| Pages:

1

..

10

11

12

13

14 |

12AX7

Post Harlot

Posts: 4803

Registered: 8-3-2005

Location: oscillating

Member Is Offline

Mood: informative

|

|

Noooo!

Look at it this way: clean 'er off with some acid (or sandpaper, or...), recoat and you'll have more surface area!

Tim

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

Gone too soon , we shall miss Gerty ......

The flower of youth is fleeting , it lasts but a moment .

She looks so ....unspeakably horribly ravaged

You can almost hear her crying out in final despair

"goodbye cruel world"

RIP Gerty , a musical tribute and farewell

http://youtube.com/watch?v=oiFTXckh0zU&feature=related

| Quote: | Originally posted by Xenoid

Long live Hubert...

I am sorry to report that the brave little anode Gertrude (known affectionatly as "Gerty" to some of you) died this afternoon local time.

|

From the looks of her , expiration came as a merciful end .

| Quote: |

During her short lifetime of approximately 146 Amp hours, in the often harsh environments of assorted perchlorate cells, Gerty is estimated to have

converted about 280g of NaClO3 to 322g of NaClO4.

Gerty died from the hideous effects of slow passivation followed by massive overvoltage application.

Please do not let this happen to your anodes!

Gerty died alone, while I was having a pleasant hike in the mountains. I had inadvertantly left the voltage limiting set to maximum (~ 30 volts) on my

lab power supply while running in constant current mode (1 amp). I am not sure what the exact "breakdown" voltage for the passivated layer is, but it

obviously less than 30 volts...  |

Evidence shows clearly that this was no accident but murder most foul . The usual suspects are believed to have been responsible . She was

overpowered and forcibly

oxygenated again and again and again , until she was dead . The body was mutilated and crows are yet observed

picking pieces of her rotting remains from the trees . It is all so .....ghastly

| Quote: |

I now have a 300 ml perchlorate cell "chocka-block" full of steaming, white, TiO2 gloop!

Moral, never apply more than about 10 volts across a Ti anode in a perchlorate cell!

I have more "bad news" but I am too distraught to report it at the present time...

|

You mean it gets worse ??? Brace yourself and tell us ,

screw your courage to the sticking place ,

and let us hear it ....the rest of the story

[Edited on 30-12-2007 by Rosco Bodine]

|

|

|

Xenoid

National Hazard

Posts: 775

Registered: 14-6-2007

Location: Springs Junction, New Zealand

Member Is Offline

Mood: Comfortably Numb

|

|

@ 12AX7

Hmmm.. I think she's past the "cleaning up with sandpaper" stage. One thing I was thinking about though, is that if this process was carried out in a

"more controlled" manner it might be possible to produce a high surface area that bonds well to any interface layers. Actually, I don't think sanding

produces all that great a surface, it's more like lots of smooth grooves.

If the Ti was corroded using say 10 mA, or 100 mA, who knows, at the breakdown voltage, it might produce a superb bonding surface akin to

sandblasting, but better. This could be further enhanced with HCl etching. One problem, is that the high voltage breakdown starts at defects and

pinholes, and might not produce an even surface. A low current over a longer time might solve this though.

@ Rosco

Don't fret Rosco, my "bad news" has nothing to do with coating Ti anodes. It concerns "Big Bertha", my 10 litre, 12 gouging rod chlorate cell. It

relates to the application of 25 amps through SS junctions in the presence of saline solution, chlorine and air. I can't believe I cocked this up

twice in about a week...

|

|

|

12AX7

Post Harlot

Posts: 4803

Registered: 8-3-2005

Location: oscillating

Member Is Offline

Mood: informative

|

|

Hmm, check out electropolishing titanium -- if it exists. I get a nasty feeling the bath would require fluoride, though. Well, that's still not too

bad, under electrolysis, the bath could be pH-neutral for the most part. The anode might give off some HF fumes though.

Tim

|

|

|

man_from_mystery_babylon

Harmless

Posts: 7

Registered: 17-7-2005

Member Is Offline

Mood: No Mood

|

|

Yes titanium can be electropolished. There is even a company that claims to be using a "saline" solution to do it.

I emailed them with some questions about their process, but of course they never responded.

As I understand it, you need a rather high current density to electropolish...as below some threshold point, you only etch.

|

|

|

chloric1

International Hazard

Posts: 1140

Registered: 8-10-2003

Location: GroupVII of the periodic table

Member Is Offline

Mood: Stoichiometrically Balanced

|

|

@Xenoid-You said Gerty got ate up by a condition of overvoltage because you did not set your limit to a lower level. I know the voltage increased

slighty with your first cobalt anode, but I am not sure at what rate Gerty increased in voltage. If you could ballpark some relative graph or

something to see if this manganese thing is indeed a step forward. Also, figuring total hours of use between the two. I believe that you stated your

initial cobalt anode was useless for perchlorate. Once more data is produced the more it will have to be consolidated and organized.

@Rosco-A tad melodramitic dont ya think?!

I did enjoy the video you linked to it went well with my toast and coffee this morning.

[Edited on 12/30/2007 by chloric1]

Fellow molecular manipulator

|

|

|

Xenoid

National Hazard

Posts: 775

Registered: 14-6-2007

Location: Springs Junction, New Zealand

Member Is Offline

Mood: Comfortably Numb

|

|

| Quote: | Originally posted by chloric1

@Xenoid-You said Gerty got ate up by a condition of overvoltage because you did not set your limit to a lower level. I know the voltage increased

slighty with your first cobalt anode, but I am not sure at what rate Gerty increased in voltage. If you could ballpark some relative graph or

something to see if this manganese thing is indeed a step forward. Also, figuring total hours of use between the two. I believe that you stated your

initial cobalt anode was useless for perchlorate. Once more data is produced the more it will have to be consolidated and organized.

|

Well, part of the problem was I messed around with solutions and current settings for the first 76 hours. I would say that based on 1 amp at

50mA/cm^2 she started the run at 3.7 volts which rose to 4.0 volts at the end of the 76 hours.

I then put her in a new cell where she lasted for about 70 hours, she started at 4.0 volts and after 50 hours was at 4.8 volts, on the morning of her

demise the voltage had risen to 5.5 volts. I should have shut her down then, and she would have lived to make perchlorate another day, but the black

coat still looked intact and "I just wanted to see what would happen". Now I know...

The beta-MnO2 coat was definitely a step forward as far as perchlorate goes. The 12 coat Co3O4 anode only ran for about 25 hours, under similar

conditions.

The straight 4 coat Co3O4 was good in a chlorate cell, I think it was 13 days, I haven't tried beta-MnO2 in chlorate yet!

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

The interface works and the outside reaction layer works .

But both are porous . An intermediate layer is needed .

|

|

|

chloric1

International Hazard

Posts: 1140

Registered: 8-10-2003

Location: GroupVII of the periodic table

Member Is Offline

Mood: Stoichiometrically Balanced

|

|

@Xenoid-Ok that gives me some idea how you are operating. I have been stalling for a few reasons getting started. I got half of my nitrate

solutions made up already but I ordered some 1L beakers so I could do the boiling oxalic acid etch. I always liked oxalic acid and I am not real

excited about hot concentrated HCl. But then yesterday I reread some of your post in cobalt earlier on. You used a beaker of water to heat the test

tube of HCl. This is what I will do until my beakers arrive. My first anode will be tested in a brine to make chlorate because I need to see and

show how it compares to your cobalt spinel alone. Manganese coatings and perchlorates a little later.

@Rosco- Yes I know. Don't know if it is necessary for a seal for making only chlorate but it is definately true for perchlorate. My answer,when I

got the time and if I find my 5 year old stannous choride, is to dissolve stannous chloride in conc. HCl,oxidize with H2O2,and then add ammonia to

precipitate stannic oxide and remove pesky chlorides, then redissolve in nitric acid at specific gravity 1.2. Then I will either add cobalt nitrate

or nickel nitrate. Probably 10% concentration of the secondary components seems adequate.

Chlorides, I feel, might even be atogonistic agents for titanium passivation and should be avoided. These ions have a nasty reputation in

electroplating as well as metal finishing. Ever heard of "bronze disease" ? Find a bronze statue close to the coast and you will see.

[Edited on 12/31/2007 by chloric1]

Fellow molecular manipulator

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

| Quote: | Originally posted by chloric1

@Rosco- Yes I know. Don't know if it is necessary for a seal for making only chlorate but it is definately true for perchlorate.

|

It serves a larger purpose than just a seal to have an

intermediate layer of SnO2 . That larger purpose is something which I don't think has been discussed in any of these threads before , but it is

important . There is a logical

strategy where plural coatings are laminated on a substrate

which should attempt to have a sequence of coatings that

ideally obey an *ascending* oxygen overvoltage value from

the outermost layer inwards towards the substrate . The

outermost coating is optimized for catalytic activity for the

desired product , but will probably not be optimized physically

and likely will be porous . Desirably the next layer which resides beneath that porous outer coating will have a slightly

higher oxygen overvoltage so that oxygen is preferentially

evolved from the outer coating , rather than being encouraged to spread laterally *between the layers* at those places where the bottom of a pore in

the outer layer

contacts the intermediate layer . A pressure gradient is

created by the oxygen overvoltages . By having the underlayment layer have the *higher* oxygen overpotential ,

it creates a *physical* effect for oxygen evolution that is

a parallel similar to how a body of water seeks its own level

rather than trying to flow uphill . The equilibrium favors that

oxygen will evolve preferentially at its path of least resistance , on the outside layer material exposed to the electrolyte .....rather than trying

to migrate between the layers and delaminate the outer coating . You see the nascent reaction products are going to actively seek the

easiest path for their "birth" , and the easiest path for

evolution of those electrolytic products must be kept located

preferably with the outermost "working coating" .

Oxygen overvoltage is sort of an indicator because it is

pretty much a concensus that it is oxygen permeation , diffusion of oxygen downwards through the coatings and reaching the substrate which ultimately

passivates the anode . And by having the layers create an effect that presents an unfavorable gradient for that diffusion , the substrate is more

protected . The idea is that oxygen should have to "flow uphill" to reach the substrate . When voltage

is applied to the anode and current flows , the goal is that the energy be dissipated on the outer surface preferentially

as much as possible , rather than following a path of less resistance presented by an interface at underlying layers .

| Quote: |

My answer,when I got the time and if I find my 5 year old stannous choride, is to dissolve stannous chloride in conc. HCl,oxidize with H2O2,and then

add ammonia to precipitate stannic oxide and remove pesky chlorides, then redissolve in nitric acid at specific gravity 1.2. Then I will either add

cobalt nitrate or nickel nitrate. Probably 10% concentration of the secondary components seems adequate. |

The best initial sealing layer over the cobalt spinel could very well be an oxidative soak deposition of SnO2 precipitated from dilute SnCl2 + NaNO3 ,

then baked . This would involve

no complicated preparations .

The use of Sn nitrates certainly intrigues me because they are mentioned as useful precursors in several patents , but

no details given ....almost as if this could be something of a "secret hidden in plain sight" if you follow what I mean .

| Quote: |

Chlorides, I feel, might even be atogonistic agents for titanium passivation and should be avoided. These ions have a nasty reputation in

electroplating as well as metal finishing. Ever heard of "bronze disease" ? Find a bronze statue close to the coast and you will see.

|

Yeah , I have had some reservation about the "chlorides fluxing scenario" with regards to the DTO on Ti scheme ,

but not because of any prejudice against chlorides themselves since they are useful intermediates . My

reservations concerning chlorides involves the way they are described being used , which I know is oversimplification in describing a "reagent

preparation" where the reagent itself is more than its ingredient list , but rather a reaction product which changes minute by minute . These

mixtures are unstable and react to form sols , alkoxides , and complex mixtures for which there are alternatives . There are several ways of doing

the same thing , with variants that are more appropriate depending on compatability with other coatings , dopants , and the temperatures which will be

used .

I am still looking at these SnO2 based coating references ,

trying to find anything useful . Went through a search hits list of several hundred abstracts yesterday and found five more articles , a couple of

them especially interesting ,

requested in the references needed thread .

One of those articles abstract describes what evidently may be a variant on the soak deposition method , where a

simple solution of SnCl4 at a specific concentration and pH ,

is deliberately made unstable via hydrolysis and gradually

"slimes" a coating of SnO2 onto an immersed substrate ,

which is no slime at all of course , but a tough and adherent

coating , which may be baked to further vitrify .

Also of interest are other articles which involve nanocrystallites of SnO2 formed *in solution* where

dopants are included at the molecular level *before any baking* , as these materials may be used as thickeners

in mixture with other precursors for baked coatings .

It is very interesting to have a colloid , whose particles

are not amorphous at all , but rather are crystals a few nanometers in dimension . Like having a bag of tiny conductive jewels so small they suspend

in water without sinking .

|

|

|

tentacles

Hazard to Others

Posts: 191

Registered: 11-11-2007

Member Is Offline

Mood: No Mood

|

|

Rosco: Re: "uphill substrates" - That would track along with something I'd read (somewhere) about PbO2 plating in industry - that PbO2 plating was

typically conducted at 70C. I've read (somewhere else, probably) that plating PbO2 at higher temperatures will lower it's oxygen overpotential.

Obviously this would make it easier to find intermediates with a higher overpotential, or perhaps cause the intermediates to last much longer with a

greater difference.

[Edited on 1-1-2008 by tentacles]

|

|

|

Xenoid

National Hazard

Posts: 775

Registered: 14-6-2007

Location: Springs Junction, New Zealand

Member Is Offline

Mood: Comfortably Numb

|

|

@ tentacles

See the list of anode compositions posted by R.P.Wang on page 8 of this thread!

http://www.sciencemadness.org/talk/viewthread.php?tid=9572&a...

Ti / SnO2 + Sb / alpha-PbO2 / beta-PbO2 is claimed to be "reliable".

[Edited on 1-1-2008 by Xenoid]

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

There is probably an inherent benefit from the differing

oxygen overvoltage effect derived automatically when

alternating layers of different materials are used in sequence , for *two* paired layer cycles like A-B/A-B as a configuration , because even if you

don't know which

of the materials A or B has the higher oxygen overvoltage ,

the barrier will still exist for that labrynth if B turns out to be the layer with the higher O2 overvoltage . It would

result in shedding of the outer layer B , but then the

correct ordering would be encountered and further erosion

would then be opposed .

So using different layers in alternating fashion makes good sense as a strategy , even if there is not good specific information about the differences

between the O2 overvoltage for the different layer materials being used ....

but only if at least four layers are used to hedge the bet

for that unknown . In scientific terminology , that is known as covering ones ass

|

|

|

Xenoid

National Hazard

Posts: 775

Registered: 14-6-2007

Location: Springs Junction, New Zealand

Member Is Offline

Mood: Comfortably Numb

|

|

Hubert's Fate

The fate of Hubert has been decided! He is to spend his life in the confines of a KClO3 cell. Why POTASSIUM chlorate,

I hear you say. Well, a number of reasons;

1) I have never run a KClO3 cell, not much point with only graphite and gouging rods for anodes. I am approaching this with an air of optimism though

and expecting this cell will run perfectly "clean".

2) I wanted to try and make some totally Na free KClO3.

3) I already have two NaClO3 cells running.

4) Experience with "Gertrude" and earlier anodes, suggests a chlorate rather than a perchlorate cell is a safer place for an anode of Hubert's

composition.

I put together a more or less practical cell specifically to accommodate Hubert (see attached image). It has a capacity of 800 mls and an annular SS

cathode and was cobbled together from bits of previous cells. The internal connections for the SS cathode are covered in glue lined heatshrink and the

SS screw electrical connection is coated in hot glue. Hopefully this will prevent headspace corrosion of the cathode which has been causing me a few

problems lately.

The cell has been running for about 28 hours now at 2 amps and 3.6 volts (55 mA/cm^2). So far there is absolutely no black specks of MnO2 floating

around, this has plagued earlier MnO2 anodes. The cell actually looks like a large jar of pink champagne. But it's not a tipple I would like to try.

More like a cocktail from hell. I was surprised to see small, flakey crystals of KClO3 settling on the bottom only 12 hours after starting. I thought

it would take longer, but I suppose KClO3 is near insoluble in near saturated KCl solution. Looking good now, but what it will be like in a couple of

weeks time is anybody's guess!

|

|

|

jpsmith123

National Hazard

Posts: 764

Registered: 24-6-2005

Member Is Offline

Mood: No Mood

|

|

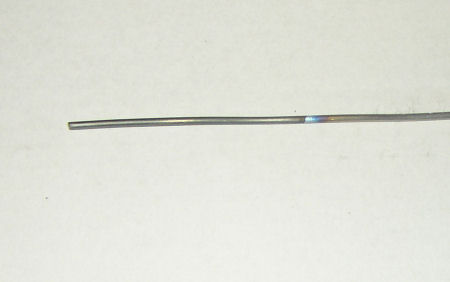

This wire had a layer of Co cathodically electrodeposited onto it from Co acetate & vinegar solution. It seemed to form a relatively thick, even,

highly adherent layer.

After that it was heated in a gas flame for about 5 minutes, during which time the color changed from grey to blue/black.

Unlike the previous anodically deposited films, this coating cannot be rubbed off, smudged, etc.

Hopefully I'll get to try it in NaCl solution later today.

[Edited on by jpsmith123]

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

@jpsmith123

In dann2's ATO thread I posted a patent US4584084

http://www.sciencemadness.org/talk/viewthread.php?action=att...

which described something like the Beer patent compositions where TiO2 was used as a component of the intermediate layer , but derived from a Ti salt

precursor

which was decomposed on baking , in mixture with the

other solid solution and dopant materials . It was significant information not only in relation to the Beer

patents similar but different use of Ti oxides as a part of the intermediate layer , but also because layers even using that TiO2 as part of a

tertiary composition with

Fe and Sn oxides , had performance several times better

than ATO intermediate layers .

I expected you to be jumping on that disclosure , since it

aligns with the Beer patents use of TiO2 as a "toughener"

component for the intermediate layer , and IIRC a couple of the Shamrock patents had similarly reported a toughened intermediate layer using a TiO2

component .

IIRC these baked intermediate layers actually even increase the longevity of Pt plated Ti anodes above what

is gotten from direct plating of Pt onto Ti , especially for thinner platings .

I don't know if the same thing will hold true for your

Co plating then oxidized to the oxide , but it might .

Or it may be that a TiO2 tertiary interface composition might similarly result from a baking and diffusion , perhaps

if you overcoat or undercoat the Co metal with an SnO2

precursor . It's going to require more heat for such a scheme than the cobalt spinel derived from nitrate .

The Fe doped SnO2 - TiO2 mixture is a very interesting

intermediate layer anyway especially if it does prove

more durable than the usual ATO .

|

|

|

Xenoid

National Hazard

Posts: 775

Registered: 14-6-2007

Location: Springs Junction, New Zealand

Member Is Offline

Mood: Comfortably Numb

|

|

Update on Hubert

Hubert has been running in the 800 ml KClO3 cell for 3 days now.

The solution is a pale pink from MnO4- but has not increased in colour from beyond the first 12 hours. I think an equilibrium has been achieved with

the MnO2 on the anode. This may be some sort of "common ion effect" as mentioned by Rosco. The colour looks worse than what it is, due to the strong

colouration ability of MnO4-, and is really a miniscule amout that can be cleared away with a few drops of H2O2.

Other than the pink colouration, the solution is crystal clear (literally). I have dropped in a magnetic stirrer bar to improve the efficiency and

this brought about a "snow storm" of 5mm of KClO3 overnight. There is now about 10 mm of crystal "snow" accumulated on the bottom, and it's really

blowing a blizzard in there.

I'm very pleased with Huberts performance "so far".

In the background of the attached image you can see my chlorinator anode cell, note the disgusting colour. This is mainly caused by corrosion of the

cathode in the "headspace" area. Some of the black "dusty" material appears to be coming off the MMO anodes.... gulp! The "theoretical" runtime

finished a few days ago, but I'm going to let it go a few more days!

|

|

|

dann2

International Hazard

Posts: 1523

Registered: 31-1-2007

Member Is Offline

Mood: No Mood

|

|

Hello,

The 'Alembic' anode way way back used the same system and he has stated that many hundreds of hours were obtained from the anode without any visable

signs of wear.

The anode is a bit of bother to make though. Did I mention it's of holy grail status??

Finally got around to titrating the product from a Perchlorate cell which had the DTO anode running in it. 5 coat anode.

This cell had been run for much much more than the run time of the cell (going from Chlorate to Perchlorate).

The cell product contains 79% Chlorate.

You also get ignition when the product is mixed with sugar and a drop of Sulphuric applied.

DTO is a hopeless anode for Perchlorate making. It lasts quite a long time though, approx 450 hours as far as I can remember.

The pink Chlorate cell is a VERY confusing sight. I could make some politically incorrect jokes........... but I won't.

Keep it up.

Dann2

|

|

|

Xenoid

National Hazard

Posts: 775

Registered: 14-6-2007

Location: Springs Junction, New Zealand

Member Is Offline

Mood: Comfortably Numb

|

|

Hubert and Purple Haze

"Hubert" and "Purple Haze" seem to be getting on very well together. This cell has now been running for over 6 days with absolutely no change in the

electrical parameters, still 2.0 amps at 3.5 volts. I switched it off this morning and when the bubbles cleared Hubert's shiny blackness could be

readily observed. The cell is still crystal clear, other than the pink tint. The KClO3 crystals are now twice as deep as in the image shown

previously, and there are clusters of crystals adhering to the outside of the annular cathode. The KClO3 is now interfering with the stirrer bar and

the electrolyte circulation. I guess I should "harvest" the KClO3 and top up the cell with saturated KCl and just keep it running.

@ dann2 - Yes I thought of all those jokes as well....

|

|

|

chloric1

International Hazard

Posts: 1140

Registered: 8-10-2003

Location: GroupVII of the periodic table

Member Is Offline

Mood: Stoichiometrically Balanced

|

|

Its just a one eyed, one horned flyin purple chlorate maker...

I am happy for you and for Hubert. In this gray and endless winter it is nice to see the colors of spring! I guess this anode is going to have a life of several hundred ours. I guess this anode is going to have a life of several hundred ours.

It appears that 50 to 60mA/cm2 is ideal for this kind of anode.

[Edited on 1/7/2008 by chloric1]

Fellow molecular manipulator

|

|

|

Xenoid

National Hazard

Posts: 775

Registered: 14-6-2007

Location: Springs Junction, New Zealand

Member Is Offline

Mood: Comfortably Numb

|

|

| Quote: | Originally posted by chloric1

It appears that 50 to 60mA/cm2 is ideal for this kind of anode.

|

Well, I don't really know! I just used a current density that wasn't too extreme. It's a useful, practical density, and higher than what I use for

gouging rods. The coating may work just as well at 100 mA/cm^2 or may blow to bits. It's something that needs more testing, but is not all that

important at the moment!

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

@Xenoid

You mentioned earlier about the heat gun being pressed

to produce hot enough temperatures inside the tube

you are using as an oven . Is that a solid tube you are using and what diameter ? Are you using any sort of insulation wrapping around the tube ?

The heat gun tube oven is something I have been

giving some thought . I am considering using some

perforated stainless tubing and then wrapping it with

insulation , perhaps the 2 inch wide woven fiberglass

ribbon that is sold as exhaust header wrap for keeping

engine compartments cooler . I am thinking that the

heat loss from the tube itself would be greatly reduced

by using such a scheme , which should raise the temperature capability .

|

|

|

Xenoid

National Hazard

Posts: 775

Registered: 14-6-2007

Location: Springs Junction, New Zealand

Member Is Offline

Mood: Comfortably Numb

|

|

| Quote: | Originally posted by Rosco Bodine

Is that a solid tube you are using and what diameter ? Are you using any sort of insulation wrapping around the tube ?

|

It's just a piece of scrap Al tube (~50 mm dia. 2mm wall) I happened to have lying around that fitted fairly tightly on the end of the gun. I have now

wrapped a strip of thin tinplate around the end of the heat gun so it fits really tightly, it was a bit wobbly before. I don't think insulation is

required, I'd say 98% of the heat loss was as hot air out the top! I'm using solid Ti rods, they absorb a lot of heat, and for the first couple of

mins. the "heat setting" knob needs to be higher to reach, say 380 oC, then I can "back it off" a bit for the rest of the time.

My heat gun has 4 inlet slots, I taped over the two smaller ones. When I checked the temp. on max setting it rose steadily and would have exceeded 400

0C. So I am running it at about 80 - 90 % setting for the pyrolysis.

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

It would have to be losing a whole lot of heat off the tube . I bet if you wrapped the tube with some foil backed fiberglass pipe wrap , the temp

inside the tube

would jump up 200C from where it is .

|

|

|

chloric1

International Hazard

Posts: 1140

Registered: 8-10-2003

Location: GroupVII of the periodic table

Member Is Offline

Mood: Stoichiometrically Balanced

|

|

Might sound sloppy but I have 1/4" diameter rods(6.35mm) and I am going to heat with the airgun and mount the rod with a clamp on a ringstand so I can

hold horizontal. I use a heat gun every day at work so I am used to waving it and distributing the heat. I won a thermocouple on ebay for my digital

multimeter but it will not be here for some time. Will have to watch the process to see what going on. When my thermocouple probe gets here, I may

use a vycor tube and just support the titanium with one hole stoppers.

[Edited on 1/7/2008 by chloric1]

Fellow molecular manipulator

|

|

|

| Pages:

1

..

10

11

12

13

14 |