Adas

National Hazard

Posts: 711

Registered: 21-9-2011

Location: Slovakia

Member Is Offline

Mood: Sensitive to shock and friction

|

|

Citric acid to Isopropanol. Possible method?

Hello,

Few weeks ago, I noticed that when you remove all CO2 from citric acid, you'll get isopropanol.

Would the classical way of decarboxylation work?

C6H8O7 + 3 NaOH ----> C6H5O7Na3 + 3 H2O

C6H5O7Na3 + 3 NaOH ----> 3 Na2CO3 + (CH3)2COH

I didn't find any info about this on google, but if my procedure works, then it is an easy way to homemade IPA.

Rest In Pieces!

|

|

|

vmelkon

National Hazard

Posts: 669

Registered: 25-11-2011

Location: Canada

Member Is Offline

Mood: autoerotic asphyxiation

|

|

Sounds interesting but what conditions do you need to decarboxylate with NaOH? Because if you need to heat it, wikipedia says that the decomp temp =

175 °C

which is very low.

Also, there are 3 COOH groups that need to be removed. That would probably effect the yield.

|

|

|

Adas

National Hazard

Posts: 711

Registered: 21-9-2011

Location: Slovakia

Member Is Offline

Mood: Sensitive to shock and friction

|

|

Note that in the reaction, that needs heating, uses sodium citrate which melts at 300°C

Rest In Pieces!

|

|

|

GreenD

National Hazard

Posts: 623

Registered: 30-3-2011

Member Is Offline

Mood: Not really high anymore

|

|

From my experience working with these small organic poly-acids, is you're going to get a very sticky brown/orange mess.

We used to decarboxylate citric acid (when I wasn't busy eating it) in benzene (we also tried xylene and toluene) at high temps. We were trying to get

a route to lactic acid to make PLA. The decarboxylation worked well - eventually everything would go into solution after about 24 hours of reflux, a

nice yellow solution.

We attempted to extract, but for some reason slight basification yielded some messy product (can't remember exactly what happened).

Distillation provided char, often.

Most importantly - you will not get IPA. The hydroxy group gets knocked off and water forms. We used a modified dean-stark trap to remove water, to

prevent the reversal, so I'm not sure what the equilibrium constant is (whether you'll get more hydroxy or more water). Our main product was maleic

acid. however - as above, vacuum distillation produced tar, and base extraction yielded a mess (but I can't remember why!)

In short: this is not a feasible route to IPA. IPA is cheap, buy it at the store.

[Edited on 17-2-2012 by GreenD]

|

|

|

Nicodem

|

Thread Moved

18-2-2012 at 11:27 |

Hexavalent

International Hazard

Posts: 1564

Registered: 29-12-2011

Location: Wales, UK

Member Is Offline

Mood: Pericyclic

|

|

Frankly, if you want IPA, as GreenD says just purchase it online or as either a solvent or rubbing alcohol. Citric acid is probably much more

valuable.

"Success is going from failure to failure without loss of enthusiasm." Winston Churchill

|

|

|

Geocachmaster

Hazard to Others

Posts: 146

Registered: 5-3-2016

Location: Maine, USA

Member Is Offline

Mood: Corroded, just like my spatulas

|

|

Despite GreenD saying this would not work, I decided to try it anyway. After all, aga is always complaining about too much talk and not enough

chemistry . IPA is super cheap, much cheaper that citric acid, so this was only a

proof of concept and you should just buy some at the store if it's needed. . IPA is super cheap, much cheaper that citric acid, so this was only a

proof of concept and you should just buy some at the store if it's needed.

Intended reaction: one mole citric acid + heat → one mole IPA + three moles CO2

20.01g of anhydrous citric acid was added to a 100ml round bottom flask. This represents a .104 molar scale. The flask was fitted with a short path

condenser (for ease of use, not efficiency) and placed in a salt bath. A thermometer was added to the salt bath and heating commenced. 5 minutes of

heating brought the bath to ~165C when the contents of the flask began to liquefy. The reaction mixture was colorless and slowly bubbling at this

point. Condensation was observed in the flask and still head. 4 minutes later it had completely liquified and was bubbling more vigorously, getting

first drops in the receiving flask. 10 minutes passed collecting distillate while the contents of the flask had slowly become a dark yellow/orange.

Soon after small amounts of yellowish liquid started to come over and white wispy vapors were seen in the still head, heating was stopped. Dark,

orange, viscous liquid was left in the distillation flask and very slightly yellow liquid was in the receiving flask.

The product was approximately 4 ml of liquid having a mass of 3.84g. It had a distinct odor of IPA and rubbing alcohol. It was found to be flammable

and had a flammability close to that of 65% w/w isopropyl alcohol in water (found through experimentation).

3.84g of 65% IPA is 2.5g of the pure alcohol. Assuming what came over was only Isopropanol and water, 2.5g / 6.26g theoretical yield is a 39.9% yield.

This procedure could definitely be optimized and changed to get higher yields, but it would not be worth it, other than for the fun of it. For example

the short path condenser did not condense all of the vapors coming over. The method of finding the yield was very likely inaccurate but that was

deemed unimportant because the experiment was only meant to find out if any isopropanol was made.

The setup and partway through the reaction.

The salt bath works pretty good!

At the end

The product burning, sorry my camera is awful in the dark...

|

|

|

Amos

International Hazard

Posts: 1406

Registered: 25-3-2014

Location: Yes

Member Is Offline

Mood: No

|

|

Add some of the distillate to water and use pH paper or some indicator to see if the pH is changed substantially. You may have some organic acids as

byproducts.

If you've got largely IPA in there, it should separate out from any water if you saturate with sodium hydroxide.

If you want to confirm once and for all that you have a secondary alcohol there, you may want to try testing with Lucas' reagent, but this may require

more of your distillate than you currently have.

[Edited on 2-9-2017 by Amos]

|

|

|

Praxichys

International Hazard

Posts: 1063

Registered: 31-7-2013

Location: Detroit, Michigan, USA

Member Is Offline

Mood: Coprecipitated

|

|

So as a pedagogical exercise, in theory one could probably produce ethanol from malic acid as well, and also perhaps n-propyl amine from glutamic

acid.

|

|

|

Nicodem

Super Moderator

Posts: 4230

Registered: 28-12-2004

Member Is Offline

Mood: No Mood

|

|

I don't understand what you mean by all this talk about 2-propanol. There is no reference, or anything else in this thread, that would suggest

2-propanol as a possible product from citric acid thermolysis.

Thermal decomposition of citric acid is well known to give a mixture of products (the so called "pyrocitric acids"), composed mainly of citraconic

acid, itaconic acid, mesaconic acid, 3-hydroxyglutaric acid, their cyclic anhydrides and other stuff. On the other hand, you offer no indication that

the distillate contains 2-propanol (flammability is no specific property of this alcohol). And anyway, what would the mechanism of its formation be?

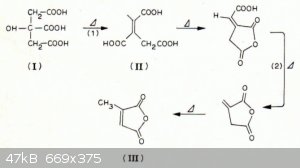

A scheme from DOI: 10.1016/0040-6031(86)87081-2

…there is a human touch of the cultist “believer” in every theorist that he must struggle against as being

unworthy of the scientist. Some of the greatest men of science have publicly repudiated a theory which earlier they hotly defended. In this lies their

scientific temper, not in the scientific defense of the theory. - Weston La Barre (Ghost Dance, 1972)

Read the The ScienceMadness Guidelines!

|

|

|

JJay

International Hazard

Posts: 3440

Registered: 15-10-2015

Member Is Offline

|

|

A quick way to check to see if it contains a significant amount of isopropanol would be to redistill it and check the boiling point. Of course, if any

of the products have similar boiling points to isopropanol, the results might be confounding.

Neutralizing any acids present would help to eliminate potential confounders. I'm pretty sure that strong sodium hydroxide solution would break up

those anhydrides (use eye protection, gloves, respirator if dealing with its powdered form, lab coat, etc.).

[Edited on 9-2-2017 by JJay]

|

|

|

PirateDocBrown

National Hazard

Posts: 570

Registered: 27-11-2016

Location: Minnesota

Member Is Offline

Mood: No Mood

|

|

Well, I don't know about this exactly. But it would occur to me that there are 2 decarboxylations happening here, the ones for the terminal acids, and

the one in the middle of the chain. Different conditions might be optimal for each.

That said, I wrote my first paper in grad school on the body's use of iron as a catalyst for the metabolism of citrate.

Some experimentation using iron, or some other transition metal, might not go awry here.

|

|

|

Fluorite

Hazard to Others

Posts: 139

Registered: 26-12-2018

Location: United Arab Emirates

Member Is Offline

|

|

OMG Geocachmaster is a life saver! I wanted IPA to make luminol but I didn't find any! It always mixed with ethyl acetate and acetone in a 6$ 70ml

nail Polish remover :/

Citric acid can be veryy cheap if you extract it from rotten lemons OR just heat lemon juice to dryness and pyrolyse the product directly?

|

|

|

Bedlasky

International Hazard

Posts: 1242

Registered: 15-4-2019

Location: Period 5, group 6

Member Is Offline

Mood: Volatile

|

|

Decomposition with ferric ions under UV light should work. Each mole of citric acid release three moles of CO2 in this reaction.

|

|

|

macckone

Dispenser of practical lab wisdom

Posts: 2168

Registered: 1-3-2013

Location: Over a mile high

Member Is Offline

Mood: Electrical

|

|

decomposition reactions are always messy.

Pyrolysis of wood as a classic example.

The primary products are carbon and water because wood is primarily carbohydrates and lignin.

But the by products are acetic acid, formic acid and methanol as well as many other compounds.

The methanol produced is actually rather low but it is usable.

IPA may not be the main product but it could still be a significant one.

For a while isopropyl alcohol could not be had for any price outside of a hospital and we are headed there again so this may be useful.

Of course this is science and it must be replicated.

This study decomposed citric acid but was looking at the carbon products:

https://link.springer.com/article/10.1007/s40097-017-0222-9

and another:

https://www.nature.com/articles/s41598-017-11572-8#:~:text=D...

If the by-product is the valuable quantum carbon dots, then yes this may be practical and increase the financial returns.

So yes it may be feasible to do this and even financially so.

|

|

|