| Pages:

1

2

3 |

Praxichys

International Hazard

Posts: 1063

Registered: 31-7-2013

Location: Detroit, Michigan, USA

Member Is Offline

Mood: Coprecipitated

|

|

Yes, the paper I posted a few days ago gives the mechanism and the rate constants for each step at various temperatures. Another key factor is phase

transfer since initially the acid and the alcohol are immiscible.

It is no surprise that you either need conc. HNO3 or a nitrite initiator with dilute acid since nitrite plays a catalytic role. You either get it from

decomp. of the acid or by adding some directly. Using dilute acid is clearly preferable since the aldehyde forms through hydrolysis and you will end

up with less BnONO and ring-nitrated products as impurities.

|

|

|

kmno4

International Hazard

Posts: 1503

Registered: 1-6-2005

Location: Silly, stupid country

Member Is Offline

Mood: No Mood

|

|

See interesting article, posted long time ago on the board :

http://www.sciencemadness.org/talk/files.php?pid=125689&...

Слава Україні !

Героям слава !

|

|

|

Texium

|

Thread Split

21-2-2017 at 19:04 |

LD5050

Hazard to Others

Posts: 182

Registered: 16-1-2017

Member Is Offline

Mood: No Mood

|

|

Is it important the concentration be at 90% or can higher concentrations be used? I'm performing this experiment right now and I have some pretty

concentrated acid probably around or over 95%. I'm getting a very strong reaction with the addition of Benzyl alcohol and a hint of Benzaldehyde smell

that quickly dissipates. I'm not getting a separation of layers or green coloring yet but I only added a few ml's at this point.

Also you say that when left to sit over night you then put into a seperatory funnel and remove the lower aqueous layer. For me it seems that the lower

layer is oily and im thinking that it is the benzaldehyde/benzyl alcohol layer. could for some reason my benzaldehyde be on the bottom?

[Edited on 2-27-2017 by LD5050]

|

|

|

CaptainMolo

Harmless

Posts: 30

Registered: 24-8-2017

Member Is Offline

Mood: No Mood

|

|

I've been after a good way to do this lately so I thought I'd throw in my two cents, although depending on it's usefulness, the market value of my

input my vary.

| Quote: |

For me it seems that the lower layer is oily and im thinking that it is the benzaldehyde/benzyl alcohol layer. could for some reason my benzaldehyde

be on the bottom?

|

During my most successful trial to date, I had this exact thing happen, so yes, in my experience it very much can depending on the density of the

aqueous layer.

I was trying an oxidation using a dilute piranha solution, which appeared to work reasonably well, the place where I messed up appears to be during

the workup.

I formed the bisulfite adduct, and filtered it off, but when trying to break the adduct I boogered it up somehow and ended up with a mess. It was a

very small scale run, 20 milliliters of BnOH to start with so I scrapped it to try a different approach.

I'm going to prepare some nitric acid in the next few days and give this a whirl, and I'll report back with my results.

[Edited on 13-9-2017 by CaptainMolo]

|

|

|

Corrosive Joeseph

National Hazard

Posts: 915

Registered: 17-5-2015

Location: The Other Place

Member Is Offline

Mood: Cyclic

|

|

Posted recently on another forum -

"Method 1

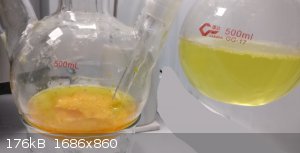

In a 2L flask, 800 ml of a 10% solution of HNO3 was added, to which 150 ml of benzyl alcohol was added. The flask is placed on medium heat, reflux

with a reflux condenser (put on the hose and vent it). Continuous stirring, after about 40 min rm boils and begins a self-sustaining reaction, the

mixture turns orange, apparently the oxides of nitrogen. It's time to remove the flask from the heating and help stirring. After about 30 minutes the

reaction subsides, and it must be maintained, put on average heating, reflux 2-2.5 hours. After a certain time, remove the reaction mass from the

heating, cool and rinse 3 * 500 ml of 15% K2CO3 solution. Carbonate washing allows to get rid of HNO3 residues, if this is not done, the yields

decrease to 40-50% due to oxidation of part of BA to benzoic acid. Next, we separate the lower phase of the dirty benzoic aldehyde and put it on

distillation with steam (you can not do this, and so it condenses well). The yield of the ready-pure benzoic aldehyde in the region of 80-84%

Method 2

Nitric acid was diluted to 1.59M (10% by weight). 4.6 g (42 mmol) of benzyl alcohol were added to a round bottom flask, and 18 g of 10% acid (28 mmol)

was added, maintaining the molar ratio of benzyl alcohol to acid, approximately as in article 1: 0.625. About 0.3 g of NaNO2 was added to the eye **

and heated to 90 ° in a water bath at high agitator speeds.

The entire mixture was heated for 4 hours (70-90 degrees) in a bath with a reflux condenser with running water. During the reaction, brown nitric

oxide is released, so an extract (or at least an open balcony) is necessary. The organic phase became yellowish.

The organic phase is separated on a separatory funnel, the water is extracted with DCM a couple of times. The organic phase is fused with DCM and

washed with a small amount of weak NaOH (while it is strongly yellowed), then saturated with the r-rum salt. The hydrochloric solution is extracted

with DXM just in case. After evaporation of DCM, 3.9 g (85%) of dirty benzaldehyde was finally obtained. Further purification was not carried out,

because, as practice shows, impurities of benzyl alcohol do not interfere with condensation.

** The amount of NaNO2 is not important, since it is only needed to initiate the process."

/CJ

|

|

|

Dennis A

Harmless

Posts: 13

Registered: 13-4-2018

Member Is Offline

Mood: No Mood

|

|

Has this method only tried with un-subsituted benzyl alcohols ?

Regards

|

|

|

Dennis A

Harmless

Posts: 13

Registered: 13-4-2018

Member Is Offline

Mood: No Mood

|

|

Error i meant to say substituted benzyl alcohols

|

|

|

sumatra

Harmless

Posts: 25

Registered: 15-8-2018

Member Is Offline

|

|

Must the nitric acid be 90%? Will 58% suffice?

|

|

|

Fyndium

International Hazard

Posts: 1192

Registered: 12-7-2020

Location: Not in USA

Member Is Offline

|

|

Quote: Originally posted by Praxichys  |

0.3 mol benzyl alcohol is charged into a flask with 1g NaNO2 and 118mL of 10% aqueous nitric acid preheated to 90°C. This is stirred as rapidly as

possible and kept at 90°C for 4 hours. The final product shows >86% conversion of the benzyl alcohol to benzaldehyde and benzyl nitrite, with a

yield of >95% for benzaldehyde and <1% for the nitrite, with <5% unconverted alcohol. |

I tested the reaction and it was about to turn a big mess. I pre-heated the 10% HNO3 to 90C, added the nitrite which fizzed a little and immediately

created a brown cloud, and then I dropped in the benzyl alcohol in during a couple of minutes instead of just pouring. At first it was looking ok, but

then proggressively more red gas was emitted and it started to fume through the inverted funnel in a runaway type scheme, so I quenched the reaction

by quickly pouring in a liter of cold water. Why this happened, even though I followed the above conditions?

Should the benzyl alcohol be added into the acid solution slowly, because if it is poured in fast, large amounts of brown nitrogen dioxide gas is

formed?

Or should they first be mixed cold, and then slowly heated to 90C?

It is certain that BzH was formed because the odor of it was pervasive. I vacuum distilled some of the benzyl alcohol and it appeared and smelled the

same, so it's mostly itself.

[Edited on 10-11-2020 by Fyndium]

|

|

|

Fyndium

International Hazard

Posts: 1192

Registered: 12-7-2020

Location: Not in USA

Member Is Offline

|

|

I think I'll try to alter the reaction so that I first mix and heat the 10% HNO3 and nitrite to 90 and then drop in the BnOH during 4 hours to control

reaction rate. Dumping all in sounds too uncontrollable to me. I don't know how they did this in study, but I managed to just create a blast of NO2

brown cloud and got exposed to it, and inverted funnel over conc NaOH was a mere joke absorbing the gas, such was the rate of formation.

|

|

|

nzlostpass

Hazard to Self

Posts: 66

Registered: 3-9-2019

Member Is Offline

|

|

It seems to always take off when temp hits about 80 to 90 degrees and all reactants are in.......last time, I heated the BnOH first then added in the

sodium nitrite in one go then the nitric acid in small bursts......that seemed to work but I guess it would make more sense to heat the acid first and

add the BnOH but I was worried about the ratio of nitric to alcohol being too high if adding the BnOH last.

|

|

|

Fyndium

International Hazard

Posts: 1192

Registered: 12-7-2020

Location: Not in USA

Member Is Offline

|

|

I suppose the method works without big issues because the OP did so and even with 90%, not 10% HNO3.

|

|

|

Fyndium

International Hazard

Posts: 1192

Registered: 12-7-2020

Location: Not in USA

Member Is Offline

|

|

Well, whatever I did, the main composition was not benzaldehyde, although the smell was there.

At least a significant part of it appears to be benzoic acid. Upon cooling to room temp, crystalline mass formed and made the entire reaction a mush,

and dark gunk accumulated at the bottom, which did only partially react with sodium bicarbonate and it had very powerful yellow staining ability to

fingers.

There were no recoverable layer or form of benzaldehyde, everything seem to have turned into benzoic acid and something else alongside.

How could it have overoxidized?

|

|

|

Amos

International Hazard

Posts: 1406

Registered: 25-3-2014

Location: Yes

Member Is Offline

Mood: No

|

|

Quote: Originally posted by LD5050  | Is it important the concentration be at 90% or can higher concentrations be used? I'm performing this experiment right now and I have some pretty

concentrated acid probably around or over 95%. I'm getting a very strong reaction with the addition of Benzyl alcohol and a hint of Benzaldehyde smell

that quickly dissipates. I'm not getting a separation of layers or green coloring yet but I only added a few ml's at this point.

Also you say that when left to sit over night you then put into a seperatory funnel and remove the lower aqueous layer. For me it seems that the lower

layer is oily and im thinking that it is the benzaldehyde/benzyl alcohol layer. could for some reason my benzaldehyde be on the bottom?

[Edited on 2-27-2017 by LD5050] |

This will depend on the concentration of leftover nitric acid that you end with, since nitric acid is far more dense than benzaldehyde or benzyl

alcohol. Your intuition about the benzaldehyde being on the bottom is likely correct, which would indicate that you used up most of the nitric acid

during the course of your reaction, or that your initial concentration was lower than estimated. I know this was a 3-year-old question but I wanted to

clarify this to anyone who decides to attempt the reaction in the future.

[Edited on 11-13-2020 by Amos]

|

|

|

nzlostpass

Hazard to Self

Posts: 66

Registered: 3-9-2019

Member Is Offline

|

|

Quote: Originally posted by Fyndium  | Well, whatever I did, the main composition was not benzaldehyde, although the smell was there.

At least a significant part of it appears to be benzoic acid. Upon cooling to room temp, crystalline mass formed and made the entire reaction a mush,

and dark gunk accumulated at the bottom, which did only partially react with sodium bicarbonate and it had very powerful yellow staining ability to

fingers.

There were no recoverable layer or form of benzaldehyde, everything seem to have turned into benzoic acid and something else alongside.

How could it have overoxidized?

|

That happened to me when I heated it for too long.....once its up to 90 degrees, turn down heating and let the reaction take place, it finally cools

down after 2-4 hours and then proceed.

The first time i tried it, I did it in an open beaker and heated/stirred it too long and got what you describe. Another time I started it and had to

turn it off and go to sleep and when I awoke it looked like a good amount of benzaldehyde had been produced but I was greedy and heated it again to

try get more as it hadnt had the full 4 hours....bad idea....it did what you described.

Now i just let it do its thing after it gets to 90 degrees and it seems to work great.

The yellow stains are a bastard but you cant seem to avoid that.

I'm still a beginner myself so take what I say with a grain of salt but that is my observations/experience.

|

|

|

Fyndium

International Hazard

Posts: 1192

Registered: 12-7-2020

Location: Not in USA

Member Is Offline

|

|

Hmm, thanks for the input. Funny how the research paper states to heat for 240min instead of just starting a reaction and letting it cool. I suppose I

gotta try your method since you state it works, apparently mine doesn't.

What I was looking into was this vid on Tube:

https://www.youtube.com/watch?v=FYZpsOsUxnU

|

|

|

nzlostpass

Hazard to Self

Posts: 66

Registered: 3-9-2019

Member Is Offline

|

|

Well it kinda goes for that sort of time by itself....I may have added a small amount of heat to keep it at 90ish degrees but it definately has

exothermic properties.....and prolonged heating definately caused the benzoic acid

formation.

And I too, followed that Toms Lab video and the posts that have been mentioned.

[Edited on 13-11-2020 by nzlostpass]

|

|

|

Fyndium

International Hazard

Posts: 1192

Registered: 12-7-2020

Location: Not in USA

Member Is Offline

|

|

Just wonder if NO2 catalyzes benzyl nitrite formation, could nitrate residues cause formation of benzyl nitrate, hence affecting yield?

|

|

|

Fyndium

International Hazard

Posts: 1192

Registered: 12-7-2020

Location: Not in USA

Member Is Offline

|

|

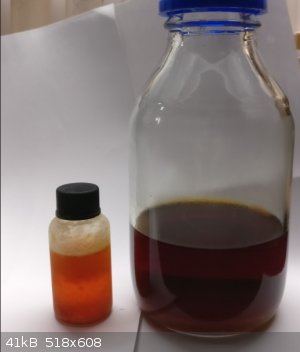

I replicated the Tom's Lab method by the book and got 26.3g yield of crude BzH from 31.5mL of BnOH. Only difference was using only 0.5g of NaNO2,

which is self-made and appears to contain significant amount of carbonate based on strong effervescence upon mixing with HNO3. Being an initiator

catalyst, the amount does not matter as long as there is, difference between 0.1 and 1g was negligible in the research.

I mixed up the ingredients and heated up to 90C for 4h and an extra 30 minutes because I hesitated at the middle for ½h and let it cool for a while

for not being able to decide which method I try first, but I ended up using the Tube/Research paper method. The BzH conversion from nitrite occurs

strongly at the last hours of the reaction according to the research paper, hence running it hot seems to do the job. Using water bath the temp hovers

steadily between 90-94C, adding water a couple of times. I used a 150mL fritted funnel as a trap because it allowed significant negative pressure

buildup without letting oxygen in the system. No benzoic acid crystals were noticed at any given point, compared to the previous reaction which ended

up as a crust of BzOH and some yellow gunk, probalby unreacted nitrite. I cooled down the reaction completely to ntp before opening the system,

separated the bottom layer, washed it once with water, twice with conc bicarb solution for zero CO2 emissions and then with brine, bottled it as a

slightly cloudy brown liquid and added a pinch of CaSO4 and it cleared up. The layer darkened as it was washed, it started as orange, and ended up as

dark brown.

Gonna do a few more reactions before I vacuum this and add to my bottle of previous vacuum BzH extract from bitter almond extract that consisted

mostly of oil and BzH.

Is there a danger of detonations from any possible remaining nitro compounds within the crude BzH upon distillation? I generally add a dose of mineral

oil into the reaction flask so I can distill it till the end without going dry. Would it be less risky to strip it by steam distillation instead?

PS. The yellow staining property of this process is annoying. Wearing gloves is mandatory, unless one wants to be a goldfinger. I suppose it

originates from some nitro compounds, as I remember that nitrophenols appear to be quite stainy too. It is very easy to rinse off from glass and hard

surfaces, but it just sticks to the skin and nails.

[Edited on 13-11-2020 by Fyndium]

[Edited on 13-11-2020 by Fyndium]

|

|

|

nzlostpass

Hazard to Self

Posts: 66

Registered: 3-9-2019

Member Is Offline

|

|

I steam distilled mine as im not very confident doing vacuum distillations yet...let us know what you decide and how you got on please.

|

|

|

Fyndium

International Hazard

Posts: 1192

Registered: 12-7-2020

Location: Not in USA

Member Is Offline

|

|

Absolutely I will. I should have time to do further processing during next week so I know better.

I would love to test out steam distillation as I haven't never done it. Vacuum distillation is more of a routine to me nowadays, whatever cannot be

distilled with bleeder tube(because haven't got no inert gas) goes with a stirrer.

|

|

|

Fyndium

International Hazard

Posts: 1192

Registered: 12-7-2020

Location: Not in USA

Member Is Offline

|

|

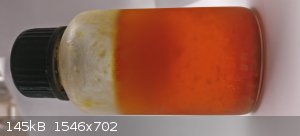

I prepared another batch, which is 205 grams from 250g of BnOH, after washing twice with saturated NaHCO, once with pure water and finally with brine.

The result is much darker than the previous batch, dried with CaSO4.

Another curious notice is that the first batch I put in freezer has crystallized out something. Not sure if it could be BzOH, BnOH or some other

impurity? I put the second batch also in freezer to see if same happens. BnOH has mp of -15.4C so it could easily be residual which should be removed

by distillation.

I'm still not confident distilling the substance as I'm not sure if there are anything left that could decompose violently?

|

|

|

morganbw

National Hazard

Posts: 561

Registered: 23-11-2014

Member Is Offline

Mood: No Mood

|

|

A byproduct of this synthesis is benzyl nitrite. It has a close boiling point to benzaldehyde. It seems doubtful that distillation would separate the

two.

By the way it should not be a huge amount but it will be there.

Perhaps making the adjunct, filtering, rinse the organics from the adjunct.

Carry on from there?

Just thinking through my keypad.

Good luck.

|

|

|

Fyndium

International Hazard

Posts: 1192

Registered: 12-7-2020

Location: Not in USA

Member Is Offline

|

|

Adduct is an option to separate it really pure, yes, I gave a thought for that and got bisulfite at hand, but keep it as a last resort because it is a

high loss process.

If the BnONO amount is small enough and it does not interact with the possible further uses of the BzH, it could just be left in. The content of it is

reported in the research paper as few % max when going at 90C. It's BP is almost identical to BzH so separation by distillation does not work. On the

other hand, the concentration of BnONO should hence remain so marginal as it co-distillates that no complications should occur. If the mere heating or

enrichment in the reaction vessel could cause issues, that's more of a question.

I'm not sure if BnONO react with NaHCO3 or would it decompose back to HNO3 and BnOH during processing?

|

|

|

morganbw

National Hazard

Posts: 561

Registered: 23-11-2014

Member Is Offline

Mood: No Mood

|

|

Looks like you knew already what I was cautioning you about.

The questions you now have seem to be as mine are.

My main problem is that I do not know benzyl nitrite well enough to know how it would behave in certain reactions.

|

|

|

| Pages:

1

2

3 |