| Pages:

1

..

7

8

9

10

11

12 |

Motherload

Hazard to Others

Posts: 245

Registered: 12-8-2012

Location: Sewer

Member Is Offline

Mood: Shitty

|

|

I can't seem to remember where I kept the printouts. I am sure I'll find them when I am looking for something else.

Since I am doing this on my iPhone ... I can't do the calculations, but .......

3 moles of formaldehyde combine with 3 moles of AN to produce 1 mole of RDX and 3 of water.

Molar mass of formaldehyde is ~30 gms

Molar mass of NH4NO3 is ~ 80 gms

So to keep it simple 3 moles = 90 gms CH2O and NH4NO3 is 240 gms.

The ratio is closer to 1:3 by weight whereas the patent suggests 1:5.

1 being CH2O

Besides that ... The catalyst is only supposed to lower the reaction temp.

Are you sure your AcAn is not mixed with Acetic acid due to water contamination ?

With water present in reaction ... You will end up with HDN.

"Chance favours the prepared mind"

"Fuck It !! We'll do it live !!"

|

|

|

markx

National Hazard

Posts: 646

Registered: 7-8-2003

Location: Northern kingdom

Member Is Offline

Mood: Very Jolly

|

|

Quote: Originally posted by Motherload  | I can't seem to remember where I kept the printouts. I am sure I'll find them when I am looking for something else.

Since I am doing this on my iPhone ... I can't do the calculations, but .......

3 moles of formaldehyde combine with 3 moles of AN to produce 1 mole of RDX and 3 of water.

Molar mass of formaldehyde is ~30 gms

Molar mass of NH4NO3 is ~ 80 gms

So to keep it simple 3 moles = 90 gms CH2O and NH4NO3 is 240 gms.

The ratio is closer to 1:3 by weight whereas the patent suggests 1:5.

1 being CH2O

Besides that ... The catalyst is only supposed to lower the reaction temp.

Are you sure your AcAn is not mixed with Acetic acid due to water contamination ?

With water present in reaction ... You will end up with HDN.

|

Yes, in a very simplified manner it can be viewed as a 1:1 molar ratio reaction....not considering the side reactions.

According to the stoichiometry presented by Urbanski the ratios would work out following:

Ac2O: 2mol M=102g/mol 204g

AN: 1mol M=80g/mol 80g

CH2O:1mol M=30g/mol 30g

The patent of Schissler Ross suggests a ratio of at least 1:1,25 mol of CH2O/AN to 2.64mol of Ac2O. Although in the example they give the ratio is 1:2

CH2O/AN (3/16g).

Taking this fact into regard the corrected ratios would work out as.

Ac2O: 2,64mol-> 270g

AN: 1,25mol-> 100g

CH2O: 1,0mol-> 30g

Which is closer to the conditions of my first synthesis.

The quality of my Ac2O is unverified as is and it is entirely possible that a partial hydrolysis has taken place over time. It is from an old

batch...I have no idea when it was produced or in what conditions it was stored. I guess I'll have to try the synthesis with extra Ac2O to sompensate

for the possible acetic acid and see if that has an effect on yield. A reasonable return with 3g CH2O input with 65% yield would be around 5g.

As for the catalyst I think the effect may not only involve the lowering of the activation barrier, but also include the altering of reaction

pathways, thus possibly lowering also the probability of side products. But it has to be tested...speculations on this part of the topic tend to be

rather futile without any experimetal evidence

Exact science is a figment of imagination.......

|

|

|

ethicalhacker

Harmless

Posts: 4

Registered: 24-2-2012

Member Is Offline

Mood: No Mood

|

|

K-Process

Agrawal and Hodgson mention the K-process. Their description of it makes it seem like the obvious choice for those with limited resources. I haven't

had success digging up the sources they reference though. I'm not finding much on that particular process via the search tool here either. Have others

used this process successfully? From my reading of Agrawal and Hodgson, it seems like the temperature is the tricky component of the K-process. With

HNO3's boiling point being so close to the reaction temperature, no doubt there's little room for error. Their suggestion that the addition

of NH4NO3 reduces the risk of oxidation (e.g. fireballs) known to occur during direct nitration is attractive.

|

|

|

markx

National Hazard

Posts: 646

Registered: 7-8-2003

Location: Northern kingdom

Member Is Offline

Mood: Very Jolly

|

|

Synthesis of heterocyclic nitramines is by no means a low budget/limited resource type of endeavour....no matter which synthesis method one chooses.

It can be done efficiently on industrial plant scale level, but for the amateur experimetalist the synthesis of the highly concentrated nitric acid is

the bottleneck for most of the available methods. And the obtaining of acetic anhydride for the remainder of routes. The bill of materials becomes

outrageously high without the means to recover, reconcentrate and recycle the acids.

The topic of nitramines is an interesting and captivating one, but as for the economy in amateur settings...definitely not the winner.

Exact science is a figment of imagination.......

|

|

|

ethicalhacker

Harmless

Posts: 4

Registered: 24-2-2012

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by markx  | | It can be done efficiently on industrial plant scale level, but for the amateur experimetalist the synthesis of the highly concentrated nitric acid is

the bottleneck for most of the available methods. And the obtaining of acetic anhydride for the remainder of routes. |

I agree in principal with your statements. Both of the components you mentioned are difficult to come by; however, it is my experience that

NH4NO3 and H2SO4 are readily obtainable. With a decent sized distillation set and a few hours of time,

acceptable HNO3 is also obtainable. If my calculations of the K-process are correct, one would only need 250ml (371.2g of 95% concentration

at 25C) of HNO3 to produce a 90% yield of 588.8g of RDX. I think that is pretty good. Am I wrong?

|

|

|

markx

National Hazard

Posts: 646

Registered: 7-8-2003

Location: Northern kingdom

Member Is Offline

Mood: Very Jolly

|

|

Quote: Originally posted by ethicalhacker  | Quote: Originally posted by markx  | | It can be done efficiently on industrial plant scale level, but for the amateur experimetalist the synthesis of the highly concentrated nitric acid is

the bottleneck for most of the available methods. And the obtaining of acetic anhydride for the remainder of routes. |

I agree in principal with your statements. Both of the components you mentioned are difficult to come by; however, it is my experience that

NH4NO3 and H2SO4 are readily obtainable. With a decent sized distillation set and a few hours of time,

acceptable HNO3 is also obtainable. If my calculations of the K-process are correct, one would only need 250ml (371.2g of 95% concentration

at 25C) of HNO3 to produce a 90% yield of 588.8g of RDX. I think that is pretty good. Am I wrong? |

I think your calculations are a bit off on the bill of materials. I'm referencing to Urbanski regarding the K-method material balance and it figures

out roughly as:

50g hexamine

480g AN

860g HNO3

to produce 100g of RDX

Take into account the materials needed to produce that amount of HNO3 by distilling and you will soon realise it is a lost cause in terms of any

economy. And this is data for plant level yield....it can be less in an amateur setting. In fact whichever synthesis route you choose, the excpected

yield will realistically hover in the 70% range......90% is unfortunately a pipe dream.

Exact science is a figment of imagination.......

|

|

|

ethicalhacker

Harmless

Posts: 4

Registered: 24-2-2012

Member Is Offline

Mood: No Mood

|

|

Agrawal and Hodgson report the following chemical formula for the K-process. This is the basis for my calculations.

C6H12N4 + 2 NH4NO3 + 4 HNO3 -> 2

C3H6N6O6 + 6 H2O

|

|

|

Motherload

Hazard to Others

Posts: 245

Registered: 12-8-2012

Location: Sewer

Member Is Offline

Mood: Shitty

|

|

Shouldn't nitraamide condense with straight formaldehyde to produce RDX ?

"Chance favours the prepared mind"

"Fuck It !! We'll do it live !!"

|

|

|

markx

National Hazard

Posts: 646

Registered: 7-8-2003

Location: Northern kingdom

Member Is Offline

Mood: Very Jolly

|

|

| Quote: |

Agrawal and Hodgson report the following chemical formula for the K-process. This is the basis for my calculations.

C6H12N4 + 2 NH4NO3 + 4 HNO3 -> 2

C3H6N6O6 + 6 H2O

|

This equation reflects the summary ratios of reagents involved in the actual formation of the product...albeit in a rather simplistic manner, but that

is not even important at this stage. What is important though, is the fact that one needs to involve a considerable amount of overhead reagents to

drive up the yield and bind the formed water. In fact the ratios are 0,5/8,6 of hexamine/HNO3 by mass. This acid is recovered and reused in industrial

setups, therefore the losses are negligible, but that will not be the case in amateur synthesis.

[Edited on 27-5-2014 by markx]

Exact science is a figment of imagination.......

|

|

|

markx

National Hazard

Posts: 646

Registered: 7-8-2003

Location: Northern kingdom

Member Is Offline

Mood: Very Jolly

|

|

On the note of E-method....I also performed a run with 4g paraform to 8g of AN to study the effect of a ratio that inclines towards excess

paraformaldehyde. First observation seemed promising as the amount of preciptate formed was greatly increased (2g of yield after drying). But the vast

majority of this precipitate was unreacted paraform, as it turned out afterwards on recristallisation stage with acetone.

I have to take a closer look on the quality of the anhydride before I continue with further experimentation involving catalysts. Perhaps the cause of

all the failures is the degradation of the anhydride.

Exact science is a figment of imagination.......

|

|

|

caterpillar

Hazard to Others

Posts: 472

Registered: 8-1-2012

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by markx  | | Quote: |

Agrawal and Hodgson report the following chemical formula for the K-process. This is the basis for my calculations.

C6H12N4 + 2 NH4NO3 + 4 HNO3 -> 2

C3H6N6O6 + 6 H2O

|

This equation reflects the summary ratios of reagents involved in the actual formation of the product...albeit in a rather simplistic manner, but that

is not even important at this stage. What is important though, is the fact that one needs to involve a considerable amount of overhead reagents to

drive up the yield and bind the formed water. In fact the ratios are 0,5/8,6 of hexamine/HNO3 by mass. This acid is recovered and reused in industrial

setups, therefore the losses are negligible, but that will not be the case in amateur synthesis.

[Edited on 27-5-2014 by markx] |

Use hexamine dinitrate instead of hexamine. Diluted acid later may be used for preparation of aforementioned hexamine dinitrate or urea nitrate for

example.

Women are more perilous sometimes, than any hi explosive.

|

|

|

markx

National Hazard

Posts: 646

Registered: 7-8-2003

Location: Northern kingdom

Member Is Offline

Mood: Very Jolly

|

|

I conducted an E-method run with AlCl3 catalyst:

Half the amounts of chemicals were used in this test compared to the first one.

13,5ml of Ac2O was heated to 88C in the reactor and 100mg of anhydrous AlCl3 was added to it. Vigorous audible fizzing was observed for about 2

seconds. The Ac2O dissolved the catalyst and remained clear and uncolored.

Then 5,0g of previously dried AN was added to the preheated Ac2O. I decided to add all of the AN to the reactor to avoid the manual gradual dosing of

both ingredients...turns out I should not have done it. Temperature in the reactor jumped to 100C and a vigorous reaction started with the evolution

of NOx and a colourless gas. This was totally different compared to what was observed without the lewis acid catalyst: the temperature fell in the

reactor every time upon addition of AN and no visible reaction was observed. The temperature started to fall after a couple of minutes and the

evolution of gases seized. A considerable amount of AN had been dissolved/decomposed by visual assessment. After about 10 minutes the reactor

temperature had fallen to 90C and the gradual addition of a total of 1,8g of praformaldehyde was begun. Immediately after the first additions of

paraform the reaction began with strong evolution of gas bubbles and temperature rose to 92C. The additons of paraform were timed in order to keep the

reactor temperature around 90C. Reaction was clearly more vigorous than without the catalyst, judging by the amount of bubbles formed. After

approximately 30 minutes the additions were complete and reactor temperature was kept at 88C until the evolution of gas bubbles seized (about 30 min

after the last addition of paraform). The fluid in the reactor was loaded with a flocculent precipitate and was milky white, a very slight yellowish

coloration was observed. Without the catalyst the fluid in the reactor at the end of previous syntheses was distinctively greenish coloured and

basically clear with only a very slight precipitate noted. The reactor contents were allowed to cool down for 15 minutes and thereafter crashed into

300ml of cool water. The precipitate formed was filtered, washed with water and neutralised with sodium bicarbonate solution. The yield is drying

and I will report the numbers tomorrow, but it seems that the catalyst addition had a beneficial effect.

[Edited on 29-5-2014 by markx]

Exact science is a figment of imagination.......

|

|

|

markx

National Hazard

Posts: 646

Registered: 7-8-2003

Location: Northern kingdom

Member Is Offline

Mood: Very Jolly

|

|

Weighed the yield....0,5g before recristallisation. Seemed promising, but then I noticed a rather obvious smell of formaldehyde coming from the dried

mass, not a good omen. Rather a hint to paraforaldehyde contamination. On top of that I managed to spill about 1/4th of the product onto the floor,

damn butterfingers and sleep depravation. So I was left with 0,37g to perform recristallisation from hot acetone. And to my great dissapointment again

a very considerable amount of precipitate remained undissolved. After drying I was left with a meager 0,15g of product.

I will try the synthesis with catalyst again, but this time with the gradual addition of both reagents. This may have a profound effect, as it turned

out the AN on it's own gives a strong reaction on addition to the Ac2O with catalyst.

Since the E-method was practiced in industrial level at the plant "Fazan" in Bobingen Germany it should be possible to make it work with a reasonable

yield. Although I tend to be suspicious about the process description being complete or precise. I think there might be some important details that

have been lost in translation or were simply never leaked to the public or have been biased with intention. At the time of war the cyclonite

production was a closely guarded secret and it is all too possible that the description of german procedures is somewhat incomplete and erraneous.

But it is a captivating topic with a rather enjoyable learning curve...i will keep working on it and post the updates with the kind permission of all

the fellow mad scientists

Exact science is a figment of imagination.......

|

|

|

Manifest

Script Kiddie Asshole

Posts: 229

Registered: 7-12-2012

Member Is Offline

Mood: No Mood

|

|

Does this reaction have to be absolutely clear of Nitrogen Oxides in the Nitric Acid?

If so, is there any way of removing the impurity after distillation?

|

|

|

caterpillar

Hazard to Others

Posts: 472

Registered: 8-1-2012

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Manifest  | Does this reaction have to be absolutely clear of Nitrogen Oxides in the Nitric Acid?

If so, is there any way of removing the impurity after distillation? |

Which in particular? If you mean direct nitration of hexamine, this process is sensitive to NOx. I failed twice, using freshly distilled nitric acid.

But perhaps, I failed because of relatively large pieces of hexamine (tablets from drugstore). Neutralization of a base like hexamine is exothermic

reaction. But when I used hexamine dinitrate, I had no problems. My nitric acid was yellow and became at nearly colorless after I had added the first

portion of HDN.

Women are more perilous sometimes, than any hi explosive.

|

|

|

Turner

Hazard to Others

Posts: 197

Registered: 2-12-2013

Member Is Offline

Mood: No Mood

|

|

More importantly it has to be water free

|

|

|

Manifest

Script Kiddie Asshole

Posts: 229

Registered: 7-12-2012

Member Is Offline

Mood: No Mood

|

|

This compound is too much of a pain to make.

ETN seems preferable considering they are almost equal in detonation velocities.

|

|

|

markx

National Hazard

Posts: 646

Registered: 7-8-2003

Location: Northern kingdom

Member Is Offline

Mood: Very Jolly

|

|

Quote: Originally posted by Manifest  | This compound is too much of a pain to make.

ETN seems preferable considering they are almost equal in detonation velocities. |

Sure...if one just needs/wants a quick high yield batch of something to go off in a loud bang then heterocyclic nitramines are not the way to go.

I for a change enjoy a complicated synthesis...it poses a challenge to the intellect and makes the process more captivating.

Exact science is a figment of imagination.......

|

|

|

caterpillar

Hazard to Others

Posts: 472

Registered: 8-1-2012

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by markx  | Quote: Originally posted by Manifest  | This compound is too much of a pain to make.

ETN seems preferable considering they are almost equal in detonation velocities. |

Sure...if one just needs/wants a quick high yield batch of something to go off in a loud bang then heterocyclic nitramines are not the way to go.

I for a change enjoy a complicated synthesis...it poses a challenge to the intellect and makes the process more captivating. |

The only problem with the classic route to RDX (or K-process, no matter) is the large amount of nitric acid. Many compounds may be prepared with the

aid of salt of nitric acid plus sulfur acid- TNP for example. But if you make pure nitric acid, nitramines are the best way to use it. But there is a

route to mix of RDX + keto-RDX, and this process was discussed at this very forum. This process looks rather simple and uses mixed acid- 50% : 50%,

hexamine (dinitrate will be better) and urea. I was about to cry, reading description of this process. I had all necessary chemicals, when I was

young, but wasted mixed acid for preparation of NC.

Women are more perilous sometimes, than any hi explosive.

|

|

|

markx

National Hazard

Posts: 646

Registered: 7-8-2003

Location: Northern kingdom

Member Is Offline

Mood: Very Jolly

|

|

| Quote: |

The only problem with the classic route to RDX (or K-process, no matter) is the large amount of nitric acid. Many compounds may be prepared with the

aid of salt of nitric acid plus sulfur acid- TNP for example. But if you make pure nitric acid, nitramines are the best way to use it. But there is a

route to mix of RDX + keto-RDX, and this process was discussed at this very forum. This process looks rather simple and uses mixed acid- 50% : 50%,

hexamine (dinitrate will be better) and urea. I was about to cry, reading description of this process. I had all necessary chemicals, when I was

young, but wasted mixed acid for preparation of NC.

|

You can wipe away the tears as the 50/50 in keto rdx synthesis description only marks the proportions (by mass or molar ratio...I can't remember at

the moment) of anhydrous HNO3 and H2SO4 (or was it even oleum).

As for the E-method I found an old article in polish language from Urbanski dated in 1948 and it states that the E-method had no practical value as

there were numerous explosions during the syntheses if temperature was allowed to climb over the limit. Sadly no more information is given on the

extent of the temperature limit or on any other parameter for that matter.

Please find the article attached:

Attachment: przemysl_chemiczny_1948_s487.pdf (864kB)

This file has been downloaded 946 times

Exact science is a figment of imagination.......

|

|

|

markx

National Hazard

Posts: 646

Registered: 7-8-2003

Location: Northern kingdom

Member Is Offline

Mood: Very Jolly

|

|

Now there's a new load of information on the inner workings of the E-method!

I'm really thrilled to find this source....seems that the low yields have a rather well established connection to reaction times. I deemed the 6 hour

reaction time mentioned in Urbanski to the particulars of production facility, but it seems that there is an incubation time of several hours before

any end product is formed.

Please find the articles attached:

Attachment: The reaction to form RDX from AN and praformaldehyde in AcO2.pdf (192kB)

This file has been downloaded 1053 times

[Edited on 12-6-2014 by markx]

Attachment: IEC 40 1948.pdf (1.5MB)

This file has been downloaded 1338 times

Exact science is a figment of imagination.......

|

|

|

markx

National Hazard

Posts: 646

Registered: 7-8-2003

Location: Northern kingdom

Member Is Offline

Mood: Very Jolly

|

|

I just performed the final verification test for the recristallised E method product from my previous low yield syntheses.

0,6g of recristallised product was hand compacted into Al foil tube.

Initiated pyrotechically via 40cm visco fuse with 40mg of SADS + 50mg of loose recristallised ETN.

The detonation occurred with exceedingly satisfactory violence and the sound had a characteristic deep note to it. Metal pipe tobacco can that the

charge was taped onto was torn and twisted in a rather apocalyptic manner. I think it is pretty safe to say that the product (in large majority) was

RDX.

Exact science is a figment of imagination.......

|

|

|

markx

National Hazard

Posts: 646

Registered: 7-8-2003

Location: Northern kingdom

Member Is Offline

Mood: Very Jolly

|

|

Status update....I performed several long runs of the E-method on previous weekend to study the effect of long reaction times with and without AlCl3

catalyst on the yield.

Utter dissapointment to be honest...even with 12h reaction times it was not possible to obtain a pre recristallisation yield of over 15% calculated on

paraform. Addition of AlCl3 in a concentration of 0,6% (calculated on Ac2O used) sped up the reaction rate considerably, but yield did not increase

remarkably. Furthermore, it seems that prolonging the reaction time has no beneficial effect upon yield once all the reactants are consumed and the

reactor liquor turns transparent. The E-method seems a low yield dead end....

On a brighter note I read through the Bachmann patent nr 2798870 and found a promising reference to the possibility of using 70% nitric acid in the

synthesis....provided that an excess of Ac2O is present to account for the dehydration of the lower concentration HNO3.

After preliminary calculations on the need of Ac2O for a 10g yield (75%) of RDX via hexamine, I came up to the "not so frightening" amount of roughly

50g of Ac2O. Considering the fact that I have Ac2O available and that I can (theoretically) skip the hassle of distilling HNO3, I find it might not be

such a bad combination. Provided that it really works the way it is planned...the patent does not provide an experimental example with lower

concentration HNO3, but merely mentions that it is possible. Provided that the extra Ac2O does not have a detrimental effect on the reaction

mechanism, it might all go well.

Using hexamine dinitrate the amount of Ac2O can be further reduced since less nitric acid is required in the synthesis. If my calculations hold water,

then 32g of Ac2O is required with hexamine dinitrate+70% nitric acid and only 23g of Ac2O with dinitrate + 98% nitric acid for a 10g yield at an

optimistic 75%.

But for preliminary testing I shall begin with straight hexamine, as I have that set of reactants available and I can skip any further hassle of

making the precursors. If the concept with hexamine and 70% HNO3+excess Ac2O via Bachmann route shows promising results, then I may consider trying

the hexamine dinitrate option also.

I'll keep you posted when I have some results...

[Edited on 16-6-2014 by markx]

[Edited on 16-6-2014 by markx]

Exact science is a figment of imagination.......

|

|

|

markx

National Hazard

Posts: 646

Registered: 7-8-2003

Location: Northern kingdom

Member Is Offline

Mood: Very Jolly

|

|

Here goes....Bachmann route with 70% HNO3 and double amount of Ac2O through "all liquid feeds":

Reagents:

0,03mol -> 4,2g hexamine

0,09mol -> 7,2g ammonium nitrate

0,16mol -> 14,3g nitric acid (70%)

0,5mol -> 51g acetic anhydride

9,8g glacial acetic acid

Experimental:

The hexamine and ammonium nitrate were dried on hotplate before the synthesis and sealed into airtight containers until used.

Hexamine was dissolved in 6,8g of glacial acetic acid with magnetic stirring, the result was a viscous transparent liquid with the approximate

consistancy of syrup.

AN was dissolved in precooled (4C) nitric acid with magnetic stirring, no additional cooling was neccesary.

Acetic anhydride was weighed into a separate flask.

The reactor was heated by PID controlled waterbath and brought up to the reaction temperature of 75C. Magnetic stirring was used to agitate the

reaction mixture.

Due to unfavorable weather conditions the experiment had to be conducted inside. For that reason the reactor chamber was sealed with plastic and no

opportunity presented to install a thermometer into the reactor. Slow additions through syringes penetrating the plastic were planned to keep the

exotherm controlled and inside chamber temperature near the optimum of 75C.

Into the reactor chamber were placed 10ml of Ac2O, 3g of glacial acetic acid and 1ml of the AN+nitric acid mixture. Upon addition of the

nitric acid, the AN pricipitated.

After about 5minutes of equilibriating the inner chamber temperature the gradual, concurrent (as much as it was possible) and slow additions of the

three liquid feeds through the plastic wrap via syringe needles were begun.

The dosing was approximately in the order of

1) 0,5ml hexamine in glacial acetic acid

2) 1ml of AN in 70% nitric acid

3) 2,5ml of acetic anhydride

After the first 2 additions the reactor liquor remained transparent with a slight brownish tint, slight evolution of gas was observed upon addition of

the liquid feeds. After the third additon of liquid feeds there was a sudden and heavy precipitation of at least several grams of suppposedly RDX. The

crystals were coarse and heavy like sand and glistened in the light. If stirring was shut off, the precipitate immediately fell to the bottom of the

reactor leaving behind a clear solution on top of it. Visually a rather enjoyable spectacle...

The exotherm was quite violent as the water bath temperature was seen to rise by a few tenths of centigrade following the addition of liquid feeds.

The additions were tried to keep slow and cautiously spaced, but the inner chamber temperature most likely fluctuated wildly around the setpoint.

Additions were resumed until all of the feeds were consumed (at around 70minutes into the reaction) and the mixture was let to react for a further

25minutes after that at 75C. Slow gas evolution was observed and the torrent of heavy crystals in the vortex of the stir bar fogged the entire

reactor.

To be continued...

[Edited on 17-6-2014 by markx]

Exact science is a figment of imagination.......

|

|

|

markx

National Hazard

Posts: 646

Registered: 7-8-2003

Location: Northern kingdom

Member Is Offline

Mood: Very Jolly

|

|

After letting the reaction continue for the 25minutes, the inner chamber was removed from the water bath and the contents drowned in 400ml of warm

water. An instant and heavy precipitation of solid product(s) was observed:

The contents of the beaker were stirred for 5minutes with the magnetic bar and then filtered through 2 regular coffee filters. The filtration

proceeded with extraodrinary ease as the precipitate was coarse and did not clog the pores of the paper.

The contents of the filter were neutralised with a solution of NaHCO3, drained, washed with several portions of warm water and squeezed

more or less dry between paper dowels.

The damp weight showed a rather promising 14,75g with the filter paper mass subtracted.

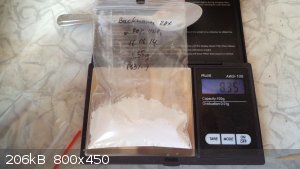

After complete drying the final yield was registered as 8,35g:

The result accounts for a 63% yield....not a miracle synthesis run, but I'm really pleased with it. As a consept verification synthesis it was a

magnificent success. If we take into account the extra anhydride, initial diluted medium for the reaction (the 10ml Ac2O + 3ml glacial

acetic acid in the reactor) and the inconsistent temperature control in the inner chamber then I must say that this is far more than I initially

expected. I would really love to perform an analysis on the resulting product with regards to the composition. I do fear that we shall see a rather

sizeable "contamination" of HMX since the extra anhydride and inital diluted nitration medium are prone to shift the product towards the formation of

the eight membered nitramine.

Ah yes....and it leaves a rather deep impression too

[Edited on 18-6-2014 by markx]

Exact science is a figment of imagination.......

|

|

|

| Pages:

1

..

7

8

9

10

11

12 |