RogueRose

International Hazard

Posts: 1593

Registered: 16-6-2014

Member Is Offline

|

|

Making grinding medium from chopped pieces of rebar?

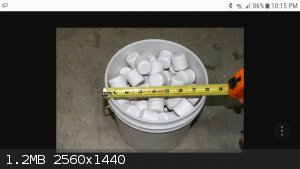

I was looking at getting various material for a large grinding mill and the cost for the medium was insanely expensive for a large container of 3-5

gallon bucket. I was planning of grinding some mostly non-reactive materials but also some things like KNO3 and IDK if the steel would be an issue

even though the container is HDPE.

I can get all different diameters of rebar from 1/4" up to 1" and have a plasma cutter which slices through it like butter. I figured I would them

grind the edges to round the sides sort of like how a hammer head is rounded on the sides, and also polish off any burs along the length of the bar

using an angle grinder to run up and down the length.

I don't think the "ridges" and bumps along the side of the rebar would be much of an issue though IDK as I've only used bearings in the past with

small containers.

I'd ideally like to use brass bar but unless I can find some lots on clearance locally then I think that would be a bit pricey.

Has anyone else found some good solutions for grinding material, I even looked into marbles and they were almost as expensive as bearings.

|

|

|

weilawei

Hazard to Others

Posts: 130

Registered: 3-12-2017

Member Is Offline

Mood: No Mood

|

|

If you're going to use them in a mill, why not tumble them to break the edges?

|

|

|

Bert

Super Administrator

Posts: 2821

Registered: 12-3-2004

Member Is Offline

Mood: " I think we are all going to die. I think that love is an illusion. We are flawed, my darling".

|

|

Marbles do NOT work well, they are too brittle and will spall, flaking off glass dust into whatever you are milling. If it is a pyrotechnic chemical,

glass dust is often used as a sensitizer to friction and shock, do you want that...

Spring for some Coors ceramic media.

[Edited on 6-20-2018 by Bert]

[Edited on 6-20-2018 by Bert]

Rapopart’s Rules for critical commentary:

1. Attempt to re-express your target’s position so clearly, vividly and fairly that your target says: “Thanks, I wish I’d thought of putting it

that way.”

2. List any points of agreement (especially if they are not matters of general or widespread agreement).

3. Mention anything you have learned from your target.

4. Only then are you permitted to say so much as a word of rebuttal or criticism.

Anatol Rapoport was a Russian-born American mathematical psychologist (1911-2007).

|

|

|

wg48

National Hazard

Posts: 821

Registered: 21-11-2015

Member Is Offline

Mood: No Mood

|

|

I wonder how long a HDPE bucket would last. I guess if its thick enough it should have reasonable life.

I have also considered using cut up steel bars as medium as I have a plasma cutter too. I was surprised how quickly it cuts even 1/4in steel. You can

cut an old l propane bottle up very effectively. Perhaps the bar could be rotated with torch at an angle to the bar to form a cone on one or both

sides of the cut. As an other poster suggested tumble them first with coarse angular sand or silicon carbide for a week or until they are roundish

I have considered using quartz (flint) pebbles as medium but I don’t know how tough they would be as flint may be too brittle, but they would be

low cost.

You could swage the end of the rod into a ball if you have a forge see below. But it would be a lot of time and effort depending on the number you

need.

|

|

|

Bert

Super Administrator

Posts: 2821

Registered: 12-3-2004

Member Is Offline

Mood: " I think we are all going to die. I think that love is an illusion. We are flawed, my darling".

|

|

PVC makes an acceptable mill jar. LOTS of pyrotechnic chemicals have been ground in this. Only a few have blown up... So start remotely, and seriously

consider NOT grinding a fuel/oxidizer mixture.

Plastic 5 gallon pails won't last forever, especially with aggressive media/abrasive charges. But they are cheap.

Purpose made rubber lined rock polisher drums are worth the money- If you have the money.

And a couple of rolls of USA 5 cent pieces are still the best, easiest to procure, least contaminating, non sparking impromptu grinding media I know

of, for small mills anyhow. Also, after use, you can just clean them and return them to the bank!

Rapopart’s Rules for critical commentary:

1. Attempt to re-express your target’s position so clearly, vividly and fairly that your target says: “Thanks, I wish I’d thought of putting it

that way.”

2. List any points of agreement (especially if they are not matters of general or widespread agreement).

3. Mention anything you have learned from your target.

4. Only then are you permitted to say so much as a word of rebuttal or criticism.

Anatol Rapoport was a Russian-born American mathematical psychologist (1911-2007).

|

|

|

aga

Forum Drunkard

Posts: 7030

Registered: 25-3-2014

Member Is Offline

|

|

Lead fishing weights are good.

Melting/casting scrap lead is easy to do and would work out cheaper.

|

|

|

wg48

National Hazard

Posts: 821

Registered: 21-11-2015

Member Is Offline

Mood: No Mood

|

|

These can be purchased for about £10. As it’s a pressure vessel it has thick plastic walls and with a bit of modification to remove the hand pump

from the screw cap it would make a good mill jar or even a hydrogenation chamber.

|

|

|

Bert

Super Administrator

Posts: 2821

Registered: 12-3-2004

Member Is Offline

Mood: " I think we are all going to die. I think that love is an illusion. We are flawed, my darling".

|

|

I see I'm not the only one "repurposing" these.

I have also removed the sprayer wand from the hose, attached it to the fluid reservoir on a hydraulically braked vehicle, filled with brake fluid.

When pressurized slightly it makes a nice unit for constantly refilling the brake reservoir as you bleed brake lines. "Power bleed", one person can

bleed brakes without spilling fluid or constantly getting out from under to pump the brakes.

Rapopart’s Rules for critical commentary:

1. Attempt to re-express your target’s position so clearly, vividly and fairly that your target says: “Thanks, I wish I’d thought of putting it

that way.”

2. List any points of agreement (especially if they are not matters of general or widespread agreement).

3. Mention anything you have learned from your target.

4. Only then are you permitted to say so much as a word of rebuttal or criticism.

Anatol Rapoport was a Russian-born American mathematical psychologist (1911-2007).

|

|

|

hissingnoise

International Hazard

Posts: 3940

Registered: 26-12-2002

Member Is Offline

Mood: Pulverulescent!

|

|

Quote: Originally posted by Bert  | Only a few have blown up... So start remotely, and seriously consider NOT grinding a fuel/oxidizer mixture.

|

I've ground numerous small batches of moistened BP in PVC sewer pipes using hardened lead balls without incident ─ draping an earthed wire over the

rotating drum prevents static build-up!

If there's no actual source of ignition, there's little danger...

|

|

|

markx

National Hazard

Posts: 646

Registered: 7-8-2003

Location: Northern kingdom

Member Is Offline

Mood: Very Jolly

|

|

HDPE containers hold up for quite a while in ball mill application. I've been using the same container for years mixing up batches of cementitious

building product samples in the lab and the container is still good. Considering the punishment of jagged sand and all the other abrasive media that

has been tumbled in this container I would say that it is a fair material for the purpose. Actually the steel mixing media wears a lot faster than the

soft container walls. This effect can also be seen on the combination of plastic bushings and steel shafts....the steel wears away whereas the plastic

bushing shows minimal effects.

Steel media I would suggest only for passive mixtures that have no possibility to engage in a violent reaction inside the jar...for reactive mixtures

(not impact sensitive of course) I think lead is quite a good option if the metal contamination is not a problem, it will grind off to some degree and

enter the final composition, but that is true for most milling media.

Just a thought...why not cut the steel rebar with an angle grinder instead of a plasma cutter or torch. It would leave a lot cleaner cut and there

would not be much less metal to grind off afterwards. Alternatively if one has access to a lathe, the cutting and rounding of rebar edges could be

done in one machining operation with good repeatability and precision.

One can actually make a casting mold for lead media using plaster of paris and utilize scrap lead to make suitable sized balls or cylinders for the

mill. It will hold up to the temperature of molten lead just fine. The initial imprint in the plaster can be formed by using suitably shaped objects

formed out of modeling clay. After the plaster has set one can dissassemble the mold and remove the modeling clay, leaving the desired cavities. Just

make sure the plaster has dried thouroughly before you cast the lead into the mold or otherwise it could happen that molten lead shoots out of the

mold under steam pressure and burns you really bad.

This is a very cheap, versatile and effective method that I've used with great success.

Exact science is a figment of imagination.......

|

|

|

hissingnoise

International Hazard

Posts: 3940

Registered: 26-12-2002

Member Is Offline

Mood: Pulverulescent!

|

|

Quote: Originally posted by markx  |

One can actually make a casting mold for lead media using plaster of paris and utilize scrap lead to make suitable sized balls or cylinders for the

mill. |

I'd be loath to fuck around with melting lead ─ very toxic dust and fumes...safer to just buy lead shot, IMO!

|

|

|

markx

National Hazard

Posts: 646

Registered: 7-8-2003

Location: Northern kingdom

Member Is Offline

Mood: Very Jolly

|

|

Quote: Originally posted by hissingnoise  | Quote: Originally posted by markx  |

One can actually make a casting mold for lead media using plaster of paris and utilize scrap lead to make suitable sized balls or cylinders for the

mill. |

I'd be loath to fuck around with melting lead ─ very toxic dust and fumes...safer to just buy lead shot, IMO!

|

Thou shalt be fine, just as long as you are not doing it in an enclosed premises without any ventilation and hanging around with your face over the

molten metal!

Besides, I'm inclined to thinking that the occasional handling of molten lead is probably quite harmless compared to the actual end product from most

of the mills. Be it BP, aluminium powder or other concoction.

Of course if one has the option to buy lead shot (and manages to find the proper sized ones) then no problem. Where I reside it is prohibited to buy

lead shot without a weapons permit and getting one for just the purpose of ball mill media is a stretch too far.

Exact science is a figment of imagination.......

|

|

|

Bert

Super Administrator

Posts: 2821

Registered: 12-3-2004

Member Is Offline

Mood: " I think we are all going to die. I think that love is an illusion. We are flawed, my darling".

|

|

Yes.

I cast Lead for bullets- You can do the same as some do for amateur chemistry without an indoor fume hood, GO OUTSIDE.

Work with the wind at your back, don't eat/drink while you're working, WASH YOUR HANDS after handling Lead/Lead alloys.

Use a temperature controlled melter so you DO NOT overheat the alloy and actually vaporize Lead. There is a WIDE margin between liquidus and vapor

temperatures here.

You can also get a small fan and a piece of dryer duct to take any fumes generated away, arrange the duct for fume extraction from over the Lead

melting pot.

This isn't handling water soluble heavy metal salts or organic Mercury! You just have to be conscious of the dangers and sensible.

All in all, I'm more worried about burns than heavy metal poisoning- For example, dropping a piece of solid scrap metal with some liquid water trapped

inside it into a melted pot of Lead leads to a steam explosion, spreading some very hot tinsel around the area. It's a good idea to pre heat scrap for

a while and make SURE It's completely dry.

If you are using range scrap? Make darn sure a cartridge someone lost at the range doesn't get into the scrap for the same reason- KABLAM!

Rapopart’s Rules for critical commentary:

1. Attempt to re-express your target’s position so clearly, vividly and fairly that your target says: “Thanks, I wish I’d thought of putting it

that way.”

2. List any points of agreement (especially if they are not matters of general or widespread agreement).

3. Mention anything you have learned from your target.

4. Only then are you permitted to say so much as a word of rebuttal or criticism.

Anatol Rapoport was a Russian-born American mathematical psychologist (1911-2007).

|

|

|

hissingnoise

International Hazard

Posts: 3940

Registered: 26-12-2002

Member Is Offline

Mood: Pulverulescent!

|

|

| Quote: | | Of course if one has the option to buy lead shot (and manages to find the proper sized ones) then no problem. Where I reside it is prohibited to buy

lead shot without a weapons permit and getting one for just the purpose of ball mill media is a stretch too far. |

I haven't bought UN lead balls for years and I could sure do with a few...

|

|

|