chief

National Hazard

Posts: 630

Registered: 19-7-2007

Member Is Offline

Mood: No Mood

|

|

Silicon electrode for electrolysis

Since in the diamond-thread nobody answered:

Has anyone tried to use Si as an electrode in a chlorate cell ? Could it stand the chemistry ? Finally it is contained in solar-cells, old

power-transistors, etc. ...

It has, at least, the very same structure as diamond, also the same sort of bonding ... ; only that carbon (diamond) has a much smaller atom and a

much stronger bond ...

|

|

|

dann2

International Hazard

Posts: 1523

Registered: 31-1-2007

Member Is Offline

Mood: No Mood

|

|

Hello Chief,

First it would have to be doped Si, as pure Si is non-conducting.

I tried a piece of pure Si once only to discover is is non-conducting.

Dann2

|

|

|

not_important

International Hazard

Posts: 3873

Registered: 21-7-2006

Member Is Offline

Mood: No Mood

|

|

Something like this :

Silicon a New Electrode for Electrochemical Reduction of Nitrates: Comparison with Boron-doped Diamond

Attachment: ise081249.pdf (33kB)

This file has been downloaded 1067 times

|

|

|

chief

National Hazard

Posts: 630

Registered: 19-7-2007

Member Is Offline

Mood: No Mood

|

|

Of course it has to be doped ; usually it's easier to get doped material, since any electronics-Si is either p- or n- doped, at least at the surfaces

... ; maybe someone could try this ? Some slaughtered power-mosfet or power-transistor or solar-cell ?

If it works for nitrate-reduction, as in the paper mentioned by not_important, then maybe it will for chlorate ??? Though there the chemistry would be

more agressive ...

Maybe even that a higher current-density would be achieved (limited by the electrolyte), since the surface of a power-mosfet is small (but it can

conduct 100 A), and the cooling is effectively in place by the electrolyte ...

[Edited on 10-2-2009 by chief]

[Edited on 10-2-2009 by chief]

|

|

|

tentacles

Hazard to Others

Posts: 191

Registered: 11-11-2007

Member Is Offline

Mood: No Mood

|

|

Chief: Why not just buy a doped wafer on ebay? They're pretty cheap.

http://cgi.ebay.ca/8-inch-Blanket-Black-Diamond-Wafer-on-sil...

http://cgi.ebay.ca/12-inch-Silicon-Germanium-Wafer_W0QQitemZ...

|

|

|

chief

National Hazard

Posts: 630

Registered: 19-7-2007

Member Is Offline

Mood: No Mood

|

|

I just want to find out before I try ; probably someone has it around and will try it anyhow, then report ... ... . One fine day I might abuse one of

my old 2N3055-Power-Transistors for that, or one of my burned diodes ...

|

|

|

Ragnarok

Harmless

Posts: 22

Registered: 22-5-2008

Member Is Offline

Mood: No Mood

|

|

The paper is about reduction of nitrates. You are talking about oxidizing chlorine. Quite a different beast.

The silicon crystal lattice is mmuch weaker than the carbon varieties. It is also much more reactive (you can find essentially pure carbon in nature,

but pure silicon has to be made). It also forms polymers (silicates), from Si(OH)4 units. A carbon analogue for that does not exist.

In my opinion, silicon would not survive a combination of water, oxigen and chorine. But you are free to try, nonetheless.

|

|

|

chemoleo

Biochemicus Energeticus

Posts: 3005

Registered: 23-7-2003

Location: England Germany

Member Is Offline

Mood: crystalline

|

|

Well, Si is certainly resistant to HCl, and it reacts with Cl2 gas only above 400 deg C. I would certainly give it a try!

Titanium is also oxidised in nature, yet it is used as an electrode.

Never Stop to Begin, and Never Begin to Stop...

Tolerance is good. But not with the intolerant! (Wilhelm Busch)

|

|

|

Ragnarok

Harmless

Posts: 22

Registered: 22-5-2008

Member Is Offline

Mood: No Mood

|

|

Titanium is covered with a layer of oxide, thus forming a quasi-inert barrier. Much like the passivation of aluminum in acids. On the other hand,

aluminum reacts energically with water in basic media. Anyway, Ti is slowly consumed. The best materials used as anodes are metal oxides, which can

not be further oxidised.

Silicon doesn't react with HCl because oxidising conditions are not present. The choride ion is not an oxidizer. Electric current, on the other hand,

is the best oxidizer known to man. The fact that oxigen and chlorine are also generated at the anode and are good oxidisers too further complicates

the issue.

The oxidation of Si would form Si-OH bonds in macro-mollecular compounds, which can then rearrange to the practically inert and highly insulated SiO2

with the help of heat. In water, however, a silicagel of some sort would form, or maybe Si-Cl compounds.

The main difference from the reduction of the nitro group is that in the reduction scenario, the Si can not be further reduced, whereas in the

oxidation scenario oxidation products can be formed and passivation is unlikely.

Hell, I'd like it to work, because it would be quite useful. I have a large assortment of big old transistors, too. But I think it's an unfounded

hope.

|

|

|

jpsmith123

National Hazard

Posts: 764

Registered: 24-6-2005

Member Is Offline

Mood: No Mood

|

|

Silicon is mentioned in a few patents such as this one as having been "suggested" for use as an anode in a perchlorate cell.

And in the archives of some ancient discussions on the newsgroup rec.pyrotechnics, someone claimed to have had promising results with

silicon, although it wasn't clear whether the cell in question was for chlorate or perchlorate.

At one time I tried to find a suitable piece of silicon for an experiment, but I couldn't find any and subsequently gave up on it.

|

|

|

dann2

International Hazard

Posts: 1523

Registered: 31-1-2007

Member Is Offline

Mood: No Mood

|

|

Hello,

The Silicon is being used for Nitrates reduction (as pointer out by others), ie. it is a Cathode in the cell.

When it is stated that Ti is use as an Electrode (Anode anyways) the writer is always referring to the substrate. Often MMO (Ti substrate) is

referred to as a 'Titanium' Anode. This is very misleading. The MMO is making all the difference.

Bare Ti can be used as a Cathode of course.

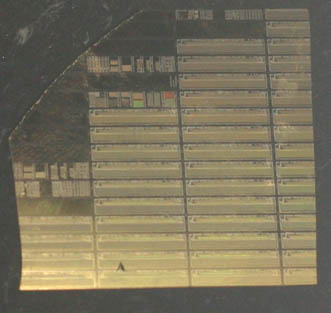

I have some Si wafers with and without circuits on them. The pure Si is non conducting.

I put a meter on the stuff with circuits and got resistances of approx. 15 ohms between some die sites (chips before they are cut out). Resistances on

the same die site are as low as 1 ohm. It depends on where on the die site you put the probes. Some adjacent die sites do not seem to have any

connection to each other at all.

A single die site a approx. 11mm by 2mm BTW!.

Will try in a cell and see what happens.

I have very very little hope of anything useful happening.

The conducting layer on a Silicon wafer is very very thin. A pure Si wafer is taken and exposed to heat and a gas (containing P say). The P diffuses

into the wafer to create N-Type semiconductor. Other methods are also used.

The layer of conducting stuff is very very thin, Microns?. This (if it works) will wear away quickly and you are left with pure Si (non conducting).

Also the Micron thick coating (if the die sites don't have it cut up in the first place) is going to be useless for carrying large Chlorate or

Perchlorate cell currents.

The fact the (say) a 2N3055 can carry 30(?) amps is not an indication of the amperage that could be run through its guts as an anode, not to talk

about corrosion of connectios.

You would need a thick piece of Silicon that has NOT been produced from the electronics business, ie. with some impurities in it to make it conductive

throughout its (reasonably substantial) mass.

Dann2

|

|

|

chief

National Hazard

Posts: 630

Registered: 19-7-2007

Member Is Offline

Mood: No Mood

|

|

Another thought: If the Si could be consumed electrolytically, then this could be a cheap way to make the expensive "aerosil", which is

nanocrystalline SiO2, for reactions (wanted for the large surface-area).

So eiher way it might be worth trying it out (and just hereby making it unpatentable ...)

|

|

|

Ragnarok

Harmless

Posts: 22

Registered: 22-5-2008

Member Is Offline

Mood: No Mood

|

|

You might end up with some chlorine in your product, instead of -OH, but it can be tried. Something useful for you has a really high combined

probability of occurring

|

|

|

tentacles

Hazard to Others

Posts: 191

Registered: 11-11-2007

Member Is Offline

Mood: No Mood

|

|

I should see if my foundry grade silicon is conductive.. Next time I run across the damn chunks, guys. I think I know where they are.

|

|

|

chief

National Hazard

Posts: 630

Registered: 19-7-2007

Member Is Offline

Mood: No Mood

|

|

I might throw in here, that gemstone-quality opal is nothing else byt nanospheres of silicon-dioxide, regularly arranged ...

It may be synthesized, and a well known Pierre Gilson made it since decades, but he keeps the process secret ...

[Edited on 12-2-2009 by chief]

|

|

|

dann2

International Hazard

Posts: 1523

Registered: 31-1-2007

Member Is Offline

Mood: No Mood

|

|

Hello Folks,

I checked the piece of wafer below with an Ohm meter. Most of the die were isolated. The resistance accross individual die was one or two Ohm. It

depended where you put the probes. In places there was no connection. There was no hope of simply placing a connection at the top of the wafer and

having currrent going to the rest of the die, because, (as I said they are electrically isolated).

I connected the piece of Si wafer to the + of a power supply and placed into a NaCl solution together with a Cathode.

About 200mA flowed at 12Volts from a single die but it was hard to tell if it was the wet wafer that carried some of the current. Each die measures

10mm by 2 mm approx. It is a hopeless Anode IMHO.

Dann2

|

|

|

not_important

International Hazard

Posts: 3873

Registered: 21-7-2006

Member Is Offline

Mood: No Mood

|

|

| Quote: | Originally posted by chief

I might throw in here, that gemstone-quality opal is nothing else byt nanospheres of silicon, regularly arranged ...

It may be synthesized, and a well known Pierre Gilson made it since decades, but he keeps the process secret ... |

Silica, not silicon.

|

|

|

chief

National Hazard

Posts: 630

Registered: 19-7-2007

Member Is Offline

Mood: No Mood

|

|

I corrected it ; That's what I meant, sorry for the typo and thaks for the hint.

Besides this gemstone-quality opal is quite something to get _very_ rich upon, one of my would-be projects, in case I had the time ... ; but I have

other projects as well, ... ...

@dann: Such a piece of waver is chemically resistent: I once dissolved several pentiums (133 pro, mmx etc.) in aqua-regia (including all the gold):

The waver was untouched ! Maybe it has a surface-layer for isolation (maybe also just for the dielectric constan of the layer) ...

Thats why I would propose an old powerdiode: It just has 2 plain regions: 1 p and 1 n ; with just a piece of silicon one might get all sorts of

rectifying-effect etc.

[Edited on 12-2-2009 by chief]

|

|

|

garage chemist

chemical wizard

Posts: 1803

Registered: 16-8-2004

Location: Germany

Member Is Offline

Mood: No Mood

|

|

As already said, those wafers are nonconducting because they are too pure. If they were made of crude industrial silicon (like, maybe, 99,5% pure)

they would conduct perfectly fine.

The answer to this problem is making your own silicon.

Two methods are viable for the amateur, one is reduction of SiO2 with Al, the other one SiO2 with Mg.

The reaction of the first one is not self-sustaining because it is not exothermic enough. It is neccesary to add an oxidiser and additional aluminium

to provide the heat.

A standard laboratory preparation of silicon, found in several german textbooks, uses a mix of SiO2 and Al with sulfur:

120g sulfur

100g aluminum

90g silica flour

This reaction gives melted globules of silicon and lots of aluminum sulfide as byproduct (produces H2S with HCl, this can be useful and is worth

collecting or absorbing with NaOH).

The silicon can be freed of adhering SiO2 by means of treatment with warm HF.

With Mg instead of Al and no sulfur (!), the reaction is self-sustaining and produces Si as a medium fine grey powder. It can be melted together in a

quartz ampule using an oxy-propane blowtorch

Si is resistant to oxidation in air at up to 1100°C and is not attacked by HF, in contrast to SiO2.

With NaOH solution, it reacts to give hydrogen and sodium silicate solution (here's a "cold" method of producing sodium silicate!).

[Edited on 12-2-2009 by garage chemist]

|

|

|

chief

National Hazard

Posts: 630

Registered: 19-7-2007

Member Is Offline

Mood: No Mood

|

|

SiC (silicon carbide) is a semiconductor too ; it industrially is made by laying out a trace of coal (several meters long), covering it with a lot of

sand (several tons), and then passing directly some 220/380 Volts through the coal, which thereby, insulated by the sand, heats up nicely and reacts

with somewhat sand to SiC .

That SiC might be even closer to diamond ... in some ways ...

By the way: Just braking a power-diode in 2 will yield some well-contacted ("bonded") and doped Si, for the quick test. Insulate the bonding-material

by some glue or paraffine ... and there you go !

[Edited on 12-2-2009 by chief]

|

|

|

ewalcacer

Harmless

Posts: 6

Registered: 23-4-2012

Location: Brazil

Member Is Offline

Mood: No Mood

|

|

I'm thinking about starting a research on this... I can't find a reliable method to analyse the reduced silicon (described as a fine grey powder) and

prove the content of the crystal. I'm also thinking about doping it with two other metals.

BTW, can anyone recommend some publications on reduction methods for silicon carbide and silicon oxide?

Thanks.

|

|

|