HellstormOP

Hazard to Self

Posts: 75

Registered: 13-8-2011

Member Is Offline

Mood: No Mood

|

|

Galvanize carbon fiber?

Hello,

recently I've got an idea, and I don't know if it's new or if there is any research about it, as I've found nothing via Google.

The idea is, that carbon fiber cloths could be coated with metals like steel via galvanization. This should create a very dense electrolytic layer of

metal, which would have unique properties due to the combination of metal (versatile, good electrical conductor, can be shaped etc.) and carbon fiber

(high strength and flexibility). The properties could be further improved by heat treatment, which would cause the formation of extremely hard carbide

layers on the border between metal and carbon fiber.

So I would like to know, if there already was any research on this subject, and what were the results.

|

|

|

Dave Angel

Hazard to Others

Posts: 128

Registered: 22-3-2005

Location: UK

Member Is Offline

Mood: 0 K

|

|

My advice would be to get a hold of some pieces of CF weave and take it to a plater, ask them if they can try plating some sections with copper,

nickel, and chrome (pretty standard automotive plater capabilites). They might look at you a bit funny, but if you can convince them to try then it

would be very interesting to see what the results are.

Alternatively, (and more in keeping with the DIY of the forum) you could try a bit of copper plating yourself, as that's relatively less of a

challenge for the home plater IIRC.

|

|

|

kristofvagyok

National Hazard

Posts: 659

Registered: 6-4-2012

Location: Europe

Member Is Offline

Mood: No Mood

|

|

Not an easy project, but who knows.

A really important part of it is the electrical conductivity of the carbon fiber. Here: LINK is an article what is about this, and you could see from that the conductivity of the CF varies a lot from the method how have it been

produced.

Start with copper plating, even if a thin layer is platen on the CF the conductivity will increase a lot.

I have a blog where I post my pictures from my work: http://labphoto.tumblr.com/

-Pictures from chemistry, check it out(:

"You can’t become a chemist and expect to live forever." |

|

|

daragh8008

Hazard to Self

Posts: 61

Registered: 15-10-2008

Location: Eire

Member Is Offline

Mood: Happy

|

|

Regularly working with thin films made from a variety of different techniques, I would think that one of the major issues you would have is coverage

and adhesion. From previous experience with electroplating I found that achieving a uniform coating can be quite challenging, particularly if the

material to be coated has non uniform electrical properties or excessive surface texture. Also, if it is possible to plate on, getting it to stay on

is often a problem. At present there seems to be a reasonable amount of papers and patents on this topic. Try searching for metallisation of carbon

fibres. Sometimes though, if a specific technique such as galvanisation has not been used it made be because it has been tried extensively and nobody

has been able to get it to work. Could be an interesting project though. As a first try I would probably look to try sensitise the carbon and use some

form of electroless plating technique. Or if I really needed it for a project, I would use a metal evaporator or sputter coater to metallise the

carbon (although I suppose I'm lucky because I have access to these at work)

|

|

|

BromicAcid

International Hazard

Posts: 3253

Registered: 13-7-2003

Location: Wisconsin

Member Is Offline

Mood: Rock n' Roll

|

|

Vaguely similar, in this case they are nickel coating polymer fibers:

http://www.techspot.com/news/46324-new-ultra-lightweight-met...

|

|

|

peach

Bon Vivant

Posts: 1428

Registered: 14-11-2008

Member Is Offline

Mood: No Mood

|

|

I believe this might be an application for something like plasma spray deposition. Or high velocity flame deposition.

Such metallised fabrics are currently available, e.g. here's a company I found supplying them called Swift Technologies.

Keep in mind that things like carbide layer formation could also be a major problem for some applications, e.g. those that require the material to

flex, as it will form a brittle layer that is likely to crack under flexing, leading to the metallic layer delaminating from the bulk carrier (the

fabric). This is quite a common problem with improperly applied chrome plating, that the difference in hardness values causes delamination (flaking).

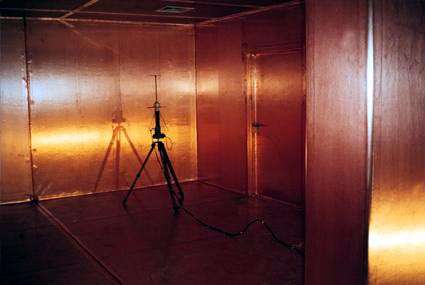

Faraday cages for radio work need only be as 'continuous' in their lining structure as the wavelength of the radio waves in question. E.g. the mesh on

the front of microwave being full of holes, but holes that are considerably smaller than the wavelength of the magnetron within.

Here you can see a Farady cage for radio work.

And a bigger one but with a finer mesh.

I would drawest thouZ attention to there being wire mesh available in numerous materials, weave patterns, mesh sizes, wire sizes and finishes. Not

limited to steel, nickel, platinum, tungsten, rhodium, carptener 20, incoloy, inconel, monel, hastealloy, titanium, copper, bronze, molybdenum, PTFE,

stainless steel and so on. These are also available plated or can be plated, or are available prefinished with nylon, PE, PTFE & so on coatings to

make them virtually bulletproof corrosion wise.

Tungsten, nickel and the nickel superalloys, for instance, have inherently high bulk melting points.

Here you see some copper wire cloth for EMI / RFI shielding;

And this rather beautiful stainless steel cloth;

The FibreGlast company has a number of interesting weaves and hybrid fabrics available. I've been perusing their site for years. Here's a weird wasp /

bee hex patterned fabric.

For an absolute barrier, the walls are getting papered with continuous electrodeposited copper foil;

And then hit with a roll of magic tape (okay, copper foil tape);

There is also carbon and silver based conductive paints (with silver being the only element that is a better conductor than copper);

And these are mirrored in electrically conductive elastomer seals, loaded with silver or carbon. Which often find use on medical equipment or in door

jamb seals for RFI / EMI chambers. And of coarse, if that works, fluffing up the elastomer to produce sponges and foams also works;

There are, naturally, conductive gels and even polymers themselves that are conductive.

I am metaphorically tossing off (;P) ideas and references so you are aware of what is already available and that it may be of use or interest.

Something, regarding composites, carbon fibre and building, that has been of great interest to me is blown foams. As they can really produce some

remarkable changes in structural rigidity / load spreading and so on.

I began wondering... what happens to the properties of this if I start mixing in brick dust, aluminium powder or micronic carbon black. Well, they do

change. But as always, some filthy bastard has beaten me to the gold because there are research papers discussing the use of carbon nano particle and

fibre reinforcement in blown foams and how these (e.g. the fibres) situate themselves in the 'walls' of the cell, acting as microscopic I-beams. A

space to watch I suspect.

Sprayable homes? Hotbox that sucker baby!

Or, of coarse, jamming massive rodes into small holes... ooo er...

But I have also seen composites that have either been spray metallic with paints (which contain free metal particles / flakes) and fabric being

treated with plasma to deposit things like metals. As well as sterilising a single strawberry at a time.

[Edited on 27-7-2012 by peach]

|

|

|

platedish29

Hazard to Self

Posts: 76

Registered: 2-9-2012

Member Is Offline

Mood: absorbing CO2

|

|

Submerge a piece of solid charcoaL in a proper plating solution. Wait until carbon absorbs it. Cool with very cold chemical chiller, apply high

current an precise voltage. Wash the plating solution left over and bring to dryness.

By means of heavily coated iron microparticles embebed in organic matter. Activated charcoal embebed with iron serves as to grant smoother

intersticial deposits as electrical current can turn 360° free in the magnetically hold workpiece.

This can further be cut into thin slides for other purposes.

[Edited on 7-9-2012 by platedish29]

|

|

|

zed

International Hazard

Posts: 2284

Registered: 6-9-2008

Location: Great State of Jefferson, City of Portland

Member Is Offline

Mood: Semi-repentant Sith Lord

|

|

Carbon fibers, and especially carbon nanofibers, are expensive. Perhaps carbon fibers derived from carbonized chicken feathers, or eiderdown....would

suit your purpose. Such fibers share many traits with carbon nanofibers, and they are far less expensive to produce.

The bonus is...you could probably produce your own, at a negligible cost.

In fact, soaking some feathers with a metallic salt, then carbonizing the feathers, might produce an interesting product immediately.

http://www.rsc.org/chemistryworld/News/2009/February/0502090...

[Edited on 3-10-2012 by zed]

|

|

|

Texium

|

Thread Moved

20-11-2023 at 12:25 |

|