| Pages:

1

2

3 |

kazaa81

Hazard to Others

Posts: 368

Registered: 30-4-2004

Member Is Offline

Mood: ok

|

|

I don't know if it's precipitating only the dye...however the reaction happened is quite unclear too.

|

|

|

12AX7

Post Harlot

Posts: 4803

Registered: 8-3-2005

Location: oscillating

Member Is Offline

Mood: informative

|

|

Could be it's adsorbed onto alumina hydroxide.

Tim

|

|

|

kazaa81

Hazard to Others

Posts: 368

Registered: 30-4-2004

Member Is Offline

Mood: ok

|

|

absorbed onto Al2O3 ?

That's would be a nice guess, if I didn't etch aluminum

with a little of aq. 15% NaOH before use...I don't know

|

|

|

16MillionEyes

Hazard to Others

Posts: 153

Registered: 11-3-2007

Location: 16 Million Eyes, US

Member Is Offline

Mood: No Mood

|

|

Maybe the Aluminum Hydroxide formed while in solution somehow. I never really heard of Al2O3 as an absorber of dyes.

|

|

|

kazaa81

Hazard to Others

Posts: 368

Registered: 30-4-2004

Member Is Offline

Mood: ok

|

|

Aluminum hydroxide is Al(OH)3...upon drying, it converts to Al2O3

that's seen in the classical gelatinous precipitation which occurs while

mixing aq AlCl3 with aq ammonia.

At this point I don't know if it would be better to place some Al(OH)3

in ethanol as it may bring further impurities, being water the first one.

[Edited on by kazaa81]

|

|

|

16MillionEyes

Hazard to Others

Posts: 153

Registered: 11-3-2007

Location: 16 Million Eyes, US

Member Is Offline

Mood: No Mood

|

|

But how do you think the Aluminum Hydroxide formed while submerged in Ethanol?

|

|

|

kazaa81

Hazard to Others

Posts: 368

Registered: 30-4-2004

Member Is Offline

Mood: ok

|

|

I'm not sure of that, but 12AX7 gave his idea...

Oxygen dissolved in ethanol or the hydroxyl group

CH3CH2OH ?

I will surely have to find some time for synth.

gelatinous Al(OH)3 and try its absorbing

ability.

|

|

|

16MillionEyes

Hazard to Others

Posts: 153

Registered: 11-3-2007

Location: 16 Million Eyes, US

Member Is Offline

Mood: No Mood

|

|

But in order for the hydroxyl group to be ripped away one of these things happen:

-The CH3CH2OH dissociates but this isn't true (as far as I'm aware) because it's being hold in place by covalent forces rather than ionic.

-Aluminum pulls the hydroxyl group away from the ethanol but this would destroy the molecule (leaving who knows what) and render the experiment

useless (if you are trying to isolate the ethanol.

Another option would be that the Al2O3 present on the surface of the foil or the aluminum itself reacts directly with the dye, whatever its nature.

Here's something I'd suggest doing. Test the precipitate to confirm the presence of aluminum ions and then one of the above reactions (or some other)

will definitely have to be considered.

|

|

|

12AX7

Post Harlot

Posts: 4803

Registered: 8-3-2005

Location: oscillating

Member Is Offline

Mood: informative

|

|

Hmm, I wonder if the aluminum could be chelated instead -- which would be very interesting, as removing the dye is then only a dash of AlCl3.6H2O

away.

Alcohol isn't very acidic, but it does dissociate. The pKa is in the 20 range. The "salt" thus formed would be something like aluminum ethoxide,

Al(CH3CH2O)3, with release of hydrogen. Such reaction occurs quicker with extremely basic things like hydrides and alkalis (sodium metal for

example), but still much, much slower than with water, because the acidity is just so little. Since the acidity is less than water (pKa = 7), such

"salts" instantly hydrolyze in water, making this impossible if any water remains in solution.

All of this is problematic because the surface layer on a chunk of aluminum tends to be unreactive, both in and of itself and by protecting against

further corrosion. If the dye combines with aluminum ions, it could dissolve some, and would open the possibility of further attack.

Tim

|

|

|

kazaa81

Hazard to Others

Posts: 368

Registered: 30-4-2004

Member Is Offline

Mood: ok

|

|

waiting to get some time for trying Al ions checking in the precipitate...

these are some ethanol purification procedures outlined on

"Purification of Laboratory Chemicals by W.L.F. Armarego C.L.L. Chai 5th edition"

Ethanol [64-17-51 M 46.1, b 78.3O, d15 0.79360, d5 0.78506, n 1.36139, pKZ5 15.93. Usual

impurities of fermentation alcohol are fusel oils (mainly higher alcohols, especially pentanols), aldehydes,

esters, ketones and water. With synthetic alcohol, likely impurities are water, aldehydes, aliphatic esters,

acetone and diethyl ether. Traces of *benzene are present in ethanol that has been dehydrated by azeotropic

distillation with *benzene. Anhydrous ethanol is very hygroscopic. Water (down to 0.05%) can be detected by

formation of a voluminous ppte when aluminium ethoxide in *benzene is added to a test portion, Rectified spirit (95% ethanol) is converted to absolute

(99.5%) ethanol by refluxing with freshly ignited CaO (250gL) for

6h, standing overnight and distilling with precautions to exclude moisture.

Numerous methods are available for further drying of absolute ethanol for making "Super dry ethanol". Lund

and Bjermm [Chem Ber 64 210 19311 used reaction with magnesium ethoxide, prepared by placing 5g of clean

dry magnesium turnings and 0.5g of iodine (or a few drops of CCl4), to activate the Mg, in a 2L flask, followed

by 50-75 mL of absolute ethanol, and warming the mixture until a vigorous reaction occurs. When this

subsides, heating is continued until all the magnesium is converted to magnesium ethoxide. Up to 1L of

ethanol is added and, after an hour's reflux, it is distd off. The water content should be below 0.05%. Walden,

Ulich and Laun [Z Phys Chem 114 275 19251 used amalgamated aluminium chips, prepared by degreasing

aluminium chips (by washing with Et20 and drying in a vac to remove grease from machining the Al), treating

with alkali until hydrogen was vigorously evolved, washing with H20 until the washings were weakly alkaline

and then stirring with 1% HgC12 soln. After 2min, the chips were washed quickly with H20, then alcohol, then

ether, and dried with filter paper. (The amalgam became warm.) These chips were added to the ethanol, which

was then gently warmed for several hours until evolution of hydrogen ceased. The alcohol was distd and

aspirated for some time with pure dry air. Smith [J Chem Soc 1288 19271 reacted 1L of absolute ethanol in a

2L flask with 7g of clean dry sodium, and added 25g of pure ethyl succinate 27g of pure ethyl phthalate was an

alternative), and refluxed the mixture for 2h in a system protected from moisture, and then distd the ethanol. A

modification used 40g of ethyl formate, instead, so that sodium formate separated out and, during reflux, the

excess of ethyl formate decomposed to CO and ethanol.

Drying agents suitable for use with ethanol include Linde type 4A molecular sieves, calcium metal, and CaH2.

The calcium hydride (2g) was crushed to a powder and dissolved in lOOmL absolute ethanol by gently boiling.

About 7OmL of the ethanol were distd off to remove any dissolved gases before the remainder was poured into

1L of ca 99.9% ethanol in a still, where it was boiled under reflux for 20h, while a slow stream of pure, dry

hydrogen (better use nitrogen or Ar) was passed through. It was then distd [Ruber Z Elektrochem 29 334

19231. If calcium was used for drying, about ten times the theoretical amount should be taken, and traces of

ammonia (from some calcium nitride in the Ca metal) would be removed by passing dry air into the vapour

during reflux.

Ethanol can be freed from traces of basic materials by distn from a little 2,4,6-trinitrobenzoic acid or sulfanilic

acid. *Benzene can be removed by fractional distn after adding a little water (the *benzene/water/ethanol

azeotrope distils at 64.9O); the alcohol is then redried using one of the methods described above. Alternatively,

careful fractional distn can separate *benzene as the *benzene/ethanol azeotrope (b 68.2O). Aldehydes can be

removed from ethanol by digesting with 8-log of dissolved KOH and 5-log of aluminium or zinc per L,

followed by distn. Another method is to heat under reflux with KOH (20g/L) and AgN03 (lOg/L) or to add 2.5-

3g of lead acetate in 5mL of water to 1L of ethanol, followed (slowly and without stirring) by 5g of KOH in

25mL of ethanol: after lhr the flask is shaken thoroughly, then set aside overnight before filtering and distilling.

The residual water can be removed by standing the distillate over activated aluminium amalgam for 1 week, then

filtering and distilling. Distn of ethanol from Raney nickel eliminates catalyst poisons.

Other purification procedures include pre-treatment with conc H2SO4 (3mL/L) to eliminate amines, and with

KMnO4 to oxidise aldehydes, followed by refluxing with KOH to resinify aldehydes, and distilling to remove

traces of H3P04 and other acidic impurities after passage through silica gel, and drying over CaS04. Water can

be removed by azeotropic distn with dichloromethane (azeotrope boils at 38.1O and contains 1.8% water) or

2,2,Ctrimethylpentane.

Rapid purification: Place degreased Mg turnings (grease from machining the turnings is removed by

washing with dry EtOH then Et20, and drying in a vac) (5g) in a dry 2L round bottomed flask fitted with a

reflux condenser (protect from air with a drying tube filled with CaC12 or KOH pellets) and flush with dry N2.

Then add iodine crystals (0.5g) and gently warm the flask until iodine vapour is formed and coats the turnings.

Cool, then add EtOH (50mL) and carefully heat to reflux until the iodine disappears. Cool again then add more

EtOH (to 1L) and reflux under N2 for several hours. Distil and store over 3A molecular sieves (pre-heated at

300' -350' for several hours and cooled under dry N2 or argon).

|

|

|

kazaa81

Hazard to Others

Posts: 368

Registered: 30-4-2004

Member Is Offline

Mood: ok

|

|

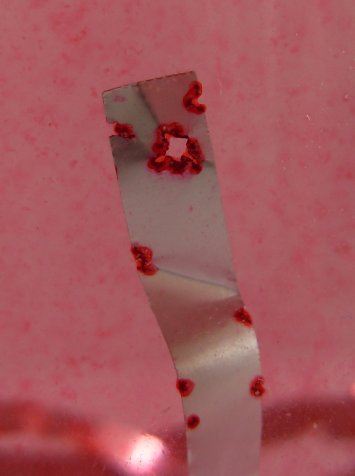

Waiting for checking the precipitate, I left a bottle full of

denatured alcohol (the heaviest dyed I could buy) with

the previously used aluminum strips...that's the result

after 6 days

6 days ago:

today :

closeup, showing reacted aluminum :

That last picture clearly show how aluminum is attacked, probably not as metal itself, but as oxide which is continuously produced and combines with

the dye.

I dried some of the precipitate in the last experiment and it showed the presence of Al+3 ions.

|

|

|

jarynth

Hazard to Self

Posts: 76

Registered: 12-8-2008

Member Is Offline

Mood: No Mood

|

|

Given the relatively expensive and somewhat controlled nature of pyridine, a reasonable alternative OTC source could be its extraction from denatured

alcohol. Then on to remove the other denaturants.

(I moved my post to the pyridine extraction thread

http://www.sciencemadness.org/talk/viewthread.php?tid=9717&a...)

[Edited on 30-8-2008 by jarynth]

|

|

|

Arrhenius

Hazard to Others

Posts: 282

Registered: 17-8-2008

Location: US & A

Member Is Offline

Mood: Stochastic

|

|

Aluminum does absorb dyes, as in the process of anodizing. If you soak your aluminum in some aqueous NaOH first, then rinse off the base in DI water,

and then place it in the alcohol it may react a bit faster. As to why it gives you the precipitate, I can't say... It could be that some of the

aluminum is dissolved (this is probable) and then reacts. I do know that most cars are not E85 ethanol compatible because they use lots of aluminum

fuel parts.

|

|

|

16MillionEyes

Hazard to Others

Posts: 153

Registered: 11-3-2007

Location: 16 Million Eyes, US

Member Is Offline

Mood: No Mood

|

|

| Quote: | Rapid purification: Place degreased Mg turnings (grease from machining the turnings is removed by

washing with dry EtOH then Et20, and drying in a vac) |

Kind of useless if you have to use dry ethanol in order to obtain dry ethanol when you don't have it (and want it) in the first place.

Assuming that Al2O3 is the sole responsible for this, would it be reasonable to assume that as it absorbs the dye it eventually "flakes off" due to

inhibiting interactions with the metal layer below, and this in part would allow the actual metal layer to start to act on the alcohol making the

ethoxide?

This paper talks about a similar process (using a catalyst but hey, it only lowers the activation energy, the free energy must be there from the

beginning in the first place) with aluminum cans, ethanol, xylene as solvent and HgI2 as the catalyst claiming to get high purity aluminum ethoxide

after careful processing. The paper It isn't free but you can see the abstract and preview anyway.

http://www.springerlink.com/content/j832762327374j6x/

|

|

|

chloric1

International Hazard

Posts: 1146

Registered: 8-10-2003

Location: GroupVII of the periodic table

Member Is Offline

Mood: Stoichiometrically Balanced

|

|

That is very interesting kazaa! I kind of wish we had those denaturants in the alcohol over here!

| Quote: |

25% solution w/w of C.I. Reactive Red 24 (red dye): 3 g.

|

Now this has got my attention because of my limited experience with fibre reactive dyes. IRC Kirk talk about diazine fiber reactive dyes that

actually reacted with natural fabrics cellulose. Apparently, the dye part is attached to a cyclic nitrogen diazine group that ha two active chlorides

which interact with hydroxyl groups in the cellulose. With cotton, hemp, and other natural fabrics, Sodium carbonate is necessary as the pH has to be

at least 10. Now aluminum with its oxide skin might behave simularly without the pH increaser. Although I would love a video of this reaction if you

added a few prills of NaOH to it.

Fellow molecular manipulator

|

|

|

jarynth

Hazard to Self

Posts: 76

Registered: 12-8-2008

Member Is Offline

Mood: No Mood

|

|

| Quote: | This paper talks about a similar process (using a catalyst but hey, it only lowers the activation energy, the free energy must be there from the

beginning in the first place) with aluminum cans, ethanol, xylene as solvent and HgI2 as the catalyst claiming to get high purity aluminum ethoxide

after careful processing. The paper It isn't free but you can see the abstract and preview anyway.

http://www.springerlink.com/content/j832762327374j6x/ |

Here it is:

[Edited on 3-9-2008 by jarynth]

[Edited on 3-9-2008 by jarynth]

Attachment: Al(OEt)3.pdf (596kB)

This file has been downloaded 1095 times

|

|

|

Panache

International Hazard

Posts: 1290

Registered: 18-10-2007

Member Is Offline

Mood: Instead of being my deliverance, she had a resemblance to a Kat named Frankenstein

|

|

Vogel distilled denatured ethanol from a refluxing al amalgam to obtain 99.9%ethanol. I have actually done this and it works fairly well. you

initially reflux the mix for sometime, say thirty minutes, the amalgam will consume the water first before it begins on the ethanol, at which point

you distill some, discarding the first 50mL ass it has dried your glassware for you, empty the flask and voila.

i'm getting a strange sense i have posted this information already. hmm

anyway i'm fairly sure that in doing this most dyes will not distill over also.

|

|

|

jarynth

Hazard to Self

Posts: 76

Registered: 12-8-2008

Member Is Offline

Mood: No Mood

|

|

| Quote: | Originally posted by kazaa81

That last picture clearly show how aluminum is attacked, probably not as metal itself, but as oxide which is continuously produced and combines with

the dye. |

I left about 1sqm kitchen Al foil (duly cut up in ~1sqcm pieces) in 250ml of my denatured alcohol in a loosely capped jar. The Al wasn't attacked in

the least after 10+ days. Your pink stuff must contain something interesting... what's the pH?

|

|

|

kazaa81

Hazard to Others

Posts: 368

Registered: 30-4-2004

Member Is Offline

Mood: ok

|

|

@jarynth: why did you leave if loosely capped? I don't think gases are produced, and in this way you let EtOH evaporate.

Dunno about the pH, but the denaturants/colorants have been listed some posts ago in this thread

|

|

|

Ephoton

Hazard to Others

Posts: 463

Registered: 21-7-2005

Member Is Offline

Mood: trying to figure out why I need a dark room retreat when I live in a forest of wattle.

|

|

yep Panache beat me too it that's how I do it. add some hg salt and you not only loose the denaturant but also dry the ethanol at the same time

e3500 console login: root

bash-2.05#

|

|

|

jarynth

Hazard to Self

Posts: 76

Registered: 12-8-2008

Member Is Offline

Mood: No Mood

|

|

| Quote: | Originally posted by kazaa81

@jarynth: why did you leave if loosely capped? I don't think gases are produced, and in this way you let EtOH evaporate. |

If the Al gets oxidized, then H2 is produced. But this would have been too good to be true.

|

|

|

ycheff

Harmless

Posts: 5

Registered: 18-10-2008

Member Is Offline

Mood: No Mood

|

|

Try to purify ethanol by pinch of KMnO4. Decantation - in a week.

|

|

|

HydroCarbon

Hazard to Self

Posts: 77

Registered: 7-7-2008

Location: Anytown, USA

Member Is Offline

Mood: No Mood

|

|

| Quote: | Originally posted by __________

But in order for the hydroxyl group to be ripped away one of these things happen:

-The CH3CH2OH dissociates but this isn't true (as far as I'm aware) because it's being hold in place by covalent forces rather than ionic.

-Aluminum pulls the hydroxyl group away from the ethanol but this would destroy the molecule (leaving who knows what) and render the experiment

useless (if you are trying to isolate the ethanol.

Another option would be that the Al2O3 present on the surface of the foil or the aluminum itself reacts directly with the dye, whatever its nature.

Here's something I'd suggest doing. Test the precipitate to confirm the presence of aluminum ions and then one of the above reactions (or some other)

will definitely have to be considered. |

If it did happen a double bond would most likely form between the carbons and make ethylene, which would be quite obvious as it's a gas.

|

|

|

12AX7

Post Harlot

Posts: 4803

Registered: 8-3-2005

Location: oscillating

Member Is Offline

Mood: informative

|

|

Ethanol's proton comes off about as easily as water's. That is to say, ethoxide has nearly the same pKa as the hydroxide ion. The hydroxyl is much

harder to remove, C-O bonds are stronger.

Tim

|

|

|

Tsjerk

International Hazard

Posts: 3032

Registered: 20-4-2005

Location: Netherlands

Member Is Offline

Mood: Mood

|

|

To come back onto the spiritus sold in the Netherlands, I was able to purify it to 99% with the last percent as a bit of methanol, acetone and a trace

of water (0,1%). This was checked with a GC.

I first did a destillation over a 30cm vigreux colom with a couple of drops H2SO4 to protonate the pyridine. Discarded the first 10%, to get rid of

most methanol. I captered the middle 80%. The bleu dye didn't come over.

Then dried with MgSO4 and then refluxed over grignard grade magnesium turnings (about 10-15g) for a couple of hours followed by a second destillation,

again captured the middle 80% after which I did a GC to come with the earlier stated purity.

I got 600-700ml ethanol out of 1L spiritus, which costs about 1,50 euro's, very economical if I may say.

[Edited on by Tsjerk]

|

|

|

| Pages:

1

2

3 |