cold morning.

That warning was very prudent, and another good idea.

But the guys at NASA had an even better idea:

We'll just go ahead and launch anyway.

Pyrotechnics and good ideas. So much for that.

The above story relates to the ematch thread because

it involves good ideas, long-term reliability, human

nature and shortcomings. These factors need to be

considered.

"Opportunity is missed by most people

because it is dressed in overalls and it

looks like work" T.A. Edison

|

|

|

Bert

Super Administrator

Posts: 2821

Registered: 12-3-2004

Member Is Offline

Mood: " I think we are all going to die. I think that love is an illusion. We are flawed, my darling".

|

|

One other issue: An ematch has to be CHEAP. Typically, less than $1.00 in USA, including about 10' of 26 gauge duplex wire.

If I use 6,000+ igniters for a choreographed show, this adds up by the end of the year.

The reason they turn up the sensitivity of the first fire to a degree where it will be fired by the coolest, most out of spec lowest resistance

bridgewire before the hottest, most out of spec highest resistance bridgewire melts and breaks the circuit instead of tweaking the electrical

characteristics to be more uniform and making the first fire JUST sensitive enough? It costs less than more precise manufacturing of the resistance

elements and more uniform assembly techniques (and/or tighter QC standards with more rejected units).

It is what they call a "low margin business".

| Quote: |

The engineers at Thiokol had specifically warned everyone

involved against launching on that very cold morning.

That warning was very prudent, and another good idea.

But the guys at NASA had an even better idea:

We'll just go ahead and launch anyway.

Pyrotechnics and good ideas. So much for that.

|

Well, the top administrators in any government run operation are essentially involved in politics. So if it is strongly implied to a politicized

technocrat that the president's handlers would REALLY like that shuttle launch that keeps being delayed and delayed yet again to coincide with his

second state of the union address? What are a few degrees farenheit out of some engineers spec compared to such a consideration.

[Edited on 7-3-2018 by Bert]

|

|

|

Vomaturge

Hazard to Others

Posts: 286

Registered: 21-1-2018

Member Is Offline

Mood: thermodynamic

|

|

What's ironic is that 5% resistors are available for pretty cheap:

https://www.amazon.com/-Projects-100EP5141R00-Ohm-Resistors-...

But when you need a heating element for something critical, where a hang-fire could be risky and an accidental ignition would be downright dangerous

it's 20% on either side? To be absolutely fair, the bridgewires of an e-match have to be smaller, and develop high temperature while embedded in

chemicals. But it still seems like they should be able to make them within 5%. How hard can it be?

If not, they (the manufacturer) should probably try twospoons' suggestion. Use automated equipment to sort them. Have maybe ten different types of "1

ohm" ignitors, sorted based on resistance. They all would work the same way, but the user could arrange it so that all the devices in a given string

were nearly identical. Then they might not need such a touchy composition.

|

|

|

Twospoons

International Hazard

Posts: 1327

Registered: 26-7-2004

Location: Middle Earth

Member Is Offline

Mood: A trace of hope...

|

|

5% resistors are cheap because of the volumes - in the billions annually. So its worth putting in the equipment. In fact 1% resistors are pretty cheap

too. Same reason.

I suppose Bert could buy a bunch of less sensitive ematches and sort them himself, but thats going to be a slow and costly process.

BTW those resistors you linked to, at 6c each, are actually pretty expensive! Industrially SMT resistors are around 0.2c or less - if you are buying

in reels of 20,000.

I remember years ago my boss told me not to pick up dropped resistors off the floor. It was actually cheaper to buy new ones than pay me to pick them

up!

[Edited on 7-3-2018 by Twospoons]

Helicopter: "helico" -> spiral, "pter" -> with wings

|

|

|

roXefeller

Hazard to Others

Posts: 463

Registered: 9-9-2013

Location: 13 Colonies

Member Is Offline

Mood: 220 221 whatever it takes

|

|

Typically when I read the blasters handbook, there is a number of detonators that causes a need for parallel circuit of series legs. At what point in

your shots do you go that way?

|

|

|

roXefeller

Hazard to Others

Posts: 463

Registered: 9-9-2013

Location: 13 Colonies

Member Is Offline

Mood: 220 221 whatever it takes

|

|

| Quote: |

To be absolutely fair, the bridgewires of an e-match have to be smaller, and develop high temperature while embedded in chemicals

|

When I consider the transient thermal conduction equations, I find the added chemicals to be insignificant to other factors. I can see a real energy

hurdle to get the wire to ignition temperature. Additionally the heat sink at the ends where the fine wire meets the lead wires. But my estimate of

thermal diffusivity of an organic molecule is far less, like 26 times less than the bridge wire. So the wire should effectively be isothermal at the

steady state amperage temperature while the first fire warms/ignites. The lead wire will likely cool the bridge more effectively.

|

|

|

Bert

Super Administrator

Posts: 2821

Registered: 12-3-2004

Member Is Offline

Mood: " I think we are all going to die. I think that love is an illusion. We are flawed, my darling".

|

|

Quote: Originally posted by roXefeller  | | Typically when I read the blasters handbook, there is a number of detonators that causes a need for parallel circuit of series legs. At what point in

your shots do you go that way? |

Commercial blasting with those $15-20 detonators is different. For that money, your caps are ACCURATELY made, also several varieties contain their own

small capacitor and timing circuit so they will charge from system, receive the start signal and then fire in their hole at correct time, regardless

of any surface activity or fly rock that may cut wires or signal cord.

Building implosion crews and commercial blasters doing really big shots may use series parallel wiring, but it is mostly due to physical layout of the

shots. Such crews also go out and check each series with a blasting safe galvanometer and then may ballance circuits by adding resistors to ensure

correct current to all branches.

Our igniters are stupid simple. They are just a bridgewire somehow connected to the firing wire, usually dipped in 2 layers of pyro chemicals- a

sensitive first fire mix, then a hot gas/hot particle producing one.

We NEVER do series/parallel. We wire in series ONLY, if you need something else on the same cue but at a different location, a digital programmable

controller and additional field module(s) which are cued to fire at same time with the same output can takes care of that as essentially two (or

however many are required) electrically isolated series shots.

In analogue firing, the resistance of cables and the daisy chaining of several dumb field modules on a single output port can combine to create an

UNBALLANCED series/parallel circuit, I have seen such a layout done by a thoughtless crew lead fail with only a couple of ematches in series at each

of 3 field modules, + 3X 100' connecting cables with 24 V output. She didn't think about the additional cable resistance added to the second parallel

box's series, and then DOUBLE that cable resistance added to the third- Which cable resistance is pretty high, using any kind of multi conductor cable

you can carry enough of. The net result: All of the modules tested as having continuity individually, but only the first one, just 100' of cable from

contoler fired. The bridge wires frequently do not melt, so box 1 didn't go open circuit and was still the lowest resistance parallel- even

repeatedly holding down the firing switch didn't get box 2 and 3 to fire, regardless of the continuity check looking good.

To avoid that failure scenario, I would either run some quickmatch from ONE field module's ematch to the other effects wanted on that hit, if less

than 5' or so to something beyond system capability, or run a scab wire from ONE field module and wire in SERIES to the other hit(s)if further away

(and if system still had some margin of output to work with the additional igniter(s)/additional resistance of scab wires) It costs more for the scab

wire, but it WORKS.

I carry an ematch safe continuity tester in the field. I have been wanting to get a blasting safe galvanometer for years. But they are quite

expensive, you can avoid needing one if you think it through, so very few fireworks people carry one.

[Edited on 10-3-2018 by Bert]

|

|

|

Bert

Super Administrator

Posts: 2821

Registered: 12-3-2004

Member Is Offline

Mood: " I think we are all going to die. I think that love is an illusion. We are flawed, my darling".

|

|

| Quote: |

I can see a real energy hurdle to get the wire to ignition temperature. Additionally the heat sink at the ends where the fine wire meets the lead

wires. But my estimate of thermal diffusivity of an organic molecule is far less, like 26 times less than the bridge wire. So the wire should

effectively be isothermal at the steady state amperage temperature while the first fire warms/ignites. The lead wire will likely cool the bridge more

effectively.

|

YES. The first fires are way less thermally conductive than Copper/solder.

Some of the best, most uniform ematchest I have used were Oxral brand, these did NOT use a chip with soldered wires, but had a little brass piece

crimped to the lead wires connecting the resistance element, resulting in a lot less (variable by solder blob size/position) cold metal right at

connection to bridge wire. These igniters were also much more uniform in resistance than what we can buy now, they were the same ones Oxral built into

their detonators.

Then someone in USA went and killed themselves using Oxrals, probably his fault, not the ematch. But a jury was convinced otherwise by a lawyer suing

Oxral and awarded his survivors. So Oxral quit selling these to the USA market, we are not thought worth the legal and financial risks.

|

|

|

roXefeller

Hazard to Others

Posts: 463

Registered: 9-9-2013

Location: 13 Colonies

Member Is Offline

Mood: 220 221 whatever it takes

|

|

| Quote: |

For that money, your caps are ACCURATELY made, also several varieties contain their own small capacitor and timing circuit so they will charge from

system, receive the start signal and then fire in their hole at correct time, regardless of any surface activity or fly rock that may cut wires or

signal cord.

|

I've been studying the electrical dynamics of that design recently. One thing that really stands out to me is the relatively small amount of energy

that can be stored in one of those capacitors. The energy stored in one patent I read was 22mJ.

The energy to heat the bridge wire was like 15mJ. So much so that equivalent series resistance in the wiring and timing components is powerful at

disabling the pulse. And the bridge wire length only serves to dilute that energy if it is longer than necessary. I'm still wondering if the time

constant has an important effect. I feel like if the time constant is too short that arcing could be likely. But too long a time constant will

reduce the peak temperature. I suspect that your graph above is probably good empirical data on that fine line.

|

|

|

aga

Forum Drunkard

Posts: 7030

Registered: 25-3-2014

Member Is Offline

|

|

Is there a possible Commercial outcome of this thread ?

I mean, if the current 'matches' are perfectly good, there is no room for an improvement.

If an Improvement is possible ... possibly a few $.

Bert, what do you Really want from these firing mechanisms ?

|

|

|

Bert

Super Administrator

Posts: 2821

Registered: 12-3-2004

Member Is Offline

Mood: " I think we are all going to die. I think that love is an illusion. We are flawed, my darling".

|

|

My supplier had "issues" with ematches that tested good for continuity, and then had as much as 25% failure in series of 10 or more. That caused him

to talk to a chemist, who advised him on how to make the first fire MORE sensitive, so all would light before first bridge wire melted. It also may

make them light from stray static electricity, dirty looks, being dropped...

I would rather he had solved the issues by making the ematches all very similar in electrical resistance, and kept the first fire JUST sensitive

enough.

No money in this for me, but maybe better igniters.

|

|

|

aga

Forum Drunkard

Posts: 7030

Registered: 25-3-2014

Member Is Offline

|

|

So, basically the go-to ignition system became no good and you need a new ignition system ?

|

|

|

| Pages:

1

2 |