| Pages:

1

2

3

4

5

..

7 |

VladimirLem

Hazard to Others

Posts: 204

Registered: 24-5-2010

Member Is Offline

Mood: Have no fear <Vlad> is here.

|

|

Is the product really the TETRA-Nitrate ?

I think, that i read in some online book, ist is a TRI-Nitrate when using diluted HNO3

|

|

|

hissingnoise

International Hazard

Posts: 3940

Registered: 26-12-2002

Member Is Offline

Mood: Pulverulescent!

|

|

There is no product when dilute HNO3 (<90%) is used with pentaerythritol.

The trinitrate, along with the lesser nitrates containing (OH) is water-soluble and doesn't normally precipitate on drowning. . .

|

|

|

VladimirLem

Hazard to Others

Posts: 204

Registered: 24-5-2010

Member Is Offline

Mood: Have no fear <Vlad> is here.

|

|

***********

for PETN synth

***********

Verified efficient method of preparing PETN from diluted HNO3

use

32,7 ml of 70% HNO3 (75% excess)

18,9 ml of 96% H2SO4

10,0 g of Pentaerythrite

------------------------

or

34,0 ml of 65% HNO3 (66% excess)

24,8 ml of 96% H2SO4

10,0 g of Pentaerythrite

------------------------

or

34,8 ml of 58% HNO3 (48% excess)

36,3 ml of 96% H2SO4

10,0 g of Pentaerythrite

Let me say this; it does need to be monitored to a get degree. Temp must not exceed 15-20C or else it may run and spew NOx.

are you sure ?

Quote: Originally posted by hissingnoise  | The trinitrate, along with the lesser nitrates containing (OH) is water-soluble and doesn't normally precipitate on drowning. . .

|

that i've got wasen't water-soluble

|

|

|

franklyn

International Hazard

Posts: 3026

Registered: 30-5-2006

Location: Da Big Apple

Member Is Offline

Mood: No Mood

|

|

Attachment: PETN Synthesis of .rtf (12kB)

This file has been downloaded 1510 times

|

|

|

Microtek

National Hazard

Posts: 872

Registered: 23-9-2002

Member Is Offline

Mood: No Mood

|

|

@Vlad:

When you use dilute nitric along with concentrated sulfuric you are generating concentrated nitric in situ. So that doesn't really qualify as

using dilute nitric acid.

|

|

|

quicksilver

International Hazard

Posts: 1820

Registered: 7-9-2005

Location: Inches from the keyboard....

Member Is Offline

Mood: ~-=SWINGS=-~

|

|

Microscopic examination if crystalline structure will reveal quite a bit. Needles form at the level of PETN while lesser nitrated materials will form

other shapes. The shearing/shaving of the material will still reveal needle structure at 100x. Tri-nitrated material will often still be energetic.

Whether it will wash out or go into solution is dependent upon temp & method of nitration.

Edit:

This is also true of MHN. At the level of true MHN you'll see needles; if it doesn't make it that far, you won't. ETN forms platelets, however (it's

only my opinion) that other shapes reveal higher levels of nitration, especially if 1.51 HNO3 is used for initial nitration & H2SO4 is used to

precipitate the nitrated product out. Under magnification, platelets are seen along side hexagonal granular shapes - using that form of nitration.

[Edited on 1-6-2010 by quicksilver]

|

|

|

gnitseretni

Hazard to Others

Posts: 283

Registered: 5-1-2007

Location: Colombia

Member Is Offline

Mood: No Mood

|

|

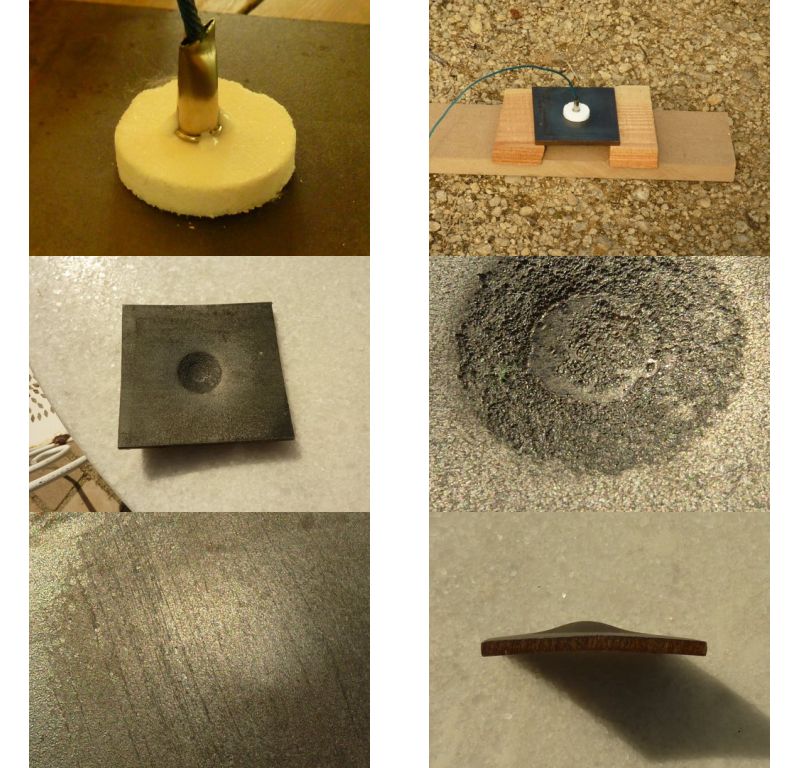

Made some PETN.

12g PE

60g KNO3

150ml H2SO4

I again used a large excess of H2SO4 just like with the ETN synth a few days ago.

I added the PE pretty fast. After the last addition I stirred for 10 minutes in the ice bath, then I took it out and placed it in 45C water and

stirred for another 15 minutes and then, after taking a picture of the thick mixture, drowned it in cold water. After washing, neutralizing,

recrystallizing, drying.. result is 21g PETN. Not too bad

Some pics..

|

|

|

Rain

Harmless

Posts: 24

Registered: 2-3-2008

Location: All over

Member Is Offline

Mood: Repellant

|

|

If I may ask...What was the temperature of your ice bath, and what was the concentration of your sulfuric acid?Was it drain cleaner or lab grade?Im so

gonna make me some pbx as soon as I get a chance.Jealousy is a great motivator.

[Edited on 3-6-2010 by Rain]

|

|

|

gnitseretni

Hazard to Others

Posts: 283

Registered: 5-1-2007

Location: Colombia

Member Is Offline

Mood: No Mood

|

|

Didn't check the temp on the ice bath, but I started PE addition when the temp of the mix was 5C. The H2SO4 was drain cleaner(Liquid Fire).

|

|

|

VladimirLem

Hazard to Others

Posts: 204

Registered: 24-5-2010

Member Is Offline

Mood: Have no fear <Vlad> is here.

|

|

Wouldn't it be better to take ammoniumnitrate to get a stronger HNO3 ?

|

|

|

quicksilver

International Hazard

Posts: 1820

Registered: 7-9-2005

Location: Inches from the keyboard....

Member Is Offline

Mood: ~-=SWINGS=-~

|

|

Doesn't work that way. Solid alkali nitrates have different rates of efficiency but the results are generally similar.

|

|

|

Sephi

Harmless

Posts: 3

Registered: 31-8-2010

Location: Italy

Member Is Offline

Mood: No Mood

|

|

Hi

I'm new on this forum, I think this is the best place to expose my doubts

This summer I've done about 20g of PETN (I used the synthesis of powerlabs) and I've took some pics of the dry crystals.

60X 60X

150X 150X

150X 150X

600X 600X

anyone have other pics to compare?

There is a system to distinguish PETN from other esters?

Thanks and sorry for my bad english

|

|

|

pdb

Hazard to Self

Posts: 90

Registered: 8-4-2004

Member Is Offline

Mood: No Mood

|

|

For those worried about the effectiveness of PETN synthetized from mixed acids, here is a test of a 2.9gr pill on a 5mm thick steel plate :

The side in contact with PETN exhibits typical detonation wavelets, when on the other side, the creeks reveal the lamination direction.

[Edited on 1-9-10 by pdb]

|

|

|

VladimirLem

Hazard to Others

Posts: 204

Registered: 24-5-2010

Member Is Offline

Mood: Have no fear <Vlad> is here.

|

|

Hi

"pdb" is right, it IS a strong explosive. I tested it as a little shaped charge (3cm Copperpipe, tulp-glasliner, 3cm Standoffs at a 5cm thick

steelplate. Around 20g of that kind of "PETN" where used and penetrated around 2cm...

------------------------------------------------

Back to Topic ("real" PETN)

In this Thread is a Synth of (real) PETN with high conc. HNO3 (look at the Link)

http://www.sciencemadness.org/talk/viewthread.php?tid=6151&a...

...do i have this right, that only 100ml HNO3 Acid are used at 33g PE, because the themerature of the mixture is such high (18-23C)

so that the Acid can better work - (but everything else is like a "normal" PETN synth where only high conc. acid is used)...right?

I ask this, because the most synth of PETN which are on the internet use only 25g PE on 100ml...(1:4 ratio)

|

|

|

quicksilver

International Hazard

Posts: 1820

Registered: 7-9-2005

Location: Inches from the keyboard....

Member Is Offline

Mood: ~-=SWINGS=-~

|

|

I know I have mentioned this before but for those who have not read back some time, etc there is the reagent grade (or mil-spec) grade

pentaerythritol. that is used in making energetics (in Europe it's often know as pentaerythritol.-M, Penta-M, etc) & there is the material in the

30gal tins used in the vinyl and paint industries that is below common technical grade material (93% +). The "big tin-cans" of pentaerythritol. used

to be available frequently and sold off at the pound level. The best you could hope for was getting a very poor yield of PEN for this. In general; it

was garbage for making PETN. Reagent pentaerythritol is often note to be extremely light yellow-white; the paint-grade is identified by a beige

coloration (very light beige and also "fluffy" not granular). Reagent level pentaerythritol would never be cheap. It's cost would not be low.

Paint-grade pentaerythritol is (IMO) a waste of acid.

Since the abuses of energetics the paint-grade material is much more difficult to obtain than it once was. However there may still be some cans of

that crap floating around. Don't waste your money as you could make pentaerythritol that would have a higher purity level & would not be

adulterated with a fairly large percentile of paint-oriented items.

[Edited on 5-12-2010 by quicksilver]

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

The procedure was accurately described. However you must note the stirring difficulty due to the proportions which involve a high solids content.

Excellent stirring is required to achieve that efficiency. If you don't have excellent stirring

then you should adjust your proportions for a thinner mixture.

Reagent grade pentaerythritol was used for the experiment. It is a snow white material and so is the recrystallized nitrated form, which looks and

glitters exactly like table sugar.

[Edited on 5-12-2010 by Rosco Bodine]

|

|

|

nitro-genes

International Hazard

Posts: 1048

Registered: 5-4-2005

Member Is Offline

|

|

What is the purity of this reagent grade? My PE is 98% purity, although it has a slight acetic acid/acetaldehyde smell to it. With efficient stirring

and cooling I usually got something like 22 grams of PETN from from 10 grams of PE and 30 ml of 97% WFNA. Strange thing is though that the PETN goes

from snow-white to a very slightly shade of yellow upon neutralization of the water-washed PETN with a few ml's of 10% ammonia. Never had any

runwaways though...

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

It was 98% or better, that has been some years ago and I'm not certain. The yellowing you got may be from overneutralizing.

|

|

|

nitro-genes

International Hazard

Posts: 1048

Registered: 5-4-2005

Member Is Offline

|

|

Not sure about the over neutralizing, the yellow colour became visible with the first addition of ammonia. PETN crystalizes as very pure PETN though,

forming 1-2 cm long needles from a slowly cooled 40% PETN/acetone solution. Couldn't find the pictures from these anymore, though here is one after

blending with water for a couple of minutes. Estimated size is 20-50 micron. (40 times enlarged)  Crystals show lots of surface damage as they are not translucent, also experimented with water/solvent treatment

afterwards to improve surface imperfections, though it is quit tedious work to do so... Crystals show lots of surface damage as they are not translucent, also experimented with water/solvent treatment

afterwards to improve surface imperfections, though it is quit tedious work to do so...

[Edited on 6-12-2010 by nitro-genes]

|

|

|

quicksilver

International Hazard

Posts: 1820

Registered: 7-9-2005

Location: Inches from the keyboard....

Member Is Offline

Mood: ~-=SWINGS=-~

|

|

It sounds appropriate to me. As long as you're getting tiny needles in the end result instead of a poor-yield granular mass; the pentaerythritol is

clean enough. An extremely buff white yellow can also be an age issue: however I'm talking about JUST off white; any real yellowing may be also be UV

exposure. You really don't what beige or a light brown! As I remember 98% would be acceptable. The commercial vinyl product is really low (such as

89-91%).

|

|

|

iHME

Harmless

Posts: 30

Registered: 29-10-2008

Location: the arctic circle

Member Is Offline

Mood: No Mood

|

|

My PE appears to be the paint-grade type.

It was reasonably cheap.

It's not granular but instead a freeflowing white powder that feels light.

What kind of yields can be expected from this starting material?

What are the common impurities in the paint-grade stuff?

And are those easy to get rid off? As in a simple recrystallisation or solvent wash?

All in all, what can be done to attempt improving yields from this starting material?

Sorry for multiple questions, but they should be in theme with the topic.

It\'s a catastrophic success.

|

|

|

mabuse_

Hazard to Self

Posts: 56

Registered: 3-6-2010

Member Is Offline

Mood: No Mood

|

|

| Quote: |

a freeflowing white powder that feels light. |

Just like mine. The Vendor made no statement about purity.

I got exactly 20g of flawless locking white matter from 10g using 65% HNO3 with H2SO4.

Seems to work fine.

|

|

|

nitro-genes

International Hazard

Posts: 1048

Registered: 5-4-2005

Member Is Offline

|

|

Recrystallization should remove some impurities, which are definitely there when using mixed acids instead of 90+% HNO3 alone to produce PETN. After

watering down the mixed acids + PETN I then filter, thoroughly wash, neutralize, and finally a second wash and drying. However, there is always some

left over PE or lower nitrate portion that doesn't dissolve when it is subsequently recrystallized from acetone. It stays on the bottom as a

flocculent mass which represents about 1-2% of the total amount of PETN added to the acetone. Then I also noticed that upon the addition of water to

precipitate the last amount of PETN from the acetone, the filtrate is slightly milky. This impurity won't collect at the bottom, possible also lower

nitrates that are still soluble in the acetone/water mix. It appeared to me that these impurities are reduced when longer nitration times/better

stirring/final 40 deg. step are used, and are nearly absent when conc. HNO3 is used alone...

Then again... I stored a small amount of PETN/Pib plastique made with mixed acid PETN for over 2 years, still detonated fine.

[Edited on 6-12-2010 by nitro-genes]

|

|

|

hissingnoise

International Hazard

Posts: 3940

Registered: 26-12-2002

Member Is Offline

Mood: Pulverulescent!

|

|

Technical grade PE contains a few per cent of di- and tri-pentaerythritol.

Their presence reduces PETN's stabily and explosive strength!

They could be removed by careful fractional crystallisation, I expect . . .

|

|

|

quicksilver

International Hazard

Posts: 1820

Registered: 7-9-2005

Location: Inches from the keyboard....

Member Is Offline

Mood: ~-=SWINGS=-~

|

|

There is a rare book entitled The Pentaerythritols by Berlow, Barth, & Snow that is generally the bible of the industry and of all the

idiosyncrasies surrounding it. I read that thing from cover to cover many times as I have made a lab of pentaerythritol itself in an attempt to get

the finest product. It's actually not that hard.

So I'm with nitro-genes on this; I think a re-crystallization should be fine if you have any doubt. HOWEVER - if you DO have some doubts don't neglect

that step as you'll really only get a 40-60% yield of PEN if you don't.

The paint grade stuff can also have real extraneous garbage in it. This almost sounds ridiculous but it can actually have everything from clear and

white enamel. crushed vinyl siding, and white powder-coating all used as both adulterants / recycling, & means to stop it's use as an explosive.

Remember this stuff was sold in what looked like a huge coffee can of 30 gal volume for about 60-70 USD. Large scale attention was paid to it starting

back in the 1980's but only as a method to recycle. Today.....I'm fairly sure they do not use anything but a lightly adulterated product. The main

difference between manufacturing RDX and PETN was always the cost of the precursor in PETN that was responsible for the cost difference.

edit:

If you compare the major precursor of PETN and RDX you'll clearly see that RDX is a cheaply manufactured material. The acid being the real expense;

the hexamine being only formaldehyde and ammonia while quality Pentaerythritol has always been fairly expensive - even on a plant level. It's often

quoted that the shelf life for both being at the 20yr mark. (Federoff, Urbanski, etc)

[Edited on 7-12-2010 by quicksilver]

|

|

|

| Pages:

1

2

3

4

5

..

7 |