Rocinante

Hazard to Others

Posts: 121

Registered: 13-11-2017

Member Is Offline

Mood: No Mood

|

|

Blast Mitigation Devices - Blasting Caps

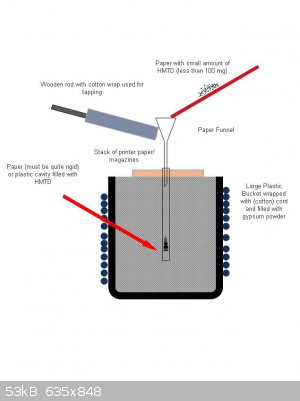

One takes several 5 - 10 l buckets, places them inside each another. The central one is filled with about 5 - 10 kg of fine inert powder like gypsum.

Then a hole is made in the center and 1 cm by 15 cm long cavity is placed inside. 4 stacks of magazines are placed around the cavity, so as to cover

the surface. A funnel made out of paper is inserted into said cavity. One takes 10 pre-bent papers, each one with less than 50 - 100 mg of primary

explosive. Then he/she uses wooden stick wrapped in cloth/cotton wool to move the primary inside the cavity. The cavity is filled with ~ 1 g of said

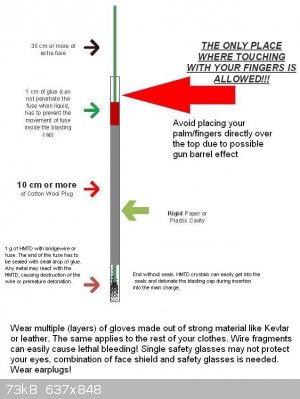

primary. Then a fuse or e-match is inserted. One uses a T-shaped stick to ram down a cotton wool plug that is about 10 cm long (made from multiple

small pieces), this plug is slightly compressed. The end of the blasting cap is sealed with glue. Then, the only place where fingers will ever come

into contact with the blasting cap is the end with glue (right next to the seal).

Do you like the idea? Of course, this process should work with compound blasting caps (SA.DS/ETN, dextrinated lead azide/PETN..) and with pressing and

arbitrary amounts of said explosives.

|

|

|

greenlight

National Hazard

Posts: 755

Registered: 3-11-2014

Member Is Offline

Mood: Energetic

|

|

I like the bucket idea which would pretty much reduce the risk of shrapnel to zero with <1gram of explosive.

It would need to be able to fit in a press and have a solid base to take weight because most caps have a secondary pressed in with a small amount of

initiating primary on top. A press would be much much safer than ramming it (even lightly) with a wooden rod even if it is wrapped in soft material

like pictured.

Keeping the hands off and away is important too (I am using lab tongs at the moment). I have a pair of kevlar gloves like you mention that I wear

under leather welding gloves and kevlar forearm sleeves (as well as face shield, ear plugs and muffs).

I brought them as soon as I saw a test by Klapotke where 1g of primary in glass test tube is initiated 10cm from different material gloves filled with

ballistic gel.

I think it was 40+ pieces of shrapnel dug out of the unprotected hand and just 2 or 3 in the kevlar cut resistant gloves. That sold them for me.

[Edited on 11-1-2018 by greenlight]

Be good, otherwise be good at it

|

|

|

Rocinante

Hazard to Others

Posts: 121

Registered: 13-11-2017

Member Is Offline

Mood: No Mood

|

|

The bucket reduces the sound levels, too. Indeed, the ramming rod (the second one, not pictured) is a T, so that you don't have your hands above the

small 1 cm hole in the paper shield/cover. The first rod is just for tapping the paper funnel.

I have both, Dyneema and Kevlar cut resistant gloves and sleeves due to work/job. They're awesome. It is hard to pciture anything penetrating the

kevlar glove/leather glove combination.

You can easily handpress ETN or PETN to 0.9 g/cm^3 and 4500 - 5000 m/s. That does it for me, 1 g of either are perfectly enough to inititate anything

I can imagine.

The only problem is that I can't find aluminium tubing that is less than 0.2 - 0.3 mm thick and that seems to be too thick for (my)safety precautions.

Do you know any source of 10 mm diamater Al tubes that are 0.15 - 0.1 mm thick?

I (I = my pet cat) also don't make compound caps out of single tube. I have one inner one with the primary and one outer one (300 mg of primary and 1

g of secondary in the bigger one). To eliminate the effect of friction/bending. Of course, there has to be sizable gap between the tubes as not to

create small gaps that could generate enough friction to set of the ETN/PETN. So you have like 6 - 10 mm inner tube and 15-17 mm outer tube, so that

you have at least 2 - 3 mm of space between the walls. Or do you think that SA.DS pressed directly above the ETN/PETN is better than two tubes? The

only thing that matters in the assebmly that you have to change the geometry of the bucket thingy as to cover yourself in the event of detonation just

as you are inserting the first cm of the inner tube into the outer tube.

The second problem is friction - what's worse, side-ways induced friction in a single tube due to bending or possible movement of two tubes inside

each other due to impropper joint at the end? The movement of the joint is much less likely but maybe more capable of inducing detonation..?

[Edited on 11-1-2018 by Rocinante]

|

|

|

Gargamel

Hazard to Others

Posts: 166

Registered: 9-3-2013

Member Is Offline

Mood: No Mood

|

|

| Quote: |

I brought them as soon as I saw a test by Klapotke where 1g of primary in glass test tube is initiated 10cm from different material gloves filled with

ballistic gel. I think it was 40+ pieces of shrapnel dug out of the unprotected hand and just 2 or 3 in the kevlar cut resistant gloves. That sold

them for me. |

greenlight, would you provide me with that article?

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1415

Registered: 2-9-2014

Location: Technion Haifa

Member Is Offline

Mood: old jew

|

|

Manufacture detonators is interesting for everyone around the energetics materials. If you use ETN, is SADS best choice as primer.

Development of primarily - secondary substances CHP (2015) Lithex (2022) Brightelite (2023) Nitrocelite and KC primer (2024)

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

Wood is good for absorbing blasts. Wood is a good material for loading blocks made in halves and securely clamped together so the blocks can be

separated for removal of a loaded detonator capsule that will expand during loading and anchor itself by that expansion. Oak timber is used as decking

material on steel war ships because it is the best material for absorbing the impact of bombs or shells.

|

|

|

Rocinante

Hazard to Others

Posts: 121

Registered: 13-11-2017

Member Is Offline

Mood: No Mood

|

|

Have you tried a full scale detonation in your blocks? Does it fragment? Does it muffle the sound of detonation? Is there any real difference for an

amateur with pressed/non pressed ETN/PETN? I think that the deifference between 800 mg of 1.5 g/cm^3 ETN and 1100 mg of 0.9 g/cm^3 ETN doesn't matter

that much, e.g. it doesn't justify the extra cost of a press.

Anyway, do you have a source of 0.1 - 0.15 mm aluminium tubes? Most e-shops max out at 0.2 mm and the viable tubes (inner diameter of 6 mm+) or 0.3

mm. They are too thick for my liking. In can imagine 0.1 mm Al fragments being stopped by kevlar sleeves on my arms (not forearms) and two layers of

cotton jacket, but 0.3 mm sounds too dangerous for me (dropping the blasting cap on ground etc.., any detonation outside the block/bucket).

|

|

|

greenlight

National Hazard

Posts: 755

Registered: 3-11-2014

Member Is Offline

Mood: Energetic

|

|

@ Rocinante,

I use Al tubing from a hobby shop, I think it is used for model aeroplanes to support the wings because it is in the planes section. I have uploaded

a photo with thickness included. They are thicker than what you describe but work excellently, I believe the shock of the casing fragmenting improves

initiating efficiency. Commercial caps are thick walled like these.

I have done a test with these exact tubes used as detonators (700mg PETN base/200mg Lead azide too) detonating them in close proximity to a small

block of ballistic gel. I found that with these explosives in them the fragments are small and very light and do not penetrate very far into the gel.

The friction problem you describe depends on what primary you are using. Some are more sensitive to friction, some more to spark, some still when wet

others not. They are all different Depends on the compound.

Having the primary pressed directly onto the secondary is the best way in my opinion...Thats a perfect interaction between the two. Use a powerful

primary like Lead azide and you should have no initiation problems. Im sure silver acetylide would be good though, its initiating efficiency is high.

Not sure about storage stability if you want to store the caps though.

I would minimize friction as much as possible because nearly all the primaries are sensitive to it, just on different levels.

[Edited on 12-1-2018 by greenlight]

[Edited on 12-1-2018 by greenlight]

[Edited on 12-1-2018 by greenlight]

[Edited on 12-1-2018 by greenlight]

Be good, otherwise be good at it

|

|

|

greenlight

National Hazard

Posts: 755

Registered: 3-11-2014

Member Is Offline

Mood: Energetic

|

|

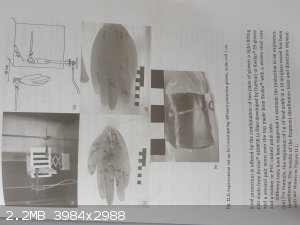

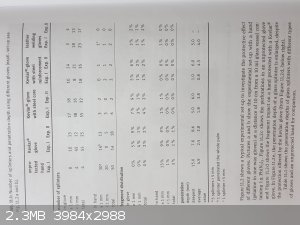

@ Gargamel,

Here is pictures of the article, should be able to zoom on them. The test is using glass container as the fragmebts, these would be heavier and

nastier than Aluminium. They are from Thomas Klapotke's newest textbook Chemistry of high energy materials:

[Edited on 12-1-2018 by greenlight]

[Edited on 12-1-2018 by greenlight]

[Edited on 12-1-2018 by greenlight]

Be good, otherwise be good at it

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1415

Registered: 2-9-2014

Location: Technion Haifa

Member Is Offline

Mood: old jew

|

|

I have a same opinion as GreenLight. Cavity is the last thing, where is problem in the safety. Main is behaviour of primary substance. Because

"primary" is pretty large, wide notion. Much better is use grain (for primary compound) 1x1 - 2x2 mm. Adding dextrine, nitrocellulose, or else

compatable binder. Very fine powder has partially behavoiur as liqide and get between pressing rod and wall of cavity. But grain not. Any manipultion

with grains is of course much easily.

Development of primarily - secondary substances CHP (2015) Lithex (2022) Brightelite (2023) Nitrocelite and KC primer (2024)

|

|

|

Rocinante

Hazard to Others

Posts: 121

Registered: 13-11-2017

Member Is Offline

Mood: No Mood

|

|

Assuming that we have powdered primary, I'm talking about these two cases.

In case one, there is slight bending of the outer tube (enlarged), there is friction between the two walls and ETN/PETN, but the primary is isolated

from any of that.

In case 2, there is presumably much less friction due to absence of multiple walls, but the boundary layer of primary and secondary is pressing

against itself (between the crystals) and the wire + there might be microcracks in the wall with primary, primary/ETN mixture inside them that

compress due to the bending.

So, which one is safer? (Likely) larger forces on the ETN or smaller forces on ETN/PETN/azide/SA.DS mixture? How would you granulate SA.DS (quite

unstable compound) and would it affect DDT? Has anyone tried this?

Furthemore, I think that case one is better isolated against shock (fall to the ground), since the ETN can act as a cushion in this case. Or.... not?

|

|

|

greenlight

National Hazard

Posts: 755

Registered: 3-11-2014

Member Is Offline

Mood: Energetic

|

|

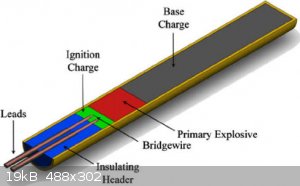

I see what you mean with the two tubes method. If the inner tube is secured in its outer tube with out any play it would be safe. In the end there

is still the same chance it will go off if accidentally dropped as the second design I think, more chance if the inner tube is loose in any way.

Detonators (commercial and homemade) I have seen haven't been able to be bent accidentally, the casing tube is quite strong.

I use the design in the diagram at bottom of my post. The PETN is recrystallized from acetone and like soft sand and the lead azide is powder

obviously. Once they are pressed and sealed, the whole design is compact and sturdy and I am sure they could survive getting dropped without

initiation.

I use a small amount of granulated black powder as the ignition charge and have the igniter wires and igniter head in this layer so it cannot create

friction with the primary explosive layer.

I honestly would not try and mess with recrystallizing or granulating any sensitive primarys especially the salts of silver, mercury or lead or

peroxides. This would mean increasing crystal sizes would it not.

I think it is not possible to do for most of them. The tests I have read on crystallizing the primaries that allow larger crystal formation alway

results in spontaneous detonation from internal stresses while drying, precipitating, filtering, or my favorite, just sitting there . .

Large crystals of lead azide are one of the more "exciting" ones to precipitate that I have read about..

[Edited on 12-1-2018 by greenlight]

Be good, otherwise be good at it

|

|

|

Rocinante

Hazard to Others

Posts: 121

Registered: 13-11-2017

Member Is Offline

Mood: No Mood

|

|

Yea, ß-lead azide is deadly. It can detonate in solution. HMTD recr. from CCl3 is known to detonate just by "sitting there", too.

How far did you fragments travel in the balistic gel? 2 cm? Have you done any tests involving clothing? My pet camel once detonated a ~ 1.5 g ETN

(~0.9 g/cm3) blasting cap inside a plastic syringe and it failed to penetrate two walls of a PET-bottle. Only one wall was penetrated (the distance

between the cap and the bottle was about 3 cm). My pet camel detonated a similair cap beneath a small book and it didn't even peirce it's cover (1-2

mm of leather-like material), pages inside were dislodged, though.

Do the 0.4 mm Al hobby tubes have an end? I know about Dr. Liptakov's method of using pressed Al foil, but I'm afraid of possible movement being

transmitted into the filling in case the plug fails (blasting caps are not for ramming, but many things happen..e.g. epilepsy..). Also, how about

microsopic movements of the foil with ETN near the wall /between the foil and the wall/?

I am thinking about using a ~loose wire (at least as loose as possible, though not rly sure how to do that inside the cap) and gluing the wire to the

wall (at the top end, just above the end of the cotton plug).

What would you recommend as an ingition charge? I know that SA.DS is far more heat sensitive than LA, but your idea of reducing friction sounds nice.

I'm looking for something that won't degrade the SA.DS over a day or ~ week.

[Edited on 12-1-2018 by Rocinante]

|

|

|

greenlight

National Hazard

Posts: 755

Registered: 3-11-2014

Member Is Offline

Mood: Energetic

|

|

I can't remember the exact details and results of the test it was 2 years ago. It was not as much as 2 cm though. I think it may be time to repeat

it with a layer of clothing over the ballistic gel I think. This time I will put up the results.

The tubes are open ended and quite long, I cut them to size for use. I used to use foil as the end cap, as long as the cap is pressed and sealed

well, there will be no movement to allow friction.

For the last batch of caps, I have been using metal epoxy to make a sturdy thin plug on the ends.

I use a small layer of granulated black powder as the ignition charge. The igniter wire is in contact with this and a cotton plug is pressed in to

hold the wires there. Then I use clear silcone sealant over the cotton to ensure they are air and water tight. You can throw them in water and

initiate them if needed.

[Edited on 13-1-2018 by greenlight]

Be good, otherwise be good at it

|

|

|

Rocinante

Hazard to Others

Posts: 121

Registered: 13-11-2017

Member Is Offline

Mood: No Mood

|

|

That's nice.... maybe you could add some drop testing, insertion testing, slight strikes against concrete, rolling around in a mixer/tumbler. That

would be very nice. Please

|

|

|

Rocinante

Hazard to Others

Posts: 121

Registered: 13-11-2017

Member Is Offline

Mood: No Mood

|

|

I think that some parts of this post should be added to the topical compendium thread.

|

|

|

Gargamel

Hazard to Others

Posts: 166

Registered: 9-3-2013

Member Is Offline

Mood: No Mood

|

|

Thank you greenlight.

|

|

|

Rocinante

Hazard to Others

Posts: 121

Registered: 13-11-2017

Member Is Offline

Mood: No Mood

|

|

Is there any realistic static danger presented by the cotton plug? Assuming metal body and short-circuited lead wires (and quite possibly insulated at

the ends, too).

|

|

|

roXefeller

Hazard to Others

Posts: 463

Registered: 9-9-2013

Location: 13 Colonies

Member Is Offline

Mood: 220 221 whatever it takes

|

|

As a damage mitigation measure, I've considered pressing the primary in first and by itself in the middle of the tube inside of a plastic capsule,

open to the topside. A supporting rod from the bottom would oppose the ramming force. Then all the firstfire, fuse head, and plug are installed

above the primary. The sealed tube is then turned over and a plug of base charge with small amount of binder is pressed gently in the cavity adjacent

to the primary. In this way the most forceful pressing operation is done without a base charge to feed the beast.

|

|

|

roXefeller

Hazard to Others

Posts: 463

Registered: 9-9-2013

Location: 13 Colonies

Member Is Offline

Mood: 220 221 whatever it takes

|

|

I was reading today patent 3,361,602 about compositions of lead azide containing molybdenum disulfide. Interesting things contained in the

description of the art. The familiar ASA azide styphnate aluminum is said to be formulated for compacted cohesion from the lead styphnate addition

along with the need for flame sensitivity for lead azide. But, it continues, that ability to increase cohesion causes an increase in punch adhesion

for the primary powder. Which in some circumstances causes detonation on ram withdrawal. The patent then explains the addition of aluminum powder as

providing the necessary release from the punch to prevent this adhesion, but that it introduces static accumulation and sensitivity to static

discharge. Finally the claims of the invention are that a replacement of the aluminum with molybdenum disulfide provides for release without the

added static sensitivity. Additionally, applying the disulfide at the time of colloidal precipitation provides the greatest benefit. I hadn't seen

these things mentioned in other posts so I thought it helpful to mention here.

Attachment: US3361602.pdf (355kB)

This file has been downloaded 310 times

|

|

|

Microtek

National Hazard

Posts: 872

Registered: 23-9-2002

Member Is Offline

Mood: No Mood

|

|

Adding a little graphite powder might also reduce the likelyhood of static build-up and ease ram withdrawal, and is probably easier to get than MoS2.

It may also make the charge too prone to breakup due to poor cohesion.

|

|

|

roXefeller

Hazard to Others

Posts: 463

Registered: 9-9-2013

Location: 13 Colonies

Member Is Offline

Mood: 220 221 whatever it takes

|

|

I would agree that adding graphite would probably achieve the same purpose. As a courtesy the patent author includes a second part of his experiments

in which he mechanically combined the composition together. As opposed to a colloidal combination. In this experiment he concluded that the

sensitivity properties were all improved for friction and static discharge. But additionally he found that the initiation efficiency also decreased.

When he reached 6% lubricant in the composition the composition efficiency had reduced by half as an initiator. With the colloidal method in which the

patent author claimed and actual Improvement in initiating efficiency over the unmodified bass.

|

|

|

XeonTheMGPony

International Hazard

Posts: 1640

Registered: 5-1-2016

Member Is Offline

Mood: No Mood

|

|

I direct press 1 gram ETN into the tube, but then I use a paper sabot that is sized to tightly fit in the tube, there in that paper tube I press the

HMTD to full loading pressure, then press that assembly into the tube with a bit of lose ETN to "seal" the two assemblies.

the electric initiator is made much the same way then lightly pressed over top the primer tube with a dash of lose HMTD to seal the gap.

So if primer assembly goes makes loud pop and paper every where, Added bonus is removes any issue of it reacting with the metals. I used this for many

years and never had issues and very rar failure rate.

if one wishes to use internal time delays just fill another paper tubule with delay comp, then e-match as usual

|

|

|