| Pages:

1

2

3

4

5

6

..

18 |

BromicAcid

International Hazard

Posts: 3253

Registered: 13-7-2003

Location: Wisconsin

Member Is Offline

Mood: Rock n' Roll

|

|

Actually I bought that nickel crucible for use as my bell in the larger setup that I've been working on. It will hold about 1 Kg of hydroxide

and I am going to purchase a good power source. I basically just wanted to see what molten hydroxide looked like and how it flowed etc before I did

my massive cell. So I guess the consesus is that I should have massive amps. Not just a car battery charger or something of that sort, right?

Actually the power supply is the last part that I need. So I'm glad I tried a proof of concept, I was just going to go with my car battery

charger 12 V 1 Amp.

Also I got no sparks at the cathode, just a few bubbles that solidified in the air and re-melted shortly thereafter. I also vouch for

Organikum's point further up thread that inserting metal into the molten hydroxide instantly coats it with a solid coating that prevents

electrolysis, I had to stir my electrodes around until all the hydroxide had melted off and go deep. I'm sure that if they had remined

stationary the coating would have remained and insulated.

|

|

|

Saerynide

National Hazard

Posts: 954

Registered: 17-11-2003

Location: The Void

Member Is Offline

Mood: Ionic

|

|

May I ask why the nickel anode doesnt get oxidized?

|

|

|

BromicAcid

International Hazard

Posts: 3253

Registered: 13-7-2003

Location: Wisconsin

Member Is Offline

Mood: Rock n' Roll

|

|

| Quote: |

May I ask why the nickel anode doesnt get oxidized?

|

My nickel anode did get a slight grey tinge to it probably from it being oxidized slightly. But nickel is probably the one of the most resillant

metals to hydroxides, it's just that the oxygen being produced there is doing a number on it. I would guess that the oxide will go into the melt

as it is slowly formed and thereby allow the cell to continue electrolysis.

In the Castner tiegel on the first page I believe the anode is copper also I have heard of iron being used as an anode. However I have not heard of

graphite being used. Probably disintigrates quickly, contamination possibly from flaking off? I don't know, but basically to answer your

question the nickel anode does oxidize, albiet slowly.

[Edited on 4/5/2004 by BromicAcid]

|

|

|

chemoleo

Biochemicus Energeticus

Posts: 3005

Registered: 23-7-2003

Location: England Germany

Member Is Offline

Mood: crystalline

|

|

yes, the graphite electrodes essentially are eaten up by the hydroxide. Just like when you electrolyse a NaCl solution.

I experienced both first hand, and moved on to different electrodes thereafter.

PS on the note of little explosions happenenig upon the electrolysis of molten NaOH - the same happened to me. Beware of that, molten NaOH on the skin

is not pleasant

[Edited on 5-4-2004 by chemoleo]

Never Stop to Begin, and Never Begin to Stop...

Tolerance is good. But not with the intolerant! (Wilhelm Busch)

|

|

|

darkflame89

Hazard to Others

Posts: 255

Registered: 1-3-2004

Location: With probability 1, "somewhere" in this

Member Is Offline

Mood: No Mood

|

|

Dunno about this, i am new to electrolysis anyway. If have 2 bowls of aqueous NaOH, of which the anode side has a copper electrode, and the cathode

side also copper electrode, and the entire setup is connected to battery supply, will the get Na metal at the cathode in the end. Since copper

dissolves at the anode to form Cu(OH)2 and H2 gas is given off at the cathode, won't i get Na in the end??!!

If there are any flaws in the system, please enlighten me, and i will go back to the thermite mixture setup.

Ignis ubique latet, naturam amplectitur omnem.

|

|

|

Marvin

National Hazard

Posts: 995

Registered: 13-10-2002

Member Is Offline

Mood: No Mood

|

|

Read the whole thread Darkflame, if there is any water sodium metal will not be produced. This is why molten NaOH must be used.

|

|

|

ballzofsteel

Harmless

Posts: 31

Registered: 13-3-2004

Member Is Offline

Mood: No Mood

|

|

This is an interestinng patent describing

electrolysing sodium nitrate with sodium carbonate at lower temps.

A good read anyhow GB440139 .

|

|

|

patu

Harmless

Posts: 9

Registered: 9-4-2004

Member Is Offline

Mood: No Mood

|

|

I obtained sodium from NaOH by using a battery charger. I used a soup can as the anode. For the cathode, I used an iron wire with a small loop at the

end. I melted the sodium hydroxide on a hot plate and plugged in the charger. I dipped the loop on the surface of the melt. Liquid globules of sodium

started forming and popping with an orange flame. After the liquid sodium filled up the loop, I took the loop out of the melt and tapped it on the

side of a glass filled with mineral oil. Using this method, I produced a few dozen balls of sodium the same size and shape of B.B.s

|

|

|

ballzofsteel

Harmless

Posts: 31

Registered: 13-3-2004

Member Is Offline

Mood: No Mood

|

|

Heh,I swear Ive heard this before.

|

|

|

Tacho

National Hazard

Posts: 582

Registered: 5-12-2003

Member Is Offline

Mood: No Mood

|

|

patu, I liked that.

You mean that the liquid sodium got trapped under the molten sodium surface, in a loop, like solder does to copper wire?

What size was your loop? Could you elaborate?

Edit: Have you tried multiple loops?

[Edited on 10-4-2004 by Tacho]

|

|

|

patu

Harmless

Posts: 9

Registered: 9-4-2004

Member Is Offline

Mood: No Mood

|

|

The sodium formed around and inside the loop. When the loop was removed from the sodium hydroxide, all the liquid sodium on the outside of the loop

collected in the middle. the wire was still very hot so the sodium stayed molten long enough to be shaken off in a cup of mineral oil. The loop was

about a centimeter wide, and yes it's just like a bead of solder. I really should try multiple loops, but lately i've been trying to isolate

potassium.

|

|

|

The_Davster

A pnictogen

Posts: 2861

Registered: 18-11-2003

Member Is Offline

Mood: .

|

|

Patu:What voltage and current were you using to get the sodium?

[Edited on 11-4-2004 by rogue chemist]

|

|

|

patu

Harmless

Posts: 9

Registered: 9-4-2004

Member Is Offline

Mood: No Mood

|

|

I used a 12 volt battery charger to make the sodium. When the sodium was being produced, the amperage needle jumped all the way to 15 amps!

|

|

|

BromicAcid

International Hazard

Posts: 3253

Registered: 13-7-2003

Location: Wisconsin

Member Is Offline

Mood: Rock n' Roll

|

|

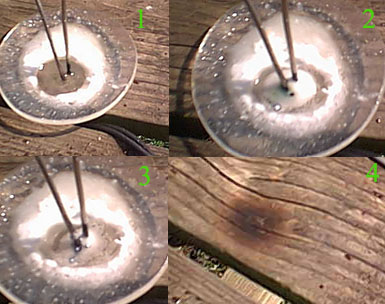

Finally, Sodium from Sodium Hydroxide for me!

This picture was taken when I turned off the voltage for a minute. What I had done to this point was take a quantity of sodium hydroxide and

place it on a watch glass. Electrodes were inserted into the mass and it was spritzed with water. When I saw a few bubbles spring up from the

electrodes I just sat back and watched. As you can see eventually the sodium hydroxide melted in the middle and made a shell around itself to contain

itself in the middle of the watch glass. For the power supply I used a car battery charger. I ran it at 12 V and when it melted the current was only

1 A or less. When electrolysis was commenced again bubbles continued to come to the surface, electrolysis of residual water probably, NaOH holds a

firm grasp on some of it.

Lower left-hand side, that little glistening spot, sodium! At first it looked like green coming up from the cathode and I thought that the

nickel was corroding and salts were flaking off but after it moved away from the frothing it had the color of mercury like the time I made sodium by

electrolysis of NaNO3 using soda glass as the membrane between the two. The gobule did not burst into flames though until provoked by jabbing at it

with a separate nickel rod.

Several gobules now, they grow in number, huzzah! The current had risen to 5 A by this time but was holding steady. If the electrodes were

submersed in the melt more the amps would have risen but it even worked with just the tips in. Electrolysis was discontinued at this point as I had

shown myself that the battery charger was sufficient to produce sodium.

The Aftermath - See that burnt spot, that is where the watch glass that I did this in rested. Didn't expect that, also the watch glass

survived surprisingly intact, it only had a depression in the bottom directly beneath were the electrodes contacted the melt. All in all I think this

shows that the solid hydroxide is an excellent material from which to furnish the protective layer in a sodium production vessel.

I'm just glad that it worked. Finally some hope that my castner cell might work. I've got a picture of my progress

here.

|

|

|

Saerynide

National Hazard

Posts: 954

Registered: 17-11-2003

Location: The Void

Member Is Offline

Mood: Ionic

|

|

Wow  Sweet Sweet

So the slightly moist NaOH will melt itself during the process?

Now I really want to try this sometime

"Microsoft reserves the right at all times to monitor communications on the Service and disclose any information Microsoft deems necessary to...

satisfy any applicable law, regulation or legal process"

|

|

|

Tacho

National Hazard

Posts: 582

Registered: 5-12-2003

Member Is Offline

Mood: No Mood

|

|

Congratulations Bromic!

Your work seems clean and easy! I tried melting some NaOH on a hotplate last weekend to try Patu's loop idea and all I got was NaOH all over my

benchtop, my hotplate and my arms.

I realized that the orange sparks might be trapped hidrogen popping. Na ions all over makes the spark orange.

I'll try this as soon as possible.

|

|

|

BromicAcid

International Hazard

Posts: 3253

Registered: 13-7-2003

Location: Wisconsin

Member Is Offline

Mood: Rock n' Roll

|

|

The slightly moist NaOH allowed a current to be established, I just piled some prills around both of the electrodes and between them and used a spray

bottle for my hair just to put a sheen on them, not saturate them. Once the connection was established it generated enough heat to melt the NaOH but

did not require any additional outside heating.

Actually I might run my castner cell with KOH in place of NaOH. My most recent reading has shown that for NaOH the yeild is usually 27% but with KOH

it is 55%. However I really don't want to store potassium in that it forms those superoxides that can explode when you cut into them from being

stored under oil. Well it's just still under consideration, let's put it that way.

[Edited on 4/21/2004 by BromicAcid]

|

|

|

BromicAcid

International Hazard

Posts: 3253

Registered: 13-7-2003

Location: Wisconsin

Member Is Offline

Mood: Rock n' Roll

|

|

Here is a design I was thinking for collecting the sodium during the use of a Castner cell. The main part of it would be an inverted petrii dish so

that the open part would be directed down toward the melt. Now this part would not have to be made out of glass but that would make it easier.

Because it would only be dipping into the top of the hydroxide I would hope that it would not be attacked too readily. From this would lead a glass

tube straight out from the side. This would follow along just an inch or less above the hydroxide. This would go up and over the rim of the cell and

go into a jar. The jar would have that tube going in and another tube going out, applied to the tube going out would be a hand vacuum pump.

The purpose of all of this. The dish would be over the cathode beneath the melt. Vacuum could be applied to draw a small amount of the hydroxide

into the dish a tiny amount and as more sodium is produced vacuum is increased to pull up more sodium that would be formed. Being close to the

hydroxide @300+C the tube would keep the Na nice and molten and at the end it would go in to the jar. In this way the collection of sodium would

exceedingly easier.

Other Stuff:

A few patent numbers have been thrown around in this thread but here are a few more US patent numbers:

452030 is Castner's original US patent for his cell and ideas behind it, he emphasizes strict temperature control. Also he mentions the

perforated spoon, it seems like it is just full of tiny holes and the surface tension of the Na keeps it in the spoon. I might make a couple spoons

for use with my cell. But realistically I was expecting to use a ladle.

517001 is a patent for the production of both nitric acid and sodium or potassium metal from nitrates by electrolysis. Also patent 590826 issued to

the same person later shows interesting schematics for a porous diaphragm for separating cells. Really though, I never thought that one could perform

electrolysis on NaNO3 if the sodium ended up in contact with it, figured that Na and NaNO3 might lead to an explosion but the patent states that some

of the Na might reduce the nitrate to the nitrite but it is not a major occurrence. Also the patent calls for everything to be made of aluminum,

sounds like a job for axehandle

|

|

|

chemoleo

Biochemicus Energeticus

Posts: 3005

Registered: 23-7-2003

Location: England Germany

Member Is Offline

Mood: crystalline

|

|

What's the difference?

Bromic, your method doesn't seem all that different, except maybe the water addition.

I dont understand why you'd get metalic Na globules - everyone who's tried it (inc. myself), one gets a dark grey mass, with the occasional

yellow explosion from igniting H2/O2/Na.

It's not like your temperature is low (judging by the mark on the wooden bench  ), or that there is an oxygen deficiency in your local atmosphere (you wouldnt be writing this otherwise ), or that there is an oxygen deficiency in your local atmosphere (you wouldnt be writing this otherwise  ) )

But seriously, I can't figure out why you'd get metalic sodium, as a nice little globule.

How about upscaling this?

Comments?

Never Stop to Begin, and Never Begin to Stop...

Tolerance is good. But not with the intolerant! (Wilhelm Busch)

|

|

|

BromicAcid

International Hazard

Posts: 3253

Registered: 13-7-2003

Location: Wisconsin

Member Is Offline

Mood: Rock n' Roll

|

|

Anode Material: Nickel

Cathode Material: Nickel

Heating Method: Current Heating

Distance between electrodes: 1 - 1.5 cm

Estimated depth of immersion: 2 - 3 mm

Hydroxide present in both solid and liquid state

Humidity: 83% ish

Air Quality: (Sensitive individuals should stay inside)

Hydroxide Source: Crappy OTC Red Devil

Power: 12V 5A at time of production

Observations: Initially tiny tiny bubbles produced at the top of the pellets where contact was made with rods. Amps were at 0 on the meter.

Hydroxide around cathode took on a grayish tint, I continuously piled the hydroxide back between the electrodes. Hydroxide at the edges did their

disquesence thing and liquefied on their own. Eventually the middle are liquefied and I thought that it had just taken on too much water from the

air. Evolution of gas started to increase rapidly. At the outside edges solid hydroxide, middle molten. Gas evolution continued for about 8 - 12

minutes and then eventually started to yeild the gobules. Amps were at 5 at this time. The sun was about 3/4 of the way to the horizon and there

were no spectacular planetary alignments in the sky. My power source was a battery charger as said before.

So what was different?

One other interesting thing:

Composition (mol percent):

77.7 NaBr 22.3 NaOH Mp 260C

|

|

|

The_Davster

A pnictogen

Posts: 2861

Registered: 18-11-2003

Member Is Offline

Mood: .

|

|

My first Sodium :D

Thanks to BromicAcid. I tried your method but my power supply was 2A max so it did not melt the sodium hydroxide, either that or I was not patient

enough . I used the concave bottom of a pepsi can as the crucible and melted the

sodium hydroxide over an alcohol burner. Nickel electrodes were placed in the melt and 12V @ 2A from a car battery charger powered the electrolysis.

No sodium was evident for about a minuit but there was constant orange sparks. At around the minuit mark there was a crack which sent molten sodium

hydroxide flying, and now a tiny globule of sodium was visible. Not grey, but like mecury, nice and shiny. Most of the sodium hydroxide had

solidified by this time except for the 1 square centimeter between the 2 electrodes. After a while the sodium that was formed must have shorted the

electrodes because there was another crack, more molten material flying, and then the electrolysis stopped. I did 2 trials and both times I got loud

"cracks" when the sodium started and completed being formed. Strange. . I used the concave bottom of a pepsi can as the crucible and melted the

sodium hydroxide over an alcohol burner. Nickel electrodes were placed in the melt and 12V @ 2A from a car battery charger powered the electrolysis.

No sodium was evident for about a minuit but there was constant orange sparks. At around the minuit mark there was a crack which sent molten sodium

hydroxide flying, and now a tiny globule of sodium was visible. Not grey, but like mecury, nice and shiny. Most of the sodium hydroxide had

solidified by this time except for the 1 square centimeter between the 2 electrodes. After a while the sodium that was formed must have shorted the

electrodes because there was another crack, more molten material flying, and then the electrolysis stopped. I did 2 trials and both times I got loud

"cracks" when the sodium started and completed being formed. Strange.

A few questions now:

1. If I scale this up will I need to use more amps to maintain a good current density?

2. What is the best way to extract/purify the sodium formed in a small scale experiment like this?

3. What is the best liquid to keep the sodium under? Is there any problems with using xylene?

Out of curiosity BromicAcid, How much sodium were you able to produce each run? I was only able to get a fraction of a pea sized ammount each time.

[Edited on 27-4-2004 by rogue chemist]

|

|

|

Saerynide

National Hazard

Posts: 954

Registered: 17-11-2003

Location: The Void

Member Is Offline

Mood: Ionic

|

|

I got a question. How do you collect the sodium? Pipette it?

"Microsoft reserves the right at all times to monitor communications on the Service and disclose any information Microsoft deems necessary to...

satisfy any applicable law, regulation or legal process"

|

|

|

darkflame89

Hazard to Others

Posts: 255

Registered: 1-3-2004

Location: With probability 1, "somewhere" in this

Member Is Offline

Mood: No Mood

|

|

I was jus about to ask that too. Do you pull the electrode out with the blob on it and immediately plunge it under oil or xylene?

And, must nickel rods be used? I can't get nickel..

Ignis ubique latet, naturam amplectitur omnem.

|

|

|

BromicAcid

International Hazard

Posts: 3253

Registered: 13-7-2003

Location: Wisconsin

Member Is Offline

Mood: Rock n' Roll

|

|

A few questions by Rouge Chemist:

| Quote: | 1. If I scale this up will I need to use more amps to maintain a good current density?

2. What is the best way to extract/purify the sodium formed in a small scale experiment like this?

3. What is the best liquid to keep the sodium under? Is there any problems with using xylene?

Out of curiosity BromicAcid, How much sodium were you able to produce each run? I was only able to get a fraction of a pea sized amount each time

|

1. If you increase the depth your electrodes go into the melt you will of course have to increase the current to increase the current density step

for step. According to Organikum in his posts on the castner tiegel :

| Quote: | | The distance between anode and cathode is only 2cm. The amperage at the cathode is about 1,6Amp/cmxcm at the anode about 1,1Amp/cmxcm. (Smaller units

call for higher current density). The voltage should be about 4V to 5V then, the current density is the more important point. |

2. As for extraction you can skim off the sodium with a spoon with small holes in it or without and drop in xylene or toluene or kerosene or mineral

oil or something of that nature. Then after you get your fill you put it in, jeeze, I forget the exact name so you're going to have to settle

for a phonic equivalent, linindale or something of that nature, regardless it is an inert substance, I think a paraffin of some sort with a low

density around .56 and apply heat. The sodium will melt and float to the surface leaving hydroxide behind from there scoop it back up and store under

your final storage solution.

3. I have no clue what is the best but xylene will work although it will still oxidize to a small extent.

For electrolysis of molten NaOH I was only able to get small amounts with each run. I have got better results with molten NaNO3 with soda glass as a

membrane but it becomes brittle and can basically explode, I will do some work with NASICON materials this summer though, supposedly much better.

A question from Saerynide:

| Quote: | | I got a question. How do you collect the sodium? Pipette it? |

Procedures that I have saw call for a spoon full of tiny holes, the higher surface tension of the Na(l) keeps it in the spoon while the hydroxide

spills out. Although that really is only suited to a larger scale. On a smaller scale you could take a metal rod and sufficiently cool it then touch

it to the top of a gobule freezing it and lift it up and scrape it off into your protective liquid. Or you could pipette it, take your pipette and

put it into your protective solution being held at a higher temperature then molten sodium to keep it liquid inside and suck it up and put it right

back into the protective liquid.

And from Darkflame89:

| Quote: | | And, must nickel rods be used? I can't get nickel.. |

According to Organikum's first post on what kind of rods should be used the conclusion is Cathode: Copper Anode: Nickel also I have heard of

iron being used as the cathode and copper being the anode. I'm sure to some extent you have your choice of Copper, Nickel, Iron, Platinum (and

other nobel metals). Although if you're only going for it for a short period of time then there should be no problem experimenting with

different anode/cathode materials.

|

|

|

Hermes_Trismegistus

National Hazard

Posts: 602

Registered: 27-11-2003

Location: Greece, Ancient

Member Is Offline

Mood: conformation:ga

|

|

| Quote: | Originally posted by darkflame89

And, must nickel rods be used? I can't get nickel.. |

Yes you can, just U2U whatever member you are currently most friendly with, Coiling up a nickel wire and sending it through the mail isn't THAT

pricey for an electrode that'll last you practically forever.

If you need I'll send it, but you are probably better off getting it sent from the states, (everything seems to be cheaper there)

Arguing on the internet is like running in the special olympics; even if you win: you\'re still retarded.

|

|

|

| Pages:

1

2

3

4

5

6

..

18 |