| Pages:

1

..

21

22

23

24

25

..

66 |

garage chemist

chemical wizard

Posts: 1803

Registered: 16-8-2004

Location: Germany

Member Is Offline

Mood: No Mood

|

|

I just turned off the water completely and let convective air cooling do the job. If too much alcohol gets lost, I'll add some more later.

The reaction products have formed a hard porous mass that encloses the K globules and prevents coalescence, so I interrupted the heating and broke it

up with a spatula. I'll further look after it in an hour.

Manual agitation seems to be required at some point.

|

|

|

garage chemist

chemical wizard

Posts: 1803

Registered: 16-8-2004

Location: Germany

Member Is Offline

Mood: No Mood

|

|

I added 0,2g extra t-BuOH and resumed the water cooling.

No more alcohol is solidifying on the condenser- a sign that most of it has reacted with the K.

The solvent has become very turbid and opaque. There is still no coalescence, and the reaction mass is hard and crunchy, just in smaller pieces.

|

|

|

ThatchemistKid

Hazard to Others

Posts: 132

Registered: 2-6-2010

Member Is Offline

|

|

If someone is really interested in obtaining tetralin birch reduction of naphthalene yields tetralin and 1,2-dihydronaphthalene

But, this might be beside the point if access to Lithium is limited.

I do not have access to this article but the abstract on the first page seems to be relevant.

Chem. Eng. News, 1966, 44 (51), pp 70–72

DOI: 10.1021/cen-v044n051.p070

Publication Date: December 1966

Copyright © 1966 AMERICAN CHEMICAL SOCIETY

|

|

|

Sedit

International Hazard

Posts: 1939

Registered: 23-11-2008

Member Is Offline

Mood: Manic Expressive

|

|

Electroreduction of aromatics using magnesium electrodes in aprotic solvents containing alcoholic proton donors

DOI: 10.1016/S0013-4686(03)00259-7

| Quote: |

Regioselective electroreduction of the aromatics, including methoxybenzenes, by using LiClO4 as a supporting electrolyte in an aprotic solvent (THF)

containing alcoholic proton donors such as t-BuOH was successfully achieved to afford the corresponding 1,4-cyclohexadienes regioselectively in high

yield. The electrolysis can be performed under constant current conditions at ambient temperature. The effect of electrode materials was remarkable,

that is, the use of Mg electrodes gave the best result. Moreover in the presence of t-BuOD instead of t-BuOH, the deutrated 1,4-cyclohexadienes were

obtained in high deuterium incorporation at 1- and 4-positions. A direct electron transfer to the aromatics is unlikely, and it is reasonable that the

solvated Li(0), which is generated by the cathodic reduction of LiClO4, is intermediately involved in the electron transfer with being assisted by the

anodically generated Mg2+ as an electron transfer catalyst.

|

Author Keywords: Cathodic reduction; Aromatic compounds

If someone could kindly aquire this paper is would eliminate the issue with Lithium avalibility. Abstract link embedded in the title.

Knowledge is useless to useless people...

"I see a lot of patterns in our behavior as a nation that parallel a lot of other historical processes. The fall of Rome, the fall of Germany — the

fall of the ruling country, the people who think they can do whatever they want without anybody else's consent. I've seen this story

before."~Maynard James Keenan

|

|

|

trilobite

Hazard to Others

Posts: 152

Registered: 25-2-2004

Location: The Palaeozoic Ocean

Member Is Offline

Mood: lonely

|

|

Cool stuff!

Here is an idea regarding how to reduce the amount of magnesium needed (and the amount of Mg(II) byproducts formed, maybe even helping purification if

the magnesium alcoholate is soluble enough in a purification solvent) by preforming the potassium tert-alcoholate in stoichiometric amount.

Water-immiscible alcohols form an azeotrope with water, so distilling the alcohol with KOH would displace the equilibrium of alcohol + KOH <==>

K-alcoholate + H2O to the right. This is an established method of preparing sodium 1-butoxide. If the solubility of the alcohol in water is low

enough, it might even be possible to perform the reaction with a Dean-Stark apparatus to return the alcohol back to the distilling flask while tapping

off water. Tert-amyl alcohol is soluble in 8 parts of water, so it is not as favourable as it could be but adding toluene might have a positive

effect, also in formation of a tertiary azeotrope. Alternatively one could use a higher-boiling tertiary alcohol.

Azeotropes of t-amyl alcohol (bp 102,25C)

t-AmOH + 27,5 weight-% water bp. 87,35C

t-AmOH + 44 weight-% toluene bp. 100,5C

t-AmOH + water + toluene bp. 82C (no composition data)

After distilling the reaction water, one would add the high-boiling hydrocarbon and distill off all the lower boiling components. Some of the alcohol

may stay retained in the potassium tert-alcoholate as alcohol of crystallization, but I suppose it would distill when heated enough. At least sodium

t-butoxide may be freed of the alcohol by distillation with xylene. The residue would then be ready for reduction with Mg(0). Recovery of the alcohol

would depend on separation of potassium metal from the Mg alcoholate, which could be decomposed with water to give Mg(OH)2 and alcohol.

|

|

|

MagicJigPipe

International Hazard

Posts: 1554

Registered: 19-9-2007

Location: USA

Member Is Offline

Mood: Suspicious

|

|

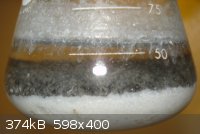

Failure (Negative Result Report)

1.58 g of Mg "shavings" from a firestarter and 3.06 g of reagent (though quite old) KOH hemispheres were added to a 125 mL flask containing approx. 50

mL of Kroger brand *mineral oil "laxative". The flask had a rubber stopper with a long glass tube in it. At the top of the tube was a balloon with a

few small "needle-holes" poked in it. A wet paper towel was wrapped around the tube near the top. The flask sat in some sand in a 600 mL beaker.

The stopper was placed on and the sand was heated (I can't find my damn glass thermometer so I couldn't measure the temp. directly) to a temperature

of 200*C over a period of about 30 mins. Then, a hypodermic needle containing 0.6 g of mineral oil and 0.6 g of Reagent t-butanol (the alcohol did

slowly dissolve with just a bit of stirring) was thrust through the stopper and injected into the solution over about 25 mins. I noticed "instant"

boiling of the alcohol/oil soln. as soon as it hit the main mixute. Once the temp. got up to around 250*C there was sporadic boiling. S

tarting at about 200*C (I'm not quite sure on this exactly and will have to check my notes at home) there was quite a bit of gas evolution and it

stayed steady for several hours. The t-butanol did seem to increase the amount of bubbles but it could've just been boiling. The reaction did not

seem to proceed at all and after about 3 hours a few black specks were noticed floating around. Then the Mg started to turn black and eventually I

started to notice a white "precipitate" on the bottom of the flask. It seems as if the reaction did not occur and the KOH just settled at the bottom

and the Mg was oxidized (by H2O/air?) I desperately added quite a bit more t-butanol (unmeasured) and just got refluxing t-butanol in the rxn

mixture. I finally stopped heating after 6 hours.

My guess is that there was not enough mixing due to the sporadic boiling. Also, the KOH could've been poorly stored and could thus be mostly the

carbonate. It could also be the Mg but I doubt it. I simply shaved off Mg from the block with the tool that was included (and damn that took a long

time and a lot of elbow grease; the battery to my drill was dead).

And before anyone says anything: Yes, I know there are different and better ways to set this up.

*The mineral oil said it contained vitamin E as a stabilizer.

The setup:

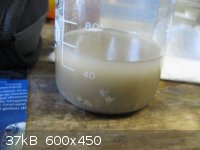

About an hour after adding t-butanol and 1.5 hours into the rxn:

The results:

Thanks for your time!

"There must be no barriers to freedom of inquiry ... There is no place for dogma in science. The scientist is free, and must be free to ask any

question, to doubt any assertion, to seek for any evidence, to correct any errors. ... We know that the only way to avoid error is to detect it and

that the only way to detect it is to be free to inquire. And we know that as long as men are free to ask what they must, free to say what they think,

free to think what they will, freedom can never be lost, and science can never regress." -J. Robert Oppenheimer

|

|

|

benzylchloride1

Hazard to Others

Posts: 299

Registered: 16-3-2007

Member Is Offline

Mood: Pushing the envelope of synthetic chemistry in one's basement

|

|

Naphthalene will not work in this reaction since it reacts very easily with potassium to form the naphthalinide. I have prepared potassium

naphthalinide several times for use in forming exotic organometallic anions. Upon mixing potassium and naphthalene in a glove box and shaking for

several minutes a greenish color develops. After adding tetrahydrofuran, the mixture turns to a very dark green color and the potassium soon

dissolves, I would assume that no potassium would be obtained if naphthalene was used as a solvent. I am very interested in this work since I would

like to have some potassium of my own for syntheses when sodium metal cannot be used. I plan on using my glove box for the isolation procedure though

for added safety.

[Edited on 5-1-2011 by benzylchloride1]

Amateur NMR spectroscopist

|

|

|

smuv

National Hazard

Posts: 842

Registered: 2-5-2007

Member Is Offline

Mood: Jingoistic

|

|

MJP, Looking at your setup, you very well may have lost your t-butanol to the atmosphere.

About the t-butanol crystallization problem, how about adding a touch of hexanes?

[Edited on 1-5-2011 by smuv]

|

|

|

woelen

Super Administrator

Posts: 8083

Registered: 20-8-2005

Location: Netherlands

Member Is Offline

Mood: interested

|

|

I did not have the problem of t-butanol crystallizing. I blew air through the Liebig cooler at a speed of 2 liters per minute, using a small aquarium

pump. This provides sufficient cooling not to loose any t-BuOH, while at the same time this does not solidify. My column was warm when touched, but

not hot.

|

|

|

Sedit

International Hazard

Posts: 1939

Registered: 23-11-2008

Member Is Offline

Mood: Manic Expressive

|

|

MJP while I don't feel that stirring is to good of an idea in this reaction I do believe that during the addition of the alcohol it would be best for

one to stir to react the alcohol as rapidly as possible with the KOH. The of the reaction goes thru a different mechanism that im not sure if stirring

would be best.

Knowledge is useless to useless people...

"I see a lot of patterns in our behavior as a nation that parallel a lot of other historical processes. The fall of Rome, the fall of Germany — the

fall of the ruling country, the people who think they can do whatever they want without anybody else's consent. I've seen this story

before."~Maynard James Keenan

|

|

|

garage chemist

chemical wizard

Posts: 1803

Registered: 16-8-2004

Location: Germany

Member Is Offline

Mood: No Mood

|

|

Here's the rest of the report on the first batch:

Last night, I was too tired to look after the reaction after the 4 hours of reflux were over, so I let it run overnight, for a total of 12 hours

reflux after addition of the t-BuOH.

The next day, after cooling down, it was still turbid and there was a large amount of brownish powder and crumbly substance under the solvent, with no

visible potassium any more.

I emptied the flask into a beaker and sorted through the crud with a spatula and tweezers.

There was a large irregular dirty lump of what first appeared to be byproducts, but upon cutting turned out to be massive potassium metal! The whole

lump was softer than sodium and could easily be deformed between two fingers.

It weighs 2,1g and is shown on the first picture, under clean fresh Shellsol. Anyone familiar with potassium will recognize the bluish appearance of

the recently cut surface.

I could have cleaned its surface with 1-butanol, but since it rapidly regrows the oxide layer upon storage, this was omitted.

There was another smaller lump of potassium, weighing 0,4g, and several more 3mm pieces that were dropped onto ice outside, making a nice show of

flames and sparks.

The K pieces were recovered from the byproducts by manual sorting based on appearance (the K pieces were dark colored on the outside, contrary to the

white/grey Mg oxide byproduct). On the second picture, the reaction mixture minus the first lump of K is shown.

So I conclude that Pok's method has worked for me and made 2,5g of useable potassium from 6g KOH and 3g Mg powder in 50ml of Shellsol D70.

Deviations from the procedure were that I added 0,2g more t-BuOH after losing some to evaporation, and boiling for 12h instead of 4h.

The most important observed difference was that I did not get any shiny potassium balls, but large lumps with oxidised surface.

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

garage chemist:

2.7 g potassium is a yield of 71 % (based on 10 % water in the KOH). And one has to account also for the K that’s bound up as K alkoxide (as the Mg

has reacted completely away). Not bad at all!

I think you and magic may also have been using a little too much head space over the reacting mix: that with intensive cooling would promote t-butanol

to crystallise out in the upper part of the reactor.

What someone really importantly should do is recover all post reaction solvent: as it should contain all the catalyst and is bone dry, it should

theoretically be directly reusable, no fresh catalyst needed!

And another important test would be to, say, double the amount of t-butanol/t-amyl to check effect on reaction time...

[Edited on 5-1-2011 by blogfast25]

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Sedit  | | MJP while I don't feel that stirring is to good of an idea in this reaction I do believe that during the addition of the alcohol it would be best for

one to stir to react the alcohol as rapidly as possible with the KOH. The of the reaction goes thru a different mechanism that im not sure if stirring

would be best. |

Sedit, if you've ever seen with your own eyes what happens when you add the aclcohol to the hot solvent, you wouldn't be writing that. The moment the

alocohol/solvent pre-mix starts hitting the hot solvent, very intensive refluxing starts and this continues mostly during addition of the alcohol.

Vigorous boiling of the solvent/alcohol mixture means that stirring is a complete waste of time.

I'm contemplating using much longer chain alcohols like 2-methyl-2-octanol, they have much higher boiling points and there some gentle swirling may be

advisable. But with Shellsol D70 and gentle boil is achieved eventually, making stirring unnecessary.

[Edited on 5-1-2011 by blogfast25]

|

|

|

garage chemist

chemical wizard

Posts: 1803

Registered: 16-8-2004

Location: Germany

Member Is Offline

Mood: No Mood

|

|

With the next batch, I will try to use selfmade Mg turnings from scrap Mg using a drill press.

I will also make myself some 2-methyl-2-hexanol via n-butylmagnesium bromide and acetone. Like Nicodem, I think that this alcohol may be one of the

best to use- relatively easy to make, suitably high boiling point (141°C) and not too long-chained.

The longer the carbon chain of the alcohol, the higher is its molar mass, and the more you will need of it to achieve a given molar concentration in

the solvent. With the "margarine tert-alcohols" proposed in the tert-alcohol thread, it may become unattractive since you will probably need quite a

large amount of your precious grignard-made alcohols.

|

|

|

Sedit

International Hazard

Posts: 1939

Registered: 23-11-2008

Member Is Offline

Mood: Manic Expressive

|

|

Quote: Originally posted by blogfast25  |

Sedit, if you've ever seen with your own eyes what happens when you add the aclcohol to the hot solvent, you wouldn't be writing that. The moment the

alocohol/solvent pre-mix starts hitting the hot solvent, very intensive refluxing starts and this continues mostly during addition of the alcohol.

Vigorous boiling of the slovent/alcohol mixture means that stirring is a complete waste of time.

I'm contemplating using much longer chain alcohols like 2-methyl-2-octanol, they have much higher boiling points and there some gentle swirling may be

advisable. But with Shellsol D70 and gentle boil is achieved eventually, making stirring unnecessary.

[Edited on 5-1-2011 by blogfast25] |

Really, if I ever seen it with my own eyes I wouldn't be writting this? Have you hacked my brain and seen what my eyes have seen?

Nope not a chance else you would know my reason for writting it was because the reflux is mostly superficial and the surface rapidly boils with no

complete mixing of the reactants. You have a bunch of settled solids with a heavy boiling at the top. Its akin to what causes bumping only in this

case the lower boiling substance is on the top and not the bottom.

Would it be so damn hard to just stir the reaction on the addition of alcohol since it would ensure more alcohol reacts with the KOH in a decent time

frame?

Knowledge is useless to useless people...

"I see a lot of patterns in our behavior as a nation that parallel a lot of other historical processes. The fall of Rome, the fall of Germany — the

fall of the ruling country, the people who think they can do whatever they want without anybody else's consent. I've seen this story

before."~Maynard James Keenan

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Sedit  | Really, if I ever seen it with my own eyes I wouldn't be writting this? Have you hacked my brain and seen what my eyes have seen?

Nope not a chance else you would know my reason for writting it was because the reflux is mostly superficial and the surface rapidly boils with no

complete mixing of the reactants. You have a bunch of settled solids with a heavy boiling at the top. Its akin to what causes bumping only in this

case the lower boiling substance is on the top and not the bottom.

Would it be so damn hard to just stir the reaction on the addition of alcohol since it would ensure more alcohol reacts with the KOH in a decent time

frame? |

Ok, calm down already.

Firstly it’s understood that len1’s experiment of years back failed, probably due to too fast stirring. pok’s experiment involved occasional

swirling of the flask and that is what most here have been doing successfully, including myself.

Secondly, refluxing isn’t ‘superficial’. Assuming you have total reflux and not a huge amount of head space, most of the alcohol is in the

liquid phase, in homogeneous solution. If that wasn’t the case you wouldn’t get reaction at all. The ENTIRE solution boils, not just the surface,

as can very clearly be seen during the reaction and as logic dictates. On top of that you’ve got hydrogen generation and heat generation (quite a

bit too: 2 KOH + 2 Mg === > 2 K + 2 MgO + H2 is highly exothermic mainly due to the formation of the high lattice energy MgO). And the alcohol is

added as a premix of alcohol and solvent. Combine all this and you have a heterogeneous solid-liquid system but with a highly homogeneous liquid

phase.

[Edited on 5-1-2011 by blogfast25]

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by garage chemist  | With the next batch, I will try to use selfmade Mg turnings from scrap Mg using a drill press.

I will also make myself some 2-methyl-2-hexanol via n-butylmagnesium bromide and acetone. Like Nicodem, I think that this alcohol may be one of the

best to use- relatively easy to make, suitably high boiling point (141°C) and not too long-chained.

The longer the carbon chain of the alcohol, the higher is its molar mass, and the more you will need of it to achieve a given molar concentration in

the solvent. With the "margarine tert-alcohols" proposed in the tert-alcohol thread, it may become unattractive since you will probably need quite a

large amount of your precious grignard-made alcohols.

|

Personally I’m hesitating between 2-methyl-2-hexanol and 2-methyl-2-octanol, the former being cheaper to synth., the latter being even higher

boiling (>180C) and the alkoxide possibly more soluble in C12-C15 based solvents (for both K, Na). The higher boiling point of 141C will still lead

to considerable refluxing unless you add it at low temperature. But refluxing isn't a problem anyway, it's part of the solution (no pun intended).

2-methyl-2-hexanol is only 2 C longer than t-amyl alcohol, would that make a decisive difference? n-hexyl bromide, BTW, is surprisingly reasonably

priced by Sigma-Aldrich...

As regards ‘The longer the carbon chain of the alcohol, the higher is its molar mass, and the more you will need of it to achieve a given molar

concentration in the solvent’, that’s been dealt with in the organics thread. I don’t think it’s an attractive proposition to make longer

chain 2-methyl-2-alkanols if it turns out they’re not considerably more active (than t-butanol or 2-methyl-2-butanol), thus requiring lower

molarities for same or better reactivity. In particular higher solubility of the K alkoxide should speed up the first two steps of the (proposed)

reaction mechanism. Personally I'm convinced it's possible to bring the whole procedure down to under an hour, as Nurdrage with his Tetralin/t-amyl

alcohol qualitative experiment already showed.

But the main purpose of longer chain t-alkanols must remain IMHO the higher solubility of the corresponding sodium alkoxides, opening up the way to Na

production.

[Edited on 5-1-2011 by blogfast25]

|

|

|

garage chemist

chemical wizard

Posts: 1803

Registered: 16-8-2004

Location: Germany

Member Is Offline

Mood: No Mood

|

|

I cleaned up my potassium pieces by melting them in dioxane.

This works marvellously, much better than my old method with IPA in kerosene.

In hot dioxane, the molten potassium floats and the impurities either sink to the bottom (MgO and Mg) or dissolve (KOH), leaving absolutely clean

shiny potassium spheres.

However, on weighing the cleaned potassium again, I found that the large 2,1g piece now only weighs 1,5g. There is a lot of brown crud in the dioxane.

So my yield is not as high as initially assumed, and the potassium directly from the Shellsol D70 method contains a lot of adhering or suspended

impurities and should be cleaned up with hot dioxane.

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

0.2 g t-butanol accounts for about 0.1 g of K (bound as alkoxide), so that doesn’t explain the lower yield.

But I think if you repeat the experiment, this time avoiding some of the butanol freezing out near the refluxer, you’ll find your results to be

close to all of ours.

And since as you have dioxane you could try and help coalescence by replacing the Shellsol (after all hydrogen has stopped evolving and cooling) with

dioxane and remelting the fine K…

|

|

|

rrkss

Hazard to Others

Posts: 193

Registered: 18-12-2009

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by garage chemist  | I cleaned up my potassium pieces by melting them in dioxane.

This works marvellously, much better than my old method with IPA in kerosene.

In hot dioxane, the molten potassium floats and the impurities either sink to the bottom (MgO and Mg) or dissolve (KOH), leaving absolutely clean

shiny potassium spheres.

However, on weighing the cleaned potassium again, I found that the large 2,1g piece now only weighs 1,5g. There is a lot of brown crud in the dioxane.

So my yield is not as high as initially assumed, and the potassium directly from the Shellsol D70 method contains a lot of adhering or suspended

impurities and should be cleaned up with hot dioxane. |

If you have some pictures I would like to see. Did you prepare the dioxane yourself from condensation of ethylene glycol or is it purchased?

|

|

|

garage chemist

chemical wizard

Posts: 1803

Registered: 16-8-2004

Location: Germany

Member Is Offline

Mood: No Mood

|

|

The dioxane was purchased. This is a quite expensive and difficult to obtain chemical, but it really pays off to get some if you're trying to make

clean potassium.

The K looked even better than the large ball of liquid potassium in tetralin that NurdRage obtained. It was like floating mercury.

I didn't make any pictures, but I will make some the next time I purify a batch of potassium.

Dioxane can be prepared at home from ethylene glycol and sulfuric acid. A friend did this a few years ago and still remembers vividly how much work it

was to get a pure product from the crude distillate. All kinds of impurities, aldehydes, unsaturated products, and so on are formed as byproducts in

the synthesis.

Dioxane is also very difficult to obtain anhydrous. If you don't have any sodium or potassium to reflux it with, you'll never make an anhydrous

product.

With the commercial product, specified at max. 0,1% water, there was clearly visible hydrogen evolution at the molten K- but this did not impair the

process, since KOH seems to be soluble in hot dioxane.

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Because some of us here will now be looking at other catalysts, I’ve rewritten the proposed reaction mechanism presented on woelen’s page in a

format that represents what we believe happens in a clearer manner (I think). Just four reactions are involved, arranged here into two SETS, where

‘(sol)’ stands for ‘dissolved in inert, aprotic, apolar solvent’ and ROH is either t-butanol or 2-methyl 2-butanol.

SET 1:

1.1. Alkoxide formation:

2 KOH(s) + 2 ROH(sol) < == > 2 KOR(sol) + 2 H2O(sol)

1.2. (= 2.2.) Redox reaction:

2 KOR(sol) + Mg(s) < == > 2 K(l) + Mg(OR)2(sol)

1.3. (= 2.3.) Hydrolysis:

Mg(OR)2(sol) + H2O(sol) < == > MgO(s) + 2 ROH(sol)

Sub Overall 1:

2 KOH(s) + Mg(s) < == > 2 K(l) + MgO(s) + H2O(sol)

===================

SET 2:

2.1. Hydrogen generation:

K(l) + 2 ROH(sol) < == > 2 KOR(sol) + H2(g)

2.2. (= 1.2.) Redox reaction:

2 KOR(sol) + Mg(s) < == > 2 K(l) + Mg(OR)2(sol)

2.3. (= 1.3.) Hydrolysis:

Mg(OR)2(sol) + H2O(sol) < == > MgO(s) + 2 ROH(sol)

Sub Overall 2:

Mg(s) + H2O(sol) < == > MgO(s) + H2(g)

Overall = Sub Overall 1 + Sub Overall 2:

2 KOH(s) + 2 Mg(s) < == > 2 K(l) + 2 MgO(s) + H2(g)

===================

This scheme relies on the same reactions woelen’s does but eliminates one step I’ve always found highly contentious (I quote from woelen's scheme):

(t-BuO)2Mg + KOH → MgO(s) + t-BuOK + t-BuOH

I just don’t see this happening. My scheme doesn’t have to call on it while still respecting catalyst conservation and overall stoichiometry.

===================

Some might still wonder how come the potassium isn’t attacked by water and I believe it can be explained as follows. Firstly we must realise that

we’re in an aprotic, apolar medium. For the potassium – water reaction we normally have:

2 H2O(l) < == > H3O+(aq) + OH-(aq) and K(s) + H3O+(aq) == > K+(aq) + ½ H2(g) + H2O(l), the latter which proceeds very quickly due to K’s

small first ionisation energy, K+ solvation enthalpy and escape of the hydrogen. This of course then drives the dissociation of water to the right.

But in an apolar, aprotic solvent, water isn’t dissociated.

Secondly we have to assume that Mg(OR)2(sol) + H2O(sol) < == > MgO(s) + 2 ROH(sol) does proceed very quickly with the very high lattice energy

of the MgO being the ΔG driver here. Kinetically the reaction somewhat resembles hydrolysis of a Grignard Reagent: although the water isn’t

dissociated, water molecules still have a partial positive charge δ+ on their hydrogen ends and a partial negative charge δ- on the oxygen

end. Similarly the Mg(OR)2 moiety may not be dissociated but contains a partial positive charge δ+ on the Mg part and partial negative charges

δ- on the oxygen ends of the alkoxide part. This makes rearranging H2O + Mg(OR)2 into MgO + 2 ROH very likely and very fast, much like the

hydrolysis of Grignard Reagents.

In any case we don’t have much choice but to assume that reaction water from 1.1. regenerates the catalyst, by reacting with Mg(OR)2 rather than

reacting with K, as otherwise no K could be formed AT ALL.

I believe Mg(OR)2(sol) + H2O(sol) < == > MgO(s) + 2 ROH(sol) are the ‘four cylinders’ which drive much of the whole edifice, at least

thermodynamically speaking.

I also see no good reason why the preliminary drying step has to be carried out without the catalyst present. As long as a small excess of Mg is

accounted for as H2O + Mg === > MgO + H2 the catalyst doesn’t seem to interfere or be interfered with.

[Edited on 6-1-2011 by blogfast25]

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Very nice, blogfast. I was really starting to wonder what was driving this remarkable synthesis. When you first look at it, it doesn't seem possible

that a less active metal (Mg) will act to reduce a more active metal (K+). Then I assumed that the generation of H2 and the solid MgO were drivers

and that the kinetics were favorable enough even at the relatively low temperature.

I was going to calculate the delta G for the overall reaction when I saw your post. Have you done this yet?

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Magpie  | Very nice, blogfast. I was really starting to wonder what was driving this remarkable synthesis. When you first look at it, it doesn't seem possible

that a less active metal (Mg) will act to reduce a more active metal (K+). Then I assumed that the generation of H2 and the solid MgO were drivers

and that the kinetics were favorable enough even at the relatively low temperature.

I was going to calculate the delta G for the overall reaction when I saw your post. Have you done this yet? |

Thanks Magpie… Kinetic barriers are lowered by the catalyst, that's its definition, basically...

ΔH @ 298 K = + 428 kJ/mol – 601 kJ/mol = - 173 kJ/mol K, quite respectable…

[Edited on 6-1-2011 by blogfast25]

|

|

|

NurdRage

Hazard to Others

Posts: 182

Registered: 11-11-2010

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by blogfast25  |

I also see no good reason why the preliminary drying step has to be carried out without the catalyst present. As long as a small excess of Mg is

accounted for as H2O + Mg === > MgO + H2 the catalyst doesn’t seem to interfere or be interfered with. |

Because the temperature at which drying takes place is well above the boiling point of the alcohols.

The alkoxides don't form until the system is dry so by the time it reaches that temperature most of the alcohol will be in the vapor phase. When

drying starts the fast hydrogen production pushes the alcohol vapor out of the condensor and is gone.

The condensor won't recapture all of it since the vapor pressure is obviously less than 100% (since it's being carried by the hydrogen).

Only when the alkoxide is produced will it become non-volatile.

If we can start working with alcohols that have boiling points higher than the solvent then we might be able to do everything in one pot.

Alternatively i suppose you could simply load up with LOTS of alcohol and hope enough is retained to form the non-volatile alkoxide

But that's just my theory, experimentally i find performance better when i add the alcohol later. but i haven't performed a rigorous test of the

theory yet.

Just like i tested aromatics and it worked, if you want to go ahead and test your alcohol theory i'd love to hear the results. You might find out that

my "vapor loss" theory is a negligible contributor.

Experiment > Theory

|

|

|

| Pages:

1

..

21

22

23

24

25

..

66 |