Sulaiman

International Hazard

Posts: 3730

Registered: 8-2-2015

Location: 3rd rock from the sun

Member Is Offline

|

|

more gold refining questions

a quick introduction to my question;

I soaked scrap cpus and a few gold plated pins in 36% HCl and got Solution A,

After rinsing I added 69% HNO3 to the scrap and got Solution B

After rinsing I added Aqua Regia (freshly mixed, 26 ml 69% HNO3 added to 100 ml 36 % HCl).

This is a photo of the Aqua Regia 'refluxing'

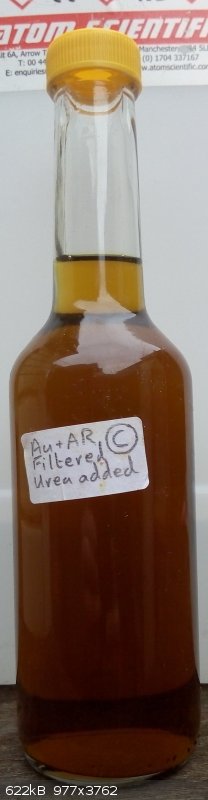

I filtered half of the green solution into a beaker on a hotplate and, based on a couple of YouTube videos,

added urea little by little, each addition of urea causing 'fizzing'

the solution kept on 'fizzing', though less vigorously, with each addition of urea, even when I thought that I must have added too much

so I increased the heat and got bubbling brown mud

I labelled this Solution C

And these are Solutions A, B and C

What is in the measuring cylinder ?

|

|

|

elementcollector1

International Hazard

Posts: 2684

Registered: 28-12-2011

Location: The Known Universe

Member Is Offline

Mood: Molten

|

|

Possibly copper? The color seems right. I don't know much about gold refining from circuitboards, though.

Elements Collected:52/87

Latest Acquired: Cl

Next in Line: Nd

|

|

|

Sulaiman

International Hazard

Posts: 3730

Registered: 8-2-2015

Location: 3rd rock from the sun

Member Is Offline

|

|

I expect that most of the copper is in Solution B as copper nitrate

and only a little carried over to the Aqua Regia 'digestion'

There is some blue visible above the brown, maybe copper plus others?

A lot of gold went into solution so some part of Solution C contains gold.

(I hope c0.4g in the measuring cylinder)

I was expecting a solution of hydrochloric and chloroauric acids with urea nitrate, not brown mud.

(The measuring cylinder (Solution C) has dH20 added to rinse out the 'mud')

I just read urea nitrate solubility is 15g/100ml which may be relevant.

P.S. my SnCl2 test solution is too weak, going to make more.

[Edited on 6-12-2015 by Sulaiman]

|

|

|

cyanureeves

National Hazard

Posts: 744

Registered: 29-8-2010

Location: Mars

Member Is Offline

Mood: No Mood

|

|

looks like copper to me too but i would still evaporate B and C and drop whatever gold is in both with sodium metabisulfite.what i hate is the white

copper because that crap keeps diluting blue to infinity and settles along with gold sometimes.yesterday i had to do a reduction with aluminum foil to

to my whole batch because no gold ever dropped. all i got was lots and lots of the white copper sand,i must have used 1/2 oz. of sodium metabisulfite

for just 3 grams of 10 kt. gold.today i melted all the aluminum,gold,copper and probably plated steel and got a semi metallic crystal glob.i

redissolve in aqua regia and finally the solution turned dark brown upon adding sodium metabisulfite.i think the gold filled chain was the culprit in

this case. correction:too much nitric acid is to blame even when i evaporate down to a crusty green and black.if i add too much nitric i always have

to add hydrochloric acid a second time and evaporate again.

[Edited on 12-6-2015 by cyanureeves]

|

|

|

cyanureeves

National Hazard

Posts: 744

Registered: 29-8-2010

Location: Mars

Member Is Offline

Mood: No Mood

|

|

|

|

|

diddi

National Hazard

Posts: 723

Registered: 23-9-2014

Location: Victoria, Australia

Member Is Offline

Mood: Fluorescent

|

|

I do 2 stage nitric.

you have to get the Cu out of your mix properly.

After digestion of all Cu in nitric. repeat nitric and heat to boiling to pull out the silver

this leaves the Au and PGMs if any

you have way to much solid left in "C"

after I do my Cu removal, I end up with less than 5 grams of solids from 100kg of e-waste

above: 100kg of e-waste ready for silver removal

Beginning construction of periodic table display

|

|

|

Sulaiman

International Hazard

Posts: 3730

Registered: 8-2-2015

Location: 3rd rock from the sun

Member Is Offline

|

|

Solution C was a clear green liquid (vacuum filtered through sintered glass) until I added urea and heat.

I will leave it to settle some more, originally c60 ml 'mud = 40 ml turbid, the photo is after c24 hr, and now after c30hr the 'mud' is below the 30

ml line.

|

|

|

etoxiran

Harmless

Posts: 9

Registered: 3-10-2010

Member Is Offline

Mood: No Mood

|

|

I read your post, but can't see any reductor (precipatant) you use for drop gold from solution. Urea work only for deNOX solution, but should't affect

gold in any matter. Why don't you use just plain hot saturated solution of FeSO4 ? After boiling all nitric will decompose without playing with shitty

urea mud, if you see no fresh NO2 boiling from vessel after addition, gold will drop from solution with minimal iron/ferrous oxide contamination. All

copper stay in solution, same as rest of metals.

Just add 1-2 amount of hot water to solution and left overnight. Easy-peasy

|

|

|

Sulaiman

International Hazard

Posts: 3730

Registered: 8-2-2015

Location: 3rd rock from the sun

Member Is Offline

|

|

I have not 'dropped' the gold yet,

I am trying to purify by chemistry,

This is all that is left of the original gold scrap CPUs and pins,

My intention at the moment is to further purify the chlorauric acid to crystals

(not fully researched yet, I may change direction again)

In the bottle;

Gold scrap soaked in 36% HCl for a week, liquid decanted off (no Au present)

scrap rinsed then soaked in 69% HNO3 for a week, liquid decanted off (no Au present)

Scrap gold dissolved in aqua regia, filtered, urea added, filtered, a drop of 96% H2SO4 added (no visible precipitate

This is now my starting solution for purification.

I expect HCl, urea nitrate, nitric acid, urea, metal chlorides and nitrates and chloroauric acid, maybe 1g.

I'm open to suggestions for the next steps ...

|

|

|

etoxiran

Harmless

Posts: 9

Registered: 3-10-2010

Member Is Offline

Mood: No Mood

|

|

I give you more hints.

1. If you drop out (reduce Au3+ to metal) gold, you will have metal with purity 90-99.9% after filtering.

2. After dissolving it in mix of HCl/H2O2 and carefully boiling out solution you will evaporate Cl2 and some of initial HCl

3. Further purification is very easy - just dissolve calculated amount of oxalic acid with NaOH to prepare sodium oxalate (potassium or ammonium work

too), Heat this soln to 50-70*C and drop to this your solution containing Au (with only minor contamination of Cu and Ni), effervescence (CO2

evolution) will occur and almost all gold will drop out as very pure powder orange - brown Au powder

4. Dissolve this powder again in HCl/H2O2 and evaporate to produce pure chloroauric acid

method you describe will not produce chloroauric acid (even if - it will be heavily contaminated with other metals)

purification with oxalic can be omited with little drop of purity (I've sold 30g of .9999 gold last week- confirmed by XRF)

I've suggest FeSO4 as reductor (precipitant  because after washing precipitated

gold with HCl it gives superior purity than any other reductor when work with solution full of other metals. because after washing precipitated

gold with HCl it gives superior purity than any other reductor when work with solution full of other metals.

AR was fast but leave in solution nitric acid which makes further purification a bit problematic. Most of FeSO4 is consumed for denox solution.

Precipitation (oxalic or FeSO4) should be make on hot solution, otherwise is not effective and it probably end with foaming and most of solution out

of vessel.

|

|

|

Sulaiman

International Hazard

Posts: 3730

Registered: 8-2-2015

Location: 3rd rock from the sun

Member Is Offline

|

|

thanks for the info.

I will have a go around the peroxide & oxalate route out of curiosity, thanks.

here is what I've done so far with the solution C since my post above;

... dropped the Au using SMB

... filtered, washed, dried, weighed = 0.83g (mainly fine black powder, some fine yellow)

... HCl wash, no activity, wash, dry, HNO3 wash, no reaction, wash ...

ACCIDENTALLY SQUIRTED SnCl2 SOLUTION INTO THE GOLD SOLUTION

... two rounds of HCl and HNO3 washes and rinses, 1 drop H2SO4, dilute, rinse, dry

... dissolve in AR, urea neutralise, SMB drop, wash, dry, weight = 0.65g (nice yellow sand)

Although I only recovered 0.65/0.83 = 78.3%

considering the scale and number of steps, not too bad,

but now I know I can do even better,

I took it as practice and actually enjoyed the exercise.

(maybe this year I'll start a proper Lab Notebook ?)

I am developing gold compound lust .......

|

|

|

deewee

Harmless

Posts: 3

Registered: 6-1-2016

Member Is Offline

Mood: No Mood

|

|

an adaptation of the industrial mining process with dissolution in cyanide to large amounts of material does not apply in this case?

|

|

|

etoxiran

Harmless

Posts: 9

Registered: 3-10-2010

Member Is Offline

Mood: No Mood

|

|

Cyanide process is more easy to spoil. It takes more time, require proper pH control, proper air pumping into solution (H2O2 works, but faster degrade

cyanide activity.

And, if you breath some vapour of AR, or chlorine, probably everything will be ok, with cyanide it might be your last breath...

SMB is good precipitant, but require no copper in solution.

|

|

|

Arthur Dent

National Hazard

Posts: 553

Registered: 22-10-2010

Member Is Offline

Mood: entropic

|

|

Quick question about Aqua Regia:

I have some e-scrap that i've been gathering over the past few years, I wanted to put it in a large beaker, put it on a hotplate, then add a mix of

100ml nitric acid and then 300 ml hydrochloric acid.

Since this will be done in a urban area (my balcony), I want to keep the evolution of nitrous gases to a minimum... Do I need heat from the hotplate

or can this be done at room temperature?

Or should I go through a safer route with HCl and bleach, at the risk of not "getting" all the gold in the e-scrap? I have about 20 cm3 of E-scrap

(mostly fingers and a few CPUs) and i'd like to salvage as much as I can...

I have Sodium metabisulfite to "drop" the gold, and I will generate in situ some SnCl2 solution to test for gold during the various stages of

salvaging...

I will of course wait for some "above zero" temperatures before proceeding.

Robert

--- Art is making something out of nothing and selling it. - Frank Zappa ---

|

|

|

Sulaiman

International Hazard

Posts: 3730

Registered: 8-2-2015

Location: 3rd rock from the sun

Member Is Offline

|

|

First, there are many methods of gold recovery, the aqua regia/urea/smb path is well trodden but may not be the best,

do a good deal of research before you start as starting materials are not cheaply replaced.

a good forum is http://goldrefiningforum.com/

As suggested to me, I suggest that if you have enough nitric acid then

before the aqua regia stage 'dissolve' the bulk of non-gold metals in nitric acid

this stage will generate lots of NOx

so add the nitric slowly with stirring and heating to prevent the generation of a toxic cloud.

When adding nitric has no effect, dilute and leave to stand for a few days,

decant off the liquid which should test negative for gold using SnCl2, and can be neutralised,

add a few drops of sulphuric acid to convert soluble metal nitrate salts to insoluble (less toxic) sulfates and discard.

Now do the aqua regia stage,

since hydrochloric acid is much cheaper and more available than nitric

add HCl first then slowly add HNO3, with heating, a little NOx with lots of HCl fumes will be produced.

For small scale gold refining I found that too much product is lost if filtering is used,

which is why I suggest patience and decanting.

I'm a noob, some other members have much more experience.

P.S. I enjoyed doing a little gold chemistry,

and learned patience in chemistry

and care to not waste any precious product.

I should have done more research before I started

and I had an accident during the process that contaminated my gold

but recovering what I could was also interesting.

The good news is that gold and its compounds are not volatile

so the gold is always somewhere available for re-refining.

next gold chemistry project for me: see if there really is 1g of recoverable gold in a Pentium Pro CPU

[Edited on 19-1-2016 by Sulaiman]

|

|

|