| Pages:

1

2

3

4

..

6 |

WGTR

National Hazard

Posts: 971

Registered: 29-9-2013

Location: Online

Member Is Offline

Mood: Outline

|

|

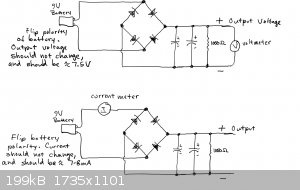

I think that everything Woolen said is correct. Here is a bit more descriptive schematic than what they gave you:

I suggest assembling the circuit board first. Where you would normally connect the rotary switch from the transformer, instead connect a 9V battery.

Measure the voltage on the output with the voltmeter. It should be about 1.5V less than the battery voltage. Now reverse the battery connection.

The output should still be the same voltage, and the same polarity. The output voltage should not flip polarity when the battery voltage does. Next,

switch the meter to measure current, and put it in line with the battery. The current should measure about 7 to 8 mA regardless of battery polarity.

If it is much higher or lower, something is wrong.

[Edited on 1-20-2015 by WGTR]

|

|

|

radiance88

Hazard to Self

Posts: 64

Registered: 18-12-2014

Location: underground volcano fortress

Member Is Offline

Mood: a little less evil than usual

|

|

So far my experience in all of this is that it's been just a lesson in pain.

The first time trying to solder an extra PC power supply plug onto the little transformer wires seemed OK enough. Lots of little globs of solder

around the wires and the connection seemed solid enough - however I had a WTF moment when using my multimeter to check the 12V output along with its

negative, as I just could not get a steady reading, and it was in the millivolt range. This was using the DC setting on my multimeter. However, using

my multimeter's AC setting gives me the desired current!

I'm at a loss for words as to what the heck is going on here.

I decided perhaps it's just sloppy soldering technique, as using the multimeter's AC setting in my wall socket gives me 230V, and testing a 1.5V

battery on DC gives me what I'm looking for, so I decide it can't be something wrong with my multimeter.

I cut off the soldered parts and start again using untouched parts of wire. I cannot for the life of me get the solder to go where I want it to go. It

either sticks to the tip or avoids seeping into my wires. I know that I should "tin the tip", and that I should heat the wire and feed the solder into

the wire to get a solid job. But despite the iron being hot enough to melt the solder on contact, holding it against the copper wire doesn't get it

hot enough even after a minute or two of contact to melt the solder.

I say "screw this" and then just try to feed the solder onto the tip and try to drip it downwards into the wire - instead the outside of the drop of

solder dries up, and it try to push it into the wire, but it won't stay there and instead falls down onto my workbench.

I'm pissed off enough to take my setup and chuck it all against the wall, but realizing that I can't inflict pain on solid objects, I just pack

everything back into a corner.

I'm not sure if my technique, my iron, or my solder is the deal here ,but I really don't think putting two wires together properly should be this

hard.

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Quote: Originally posted by radiance88  |

I'm not sure if my technique, my iron, or my solder is the deal here ,but I really don't think putting two wires together properly should be this

hard. |

You are right - don't chuck anything!

What is the watt rating of your soldering iron?

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

radiance88

Hazard to Self

Posts: 64

Registered: 18-12-2014

Location: underground volcano fortress

Member Is Offline

Mood: a little less evil than usual

|

|

It's 30 watts. It's a cheap chinese piece of junk, I know, but wouldn't this at least be enough to let me do small jobs like these? Plus it's new,

even if it did cost me only a few bucks. I've been advised here a few times to get myself a soldering station, but after spending so much cash on a

digital multiranging multimeter with temperature reading, I'm kind of set back awhile before I can make that kind of purchase again.

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

That's what I have: a 30w RadioSchack iron. Probably the same one you have. It seems to produce plenty of heat. I melt some solder on the tip,

knock off the excess with a knife, place the tip next to the joint, wait 3-4 seconds, then bring the solder down to the joint and it melts! My solder

is RS 0.050" diameter, rosin-core.

How long you heat the joint depends somewhat on the mass of metal that must be heated. Care must be taken to not overheat and damage heat-sensitive

components.

I don't see where you are doing anything wrong. I would recommend that you just get some scraps of copper wire and practice splicing them together.

Sometimes I need a 3rd hand. For that I've been using my fly-tying vice.

[Edited on 25-1-2015 by Magpie]

[Edited on 25-1-2015 by Magpie]

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

DREDD

Harmless

Posts: 1

Registered: 20-1-2015

Member Is Offline

Mood: No Mood

|

|

Hi

I dont post but some of the advice here I totally disagree with!

Electronics my first love.

Totaly self-taught for about 40 years.

You don't have a clue about the subject so here are my tips,

1 Soldering, forget it, for now.

Its an art and will break you before you start.

2 Dont spend any money on tools or kit.

Here is what you should do

Collect lots of unwanted BATTERY ONLY operated devices.(Torches are great)

Start stripeing them down and playing with them and putting them back together.

You will learn loads in a short space of time and it will cost you nothing.

Anyway thats my tuppenceworth and first post.

Best of luck.

|

|

|

WGTR

National Hazard

Posts: 971

Registered: 29-9-2013

Location: Online

Member Is Offline

Mood: Outline

|

|

I respectfully disagree with Dredd. Soldering is a very, very, basic electronics skill, and it will become much easier once you get through a few

"aha!" moments.

Back when I used the 30W irons, I noted that they took at least 5, sometimes 10 minutes to heat up. The cheap irons have no temperature regulation,

and get hotter and hotter as time goes on. Also, 30W is not a very powerful iron, so there will be some large wires that it is simply not powerful

enough to solder without assistance. It sounded like you were doing things correctly by adding a small amount of solder to the tip, and then feeding

solder directly into the joint as it was heated. Would you mind posting a picture of the problem solder joints?

Some tips for soldering objects with an underpowered soldering iron:

Not only "tin" the soldering iron tip, but also tin each part lead separately before trying to solder them together. In other words, if you're trying

to solder a large wire to a heavy pin, try soldering the wire and pin separately first. If the solder flows cleanly over them, then you know that the

surfaces are clean. Clean parts like this will solder more readily at a lower temperatures than dirty ones will. It is good to get in the habit of

doing this anyway.

If one part simply won't take solder, it is possible that it is covered with a heavy oxide layer. The flux requires higher heat from the soldering

iron in this case, before it can clean the joint. If this happens, simply clean the wires with fine sandpaper. On rare ocassions, I have found some

old parts to be so oxidized that they were unsolderable without sandpaper cleaning.

If possible, preheat the part in an oven or on a hot plate.

https://www.sciencemadness.org/whisper/files.php?pid=338528&...

In the previous example, I soldered some copper pipe to a copper plate by heating it on a hot plate and feeding solder into the joint. No soldering

iron needed.

Eutectic solder melts at 183°C. If your part cannot withstand this temperature, even preheating to 60-70°C in an oven can make it possible to

solder a problem joint with a weak soldering iron. Some plastics start softening around 100°C, so don't overdo it.

Normally these extra methods are unnecessary, and the soldering iron will be sufficient by itself.

Another possible problem is that you're trying to solder to aluminum or steel. These metals require special techniques and fluxes, and cannot be

soldered with normal electronics solders. I sometimes had this problem, but it sounds like this isn't your issue. Anyway, let's see a picture.

|

|

|

The Volatile Chemist

International Hazard

Posts: 1981

Registered: 22-3-2014

Location: 'Stil' in the lab...

Member Is Offline

Mood: Copious

|

|

Anyone know of a good site explaining RC (Resistor Capacitor, not Remote control) electronics well? Stuff similar to what tim (the A---- guy, I always

forget his name, subtitle 'post harlot', with a username for a guitar petal) does.

|

|

|

aga

Forum Drunkard

Posts: 7030

Registered: 25-3-2014

Member Is Offline

|

|

Depends what you mean/want to build.

Are you talking about time constants or filtering - there's an awful lot of RC circuit theory out there.

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Here's a site full of tutorials:

http://www.electronics-tutorials.ws/rc/rc_1.html

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

jock88

National Hazard

Posts: 505

Registered: 13-12-2012

Member Is Offline

Mood: No Mood

|

|

Soldering is a very basic skill as stated above.

If ya cannot maser some simple soldering ye may quit!

The age of components can make them difficult to solder. Brand new components and brand new board is very easy to solder (using solder with flux

core).

Old resistors and caps. that have been around for years have an oxide layer built up on the leads and can be difficult to solder. You may need to

clean the leads with a rub of sandpaper or scrape them with a knife. Same for copper strip board and pcb's (thats pwb's for those on the 'other'

side).

Some solders have very little flux contained in them. The stuff that you may get out of an electronics factory (take home in your pocket god forbid)

where they are always dealing with brand new components and boards, use solder that have very little flux as everything is very clean and new.

Purchase solder with a decent amount of agressive flux (don't know how to ask or obtain it I will admit) in it for doing home stuff that may have more

'rusty' (older) components in the project.

|

|

|

The Volatile Chemist

International Hazard

Posts: 1981

Registered: 22-3-2014

Location: 'Stil' in the lab...

Member Is Offline

Mood: Copious

|

|

Quote: Originally posted by aga  | Depends what you mean/want to build.

Are you talking about time constants or filtering - there's an awful lot of RC circuit theory out there. |

Yes, also power supply workings such as how voltage/amperage is regulated (Not just with a three-prong regulator ). ).

|

|

|

aga

Forum Drunkard

Posts: 7030

Registered: 25-3-2014

Member Is Offline

|

|

Oh i see : Electronics in General.

To get started, and experiment, i really cannot recommend this kit highly enough, or enough times :-

http://www.ebay.co.uk/itm/130-IN-ONE-ELECTRONIC-PROJECT-LAB-...

|

|

|

The Volatile Chemist

International Hazard

Posts: 1981

Registered: 22-3-2014

Location: 'Stil' in the lab...

Member Is Offline

Mood: Copious

|

|

Aga....

I saw your recommendation, and haven't ignored it, I own that kit (Purchased ~1yr ago) and have gone through it. It does not discuss power supply

theory, which is what I'm getting at. But it is a wonderful foundation for electronics, I recommend it too.

|

|

|

aga

Forum Drunkard

Posts: 7030

Registered: 25-3-2014

Member Is Offline

|

|

For power supplies, it all gets down to what you want in the final supply.

Stability mostly, being Voltage, Ripple, Current and Error Detection.

In some cases it's Current limiting or voltage limiting/boosting.

A basic voltage regulator uses a transistor (high power) to regulate the Output voltage in what is called an 'Emitter Follower' configuration.

e.g. http://www.radio-electronics.com/info/power-management/linea...

A 7805/6/8/12/15 regulator is a much more advanced version of this, yet basically the same.

Current limiting tends to be done by current detection, and limiting the Voltage to achieve the required current.

Buck and Boost regulation techniques are brilliant.

They work by using Pulse Width Modulation to either Raise a voltage or reduce it.

Basically you switch current into an inductor on/off at varying rates, and then use the energy in the collapsing magnetic field to power your circuit.

e.g. search www.microchip.com for AN626 , lead acid battery charger

Ripple (DC having a small amount of crap on it) tends to still be mitigated by adding capacitors in parallel with the output.

|

|

|

The Volatile Chemist

International Hazard

Posts: 1981

Registered: 22-3-2014

Location: 'Stil' in the lab...

Member Is Offline

Mood: Copious

|

|

Thanks. That's pretty much what I was talking about.

|

|

|

aga

Forum Drunkard

Posts: 7030

Registered: 25-3-2014

Member Is Offline

|

|

Interesting (and useful) as Buck & Boost circuits are, most modern standard PSUs (e.g. your laptop charger) use a technique called 'Switch Mode'.

The 230volts AC is rectified giving a DC supply of 324volts (rectify AC with a bridge and you get 1.41 times the AC as DC) which is then switched

off/on at between 20~40kHz through a transformer.

The physics of transformers means that the higher switching frequency allows you to use a much smaller transformer than you would at the usual 50~60

Hz for the same energy transfer.

Despite the massive difference in complexity between a simple PSU circuit (with a transformer to take 230vac to 12vac, then a bridge & a

capacitor) the reduced amount of transformer material (copper, iron) still makes it cheaper to use switch mode.

Taking the Size and Weight difference into account (=shipping costs) there's no competition, hence almost all modern PSUs are switch mode.

|

|

|

The Volatile Chemist

International Hazard

Posts: 1981

Registered: 22-3-2014

Location: 'Stil' in the lab...

Member Is Offline

Mood: Copious

|

|

Thanks for the information. That's the kind of stuff I was looking for. If I find Tim's website, or I remember his SM Username, I'll post a link to

his work with some sort of induction heating device (rather common in home chem. if I remember), and ask for info. on how it works

|

|

|

aga

Forum Drunkard

Posts: 7030

Registered: 25-3-2014

Member Is Offline

|

|

Industrially they call it an 'Inverter'

Basically all the energy gets converted to Radio Frequency energy, and gets absorbed by the Target by inducing currents in them, hence the term

'Induction Heating'.

https://www.youtube.com/watch?v=hw9OmmKVunI

Edit:

Maybe this : https://www.youtube.com/watch?v=pVYMLnXW9uo

[Edited on 29-1-2015 by aga]

|

|

|

WGTR

National Hazard

Posts: 971

Registered: 29-9-2013

Location: Online

Member Is Offline

Mood: Outline

|

|

12AX7

|

|

|

jsc

Hazard to Self

Posts: 65

Registered: 16-3-2011

Member Is Offline

Mood: No Mood

|

|

Sorry to rain on your parade, but unless you are a kid, you can probably forget learning electronics, there is just too much stuff and technique to

acquire for an adult whose best learning years are behind them. If you were one of the rare type of adults who have the capacity for adding a big new

skill like this, you would not be asking on a forum how to do it, you would already know such things.

In other words, just the fact that you are asking here "How do I learn electronics?" pretty much identifies you as someone who has a 0% chance of

getting anywhere with something like that.

I recommend sticking with things you already know how to do, and leverage your precious time where it will do the most good, which is stuff you know,

not whole new sciences and technologies.

|

|

|

guanadine

Harmless

Posts: 5

Registered: 2-2-2015

Member Is Offline

Mood: No Mood

|

|

The best way to start learning electronics is by doing. you are not going to retain anything you read but when you involve physical movements its

like Karate. start by going on ebay and search for electronics kit + op amps. buy a kit for 15 dollars, a 5 dollar solderless breadboard, a cheap

voltmeter. and a 12 volt center tap transformer from radioshack. your knowledge will increase exponentially.

|

|

|

Zombie

Forum Hillbilly

Posts: 1700

Registered: 13-1-2015

Location: Florida PanHandle

Member Is Offline

Mood: I just don't know...

|

|

Quote: Originally posted by jsc  | Sorry to rain on your parade, but unless you are a kid, you can probably forget learning electronics, there is just too much stuff and technique to

acquire for an adult whose best learning years are behind them. If you were one of the rare type of adults who have the capacity for adding a big new

skill like this, you would not be asking on a forum how to do it, you would already know such things.

In other words, just the fact that you are asking here "How do I learn electronics?" pretty much identifies you as someone who has a 0% chance of

getting anywhere with something like that.

I recommend sticking with things you already know how to do, and leverage your precious time where it will do the most good, which is stuff you know,

not whole new sciences and technologies.

|

Man that's a negative attitude.

When I'm 80 I hope to begin another career in Rocket Surgery. I just don't have time yet due to the week or two it's going to take learning Organic

Chemistry.

The fella has no reason to learn every aspect of electronics, (which by the way can be learned in just a few months for basic electronics). Just a few

skills at reading schematics, and understanding which way the water flows. It's no more complex than plumbing, and you don't need a masters to

understand plumbing.

I have a dear friend that is a retired Prof. of Electronic Engineering (Stony Brook). He calls me to repair the simple DC circuits in his boat. Not

because he does not understand them but because he can not follow the plumbing. The concept of wiring harnesses traveling between decks, and randomly

changing color from source to point eludes him.

My point is anything can be learned , and applied.

Call me in 20 years if you need your rocket fixed. I will include free spay or neutering w/ all vaccinations . .

They tried to have me "put to sleep" so I came back to return the favor.

Zom.

|

|

|

woelen

Super Administrator

Posts: 8014

Registered: 20-8-2005

Location: Netherlands

Member Is Online

Mood: interested

|

|

Quote: Originally posted by jsc  | Sorry to rain on your parade, but unless you are a kid, you can probably forget learning electronics, there is just too much stuff and technique to

acquire for an adult whose best learning years are behind them. If you were one of the rare type of adults who have the capacity for adding a big new

skill like this, you would not be asking on a forum how to do it, you would already know such things.

In other words, just the fact that you are asking here "How do I learn electronics?" pretty much identifies you as someone who has a 0% chance of

getting anywhere with something like that.

I recommend sticking with things you already know how to do, and leverage your precious time where it will do the most good, which is stuff you know,

not whole new sciences and technologies.

|

If everybody were reasoning like this, then we still would live in caves and use wooden sticks as our most advanced piece of technology. What you are

saying is utter nonsense. You never are too old to teach yourself something new. Of course, you need commitment and you will have to put some effort

in it, but it can be done. As already stated before, by doing things you also can teach yourself a lot. Just try things and try to understand what you

observe by reading and thinking about it.

|

|

|

The Volatile Chemist

International Hazard

Posts: 1981

Registered: 22-3-2014

Location: 'Stil' in the lab...

Member Is Offline

Mood: Copious

|

|

Quote: Originally posted by jsc  | Sorry to rain on your parade, but unless you are a kid, you can probably forget learning electronics, there is just too much stuff and technique to

acquire for an adult whose best learning years are behind them. If you were one of the rare type of adults who have the capacity for adding a big new

skill like this, you would not be asking on a forum how to do it, you would already know such things.

In other words, just the fact that you are asking here "How do I learn electronics?" pretty much identifies you as someone who has a 0% chance of

getting anywhere with something like that.

I recommend sticking with things you already know how to do, and leverage your precious time where it will do the most good, which is stuff you know,

not whole new sciences and technologies.

|

Haha, N/A, as I fit the interval (0, 18).

Thanks, that's him. He's a great guy (but probably thinks I'm weird  ) )

Also what I was talking about, thanks. I find such devices interesting, but don't plan on building one too soon.

|

|

|

| Pages:

1

2

3

4

..

6 |