Fulmen

International Hazard

Posts: 1718

Registered: 24-9-2005

Member Is Offline

Mood: Bored

|

|

Making an acrylic büchner funnel

What do you do when you lack a piece large enough to make something? Here's one solution, inspired by 3D-printing (during assembly):

The funnel will be 70mm and is made by gluing disks of 6mm SAN sheet together. It will then be machined internally before the top, filter disk and

bottom are glued together. It can then be machined externally.

We're not banging rocks together here. We know how to put a man back together.

|

|

|

aga

Forum Drunkard

Posts: 7030

Registered: 25-3-2014

Member Is Offline

|

|

Cool ! It's a solution for sure.

I guess it could all be 3D printed.

Easier as two parts, but i suppose glue would work to hold the disc in place.

|

|

|

Fulmen

International Hazard

Posts: 1718

Registered: 24-9-2005

Member Is Offline

Mood: Bored

|

|

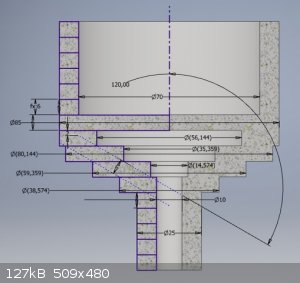

Here's the sketch of the assembly.

It''s beneficial to keep the glued area as small as possible by roughing out the parts before assembly. Since the glue is solvent based the drying

depends on diffusion, reducing the diffusion path by a factor of two should reduce drying time by a factor of four.

We're not banging rocks together here. We know how to put a man back together.

|

|

|

unionised

International Hazard

Posts: 5126

Registered: 1-11-2003

Location: UK

Member Is Offline

Mood: No Mood

|

|

It will be if he tries to filter any strong solvents

As A kid I had a filter funnel made by cutting the top off a plastic bleach bottle. The "plate" was perforated zinc- which is not really inert enough.

|

|

|

Fulmen

International Hazard

Posts: 1718

Registered: 24-9-2005

Member Is Offline

Mood: Bored

|

|

Chemical compatibility will be an issue in some cases, but I rarely work with aggressive chemicals. I will of course replace my broken ceramic funnel

in time, but this was a simple and fun fix.

We're not banging rocks together here. We know how to put a man back together.

|

|

|

Radium212

Hazard to Self

Posts: 85

Registered: 26-6-2017

Member Is Offline

Mood: Pyrophoric.

|

|

Careful of thermal expansion. If each piece expanded a different amount, after a while it would eventually shake itself apart.

|

|

|

Fulmen

International Hazard

Posts: 1718

Registered: 24-9-2005

Member Is Offline

Mood: Bored

|

|

Why would the segments expand at different rates? They are from the exact same material and glued together with SAN dissolved in MEK. Of course the

bonds will be weak points, but they will only see compressive loads.

We're not banging rocks together here. We know how to put a man back together.

|

|

|

unionised

International Hazard

Posts: 5126

Registered: 1-11-2003

Location: UK

Member Is Offline

Mood: No Mood

|

|

I'm not sure about that.

I think the bits that form the conical section will try to "peel" apart.

|

|

|

Fulmen

International Hazard

Posts: 1718

Registered: 24-9-2005

Member Is Offline

Mood: Bored

|

|

Fair enough, there might be some bending loads on the segments in the cone. But it's only subjected to vacuum, and that really isn't much of a load.

It's deliberately over-engineered for easy machinability, but I ran it through stress analysis and got a safety factor of 15. I think it will survive.

We're not banging rocks together here. We know how to put a man back together.

|

|

|

aga

Forum Drunkard

Posts: 7030

Registered: 25-3-2014

Member Is Offline

|

|

It's a good practical solution Fulmen.

Nice one.

|

|

|

unionised

International Hazard

Posts: 5126

Registered: 1-11-2003

Location: UK

Member Is Offline

Mood: No Mood

|

|

The vacuum isn't a load at all, but atmospheric pressure is about a ton to the square foot.

|

|

|

Fulmen

International Hazard

Posts: 1718

Registered: 24-9-2005

Member Is Offline

Mood: Bored

|

|

Details, schmetails.

We're not banging rocks together here. We know how to put a man back together.

|

|

|

Fulmen

International Hazard

Posts: 1718

Registered: 24-9-2005

Member Is Offline

Mood: Bored

|

|

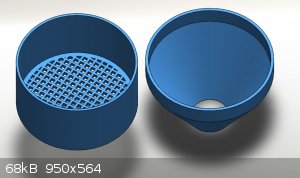

O ye, of little faith. Watch and weep:

We're not banging rocks together here. We know how to put a man back together.

|

|

|

Twospoons

International Hazard

Posts: 1324

Registered: 26-7-2004

Location: Middle Earth

Member Is Offline

Mood: A trace of hope...

|

|

Quote: Originally posted by aga  |

I guess it could all be 3D printed.

Easier as two parts, but i suppose glue would work to hold the disc in place. |

I 3d printed mine in PLA+ (some kind of modified PLA thats not as brittle). In two parts to avoid the need for support during printing.

I didn't glue the parts together, as I only wanted gravity filtering. Worked a treat.

Pic is from my cad model (Solidworks)

Helicopter: "helico" -> spiral, "pter" -> with wings

|

|

|

DrP

National Hazard

Posts: 625

Registered: 28-9-2005

Member Is Offline

Mood: exothermic

|

|

Are these acrylics and PLAs solvent resistant? How are they with weak solvents like Methanol, hexane and IPA? Should be alright I suppose - good idea.

:-)

\"It\'s a man\'s obligation to stick his boneration in a women\'s separation; this sort of penetration will increase the population of the younger

generation\" - Eric Cartman

|

|

|

Twospoons

International Hazard

Posts: 1324

Registered: 26-7-2004

Location: Middle Earth

Member Is Offline

Mood: A trace of hope...

|

|

Pretty easy to find out

Chemical resistance chart

There are half a dozen different polymers available for 3d printers, so it shouldn't be too hard to find one to suit a given purpose.

[Edited on 3-4-2018 by Twospoons]

Helicopter: "helico" -> spiral, "pter" -> with wings

|

|

|

Fulmen

International Hazard

Posts: 1718

Registered: 24-9-2005

Member Is Offline

Mood: Bored

|

|

I wouldn't use SAN for any solvent (except water) or strong acids/lye. I made the funnel for recrystallization work, if I ever need to work with

solvents I'll buy a glass funnel.

We're not banging rocks together here. We know how to put a man back together.

|

|

|

RogueRose

International Hazard

Posts: 1594

Registered: 16-6-2014

Member Is Offline

|

|

I had some success using a 3" PVC end cap and drilling holes in a plate to fit inside the plate. The caps are available in 4", 6" & 8" as well

and also in CPVC and ABS.

I posted pics in this thread of how I made it. I added a threaded hose barb and ran tubing to a vacuum flask, or placed the barb into a bung in the

flask.

https://www.sciencemadness.org/whisper/viewthread.php?tid=61...

|

|

|