Yttrium2

Perpetual Question Machine

Posts: 1104

Registered: 7-2-2015

Member Is Offline

|

|

Making A Test Tube Rack -- Evenly Spacing Holes

So, I'm here at school, have ventured into the library to be able to use the computers. (I broke my laptop) - Anyways, I'm wondering what the best way

is to make a test tube rack? There are those baskets for strawberries, that would work. Yet, I am wondering how do I evenly space 6-7 holes in a piece

of wood with a .5"-1" margin on each side?

My thought was to measure the length of the rack, and then to take off .5"-1" X 2 (this is for the marginon each side). And then divide by how ever

many holes there are. The problem is that the increments between 1" on a ruler are in 16th's of an inch, and I'm having a hard time doing the math.

Simply put.

|

|

|

j_sum1

Administrator

Posts: 6320

Registered: 4-10-2014

Location: At home

Member Is Offline

Mood: Most of the ducks are in a row

|

|

If your math is that great, space them evenly and then cut the end off.

(Or go metric and save yourself a headache. You crazy Yanks.)

|

|

|

Yttrium2

Perpetual Question Machine

Posts: 1104

Registered: 7-2-2015

Member Is Offline

|

|

Not sure if I should disturb the math tooter,

anyways, my question is what is the math/is my idea of what is necessary in the math correct?

|

|

|

Yttrium2

Perpetual Question Machine

Posts: 1104

Registered: 7-2-2015

Member Is Offline

|

|

Heading home now, please answer THE QUESTION

|

|

|

JJay

International Hazard

Posts: 3440

Registered: 15-10-2015

Member Is Offline

|

|

My advice would be to use a 3d printer. Many libraries have them these days. Do you know how big the holes are supposed to be? That's usually what

people try to figure out first.

|

|

|

OldNubbins

Hazard to Others

Posts: 136

Registered: 2-2-2017

Location: CA

Member Is Offline

Mood: Comfortably Numb

|

|

Start from the center, work your way out.

Edit:

To be clear, there are infinite approaches to this problem. None of them are correct.

You can expend more energy thinking about the problem than was used to create the wood in the first place, or you can just start drilling some holes

jam some tubes in them.

[Edited on 6-22-2018 by OldNubbins]

|

|

|

Geocachmaster

Hazard to Others

Posts: 146

Registered: 5-3-2016

Location: Maine, USA

Member Is Offline

Mood: Corroded, just like my spatulas

|

|

Make the first mark radius+0.5 inches in from the edge, then continue making marks every diameter+0.5 inches from the first mark. Stop when you have

enough, then cut off the last radius+0.5 inches from the last mark. Drill correctly sized holes centering at each mark, and you're done.

|

|

|

diddi

National Hazard

Posts: 723

Registered: 23-9-2014

Location: Victoria, Australia

Member Is Offline

Mood: Fluorescent

|

|

Y2 - i suggest you work backwards if your ruler is not accurate enough. ie Design your holes so that they will be easy to mark out (say 1.5" apart

or whatever) then cut your material to suit.

if you cannot do that, i will upload a drilling diagram to suit your material. just tape it on and start drilling. just need the material size you

have.

Beginning construction of periodic table display

|

|

|

XeonTheMGPony

International Hazard

Posts: 1640

Registered: 5-1-2016

Member Is Offline

Mood: No Mood

|

|

well first you make your end off sets, I usually use an inch for set backs.

Now from your set back lines find center and mark it

Pick a spacing that divides evenly, center punch these marks.

Drill, glue n screw, don!

|

|

|

ELRIC

Hazard to Others

Posts: 244

Registered: 23-2-2015

Location: Kentucky

Member Is Offline

Mood: No Mood

|

|

The math part is easy. Whatever you’re using, measure how long it is

Let’s say it’s 12”. Let’s say you want six holes. To get an even spacing, you will need to

divide by seven. 12/7 = 1.71. This is probably why j_sum1 suggests using metric.

But that is so close to 1 3/4 on a ruler/tape. Any way, measure from the end and mark

1 3/4”. Measure from that mark and do it again. Continue on to the end. From mark to

mark. These are you’re center marks. The center of the whole. Last one I made, I found

a drill bit that matched my test tubes perfect. You’ll need to mark you’re center going

down the length of the rack as well. Then you should have six “crosses”. X marks the

spot baby!! Now just put the drill bit on the mark and drill her straight. Nothin to it

If you really want to make it easy and want seven holes,

divide by eight. 12/8= 1.5”. You’re holes will be 1 1/2” apart.

That will give you an even inch and a half from the ends and

from center of hole to center of hole

[Edited on 22-6-2018 by ELRIC]

[Edited on 22-6-2018 by ELRIC]

[Edited on 22-6-2018 by ELRIC]

|

|

|

Sulaiman

International Hazard

Posts: 3695

Registered: 8-2-2015

Location: 3rd rock from the sun

Member Is Offline

|

|

I'll skip the calculating & measuring bit,

but thoughts on construction/finish - before you cut and drill ....

It is desirable to have a white background for observation and for photography/videography

and it is useful if the very bottom of the test tube(s) can be observed.

So provision for a white background avoids last minute hunting for a background.

(sheet of anything white, removable, cleanable etc. Opaque white allows back lighting)

I almost always spill a drop or two of something on the rack when experimenting,

- choose a durable, cleanable, or repairable finish.

No finish resists everything so expect at least cosmetic damage.

Paraffin/candle wax on raw wood seems quite a good compromise,

but it would not be difficult to make new rough-finish racks of cheap/free wood,

rather than re-finish a once high quality finish.

CAUTION : Hobby Chemist, not Professional or even Amateur

|

|

|

unionised

International Hazard

Posts: 5126

Registered: 1-11-2003

Location: UK

Member Is Offline

Mood: No Mood

|

|

Why would it matter if the holes were not evenly spaced?

|

|

|

ELRIC

Hazard to Others

Posts: 244

Registered: 23-2-2015

Location: Kentucky

Member Is Offline

Mood: No Mood

|

|

I would imagine it’s mostly an aesthetic thing, not functional.

I would want it that way too. Just the way I am though.

|

|

|

Yttrium2

Perpetual Question Machine

Posts: 1104

Registered: 7-2-2015

Member Is Offline

|

|

The part about using a metric ruler is very true.

I think I knew how to do the math, as I've done these problems before. It's minus the sum of margin length from rack length, divided by how many

holes there are.

I ran into problems using my 12" ruler, inches are imperial system, and it did cause me to run into great problems and frustration when trying to

solve the problem for spacing. I ended up with wierd fractions that I didn't have gradient markings for on my ruler.

Right now there isn't enough time to fully recover why that is.

If someone could explain the measuring aspect a bit I'd appreciate it. Also, if a tidbit could be included as to why we use SI (or metric?) units it

would be helpful to many.

Can someone explain where the problem comes in when dividing the fractions of inches?

Why is it a problem to use a standard, typical, ruler!?

[Edited on 7/20/2018 by Yttrium2]

|

|

|

mayko

International Hazard

Posts: 1218

Registered: 17-1-2013

Location: Carrboro, NC

Member Is Offline

Mood: anomalous (Euclid class)

|

|

Use something as a template that already has evenly spaced holes/markings, such as peg board?

al-khemie is not a terrorist organization

"Chemicals, chemicals... I need chemicals!" - George Hayduke

"Wubbalubba dub-dub!" - Rick Sanchez

|

|

|

ELRIC

Hazard to Others

Posts: 244

Registered: 23-2-2015

Location: Kentucky

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Yttrium2  | The part about using a metric ruler is very true.

I think I knew how to do the math, as I've done these problems before. It's minus the sum of margin length from rack length, divided by how many

holes there are.

I ran into problems using my 12" ruler, inches are imperial system, and it did cause me to run into great problems and frustration when trying to

solve the problem for spacing. I ended up with wierd fractions that I didn't have gradient markings for on my ruler.

Right now there isn't enough time to fully recover why that is.

If someone could explain the measuring aspect a bit I'd appreciate it. Also, if a tidbit could be included as to why we use SI (or metric?) units it

would be helpful to many.

Can someone explain where the problem comes in when dividing the fractions of inches?

Why is it a problem to use a standard, typical, ruler!?

[Edited on 7/20/2018 by Yttrium2] |

How long is you’re rack? If it’s 12”(which would help with the

Rest of you’re criteria, there shouldn’t be a problem) than you

Would have an even fraction for seven holes. If I need too I’ll

bust out a tape measure and lay it out on something

|

|

|

ELRIC

Hazard to Others

Posts: 244

Registered: 23-2-2015

Location: Kentucky

Member Is Offline

Mood: No Mood

|

|

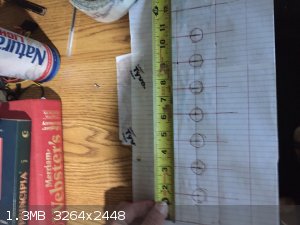

Here’s a layout for ya. Didn’t have a board to do it with. The holes are roughly 5/8”. I had to use a socket extension. It was as close as I

could get to 16mm, which I now is the diameter of a lot of test tubes. As you can see, the holes are 1.5” from center to center. It seems like it

would be a big rack after I laid

it out though.

I don’t know why my pictures come out sideways

[Edited on 20-7-2018 by ELRIC]

[Edited on 20-7-2018 by ELRIC]

|

|

|

Melgar

Anti-Spam Agent

Posts: 2004

Registered: 23-2-2010

Location: Connecticut

Member Is Offline

Mood: Estrified

|

|

Quote: Originally posted by j_sum1  | If your math is that great, space them evenly and then cut the end off.

(Or go metric and save yourself a headache. You crazy Yanks.) |

Everyone loves to diss imperial units, but they're actually way more convenient for dividing up in your head, without a calculator, especially if you

have to divide by a number that has 3 as one of its factors. In any case, virtually all Americans use both systems. I don't even understand

Fahrenheit temperatures for anything other than weather and oven temperatures. Try asking an American pharmacist for a prescription in drams instead

of milligrams sometime, and see what reaction you get.

The first step in the process of learning something is admitting that you don't know it already.

I'm givin' the spam shields max power at full warp, but they just dinna have the power! We're gonna have to evacuate to new forum software!

|

|

|