| Pages:

1

2 |

Nitrojet

Hazard to Self

Posts: 56

Registered: 21-10-2006

Member Is Offline

Mood: No Mood

|

|

Sorguyl

I have prepared 15gr of glycolurile through direct condensation of glyoxal and Carbamide. This is the primary step to synthesizing Sorguyl

(Tetranitroglycolurile) which is a very interesting explosive because of its very high detonation velocity (9150m/s @ d=1.95gr/cc). The nitrating

agent is somehow troublesome to be prepared because it has to be a mixture of HNO3-N2O5 to yield the tetranitro product. does anybody have any

experience with such a nitration agent? is it possible to prepare Sorguyl with strong Nitric acid (d=1.523)?

|

|

|

Axt

National Hazard

Posts: 814

Registered: 28-1-2003

Member Is Offline

Mood: No Mood

|

|

Can you get P2O5? N2O5 doesnt need to be isolated as such. HNO3/P2O5 will suffice and should be as readily available as say, glyoxal. I couldnt find

the detailed procedure in the literature but-

"Nitroureas II. Synthesis of Bicyclic Mono- and Dinitrourea Compounds" PEP, Vol. 21, Issue 1 , pg. 14 - 18 (1996)

I believe should have it, pitty people with access to the old PEP's are few and far between.

[Edited on 24-10-2006 by Axt]

|

|

|

Nitrojet

Hazard to Self

Posts: 56

Registered: 21-10-2006

Member Is Offline

Mood: No Mood

|

|

There are certain problems associated with P2O5 but ofcourse from legal standpoints rather than chemistry points of view! The material is a precursor

to home manufacture of Acetic Anhydrid which is itself absolutely necessary for manufacture of drugs. Aside from this, i could not find "Nitroureas

II. Synthesis of Bicyclic Mono- and Dinitrourea Compounds" PEP, Vol. 21, Issue 1 , pg. 14 - 18 (1996), even through an extensive search.

Does PEP stand for " Pharmacology Education Partnership"?

|

|

|

Axt

National Hazard

Posts: 814

Registered: 28-1-2003

Member Is Offline

Mood: No Mood

|

|

Propellants, Explosives, Pyrotechnics

Paste "Nitroureas II. Synthesis of Bicyclic Mono- and Dinitrourea Compounds" into google.

P2O5 isnt regulated here, and rather cheap.

[Edited on 25-10-2006 by Axt]

|

|

|

Nitrojet

Hazard to Self

Posts: 56

Registered: 21-10-2006

Member Is Offline

Mood: No Mood

|

|

I already have a 1kg pack of reagent grade P2O5. So legal issues can not be an obstacle for proceeding into nitration of the glycolurile. but the

problem is that i don't have the least idea of how to carry out the nitration process, i have no experince with such nitrating agents. does any body

have a detailed synthetic procedure of Sorguyl using HNO3/P2O5?

|

|

|

vulture

Forum Gatekeeper

Posts: 3330

Registered: 25-5-2002

Location: France

Member Is Offline

Mood: No Mood

|

|

You might want to try nitration with DCM/HNO3 first before going the anhydride route. If you go the anhydride route, I would suggest nitrating in

acetic acid anhydride. Direct addition of P2O5 to the nitration mixture is going to cause a mess.

Acetylnitrate is a very good nitrating agent but explosive in high concentration so use caution.

One shouldn't accept or resort to the mutilation of science to appease the mentally impaired.

|

|

|

garage chemist

chemical wizard

Posts: 1803

Registered: 16-8-2004

Location: Germany

Member Is Offline

Mood: No Mood

|

|

P2O5 dissolves cleanly and rapidly in anhydrous HNO3, the resulting solution is as mobile as the HNO3 before and the mix makes the most powerful

nitrocellulose I've ever seen.

I'd suggest to just dissolve the P2O5 in the HNO3 and using this as the nitration mix.

A nitration mix with acetic anhydride and HNO3 is explosive in itself (homogenous mix of oxidiser and flammable liquid) and also unstable, slowly

generating tetranitromethane and also capable of self- accelerating runaway nitration of the acetic anhydride.

|

|

|

chemoleo

Biochemicus Energeticus

Posts: 3005

Registered: 23-7-2003

Location: England Germany

Member Is Offline

Mood: crystalline

|

|

Nitrojet, and others:

A suggestion for the future - please post chemical structures, and reaction equations in the future (Use attach function or FTP for graphics). This

will make it much easier for the uninitiated reader to follow the nomenclatures you use. I don't think it can be expected for everyone to immediately

know what Tetranitroglycolurile (or Fox-7, see below) would look like.

I am also pretty sure it will attain more attention that way.

Much appreciated. Thanks!

Edit: I think the same goes for this thread:

https://sciencemadness.org/talk/viewthread.php?tid=5346

Many readers will be thanking you!

[Edited on 26-10-2006 by chemoleo]

Never Stop to Begin, and Never Begin to Stop...

Tolerance is good. But not with the intolerant! (Wilhelm Busch)

|

|

|

solo

International Hazard

Posts: 3975

Registered: 9-12-2002

Location: Estados Unidos de La Republica Mexicana

Member Is Offline

Mood: ....getting old and drowning in a sea of knowledge

|

|

Reference Information

Nitroureas II. Synthesis of Bicyclic Mono- and Dinitrourea Compounds

Philip F. Pagoria, Alexander R. Mitchell, Edward S. Jessop

Propellants, Explosives, Pyrotechnics Volume 21, Issue 1, Date: February 1996, Pages: 14-18

Summary

We report the synthesis and characterization of several bicyclic

mono- and dinitrourea compounds as energetic materials and discuss

their use as precursors to other energetic compounds. The

new nitrolyzing reagent, trifluoromethanesulfonic acid anhydride/

20% NzOs/nitric acid, will also be described.

Attachment: Nitroureas II. Synthesis of Bicyclic Mono- and Dinitrourea Compounds.pdf (542kB)

This file has been downloaded 3310 times

It's better to die on your feet, than live on your knees....Emiliano Zapata.

|

|

|

Axt

National Hazard

Posts: 814

Registered: 28-1-2003

Member Is Offline

Mood: No Mood

|

|

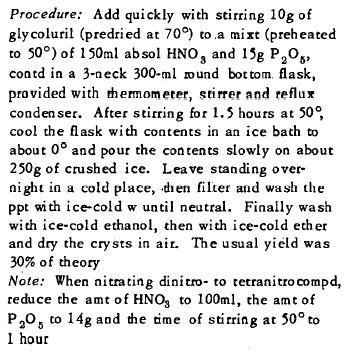

Thanks solo, nice info. Well it only referred to P2O5/HNO3 but didnt detail it. It referenced to PATR2700, gave the wrong page but the info sought is

under the entry for glycoluril G117 [attached]. Yield isnt so great, maybe better to isolate the dinitroglycoluril first instead of going it in one

step.

[Edited on 1-11-2006 by Axt]

|

|

|

chemoleo

Biochemicus Energeticus

Posts: 3005

Registered: 23-7-2003

Location: England Germany

Member Is Offline

Mood: crystalline

|

|

Ah, finally looked this up:

Glycoluril - wonderful, makes totally sense, the structure, obtained from urea and glyoxal.

What is the procedure for making it? Heat until any water vapors are driven off?

I wonder whether similar products are possible, i.e. with guanidine, semicarbazide, thiourea (from , photography supplies), biurea

etc. There should be some interesting possibilities.

Slightly off topic - does anyone know the name of the condensation product of oxalic acid and urea? It should theoretically yield a circular amide

[CO2]2[NH]2CO, which in turn could be nitrated similar to what Axt described in one of his threads (forgot which one it was).

Never Stop to Begin, and Never Begin to Stop...

Tolerance is good. But not with the intolerant! (Wilhelm Busch)

|

|

|

Axt

National Hazard

Posts: 814

Registered: 28-1-2003

Member Is Offline

Mood: No Mood

|

|

Glycoluril is relatively insoluble so the condensation is very easy in acidic aqueous solution.

Guanidine if analogous to urea forming a bicyclic product would likely only be nitrated at the imine nitrogens, so not that attractive as an energetic

material.

| Quote: | Originally posted by chemoleo

Slightly off topic - does anyone know the name of the condensation product of oxalic acid and urea? It should theoretically yield a circular amide

[CO2]2[NH]2CO, which in turn could be nitrated similar to what Axt described in one of his threads (forgot which one it was).

|

Parabanic acid, Its nitration product (if possible) would likely be very susceptable to hydrolysis. J. Phys. Chem. 1991, 95, 844-848 [attached]

Its closest relevant thread would be <a href="http://www.sciencemadness.org/talk/viewthread.php?tid=6903">PETN-based Cast Explosives</a>

with the nitration of dimethyloxamide. You were probably thinking of <a

href="http://www.sciencemadness.org/talk/viewthread.php?tid=3590#pid40213">Nitrated Organic Acids & Salts</a> where you brought up the

condensation of tartaric acid with ethanolamine. Also maybe thinking about nitration of imidazolidone as intermediate to <a

href="http://www.sciencemadness.org/talk/viewthread.php?tid=4282">ethylenedinitramine</a>.

[Edited on 2-11-2006 by Axt]

Attachment: hydrolysis of nitroureas.pdf (1.4MB)

This file has been downloaded 1273 times

|

|

|

chemoleo

Biochemicus Energeticus

Posts: 3005

Registered: 23-7-2003

Location: England Germany

Member Is Offline

Mood: crystalline

|

|

Thanks for the info. Parabanic acid it is. Given that it is an acid, I imagine it'd be very difficult to form some sort of nitramide.

Yes, cheers, it was the Nitrated Organic Acids thread. I'll have to look up the methodology for the condensation of i.e. tartraric acid with

ethanolamine. Although it's off topic - please remind me where I can find such information, by U2U if need be. Sorry for my laziness... but it seems

you keep a much better mental trackrecord as to where things have been discussed!

Never Stop to Begin, and Never Begin to Stop...

Tolerance is good. But not with the intolerant! (Wilhelm Busch)

|

|

|

Axt

National Hazard

Posts: 814

Registered: 28-1-2003

Member Is Offline

Mood: No Mood

|

|

| Quote: | Originally posted by chemoleo

Given that it is an acid, I imagine it'd be very difficult to form some sort of nitramide. |

Not saying its likely but its not unheard of, glycoluril is a feeble acid. Maybe accessable through a different route such as chlorination of the

sodium salt, then reacting with AgNO2 like brought up with dichloro-EDNA thread.

| Quote: | | I'll have to look up the methodology for the condensation of i.e. tartraric acid with ethanolamine. Although it's off topic - please remind me where I

can find such information, by U2U if need be. |

I actually dont know, Nitrojet seems to be saying that he condensed methylamine with oxalic acid <a

href="http://www.sciencemadness.org/talk/viewthread.php?tid=6903">here</a> so I guess one should hit him up in that thread about the

methodology, without resorting to the ethyl ester (or maybe he did?).

|

|

|

Nitrojet

Hazard to Self

Posts: 56

Registered: 21-10-2006

Member Is Offline

Mood: No Mood

|

|

In my attempts to synthesize Dimethyloxamide, I condensed Methylamine with both Methyl and Ethyl esters of Oxalic acid. Direct combination of the acid

itself with Methylamine gives entirely different results. The product of neutralizing Oxalic acid with Methylamine which is an organic base is known

as Methylamine Oxalate.

Based on the availability of the raw materials, Ethyl Oxalate and Methyl amine, synthesis of Dimethyloxamide is a simple straightforward route:

In a 500ml beaker, put 55gr Ethyl Oxalate and Add 90gr of 40% Methylamine solution (Equal to 36gr of pure reagent) from a separatory funnel in a

dropwise fashion. Hold vigorous agitation inside the beaker by means of a magnetic stirrer and adjust the rate of addition so that all the contents of

the funnel get discharged into the beaker in 20 minutes. Continue stirring for an additional time of 1hr after addition is completed. No special care

for temperature control is needed whole during the synthesis. Filter out the white crystals out of the solution and dry them at 30’C. The yield is

26gr or almost 50% based on Ethyl Oxalate.

In case of unavailability of Ethyl oxalate one may use more conveniently, the Methyl ester which is far less troublesome in synthesis. Methyl oxalate

is a low melting point solid which can be easily synthesized from Oxalic acid and methanol. Also for those who might not have an easy access to

Methylamine, a very good alternative is Hexamine-HCl. Treating this material with alkaline solutions give Methylamine solutions of different

concentrations.

|

|

|

Engager

Hazard to Others

Posts: 295

Registered: 8-1-2006

Location: Moscow, Russia

Member Is Offline

Mood: Lagrangian

|

|

Reciently i've successfully prepared TNGU by nitration of glycouryl. TNGU - colorless or slightly yellowish

crystaline compound, insoluble in water and is slowly hydrolized by it to tetranitraminoethane, fast decomposed in alkaline solution. Decomposes by

hot ethanol. Very powerfull, and dense explosive, easily pressed, density is 2.02 g/cm3 (from nitromethane), density of technical grade product is

1.98 g/cm3. Slightly more sensitive then PETN, soluble in nitromethane. Decomposition starts slightly above 100C, flash point 200C. Detonation

velocity is 9150 m/sec at 1.95 g/cm3. Brisance by sand test is 61.9g of crushed sand (TNT - 48g, PETN - 62.7g). Practitial use is not widespread

because of unsufficent hydrolitic stability, partialy decomposed on melt with TNT. Can be used in flegmatized state or with thermoplastic polymeres.

Here is synth procedure i've used:

Production of glycouryl. 5.84g of glyoxal (0.1 mol, 12.3 ml 40%, density 1.19 g/cm3) is mixed with 15g of powdered

urea, solution is mixed until urea is completely dissolved and then acidified by sulphuric acid to pH~0 and placed on water bath under reflux

condenser. Rection mixture is heated on water bath for 1 hour, cooled and filtered to get glycouryl. Crude product is mixed with 100 ml of boiling

water, well stirred and mixture is left to cool to room temperature. Pure glycouryl is filtered and dried at room temperature. Yield is 9.9g

(71%).

Synthesis of TNGU. 15 ml of ice cold concentrated nitric acid (density 1.51 ~100%) is slowly added drop by drop with

stirring to 45 ml of cold acetic anhydride, not allowing temperature to rise above 15C, mixture is left to stand for 30 minutes at room temperature

(Note#1). 6g of finely powdered glycouryl is added by portion with stirring, mixture is stirred at 20C for 30 minutes and then heated to 30C for 2

hours (Note#2). Precipitate of TNGU is filtered on glass filter, washed with 75 ml of ice cold water, 50 ml if ice cold ethanol and dried at

dessicator over P2O5. Yield is 7.1g (52%).

Notes:

1. Addition of nitric acid causes slight heating, acid should be added drop by drop with gentle stirring, not

allowing temperature to rise above 15C. Acetic anhydride reacts with nitric acid forming acetyl nitrate and N2O5, witch are in equilibrium with each

other. Accumulation of this products takes some time. At 20C conversion of acetic anhydride to acetyl nitrate reaches 70%.

2. Additon of glycouryl to acid mixture, produces no or very low heat, but glycouryl must be added by portions to

ensure efficient mixing. Glycouryl and product of it's nitration are insoluble in nitrating mixture, so nitration proceeds on the surface of glycouryl

particles and precipitate is slowly covered by solid layer of nitration product, blocking acess of acid to inner layers witch can be low nitrated.

Because of that all nitration must be carried out with efficent stirring, to ensure complete nitration, not allowing solid layer to settle.

|

|

|

OregonTrail

Harmless

Posts: 3

Registered: 10-9-2008

Member Is Offline

Mood: No Mood

|

|

If you can get your hands on an ozone generator (commonly used in the aquarium industry or relatively easily built), you can easily make N2O5.

|

|

|

Engager

Hazard to Others

Posts: 295

Registered: 8-1-2006

Location: Moscow, Russia

Member Is Offline

Mood: Lagrangian

|

|

Photo of Sorgyul made from microscope:

[Edited on 4-7-2009 by Engager]

|

|

|

Microtek

National Hazard

Posts: 872

Registered: 23-9-2002

Member Is Offline

Mood: No Mood

|

|

Engager:

Is that a nitration method from litterature ? I have only ever seen TeNGU produced with the use of P2O5/HNO3.

Also, what methods do you use to check that your product is in fact TeNGU and not the di- or tri-nitro derivatives?

Recently, I have been preparing some TeNGU (for use in my HNIW experiments) and checked the product via Raman spectroscopy. The absense of N-H

stretching bands were then taken to mean a fully nitrated product. The thing is however, that some experiments which were supposed to give TeNGU

(P2O5/HNO3 method) only produced lower nitrated species.

|

|

|

Engager

Hazard to Others

Posts: 295

Registered: 8-1-2006

Location: Moscow, Russia

Member Is Offline

Mood: Lagrangian

|

|

Yes synth was from russian general chemistry journal. Translated to English: A.L.Kovalenko, U.V.Serov, I.V.Tselinskij - New heterocyclic system -

1,5-di-tret-butyl-1,5-diaza-3,7-dioxobicyclo [3,3,0] octane. Journal general chem. (Russian) 1991, 61, 13, page 2778. I have this article but on

Russian language.

|

|

|

The WiZard is In

International Hazard

Posts: 1617

Registered: 3-4-2010

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Nitrojet  | | I have prepared 15gr of glycolurile through direct condensation of glyoxal and Carbamide. This is the primary step to synthesizing Sorguyl

(Tetranitroglycolurile) which is a very interesting explosive because of its very high detonation velocity (9150m/s @ d=1.95gr/cc). The nitrating

agent is somehow troublesome to be prepared because it has to be a mixture of HNO3-N2O5 to yield the tetranitro product. does anybody have any

experience with such a nitration agent? is it possible to prepare Sorguyl with strong Nitric acid (d=1.523)? |

Tetranitroglycoluril and method of preparation thereof

Jacques Boileau et al. Dec 11, 1984

US Patent 4487938

|

|

|

hissingnoise

International Hazard

Posts: 3940

Registered: 26-12-2002

Member Is Offline

Mood: Pulverulescent!

|

|

Without some way of producing N2O5 enriched HNO3 TNGU remains more-or-less out of reach. . .

Its ureic oxygen reduces the heat of explosion and its oxygen balance so that while its VoD is higher than RDX and HMX its overall performance is

similar.

Its solubility in water is problematic too!

|

|

|

Azane

Harmless

Posts: 22

Registered: 9-7-2013

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Engager  | Reciently i've successfully prepared TNGU by nitration of glycouryl. TNGU - colorless or slightly yellowish

crystaline compound, insoluble in water and is slowly hydrolized by it to tetranitraminoethane, fast decomposed in alkaline solution. Decomposes by

hot ethanol. Very powerfull, and dense explosive, easily pressed, density is 2.02 g/cm3 (from nitromethane), density of technical grade product is

1.98 g/cm3. Slightly more sensitive then PETN, soluble in nitromethane. Decomposition starts slightly above 100C, flash point 200C. Detonation

velocity is 9150 m/sec at 1.95 g/cm3. Brisance by sand test is 61.9g of crushed sand (TNT - 48g, PETN - 62.7g). Practitial use is not widespread

because of unsufficent hydrolitic stability, partialy decomposed on melt with TNT. Can be used in flegmatized state or with thermoplastic polymeres.

Here is synth procedure i've used:

Production of glycouryl. 5.84g of glyoxal (0.1 mol, 12.3 ml 40%, density 1.19 g/cm3) is mixed with 15g of powdered

urea, solution is mixed until urea is completely dissolved and then acidified by sulphuric acid to pH~0 and placed on water bath under reflux

condenser. Rection mixture is heated on water bath for 1 hour, cooled and filtered to get glycouryl. Crude product is mixed with 100 ml of boiling

water, well stirred and mixture is left to cool to room temperature. Pure glycouryl is filtered and dried at room temperature. Yield is 9.9g

(71%).

Synthesis of TNGU. 15 ml of ice cold concentrated nitric acid (density 1.51 ~100%) is slowly added drop by drop with

stirring to 45 ml of cold acetic anhydride, not allowing temperature to rise above 15C, mixture is left to stand for 30 minutes at room temperature

(Note#1). 6g of finely powdered glycouryl is added by portion with stirring, mixture is stirred at 20C for 30 minutes and then heated to 30C for 2

hours (Note#2). Precipitate of TNGU is filtered on glass filter, washed with 75 ml of ice cold water, 50 ml if ice cold ethanol and dried at

dessicator over P2O5. Yield is 7.1g (52%).

Notes:

1. Addition of nitric acid causes slight heating, acid should be added drop by drop with gentle stirring, not

allowing temperature to rise above 15C. Acetic anhydride reacts with nitric acid forming acetyl nitrate and N2O5, witch are in equilibrium with each

other. Accumulation of this products takes some time. At 20C conversion of acetic anhydride to acetyl nitrate reaches 70%.

2. Additon of glycouryl to acid mixture, produces no or very low heat, but glycouryl must be added by portions to

ensure efficient mixing. Glycouryl and product of it's nitration are insoluble in nitrating mixture, so nitration proceeds on the surface of glycouryl

particles and precipitate is slowly covered by solid layer of nitration product, blocking acess of acid to inner layers witch can be low nitrated.

Because of that all nitration must be carried out with efficent stirring, to ensure complete nitration, not allowing solid layer to settle.

|

Are there any compounds that can sufficiently dissolve glycoluril and still remain inert in the nitration mixture?

I ask because I think that adding a non-aqueous solution of GU to the nitration mixture may allow one to avoid the formation of insufficiently

nitrated particles of GU (protected by TNGU passivation layers), and, therefore, nitrate the predetermined amount of GU more quickly.

Water can't be used because it would hydrolyze the acetic anhydride, negating its viability as a dehydrating agent after the nitration. On top of

that, water just isn't a very good solvent for glycoluril (15g/100g H2O @ 100oC).

If there isn't any solvent that fits the description, it's no big deal, because your method at present works just fine.

Also, does a dehydrating agent need to be used?

|

|

|

Adas

National Hazard

Posts: 711

Registered: 21-9-2011

Location: Slovakia

Member Is Offline

Mood: Sensitive to shock and friction

|

|

Quote: Originally posted by hissingnoise  | Without some way of producing N2O5 enriched HNO3 TNGU remains more-or-less out of reach. . .

Its ureic oxygen reduces the heat of explosion and its oxygen balance so that while its VoD is higher than RDX and HMX its overall performance is

similar.

Its solubility in water is problematic too!

|

It hydrolyzes in water and in presence of weak bases to give tetranitraminoethane, which might form some explosive salts of interest.

Rest In Pieces!

|

|

|

Motherload

Hazard to Others

Posts: 245

Registered: 12-8-2012

Location: Sewer

Member Is Offline

Mood: Shitty

|

|

I am guessing sulfuric acid based nitrations won't work ?

"Chance favours the prepared mind"

"Fuck It !! We'll do it live !!"

|

|

|

| Pages:

1

2 |