| Pages:

1

2

3

4

5

..

68 |

nitro-genes

International Hazard

Posts: 1048

Registered: 5-4-2005

Member Is Offline

|

|

copperwire liner

Thanks for the references!

Especially the last one was pretty conclusive. I was amazed to see that wire having a circular cross-section has such a good (presumably) penetration

ability, as it is stated in the same reference that the performance of a shaped charge liner is directly related to the maintaining of close

dimensional tolerences on the liner. In particular the wall thickness!

Unfortunately there is nothing stated about the actual performance and jet formation of such liners in both patents. (You wouldn't expect so of

course) Also in literature I could not find anything about this...

I fear that this theory needs some experimentational evidence to be conclusive  Also do I really like the fact that a liner made in this way would be a hell of a lot cheaper, as coppersheet costs me a fortune. As a student this is

always an important factor!

Also do I really like the fact that a liner made in this way would be a hell of a lot cheaper, as coppersheet costs me a fortune. As a student this is

always an important factor!

|

|

|

Axt

National Hazard

Posts: 861

Registered: 28-1-2003

Member Is Offline

Mood: No Mood

|

|

| Quote: | Originally posted by poiu

Speaking of references, the Walter & Zukas book looks rather interesting, expensive and out of print(?) (consider that a hint, generosity will be

met with the same). |

Is it out of print? I know it was recently listed at <a

href="http://161.58.144.10/shopsite_sc/store/html/product100.html">isee.org</a> as being out of print, but that has now been

removed.

I just dont have the capability of scanning a book at my house.

|

|

|

fatkangaroo

Harmless

Posts: 43

Registered: 20-12-2004

Location: australia

Member Is Offline

Mood: disturbed

|

|

I was wondering if anyone has any more information on how to do the ANNMSA mix? I just tried it twice and ended up with a solid rock not wet crystals.

I am not sure exactly how this is supposed to go.

I put 70grams of black 1835g/L sulfuric acid in a jar then slowly add the oven dried 140 g AN to the SA, it went yellow the jar warmed up and started

giving off vapors, so I put the lid on and swirled untill it all dissolved. When I added the NM everything seemed to be going fine, added it all

swirled it all up and let it sit. with in a minute a had a solid crust on the bottom and a fluid level on top. The cake is solid as a rock. Then I

thought what the hell I will do it again and see what happens. Did it the same except let the vapours from adding AN to the SA blow away and ended up

in the same end product. This cake is so hard I dont know how I will get it out of the jar.

|

|

|

Axt

National Hazard

Posts: 861

Registered: 28-1-2003

Member Is Offline

Mood: No Mood

|

|

I can only assume the problem is you trying to <i>swirl</i> a mobile, light liquid into a heavy viscous one. Pour the NM in and give it a

<i>stir!</i>. Result is near immediate precipitation with no free pourable liquid. I just did it again to make sure of the quantities

since the others were "field weighed". This is what it should look like.

<center><img src="http://www.sciencemadness.org/scipics/axt/annmsa-crystals-sm.jpg"></center>

I havn't played with the ratios to see if there is a better one, less H2SO4 may or may not be advantageous. The 140:100:70 ratio is balanced to

CO2/H2O/N2/SO2 which seemed like a good place to start considering the following;

"Ammonium Nitrate 60% Ammonium Sulphate 40% Vod 2430 M/S @ .90g/cm3." Arthur Marshall Explosives.

(This is very close to H2O/N2/SO2 balanced as well)

BTW, whats with these dickheads (dickhead) that comes in, making good posts into this thread, ask me to scan a book, then delete their posts when I

decline. Very odd.

[Edited on 30-4-2005 by Axt]

[Edited on 7-6-2005 by chemoleo]

|

|

|

fatkangaroo

Harmless

Posts: 43

Registered: 20-12-2004

Location: australia

Member Is Offline

Mood: disturbed

|

|

Just tried again, this time vigorous stirring was used the second the NM went in. I stirred for around a minute and watched as the precipitate formed

on the bottom and worked its way up untill everything was a solid mass of wet crystals . Mine are so wet and thick I can hold the jar upside down and the mix does not move. I find it interesting that that doing the exact same

thing but with swirling produces a different end product. I ended up adding more and more AN to the hard stuff in a attempt to soak up the excess

fluid. I still have a fluid level even after adding a extra 60g AN. Its turned into a heavy block of whatever. . I am going to blow this big heavy

bloody rock I have from the swirled mix as theres a good 140ml of NM in there, no point wasting it. . Mine are so wet and thick I can hold the jar upside down and the mix does not move. I find it interesting that that doing the exact same

thing but with swirling produces a different end product. I ended up adding more and more AN to the hard stuff in a attempt to soak up the excess

fluid. I still have a fluid level even after adding a extra 60g AN. Its turned into a heavy block of whatever. . I am going to blow this big heavy

bloody rock I have from the swirled mix as theres a good 140ml of NM in there, no point wasting it.

Cheers Axt for the point in the right direction.

|

|

|

nitro-genes

International Hazard

Posts: 1048

Registered: 5-4-2005

Member Is Offline

|

|

The making of the copper cones from wire was a complete failure. It is nearly impossible to get a perfectly symmetrical cone from wire alone...

I did stumble across an old artice on Wiley interscience:

The Behavior of Shaped Charges with open-poled hemispherical liners

Richard L. Summers 1, William P. Walters 1, Richard D. Dick 2

Is there anyone who can access this article or knows more about this principle?

and to Axt:

You seem to have purchased this book of Walter and Zukas. Does it contain al lot of experimental data like penetration depths with different

explosive compositions, liner materials, shapes, standoff etc? Or is it more theoretical orientated?

[Edited on 6-7-2005 by nitro-genes]

|

|

|

Axt

National Hazard

Posts: 861

Registered: 28-1-2003

Member Is Offline

Mood: No Mood

|

|

| Quote: | Originally posted by nitro-genes

Does it contain al lot of experimental data like penetration depths with different explosive compositions, liner materials, shapes, standoff etc? Or

is it more theoretical orientated?

|

More theoretically orientated.

Contents:

1 Introduction to shaped charge concept

1.1 the shaped charge concept

1.2 Introduction to shaped charges

1.3 the nomenclature

2. history of shaped charges

2.1 the early history

2.2 the munroe effect

2.3 early shaped charge developement

2.4 the WWII era

2.5 the post WWII era

3.1 militatry applications

3.2 specialised applications

3.3 current applications

4. the gurney velocity approximation

4.1 the gurney expressions

4.2 extensions of the gurney method

4.3 the taylor angle approximation

4.4 application of the taylor and gurney methods

5. shaped charge jet formation

5.1 the birkhoff et. al. theory

5.2 comments on the birkhoff et al. solution

5.3 the PER theory

5.4 generalisation of shaped charge jet formation model

5.5 a sample calculation

6. the visco-plasti jet formation theory

6.1 the visco-plastic concept

6.2 the visco-plastic model

6.3 the equations for the visco-plastic jet formation model

6.4 jet coherency

7. comments on explosive welding, bonding and forming

7.1 explosive forming

7.2 explosive welding and bonding

8. the breakup of shaped charge jets

8.1 hydrocode simulation

8.2 analytical jet breakup models

8.3 semi-empirical formulas

8.4 the chou-carleone model

8.5 maximum jet velocity

9 shaped charge jet penetration

9.1 introduction

9.2 shaped charge jet penetration

9.3 variable velocity jets

9.4 particulated jets

9.5 compressible models

9.6 the virtual origin concept

9.7 rod penetration models

10. other aspects of shaped charges

10.1 fabrication of shaped charge liners

10.2 shaped charge precision assembly

10.3 scaling of shaped charges

10.4 shaped charge jet temperature studies

11. computational aspects of explosive - metal interactions

11.1 the governing equations

11.2 spatial discretization

11.3 mesh description

11.4 numerical integration

11.5 artificial viscosity

11.6 material models

11.7 material failure

12. wave propagation codes for shaped charge studies

12.1 summary of wave propagation code characteristics

12.2 code selection criteria

12.3 applications

13. shaped charge generalities

13.1 shaped charge variables

13.2 the explosive fill and initiation mode

13.3 jet characteristics

14. example applications

14.1 conical shaped charge liners

14.2 shaped charge liner collapse and jet formation

14.3 shaped charges with hemispherical liners

14.4 explosively formed penetrators

14.5 blasting and shaped charges

14.6 special applications and effects

14.7 shaped charge jet collisions

|

|

|

Chris The Great

Hazard to Others

Posts: 463

Registered: 29-10-2004

Location: Canada

Member Is Offline

Mood: No Mood

|

|

I was just flipping through some of my info when I stumbled across this completely by accident. It is from The Chemistry and Technology of

Explosives, Vol III, page 462

| Quote: | An unconfirmed hypothesis was also formulated that ammonium nitrate in the presence of sulfuric acid undergoes dehydration to the formation of

nitramine (Vol. III) which is a strong and unstable explosive compound.

A double salt of ammonium nitrate and sulphate, defined by the formula 2NH4NO3-(NH4)2SO4, is capable of detonating with a rate of 1000-1400 m/sec

provided an exceptionally strong initiator and completely hermetic confinement are used. However, the detonation train of this double salt has a

tendency to break up after travelling a short distance. |

Going to the Nitramine entry (page 15) we see some more interesting stuff:

| Quote: | Nitramine is believed to occur in an ammonium nitrate solution in an excess of concentrated sulfuric acid as a result of dehydration of this salt:

NH4NO3 --> NH2NO2 + H2O

Davis and Adams [8] report the following experimental observations in support of this supposition. On heating a solution of ammonium nitrate in

sulfuric acid to 150*C, nitric acid cannot be distilled, but nitrous oxide is evolved, probably from the decomposition of nitramine. If, however, the

solution is kept for a long time between 90 and 120*C, nitric acid can be obtained by distillion. The authors' conjecture is that the addition

of water to the nitramine takes place according to reaction (16):

NH2NO2 + H2O --> NH3 + HNO3 |

Could be some nitramine that is helping this mixture be as powerful as it is. Perhaps some could be mixed up and allowed to stand for a couple weeks,

and see if any gas is evolved (N2O) from nitramine decompostion. Nothing else in there should break down reapidly at room temperature.

I recently read a journal article (Diagnostic of Superfast Jets with 25 km/s Tip Velocities, Manfred Held, Propellants, Explosives, Pyrotechnics 23,

pg 229-236, 1998) about a similar cylinderical shaped charge. In this case however the explosive did not surround the cyclinder, it sat on top of a

metal slab 28mm thick, with a 20mm tall cylinder on the opposite side, 20mm diameter.

Using 3.9 kg of TNT/HMX 15/85, the jets travelled (through a vacuum) at nearly 25 km/s (the very tip looked like it was going roughly 24 km/s to me,

but it faded into a point around there so it is difficult to see exactly how fast it is going using the pictures).

However, the jet looked to be very stable and straight, so I think that Axt is right when he said that the theory probably breaks down when applied to

this type of shaped charge. When the charge was not centered, the jets went off to the side but they where still fairly straight, so I think that

they are quite stable.

I plan to do some experimenting with these types of shaped charges, and attempt to measure the jet tip velocity as well as the explosive velocity, and

see what kind of jet velocity you will get depending on the VoD of the explosive in question.

|

|

|

Axt

National Hazard

Posts: 861

Registered: 28-1-2003

Member Is Offline

Mood: No Mood

|

|

Thats some interesting stuff Chris, gives some possible reasoning to the AN/AS detonations not being as kaput as they look like they should be.

| Quote: | | and attempt to measure the jet tip velocity as well as the explosive velocity |

Your going to clock a ~25km/s jet  .. good luck .. good luck

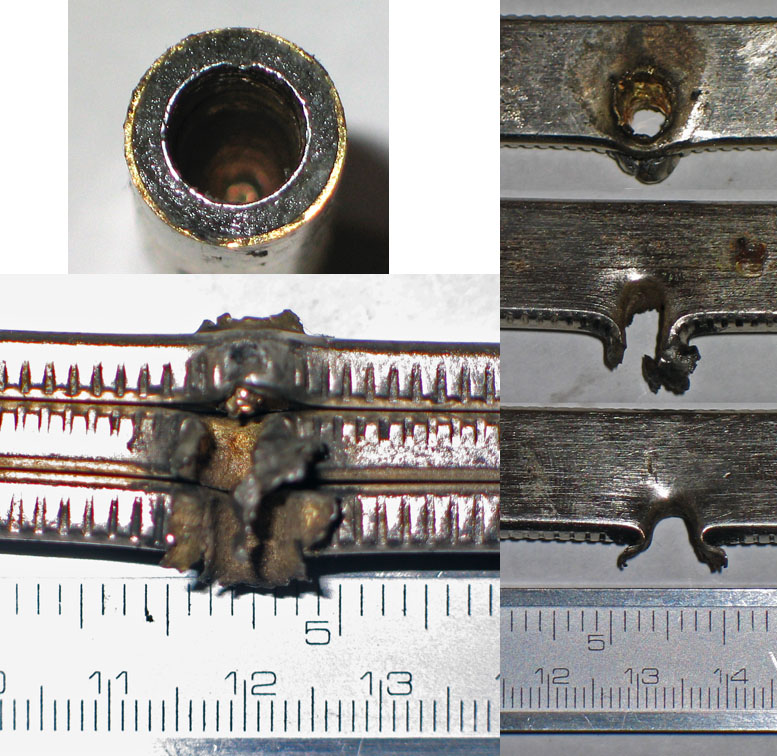

Anyhow, this threads been starved of pics for too long, melted lead from bullet jackets of .357 mag & .45 colt, charged with PETN/NG mixed to

plastic consistancy. The hemispherical liners should be a lot more resistant to irregularities then the "spitzer" shapes as I posted before.

Both penetrated the 5/8" steel, the .357 literally created a pin hole (can only fit one pin in the hole!) and the slug (carrot) was jammed in

the entry.

<center><img src="http://www.sciencemadness.org/scipics/axt/bjsc-pics.jpg">

Yeh.. theres a <a href="http://ww1.webtop100.net/~62552/xmovies.webtop100.net/banners/xmovies.html">movie</a>.</center>

|

|

|

Chris The Great

Hazard to Others

Posts: 463

Registered: 29-10-2004

Location: Canada

Member Is Offline

Mood: No Mood

|

|

Well I'm going to 'try'. I found a program to time microsecond events so I think it's getting feasible... We'll see.

Anyway, a though popped into my head about the ANNMSA mixtures. AN mixtures are generally very low density. However, in this case we add a very

dense acid, and the whole mixture also recrystalizes, probably at a higher density than the original AN. I suspect that the end product is much more

dense than a simple ANNM mixture.

Since increasing the density will cause a very large increase in explosive power, this might be the reason for the large performance increase more

than anything else.

Just some thoughts...

|

|

|

Axt

National Hazard

Posts: 861

Registered: 28-1-2003

Member Is Offline

Mood: No Mood

|

|

Note that originally SA was used to increase the <i>sensitivity</i>, The increase in actual true "power" over straight ANNM is

likely marginal or even worse, but your right, if ANNM is too saturated or pressed to too higher density it fails with 8 strength detonators. I too

think its a combination of increased density (allowed due to an increased sensitivity) combined with a more intimate mix of fuel (NM) & oxidiser

(HNO3).

But the sulphate ion doesnt add to explosive power, it should detract from it, thus the extra density it holds adds nothing to the explosive

performance. The density increase is due to intimate mix of NM/HNO3 which is sensitive to detonation at its max density where ANNM or other AN fuel

mixtures arn't.

|

|

|

Chris The Great

Hazard to Others

Posts: 463

Registered: 29-10-2004

Location: Canada

Member Is Offline

Mood: No Mood

|

|

OPPS! I must have been tired when I posted that, I meant "detonation velocity and detonation pressure" and not power, but for some reason I

put power while thinking of something completely different!

A small increase in density will have a very large increase in VoD and P, which is what I was trying to say. Hence the much greater brisance and

apparent power of the ANNMSA mixture, even though the total energy release is less than ANNM on a weight basis.

Anyway, you're right about the better mixing as well. I think there are quite a few things which make this a much better explosive than straight

ANNM.

|

|

|

Kinepak

Harmless

Posts: 11

Registered: 19-2-2005

Member Is Offline

Mood: No Mood

|

|

Ive to say a few things: First: Do you think, that there is no reaction betwenn the NM and the "nitrating mixture" (AN, H2SO4)? I sound a

bit strange to me. But i dont know. Then: Axt, i watched your movie from the tests (ANNM vs ANNMSA) several times and you definately can see, that the

plain ANNM detonation is NOT complete! There is flying undetonated ANNM away. Thus the detonation was not that strong. But your tests are really

great! Big compliment! Im very impressed from all your experiments and the sucsess! The ANNMSA could also be so strong, because of a reaction. Evt.

Dinitromethane? I really dont know  . But a little recommendation: Use UNNM . But a little recommendation: Use UNNM  ! Urea nitrate and NM.... thats the hell! I tested only 28g of it and it was

horrible ! Urea nitrate and NM.... thats the hell! I tested only 28g of it and it was

horrible  . .

lets rock!

|

|

|

Axt

National Hazard

Posts: 861

Registered: 28-1-2003

Member Is Offline

Mood: No Mood

|

|

Im not sure what the acids effect on NM, I dont think its going to be totally inert but if it does for example form an equilibrium with another

product its not likely to influence the actual performance. Some nitrations are done in NM solvent so there should be literature somewhere that gives

a more definate answer.

Just to set the context regarding the ANNMSA movie your refering to, I posted this into E&W quite a while back but was deleted after I was banned.

It shows its not a test of power rather sensitivity, and was in reply to someone using 40% NM.

| Quote: |

OK fella's I have to correct some things here, once you go too high in nitromethane concentration sensitivity diminishes not increases, most

sensitive is actually around 15%, I have no dought that you get a powerful explosion from ANNM 60:40 but its not a "cap sensitive" mix and

if left to sit for 2 minutes you end up with the AN sinking under liquid NM. Even 30:70 isnt reliable when initiated by a #8.

Nuclearattack: Where did you get the kinepak ratio of 60:40, Coming from the man himself, neither the solid is straight AN nor the liquid straight NM.

The best information I have is that its a mix of NM/xylene, and i'll guess AN is mixed with a anti-caking agent, microballoon or other inert

filler.

But but but ..... There IS a way of using a higher nitromethane percentage and make it even more sensitive, this is done by adding a portion of

concentrated sulphuric acid, which ups the content of HNO3 sensitiser and thickens the mix up into a paste. Dont worry about any sulphate as that will

happily go up with the rest, and the mix is compatible with most plastics and aluminium (at least in the short term).

((picture/movie))

The ratio Ive used is AN/NM/H2SO4 40:40:20, I fired two charges this morning to prove the point. The target and charge volume is the same as used on

the MEKP tests to allow comparisons. I compared this mix to the ANNM 60:40 using #8 dets to show the poor detonation of the 60:40 with a commercial

det. The difference is obvious with the ANNMSA creating a huge hole, the ANNM did actually manage a crack in the plate even though the detonation

looks very weak. You could of course waste concentrated HNO3 instead of H2SO4. Try direct sensitising of NM with H2SO4 (without AN)!

|

BTW: This is a SC thread!

|

|

|

Kinepak

Harmless

Posts: 11

Registered: 19-2-2005

Member Is Offline

Mood: No Mood

|

|

Ah I see.... Ive a question to Axt: You did a test with a Polyamide Resin HE made from PETN, PIB and Polyamide Resin right? Could you please tell me,

what you used exactly and how the procedure was? This mixtures should also be a good choice for LSC. What does the Polyamide Resin affect in that

mixture? And finally: What was your impression? I would be nice if you answer these questions!

lets rock!

|

|

|

Axt

National Hazard

Posts: 861

Registered: 28-1-2003

Member Is Offline

Mood: No Mood

|

|

Polyamide resin is one part of some epoxy glues, forget what solvent I used. You may be able to find references to its use as a plasticiser (It gets a

mention here http://www.rsc.org/pdf/books/pb2500sc.pdf combined with RDX).

Its convenient, but going with blu-tac or bubblegum gives a better non sticky, elacticy consistancy. PIB is likely in blu-tac and

PIB/styrene-butadiene in bubblegum. Both are main components in C4 & semtex respectively, so take your pick. Both extractable with xylene.

You'll have to add a bit of oil to the bubblegum binder to keep it soft.

[Edited on 30-8-2005 by Axt]

|

|

|

Kinepak

Harmless

Posts: 11

Registered: 19-2-2005

Member Is Offline

Mood: No Mood

|

|

Yea thanks! Ive already tried it. Ive a big solid block of PIB here  . But thats

not the problem. If I mix the PIB with the PETN and let the naphta (i used with gas, called naphta, to let the PIB swelling in) vaporize, i get a

plastik thing. But the problem: Its not sticky enough! Its only elastic....! And so I thought, that you used the polyamide resin to improve that. You

say that oil would work? What about vaseline? Hmm....Ill give it a go with vaseline. But all advices are welcome! . But thats

not the problem. If I mix the PIB with the PETN and let the naphta (i used with gas, called naphta, to let the PIB swelling in) vaporize, i get a

plastik thing. But the problem: Its not sticky enough! Its only elastic....! And so I thought, that you used the polyamide resin to improve that. You

say that oil would work? What about vaseline? Hmm....Ill give it a go with vaseline. But all advices are welcome!

lets rock!

|

|

|

Axt

National Hazard

Posts: 861

Registered: 28-1-2003

Member Is Offline

Mood: No Mood

|

|

The point was to make it non-sticky, but yeh you can make it sticky with the addition of polyamide resin.

This is a shaped charge thread, thus I see no reason to have it sticky.

[Edited on 30-8-2005 by Axt]

|

|

|

Chris The Great

Hazard to Others

Posts: 463

Registered: 29-10-2004

Location: Canada

Member Is Offline

Mood: No Mood

|

|

Bombs from bubblegum eh? Looks like I've got to visit the candy store....

Thanks for clearing up the ANNMSA issue for me. I did not realize that the test you did was to show the much greater detonability of the mixture

compared to ANNM, I thought the video was to show how much more powerful it was!

This caused some condusion on my part as I thought that it also exebited much greater performance as well as the fact it was much easier to detonate!

Now I understand!

An interesting thing I noticed about the cylinderical charges is the large diameter penetration. Looking at all of your other shaped charge tests,

none show such a large diameter penetration. I found this very surprising when I stopped and thought about it.

Is there any reason why this might happen? The very close proximity to the explosive, so the metal was driven through from the explosion, even though

it wasn't part of the jet?

|

|

|

Axt

National Hazard

Posts: 861

Registered: 28-1-2003

Member Is Offline

Mood: No Mood

|

|

I think its more likely a hole-punch effect, I dont think it a coincidence that the 16mm liner just happened to create an even 14mm hole (the inside

diametre of the liner). I think the result would be a lot different if it were provided with a bit of standoff.

I taped and uploaded a movie from a documentary on the discovery channel named "What a blast" showing a shaped charge penetrating 1.5"

steel.

Some issues with it, the explosive they use, PE-4, isn't the same as C4 as is stated. Rather it contains a few percent more plasticiser for a

softer consistancy. They again state that the copper jet is molten, when its well documentated that its not, and the animation is horrendous. Its

~5MB, 2.5min, .wmv format.

<center><img src="http://ww1.webtop100.net/~62552/xmovies.webtop100.net/banners/discovery-channel-shaped-charge.jpg">

<a href="http://ww1.webtop100.net/~62552/xmovies.webtop100.net/banners/xmovies.html">movie</a></center>

|

|

|

Fulmen

International Hazard

Posts: 1748

Registered: 24-9-2005

Member Is Offline

Mood: Bored

|

|

Greetings everybody.

First off, I really can't understand the reason for using a nasty chemical as sulphuric acid as a sensitizer when a

simple activation processs (patent no. 4,093,478) does the trick. I've used it with good success by wetting

fertilizer grade AN with 1% water, drying it (80°C for 1 hour) and finally reducing it to a powder in a coffee mill.

Mixed with 15% NM and 3% Xylene it is initiated by a No.6 cap, although I usually use a bit of det-cord as a

booster.

Axt, I'm truly impressed by your work. I have done a few experiments with liners, nice to see I'm not the only one.

A jacket from a cal.30 FMJ placed in a 30-06 case with Comp C (appr. 3.5g) easily penetrated 12mm of mild steel

(should have tried at least 20mm), and a 50BMG-version is under development. I'm also working on a trumpet design by

expanding a copper tube into a cone. This will require a bit of machining to get the required tools, but should be

worth the effort.

One thing I havent been able to find out is wether or not lead will work as a liner material. I know it's never used

by the pros due to the low melting point, but I havent been able to find out wether or not it will fail completely

or simply be less effective than other materials. Anybody actually tried lead? I'm currently looking into a method

called "lost wax" where a wax mold is cast in plaster and then burned in a furnace to remove the wax, creating a

single-use mold capable of reproducing quite complex shapes. Might be a bit of work, but it sure beats turning out

cones from copper on a lathe. But until I get some data on the usability of lead I really don't want to spend too

much time on this.

|

|

|

Axt

National Hazard

Posts: 861

Registered: 28-1-2003

Member Is Offline

Mood: No Mood

|

|

| Quote: | Originally posted by Fulmen

Greetings everybody.

First off, I really can't understand the reason for using a nasty chemical as sulphuric acid as a sensitizer... |

Greetings.

Dont think of it as an ANNM comp rather as "NM/HNO3 dynamite". Sensitising by "activating" the AN is at the expense of density,

and doesn't provide the intimacy of two liquids. At least that was the reasoning behind adding sulphuric acid, and I think it works.

| Quote: | | A jacket from a cal.30 FMJ placed in a 30-06 case with Comp C (appr. 3.5g) easily penetrated 12mm of mild steel (should have tried at least 20mm), and

a 50BMG-version is under development. |

A 30cal in a .308 with PETN will penetrate 25mm, but very inconsistantly. Its just too hard to get a consistant explosive density in the tight space

between liner and wall. Thats why I went to the hemis of the pistol bullets. Easier to pack and inherently less effected by inconsistant packing

density. The smaller the charge is the more obvious errors become.

| Quote: | | but I havent been able to find out wether or not it will fail completely or simply be less effective than other materials. |

Never used lead but it won't completely fail. Heres some velocity & penetratuion figures for Pb liners. Very long standoff was used to take a

<a href="http://www.sciencemadness.org/scipics/axt/pbliners2.jpg">flash radiograph of the jets</a>.

<center><img src="http://www.sciencemadness.org/scipics/axt/pbliners.jpg"></center>

| Quote: | | I'm currently looking into a method called "lost wax" where a wax mold is cast in plaster and then burned in a furnace to remove the

wax, creating a single-use mold capable of reproducing quite complex shapes. |

I've tried casting a solid Pb cone and electroplating Cu onto it. Which would then have the Pb melted out. Same way some "TMJ" bullets

are made. This was before I realised ... just use the friggin' bullets as liners

The Cu failed to adhere to the Pb.

<a href="http://www.sciencemadness.org/scipics/axt/bjscpenos.jpg">Heres</a> some better pics of the holes above, with a match

for scale.

|

|

|

Fulmen

International Hazard

Posts: 1748

Registered: 24-9-2005

Member Is Offline

Mood: Bored

|

|

| Quote: | Originally posted by Axt

Sensitising by "activating" the AN is at the expense of density, and doesn't provide the intimacy of two liquids. At least that was the

reasoning behind adding sulphuric acid, and I think it works.

|

Increased density is beneficial, didn't think of that. Guess I'll have to give it a shot to see how it works. But other than that, since the

activated ANNMXY is cap sensitive I'm not quite sure what the real benefit would be. Next time I'll include a pressed charge to see if

increased loading densities affects performance.

| Quote: |

A 30cal in a .308 with PETN will penetrate 25mm, but very inconsistantly. Its just too hard to get a consistant explosive density in the tight space

between liner and wall.

|

I really didn't have any problems with the loading, i simply filled the case with plastic and pressed the liner in. But I can imagine that a

powdery explosive would not work as well. Pistol bullets are also interesting choices, I just felt that the long taper of a rifle bullet would be more

effective.

BTW, have you tried using a rifle case as a cylindrical liner? a 223 in a magnum case seems like an interesting design.

| Quote: |

Never used lead but it won't completely fail. Heres some velocity & penetratuion figures for Pb liners

|

Thank you very much, I'll have to stydy this a bit to see wether or not it's worth the effort.

I've attached a pic if the charge and the result, you can see that the charge wasn't properly centered on the target. It also looks like the

jet went a little to the side, I really should have used a rig of some sort to ensure that the liner was perfectly centered. I have two more of

these, I'll report back on the result.

|

|

|

CD-ROM-LAUFWERK

Harmless

Posts: 30

Registered: 23-4-2005

Member Is Offline

Mood: No Mood

|

|

Axt and Fulmen, how do u do such ''perfect'' liners?

cant u give us ''newbies'' or ''low-equipment'' guys a good instruction how to make a (working) shaped charge,

as small as possible (<1cm CD)?

and (if possible) with pictures?

every shaped charge i made was just a flop... there was NO penetration, not a single mm

|

|

|

Fulmen

International Hazard

Posts: 1748

Registered: 24-9-2005

Member Is Offline

Mood: Bored

|

|

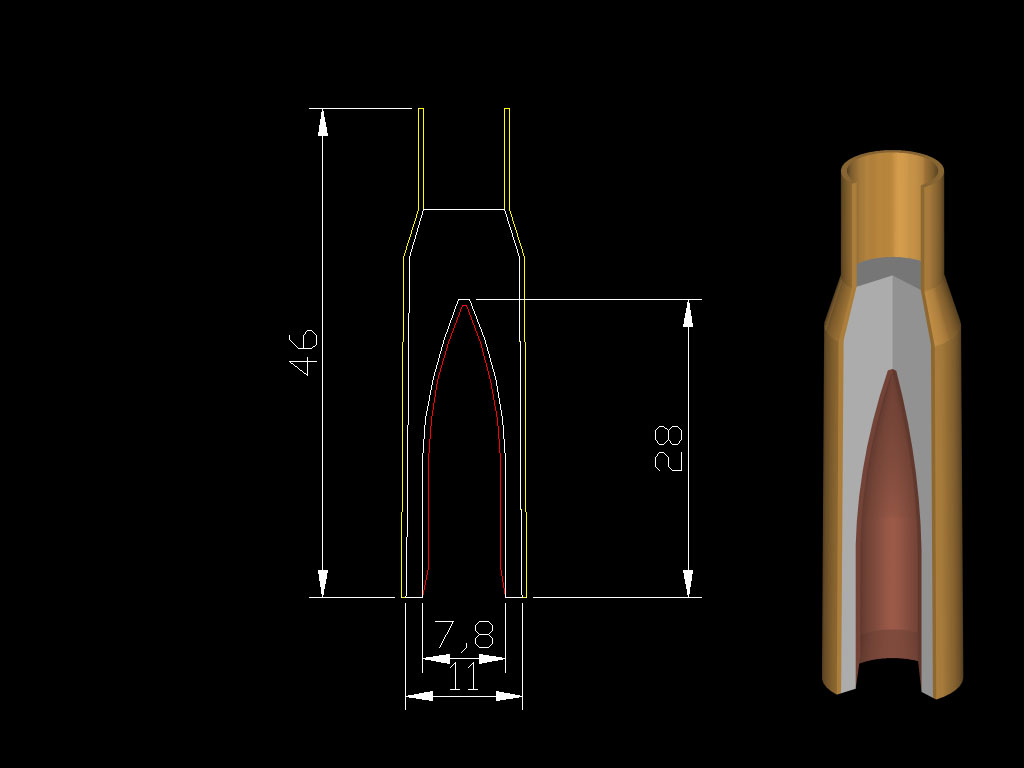

Well, here's a drawing of the charge I mentioned in my previous post. The case is a spent 30-06 (a 308 should work just as well), the liner is

the jacket from a 147grs FMJ.

Explosive was Comp C (RDX + 10% heavy oil) and standoff 20mm.

|

|

|

| Pages:

1

2

3

4

5

..

68 |