| Pages:

1

2 |

Endimion17

International Hazard

Posts: 1468

Registered: 17-7-2011

Location: shores of a solar sea

Member Is Offline

Mood: speeding through time at the rate of 1 second per second

|

|

Identifying wires of an old electric motor

So I've got this old motor from a washing machine, made in 1983 and I have absolutely no idea how to connect it to the mains. I want high rotational

speeds, just like in washing machines.

I've got a long cable with two wires ready. No ground wire, though.

There are 6 wires at one plastic junction of the casing.

white

blue, red

yellow, brown

It's an asynchronous monophase electric motor intended for 220 V @ 50 Hz.

So, what to do? I've tried several combinations and turning it on for like 0.1 s to avoid damage, and all I've got were buzzing sounds, one time

somewhat louder. The rotor is not moving, although it's not corroded or anything.

If you need me to check something with a multimeter, I've got one.

As much as I know about chemistry, I know very little about electrical engineering (OK, I'm a walking disaster) so please help me of watch me get

killed by electricity.

|

|

|

Fantasma4500

International Hazard

Posts: 1681

Registered: 12-12-2012

Location: Dysrope (aka europe)

Member Is Offline

Mood: dangerously practical

|

|

rubber gloves first of all when playing around with stuff you dont know shit about (like me)

on a computer power supply black and red means 12V 5A

perhaps connect the wires to your multimeter in different combinations and measure currents?

supposing the wires that have equal amount would be the ones fitting together

dont take any of this for truth, i know just a tiny bit more electrical than organic chemistry

|

|

|

bfesser

Resident Wikipedian

Posts: 2114

Registered: 29-1-2008

Member Is Offline

Mood: No Mood

|

|

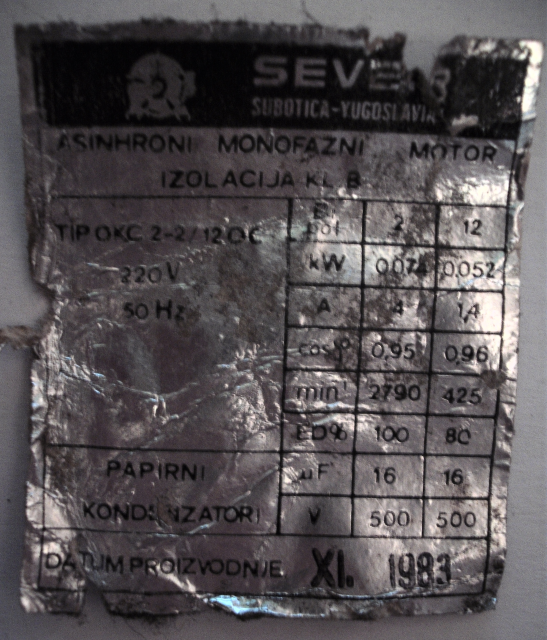

Do you have the start/run capacitor? Please post a photo of the data plate. (Also, try Google.)

[Edited on 7/21/13 by bfesser]

|

|

|

froot

Hazard to Others

Posts: 347

Registered: 23-10-2003

Location: South Africa

Member Is Offline

Mood: refluxed

|

|

Usually these motors are wired for 2 speeds and bi-directional rotation. If you still have access to the rest of the machine look for a capacitor

that's connected through that plug to the motor, you will need it to get the motor turning. All asynchronous single phase motors need a capacitor to

generate the rotating field. If you don't have the capacitor a local electrical outlet will be able to assist you if you show them the motor. The

value of the cap is important for performance but if its as much as 50% out of spec it will still turn.

Connecting is simple, take 3 of the wires with the most similar resistance between each other, connect the capacitor across 2 of them, and your supply

to the remaining wire and one of the terminals of the capacitor. If you want to reverse the motor simply move the supply from the one cap terminal to

the other. Just be sure none of the wires are grounded to the motor casing.

Edit... If the motor appears to turn too slowly, this could be the slow speed configuration, just move your connection to the other 3 wires.

[Edited on 21-7-2013 by froot]

We salute the improvement of the human genome by honoring those who remove themselves from it.

Of necessity, this honor is generally bestowed posthumously. - www.darwinawards.com |

|

|

watson.fawkes

International Hazard

Posts: 2793

Registered: 16-8-2008

Member Is Offline

Mood: No Mood

|

|

There are fifteen pairs of DC resistance given 6

terminals. Get out your ohmmeter and measure them all. Post back here with the results. Also, one of the terminals is likely connected to the metal

body frame of the motor; figure out which one this is as well.

I'm assuming there's no start/run capacitor connected.

|

|

|

bfesser

Resident Wikipedian

Posts: 2114

Registered: 29-1-2008

Member Is Offline

Mood: No Mood

|

|

If you just tell us the washing machine model or the motor model, someone could look it up in a service manual. Washing machines are designed to be

serviced, there are no secrets. This should be trivial.

http://lmgtfy.com/?q=washing+machine+motor+wiring

Unless I've forgotten how to count, that's only 5 leads. I've never seen a 5 lead washer motor before. Is

the sixth lead black?

Also, <em>every</em> washing machine I've serviced had a <a

href="http://applianceassistant.com/electricity/understanding_wire_diagrams.php" target="_blank">wiring diagram</a> <img

src="../scipics/_ext.png" /> attached to it on the back or inside somewhere, usually in a plastic sleeve.

By the way, I don't mean to be rude, just straight to the point. I feel your <a href="viewthread.php?tid=17008">pain</a>.

[Edited on 7/21/13 by bfesser]

|

|

|

jock88

National Hazard

Posts: 505

Registered: 13-12-2012

Member Is Offline

Mood: No Mood

|

|

No, it does not.

Has the motor any brushes?

[Edited on 21-7-2013 by jock88]

|

|

|

IrC

International Hazard

Posts: 2710

Registered: 7-3-2005

Location: Eureka

Member Is Offline

Mood: Discovering

|

|

http://www.youtube.com/watch?v=XrYBAVG5dT4

"Science is the belief in the ignorance of the experts" Richard Feynman

|

|

|

Endimion17

International Hazard

Posts: 1468

Registered: 17-7-2011

Location: shores of a solar sea

Member Is Offline

Mood: speeding through time at the rate of 1 second per second

|

|

I'll take a photo of the motor wires and any details tomorrow.

Yes, I presumed it needs a capacitator to start the spinning cycle, and that's kind of bringing me down because I've got a huge pile of crap taken

from perhaps two washing machines and finding the exact capacitator will be a challenge. Imagine taking a washing machine and just gutting the shit

out of it. There's like a third of cubic metre of wires and other crap.

Indeed, there are 5 wires, my mistake.

Everything I know about this motor is on this little paper that has been glued to it.

I'll see tomorrow if I can find any more details, but I really think there aren't any.

Could it be that the capacitators are somewhere inside? :/

I see no brushes. Washing machine motors shouldn't have any. They're designed to be really durable and to spin for at least ten years without

repairing. I don't know, but it seems that at high speeds, the brushes would be gone in a month or two...

Finding any diagrams for this ancient thing would be a needle in a hay or worse. I've searched for it online and I've only got one proper hit -

there's some guy selling the exact motor.

And to think I was actually considering this will be a piece of cake. I really thought I'll just have to connect it and have it spinning like crazy.

Don't worry about me getting zapped. Whenever I touch it, I always completely disconnect it from the mains, and the thing is resting on a dry wooden

block.

I know a lot about safety because it's something you know if you understand the physics behind electricity , but when it comes to electrical

engineering, I'm pretty much an ignorant.

I like that video. I've hoped it would be that simple.

[Edited on 22-7-2013 by Endimion17]

|

|

|

bfesser

Resident Wikipedian

Posts: 2114

Registered: 29-1-2008

Member Is Offline

Mood: No Mood

|

|

<em>Imagine</em> taking a washing machine apart? I've done that… many times. It's fun! Gutting household appliances is one

of my favorite things to do, and it's quite educational.

The capacitor should be very easy to find, and will be marked 16 µF (sometimes "mfd"). The capacitor won't be internal; they're external so

they can be easily replaced. The cap should look similar to one of the pictures below (or a variation thereof), and I wouldn't expect the washer to

have more than one cap. As a bonus, motor start/run caps are dirt cheap and available all over the place.

<img src="http://www.bestbuyheatingandairconditioning.com/Merchant2/graphics/00000001/p2910503.jpg" height="100" /><img

src="http://store.eurtonelectric.com/images/products/detail/370DUAL.28.jpg" height="100" /><img

src="http://www.westfloridacomponents.com/mm5/graphics/F11/ADM250E805J.jpg" height="100" /><img

src="http://t3.gstatic.com/images?q=tbn:ANd9GcRwv0ON8K78w_QYu_AOadxj5S6rfD4No59kIMGbHDke6PjfvQBb4w" height="100" /> <img

src="http://img0016.popscreencdn.com/152112022_-cbb61-15uf-polypropylene-film-motor-run-capacitor-home-.jpg" height="100" /><img

src="http://p.globalsources.com/IMAGES/PDT/B1060563668/Motor-Start-Capacitor.jpg" height="100" /><img

src="http://ecx.images-amazon.com/images/I/41LvSUpq1mL._SL500_AA300_.jpg" height="100" />

You don't need a diagram for the motor, if anything you need the wiring diagram for the washing machine.

<hr width="800" />

While we're on the topic of destroying washing machines, here share a few YouTube videos I enjoy. <a

href="http://www.youtube.com/watch?v=vROdVsU_K80" target="_blank">Washing Machine Self Destructs</a> <img src="../scipics/_yt.png" />

from one of my <a href="http://www.youtube.com/watch?v=Fl6-kqVyOqM" target="_blank">favorite</a> <img src="../scipics/_yt.png" />

YouTubers. And I honestly don't know <a href="http://www.youtube.com/watch?v=MnPobgmdYXU" target="_blank">what's going on</a> <img

src="../scipics/_yt.png" /> in this one, but I like it!

[Edited on 7/22/13 by bfesser]

|

|

|

Xenoid

National Hazard

Posts: 775

Registered: 14-6-2007

Location: Springs Junction, New Zealand

Member Is Offline

Mood: Comfortably Numb

|

|

Why? The label clearly says the capacitor is 16uF / 500V

|

|

|

Endimion17

International Hazard

Posts: 1468

Registered: 17-7-2011

Location: shores of a solar sea

Member Is Offline

Mood: speeding through time at the rate of 1 second per second

|

|

I like gutting appliances, too. I actually salvage interesting capacitators and other neat stuff whenever I come across something defunct.

But the reason this will be a difficult task is because the parts are covered in thick, damp dusty delight. God knows what's inside. I can barely see

some wire colours - it's that bad.

Reading capacitator information will take some time.

Couple of years ago my father decided he wanted to destroy a vintage washing machine that was probably functional, and to mix those guts with

other electrical crap laying around. Now it's just a huge pile of undiferentiated electrician's protoplasmic dream, covered in goo.

[Edited on 22-7-2013 by Endimion17]

|

|

|

Endimion17

International Hazard

Posts: 1468

Registered: 17-7-2011

Location: shores of a solar sea

Member Is Offline

Mood: speeding through time at the rate of 1 second per second

|

|

About that washing machine destruction, that's arguably one of the best things uploaded to YouTube, ever.

I love the remixed video, with googly eyes.

<iframe sandbox width="420" height="315" src="//www.youtube.com/embed/977siaPc4ao" frameborder="0" allowfullscreen></iframe>

I've nearly pissed my pants the first time I saw it.

|

|

|

Fantasma4500

International Hazard

Posts: 1681

Registered: 12-12-2012

Location: Dysrope (aka europe)

Member Is Offline

Mood: dangerously practical

|

|

well, 5 is an estimation, theyre said to run very stable, the stream of H2 before i ruined it seemed to be pretty well around 5A if not more, didnt

increase or anything alike

on the sticker it says

Current

5.5A

-12V +5Vsb

0.8A 2.5A

9.6W 12.5W

again.. it wasnt 2.5A and it wasnt 0.1A, so by that i suppose it could have been 5.5A

any other amperages written is 30A in which it certainly was not

also all of these computer power supplys are widely different, as in there different types, not sure how many exactly but it always varies a tiny bit

from brand to brand

|

|

|

Endimion17

International Hazard

Posts: 1468

Registered: 17-7-2011

Location: shores of a solar sea

Member Is Offline

Mood: speeding through time at the rate of 1 second per second

|

|

I've cleaned the motor from the layers of dust and spider web and smeared lots of WD-40 all over it (didn't want to spray it as it might get inside

and dissolve something), and put some lithium grease in the bearings. Other than the ugly lacquer and some surface rust, it looks fine, doesn't seem

to have any serious issues.

The last time it was in the washing machine, it was working without problems. It was not stored in a humid environment. Close inspection of the copper

wiring shows no lacquer deterioration.

photo1, photo2

Now I'm off to measure resistances between the terminals.

I think the brown and the blue wire might be the live and the neutral wire, respectively. Those are the usual colours used here.

Yellow might be the ground wire (it's yellow-green that's used today), and the red and white ones might be for changing the rpm.

[Edited on 22-7-2013 by Endimion17]

|

|

|

Endimion17

International Hazard

Posts: 1468

Registered: 17-7-2011

Location: shores of a solar sea

Member Is Offline

Mood: speeding through time at the rate of 1 second per second

|

|

OK, 5 wires, 10 combinations without repetition.

white-blue 14.2 Ω

white-red 29.1 Ω

white-yellow 70.0 Ω

white-brown 69.0 Ω

blue-red 43.0 Ω

blue-yellow 83.5 Ω

blue-brown 82.6 Ω

red-yellow 98.1 Ω

red-brown 97.1 Ω

yellow-brown 77.3 Ω

Keep in mind I've used one of those shitty digital multimeters.

I've also tested the resistance between each wire and one of the exposed screws and the multimeter shows infinite resistance, indicated by the typical

"1" error display.

I expected low values, perhaps less than 1 Ω. After all, one of the wires should've been the ground wire, directly connected to the casing.

Am I doing something wrong here? I've cloesly inspected the wires inside the casing by looking through the holes - all of them are tied together and

seem to supply the windings. Nothing seems to be connected to the casing. Is the motor supposed to be grounded by the actual contact between the

casing and the washing machine, which is grounded already?

I'm off to search for those crapped capacitators.

edit: Found the bastard.

While I wait for futher instructions, I'll prepare some wires and clean the contacts.

If you give me bad instructions so I get electrocuted, and if I turn into a ghost that can interact with you, I'll find you and be a real pain in the

ass for the rest of your life.

[Edited on 22-7-2013 by Endimion17]

|

|

|

bfesser

Resident Wikipedian

Posts: 2114

Registered: 29-1-2008

Member Is Offline

Mood: No Mood

|

|

It's likely, given the age of the machine, that the motor was simply grounded to the metal chassis through the mounting tabs. For safety, and due to

the advanced corrosion of the housing, I would recommend carefully drilling and tapping a hole in a safe place on the housing, and screwing a

terminated grounding wire to it. Ideally, you would put in a 'toothy' lock washer that will bite through oxide layers to get really good electrical

contact between the crimp terminal and the housing. This would also help to prevent the connection from loosening by mechanical vibration. I've

included a photo of the grounding wire I put on my vacuum pump and some other relevant photos.

<table cellpadding="0" cellspacing="4"><tr><td><img src="http://www.racom.eu/images/radost/images/hw/RipEX/uzemHS.jpg"

height="175" /></td><td> </td></tr><tr><td align="center">internet example</td><td align="center">my pump's

ground</td></tr></table> </td></tr><tr><td align="center">internet example</td><td align="center">my pump's

ground</td></tr></table>

<table cellpadding="0" cellspacing="0"><tr><td><img src="http://www.idealindustries.com/media/img/product/medium/30-3194.jpg"

height="100" /></td><td><img src="http://thumbs2.ebaystatic.com/d/l225/m/mpYWGfwPPj0syQDScKjDlrw.jpg" height="100"

/></td><td><img src="http://www.boltsplus.com/PartImages/5883/5883.JPG" height="100" /></td><td><img

src="http://image.made-in-china.com/4f0j00zvftAmeROYpG/Serrated-Externally-Internally-Countersunk-Lock-Washers-DIN6798-A-DIN6798-J-DIN6798-V-.jpg"

height="100" /></td><td><img src="http://ecx.images-amazon.com/images/I/31diHDKqLcL._SL500_AA300_.jpg" height="100"

/></td></tr><tr><td align="center">grounding screws</td><td align="center">crimp terminals</td><td

align="center">good</td><td align="center">better</td><td align="center">best</td></tr></table>

If you use the pictured type of grounding screw, only put a washer between the terminal and the housing, as the screw has it's own teeth. Use the

pictured type of terminal on any ground (they can't accidentally slip out or be easily removed), but choose the appropriate size for your wire gauge

(color coded) and post. Use either a bare copper wire, or an insulated green wire to avoid confusion (yellow/green stripe is acceptable).

[Edited on 7/22/13 by bfesser]

|

|

|

watson.fawkes

International Hazard

Posts: 2793

Registered: 16-8-2008

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Endimion17  | white-blue 14.2 Ω

white-red 29.1 Ω

white-yellow 70.0 Ω

white-brown 69.0 Ω

blue-red 43.0 Ω

blue-yellow 83.5 Ω

blue-brown 82.6 Ω

red-yellow 98.1 Ω

red-brown 97.1 Ω

yellow-brown 77.3 Ω |

White

appears to the neutral wire here. Note that for both red and blue wires, all the resistances "go through" the white terminal, that is, the resistance,

say, red-yellow is the sum of the red-white and white-yellow resistances (to within an ohm). So that's three down.

The yellow and brown terminals, however, are wired differently. Note that the resistances on all three legs are with 10% of each other. That seems to

speak to a three phase delta motor. The run capacitor is used to shift the phases around that they're adequately separated. The capacitance is

specified on the motor so that the phase shift is correct for the inductance of its drive coils.

The next step is look up some schematic diagrams for other motors. You don't need to get the exact model, just one of the same basic design. My guess

is that the red and blue wires go to the start windings, and that you'll find a centrifugal switch somewhere (as you've described it, in a box of

parts) that disconnects the start windings once the motor comes up to speed. You'll definitely find such a switch in the schematics.

|

|

|

papaya

National Hazard

Posts: 615

Registered: 4-4-2013

Member Is Offline

Mood: reactive

|

|

"ASINHRONI MONOFAZNI MOTOR" means asynchronous mono-phase motor!

|

|

|

Endimion17

International Hazard

Posts: 1468

Registered: 17-7-2011

Location: shores of a solar sea

Member Is Offline

Mood: speeding through time at the rate of 1 second per second

|

|

bfesser, I've cleaned one mounting tab with an emery paper and connected the terminals to a cable and made a good contact between the casing and the

ground wire. photo

The resistance between the casing and the cable end is 0.2 Ω so I guess I did a good job.

Just to add some insulating tape and I'm done. Now it's basically ready for experimenting. It's been a while since I've been soldering wires and my

old soldering gun is heavy piece of crap so it's taking some time.

watson.fawkes, I've noticed the regularities between the numbers, but that was it.

Unfortunatelly, I don't know enough about these things to understand the difference between an monophase asynchronic and three phase delta motor.

The problem is - I'm not sure how this centrifugal switch looks like. I see there are many designs. Is there something all of them have? A spring,

maybe? I'm not even sure there is one, there seems to be only a pile of potentiometers and cables. There is also a water pump, but seems to be in a

terrible condition.

Does this help? There are lots of schematics...

http://www.bellsouthpwp.net/a/w/awendt/HTML/Motor/InductionM...

BTW thank you all for helping me.

[Edited on 22-7-2013 by Endimion17]

|

|

|

bfesser

Resident Wikipedian

Posts: 2114

Registered: 29-1-2008

Member Is Offline

Mood: No Mood

|

|

Soldering isn't ideal, but I'm guessing you don't have the tools to do crimped butt splices or terminals. I've tried the crimp-less butt splice

pictured below, and it's not bad. The second type pictured I absolutely hate. And sometimes Wire-Nuts® (twist-on connectors) are better than

soldering, but your joints look alright.

<table><tr><td><img src="http://www.idealindustries.com/media/img/whatsnew/press_releases/2010-03-23_spliceline_print.jpg"

height="120" /></td><td><img

src="http://i828.photobucket.com/albums/zz205/BigRondo/Signal%20Mirror%20How%20To/Parts%20Required/4QuickSpliceConnectors.jpg?t=1285484852"

height="120" /></td><td><img

src="http://www.hometheatershack.com/forums/attachments/remotes-cables-accessories-tweaks/12703d1235502403-comprehensive-guide-splicing-speaker-wire-w

ire-nuts.jpg" height="120" /></td><td><img src="http://www.howtogeek.com/geekers/up/sshot4f4f9e85ae729.jpg" height="120"

/></td></tr><tr><td align="center">not bad</td><td align="center">hate 'em</td><td

align="center">ol' standby</td><td><a href="http://www.hq.nasa.gov/office/codeq/doctree/87394.pdf" target="_blank">NASA

spec.</a> <img src="../scipics/_pdf.png" /></td></tr></table>

How about a few pictures of the piles of junk? Perhaps we can just point out what you need.

[Edited on 7/22/13 by bfesser]

|

|

|

Endimion17

International Hazard

Posts: 1468

Registered: 17-7-2011

Location: shores of a solar sea

Member Is Offline

Mood: speeding through time at the rate of 1 second per second

|

|

I've got nothing of that kind at home. Soldering is ok, it's rigid. I used flux, so the wires were dripping wet with solder alloy. They're interlocked

now.

I'll post a few photos of some "devices" from the pile of cables tommorow as it's almost midnight right now, and the stuff is outside my apartment. I

think there are just some potentiometers and pumps.

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Quote: Originally posted by Endimion17  |

watson.fawkes, I've noticed the regularities between the numbers, but that was it.

Unfortunatelly, I don't know enough about these things to understand the difference between an monophase asynchronic and three phase delta motor.

|

3-phase power is normally only used for heavy duty, like industrial or agricultural applications. If this is a motor from a domestic washing machine

I would surely think it is monophase.

Also, papaya then confirmed this by reading the nameplate.

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

Endimion17

International Hazard

Posts: 1468

Registered: 17-7-2011

Location: shores of a solar sea

Member Is Offline

Mood: speeding through time at the rate of 1 second per second

|

|

While I understand the differences between the basic motors (it's something we've been learning in highschool physics), and what phases do, design

variations like "three phase delta" elude me.

There are lots of different designs made for particular purposes, but my understanding is pretty much basic.

It's like cars. I know the concepts, I can explain two-stroke, four-stroke internal combustion engines, spark plugs, cam shafts, chemistry of the

whole process, etc., but I can't really fix an older type car.

If I don't find an easy solution to this soon, I'll probably just let it go. It's not worth the hassle.

|

|

|

ElectroWin

Hazard to Others

Posts: 224

Registered: 5-3-2011

Member Is Offline

Mood: No Mood

|

|

i have a split-phase motor at home, that has just two phases, 90 degrees apart. but there are only 3 wires. i noticed, though, when i energize the

pairs, the shaft turns a little, so it was possible to discover the phase relationships.

maybe you can do the same?

|

|

|

| Pages:

1

2 |