Waffles SS

Fighter

Posts: 998

Registered: 7-12-2009

Member Is Offline

|

|

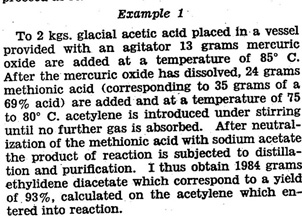

Ethylidene Diacetate Synthesis

Us patent:2011011

It is difficult to obtain methionic acid

someone know better method?

Attachment: US2011011.pdf (114kB)

This file has been downloaded 798 times

[Edited on 2-4-2010 by Waffles SS]

|

|

|

Nicodem

Super Moderator

Posts: 4230

Registered: 28-12-2004

Member Is Offline

Mood: No Mood

|

|

Just use any other properly strong acid (pKa from -5 to 0) that does not precipitate Hg(II) and is inert toward the species involved. Try a few

different acids and use the one that performs best.

You might as well use vinyl acetate instead of acetylene, as it is more practical than using acetylene gas and is relatively cheap.

|

|

|

Waffles SS

Fighter

Posts: 998

Registered: 7-12-2009

Member Is Offline

|

|

According to patent number us 1,856,251

Vinyl acetate + Acetic acid=cat(lewis acid)=>acetaldehyde+Anhydrid acetic(reflux for 1 -2 hour)

Not Ethylidene Diacetate!

May Hg(II) change product?

Attachment: VApats.pdf (313kB)

This file has been downloaded 744 times

[Edited on 2-4-2010 by Waffles SS]

|

|

|

Nicodem

Super Moderator

Posts: 4230

Registered: 28-12-2004

Member Is Offline

Mood: No Mood

|

|

I was talking about the conditions cited in your first post (Hg-catalysed addition on alkenes), not the retro-acylation of vinyl acetate to

acetaldehyde.

Edit: Actually, since vinyl acetate is much more prone toward electrophilic additions when compared to acetylene, using Hg(II) as a soft acid for

catalysis is unnecessary. Hg(II) salts are only used to promote additions of nucleophiles to double and triple bonds where these are not

nucleophilic/reactive enough (alkenes and alkynes are soft bases, thus hard acids like the proton have a hard time adding across the multiple bond and

therefore catalyse the reaction only poorly). Milder and less toxic soft Lewis acids should work in this case, for example even 1 mol% of iodine might

work. Even hard acids like protic acids should be enough to catalyse the addition on vinyl esters as these are considerably nucleophilic.

As to what is the main product from the reaction of vinyl acetate with acetic acid (ethylidene diacetate or acetaldehyde and acetic anhydride) depends

on reaction conditions, because all species are in equilibrium with vinyl acetate.

[Edited on 2/4/2010 by Nicodem]

|

|

|

halogenstruck

Hazard to Self

Posts: 61

Registered: 24-9-2009

Member Is Offline

Mood: No Mood

|

|

before i made it in this way:

98% acetic acid==adding a little HgCl2 then some drops of H2SO4 conc. [3 times or more than molecular ratio of Hg].then adding vinyl acetate and

puthing condenser on top[it will reflux by endothermic heat of reaction,no need to heat it] and after 1 Hr reaction is complete.

result is Ethylidene diacetate

after i added ectra NaCl to neutralize H2SO4 and adding ZnCl2 and slowly refuxing,on distillation,it gave good yield of Ac2O

|

|

|

Waffles SS

Fighter

Posts: 998

Registered: 7-12-2009

Member Is Offline

|

|

Wikipedia:

| Quote: |

Vinyl acetate and Acetic acid adds in the presence of palladium catalysts to give ethylidene diacetate, CH3CH(OAc)2

|

This is disharmonic with:

| Quote: |

Tetrahedron Letters No. 23, pp. 1081-1082, 1962.

"PALLADIUM CHLORIDE CATALYZED DECOMPOSITION OF VINYL ACETATE IN ACETIC ACID"

|

| Quote: |

after i added ectra NaCl to neutralize H2SO4 and adding ZnCl2 and slowly refuxing,on distillation,it gave good yield of Ac2O

|

According to patent number GB238825A this reaction need 145-160c temp in 2-3 hour (has little diffrent with your suggest)

Attachment: Palladium chloride catalyzed decomposition of vinyl acetate in acetic acid [1].pdf (228kB)

This file has been downloaded 655 times

Attachment: GB238825A.pdf (172kB)

This file has been downloaded 801 times

[Edited on 4-4-2010 by Waffles SS]

|

|

|

halogenstruck

Hazard to Self

Posts: 61

Registered: 24-9-2009

Member Is Offline

Mood: No Mood

|

|

"exothermic heat of reaction" not endothermic.

i did it and it reacted in a high yield.it does not need 140`c temperature.i think because there was Vinyl acetat and it refluxed,it should be around

it`s boiling point.

if you need to purify it,you must distil it and then u need this temperature.

if you don`t add NaCl,it resinify under presence of H2SO4

|

|

|

halogenstruck

Hazard to Self

Posts: 61

Registered: 24-9-2009

Member Is Offline

Mood: No Mood

|

|

i read the patent.

maybe.because it speaks about pure Ethylidene di acetate.mine was not purified.

i just used the raw product of reaction of VA and AcOH and it has components with low boiling point.

as i remember,acetaldehyde gas Evolves very early and not a lot ZnCl2 should be present otherwise resinifies.i passed the gas through water to be

absorbed.but after most part of it exit,temperature of boiling flask increases to reach around 100`c then sharply increase to 120 which is acetic acid

boiling point then 140 which is Ac2O boiling point.

the resulting Ac2O has trace of actaldehyde inside and during time gets yellowish due to acetaldehyde polimerization.i think this problem can be

solved by distilling it with some drops of sulfuric acid

|

|

|

halogenstruck

Hazard to Self

Posts: 61

Registered: 24-9-2009

Member Is Offline

Mood: No Mood

|

|

dear Waffles SS

i think go through the same method in ur first post just modify it like this

1-the same mercuric concentration proportionate to AcOH

2-replace sulfuric acid 98% the same molar ratio as mentioned method instead of methionic acid.[its role is just as strong acid]

3-molar ratio 1:1.1 for vinyl acetate (98%):acetic acid (98%)

first measure acetic acid then add mercuric oxide(or sulfate) and mix [or heat if necessary] till dissolves,then add sulfuric acid drop by drop and at

the end add vinyl acetate and put condenser in reflux position.it gets warm by itself and starts boiling in 20 minutes at 30`c environment

temperature.

it`s easy and progress without any problem.

[Edited on 4-4-2010 by halogenstruck]

no need to pass acetylene as it`s replaced by VA!

if it proceed ,for the next runs i think you can reduce mercury catalist ammount as i think half or even one third is enough.eveni think u can add a

little FeCl3 to oxidize mercury[as mercuric salt reduces to mercury during process and deactivates] and regenerates salt again and reduce the

mercury catalist needed for reaction

[Edited on 4-4-2010 by halogenstruck]

|

|

|

Waffles SS

Fighter

Posts: 998

Registered: 7-12-2009

Member Is Offline

|

|

Separation Ethylidene diacetate from Acetic anhydrid seems to be very difficult.

|

|

|

halogenstruck

Hazard to Self

Posts: 61

Registered: 24-9-2009

Member Is Offline

Mood: No Mood

|

|

after heating with ZnCl2 for some hours,there won`t be any EDA left.at the end of reaction there won`t be any acetaldehyde gas evolved,all will

decompose and the rest is only simple distillation

|

|

|

Waffles SS

Fighter

Posts: 998

Registered: 7-12-2009

Member Is Offline

|

|

Quote: Originally posted by halogenstruck  | dear Waffles SS

i think go through the same method in ur first post just modify it like this

1-the same mercuric concentration proportionate to AcOH

2-replace sulfuric acid 98% the same molar ratio as mentioned method instead of methionic acid.[its role is just as strong acid]

3-molar ratio 1:1.1 for vinyl acetate (98%):acetic acid (98%)

first measure acetic acid then add mercuric oxide(or sulfate) and mix [or heat if necessary] till dissolves,then add sulfuric acid drop by drop and at

the end add vinyl acetate and put condenser in reflux position.it gets warm by itself and starts boiling in 20 minutes at 30`c environment

temperature.

it`s easy and progress without any problem.

[Edited on 4-4-2010 by halogenstruck]

no need to pass acetylene as it`s replaced by VA!

if it proceed ,for the next runs i think you can reduce mercury catalist ammount as i think half or even one third is enough.eveni think u can add a

little FeCl3 to oxidize mercury[as mercuric salt reduces to mercury during process and deactivates] and regenerates salt again and reduce the

mercury catalist needed for reaction

[Edited on 4-4-2010 by halogenstruck] |

Today and yesterday i did this reaction several time with different condition and i got no anhydrid(i got just acetaldehye)

Also before i did reaction between VA and AcOH (cat:lewis acid) and got no anhydrid( us 1,856,251)

In this and That reaction i got just acetaldehyde, acetic acid,tar,little ethylidene diacetate and no more!

As i said before vinyl acetate Decomposition dont lead to anhydrid acetic(also wikipedia said this)

and this was another unsuccessful attemp to anhydrid by VA.

[Edited on 7-4-2010 by Waffles SS]

|

|

|

halogenstruck

Hazard to Self

Posts: 61

Registered: 24-9-2009

Member Is Offline

Mood: No Mood

|

|

i separated before around 350ml from this way.for sure it works.

maybe your raw materials are impure.maybe acetic acid is not >98%.EDA should not be heated very much just starting 50 till 100 then 120 then 145`c.

ZnCl2 should be minimum but sulfuric acid from last process should be decomposed by adding dry AcONa or Extra ZnCl2 Or just NaCl otherwise resinifies

a lot.

anyway because of acetaldehyde there will remain some resin and tar at the end of distillation.

to minimize,reduce the ZnCl2 to minimum needed and H2SO4 too.acetaldehyde condensation release water which reduces yield.ZnCl2 should be

anhydrous.AcOH >98%.VA.98% .

read patents/literatures more in details.

at the end you will have acetic acid but after boiling out acetic acid,boiling temperature increases sharply to reach anhydrid.

i doubt that the other method u did ,Na2S2O7 way,fails

it`s patented and for sure it works otherwise no one would have paid and patented it.although some details may not mentioned.

as i remember i tried before to distil out anhydride just by dry heating pyrosulfate and anhydrous acetate and i think because of high

temperature,acetate decomposed and almost because of water made of acetate decomposition it failed but maybe by using a solvent it works

[Edited on 7-4-2010 by halogenstruck]

[Edited on 7-4-2010 by halogenstruck]

|

|

|

Waffles SS

Fighter

Posts: 998

Registered: 7-12-2009

Member Is Offline

|

|

Quote: Originally posted by halogenstruck  |

as i remember i tried before to distil out anhydride just by dry heating pyrosulfate and anhydrous acetate and i think because of high

temperature,acetate decomposed and almost because of water made of acetate decomposition it failed but maybe by using a solvent it works

[Edited on 7-4-2010 by halogenstruck]

[Edited on 7-4-2010 by halogenstruck] |

Acetate decomposition dont produce water

as i remember this reaction produce H2S and Acetic acid and unknown componet.

I did this method several time but was unsuccessful

Hope you success

|

|

|

Waffles SS

Fighter

Posts: 998

Registered: 7-12-2009

Member Is Offline

|

|

My last attempt to DEA and Ac2O was unsuccessful

Ratio:

Vinyl acetate : 860 cc

AcOH : 660cc

Hg(II)O : 4.3 gr

H2SO4 : 3.3 cc

ZnCl2 : 2 gr

First i add HgO to AcOH and mix till dissolved then add H2SO4 and finally VA.

After adding VA temp increased to 30c and after 5 minutes temp returned to room temperature.when i stired mixture temp increased and small bubble

appeared(that was acetaldehyde and i think EDA didnt produced because acetaldehyde came.i think VA decomposed)

I reflux mixture (at 60c by heater) for 1 hour and lot of acetaldehyde produced after that i add 10 gramNaCl and add ZnCl2 and again reflux mixture

for 2 hour,lot of acetaldehyde produced.

finally i distilled mixture and got 500-600cc AcOH and lot of black Tar(but no anhydrid)

During reflux steps i lead acetaldehyde to another flask(contain water) by tube.

I used merck VA , Zncl2,AcOH

Really I dont know why decomposition of VA produce acetaldehyde but not Ac2O!!

[Edited on 9-4-2010 by Waffles SS]

|

|

|

hector2000

Hazard to Others

Posts: 127

Registered: 22-8-2006

Member Is Offline

Mood: Cool

|

|

i confirm decompose of vinyl acetate or ethyldiene diacetate dont make anhydrid

i test it many times

just you will have tar and acetic acid

dont waste your time

Chemistry=Chem+ is+ Try

|

|

|

halogenstruck

Hazard to Self

Posts: 61

Registered: 24-9-2009

Member Is Offline

Mood: No Mood

|

|

it results in acetic anhydride.i did it and with relatively high yield.there are lots of literatures about it too.

check the purity of your reagents.

|

|

|

hector2000

Hazard to Others

Posts: 127

Registered: 22-8-2006

Member Is Offline

Mood: Cool

|

|

@halogenstruck first you say to WafflesSS use hgo2 and sulfuric acid for making ethyldiene diacetate

when you add sulfuric acid all of hgo convert to hgso4 and water and no sulfuric remaining!

second i try many time va to acetic anhydrid and get acetaldehyde and tar and acetic acid(US 1,856,251)

when you have hgso4 and acetic acid and va then same reaction (US 1,856,251) happen and no ethyldiene diacetate made.

if you did this reaction please say correctly what you did

did you read acetic anhydrid topic?i test this method before and Sauron advise me and he accept this method isnot true

thx

[Edited on 24-4-2010 by hector2000]

Chemistry=Chem+ is+ Try

|

|

|