| Pages:

1

2 |

clearly_not_atara

International Hazard

Posts: 2834

Registered: 3-11-2013

Member Is Offline

Mood: Big

|

|

Why not just reduce it with potassium? Assuming you're familiar with producing K, SrCl2 + K >> Sr + KCl should be very favorable.

|

|

|

uzaymaymunu

Harmless

Posts: 34

Registered: 26-2-2012

Location: turkey

Member Is Offline

Mood: No Mood

|

|

Good idea but at which conditions? It's not possible with aqueus SrCl2 solution.

[Edited on 27-6-2015 by uzaymaymunu]

uzaymaymunu.blogspot.com

|

|

|

Molecular Manipulations

Hazard to Others

Posts: 447

Registered: 17-12-2014

Location: The Garden of Eden

Member Is Offline

Mood: High on forbidden fruit

|

|

I doubt that would work, potassium's greater volatility will negate the advantage of the small 'free energy', making separation nearly immposible.

-The manipulator

We are all here on earth to help others; what on earth the others are here for I don't know. -W. H. Auden

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

ΔH<sub>f</sub><sup>0</sup> for KCl and SrCl<sub>2</sub> resp. – 437 kJ/mol and – 829 kJ/mol (both NIST

Webbook values).

SrCl2 + 2 K === > Sr + 2 KCl, ΔH<sub>reaction</sub><sup>0</sup> = - 45 kJ/mol. Entropic effects

notwithstanding, that’s not promising ('not favourable'). And with K more volatile than Sr, heating isn't a solution here, as MM points out.

[Edited on 27-6-2015 by blogfast25]

|

|

|

uzaymaymunu

Harmless

Posts: 34

Registered: 26-2-2012

Location: turkey

Member Is Offline

Mood: No Mood

|

|

" The metal can be prepared by electrolysis of the fused chloride mixed with potassium chloride, or is made by

reducing strontium oxide with aluminum in a vacuum at a temperature at which strontium distills off. "

Sauce: CRC Handbook of Chemistry and Physics

Why chlorides, why not hydroxides?

And which ratio SrCl2/KCl should we prepare?

[Edited on 28-6-2015 by uzaymaymunu]

uzaymaymunu.blogspot.com

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

A eutectic mixture: lowest possible melting point (assuming there is an SrCl2/KCl eutectic).

[Edited on 28-6-2015 by blogfast25]

|

|

|

WGTR

National Hazard

Posts: 972

Registered: 29-9-2013

Location: Online

Member Is Offline

Mood: Outline

|

|

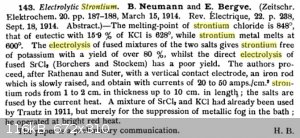

Referring to a previous page, here's the phase diagram:

https://www.sciencemadness.org/whisper/viewthread.php?tid=62...

Here's some more detail on strontium electrolysis:

(pg. 62) (pg. 62)

For whatever reason, it looks like temperatures given are wrong/sloppy in this reference.

|

|

|

Dan Vizine

National Hazard

Posts: 628

Registered: 4-4-2014

Location: Tonawanda, New York

Member Is Offline

Mood: High Resistance

|

|

The electrochemists may well agree with you Blogfast, Hg has a large overpotential for H production. But I'd stay far away from any aqueous solutions

I have a deep-seated distrust of any but a well equipped lab being able to quantitatively remove Hg from a metal lattice. Boiling and condensing Hg in

standard Pyrex is old hat, that's what all of our Hg diffusion pumps did back when those were routinely used on vacuum lines. For me, it's a more

about how would you know when you had succeeded? Just achieving constant weight, wouldn't mean all of the Hg was out, maybe it was just not

accessible. Elaborate, really extreme attempts to remove Hg from black P (catalyzed to form by it and copper-coated steel rods) fails, always.

The industrial method is, as noted, SrO and Al done at high vacuum in long heavy-walled steel retorts. Reactants and heat at one end. At a particular

temp. zone, the Sr vapor will condense. It's very difficult for most to engineer at home.

The Downs cell with a molten Sr salt eutectic is the route I'd try at home. It is what Westinghouse called a "Type 2" fused bath electrolysis. In Type

II the molten metal is deposited on a cathode that is sufficiently chilled to collect the metal as a solid from the molten bath. Atmosphere control

will be paramount in any method.

This is a far more difficult task than making sodium or potassium. That is generally true for group II elements. At one point I was convinced that I'd

find a way to make shiny barium metal. I no longer believe that I will succeed.

Does your country allow importation from China? They'll sell you nearly anything. Of course e-Bay, GalliumSource, Metallium , etc. will sell you Sr if

your import people aren't ball-breakers (and some countries really are!). But if you are intent on the manufacture, prepare yourself for a work and

time-intensive project.

"All Your Children Are Poor Unfortunate Victims of Lies You Believe, a Plague Upon Your Ignorance that Keeps the Youth from the Truth They

Deserve"...F. Zappa

|

|

|

j_sum1

Administrator

Posts: 6374

Registered: 4-10-2014

Location: At home

Member Is Offline

Mood: Most of the ducks are in a row

|

|

Quote: Originally posted by Dan Vizine  | .

At one point I was convinced that I'd find a way to make shiny barium metal. I no longer believe that I will succeed.. |

Sorry to hear that DV. Your glovebox was looking great and you were showing every indication of solving problems as they arose.

The question then is, has anyone ever produced shiny barium samples? Yours were the brightest that I have seen.

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Hmmm... the method is still used, albeit rarely now, for gold extraction for example.

There's an old sample of Ca metal in the British Museum, prepared all these decades ago with the aqueous amalgam cathode method. I'd have a go at

that, if I had enough mercury.

|

|

|

| Pages:

1

2 |