Melgar

Anti-Spam Agent

Posts: 2004

Registered: 23-2-2010

Location: Connecticut

Member Is Offline

Mood: Estrified

|

|

Any interest in a magnetic stirrer that can cycle speed/direction automatically?

We've probably all experienced a magnetic stirrer that went a bit too fast, eventually clanking around the vessel instead of stirring like it was

supposed to. To make it stop, of course, you have to turn the stirring off, or at least down very low. Then the magnets align, and you can turn the

speed up again. There's also an issue where, over time, there will be "sand dunes" of a solid reagent that get stuck to the bottom, where they form

because of the consistent fluid flow over them. To solve both problems, I was thinking that perhaps a stirrer could stop and change directions every

five minutes or so. It would go the same speed as it was set to, just the opposite direction, and adjusting the speed would reset the timer on the

cycle so that it would never change directions in the middle of adjusting the speed. I was about to build the thing finally, but figured I'd ask here

to see if there were any considerations I should be sure to keep in mind.

The motor I have is actually from an old videodisk player, and was made by Sony. It's actually a perfect DC stirrer motor, I think. Very smooth

motion at all times.

The first step in the process of learning something is admitting that you don't know it already.

I'm givin' the spam shields max power at full warp, but they just dinna have the power! We're gonna have to evacuate to new forum software!

|

|

|

Sulaiman

International Hazard

Posts: 3698

Registered: 8-2-2015

Location: 3rd rock from the sun

Member Is Offline

|

|

maybe just changing the size and/or shape of the stirbar would be easier ?

e.g.

http://www.ebay.co.uk/itm/PTFE-Magnetic-Stir-Bars-High-Magne...

http://www.ebay.co.uk/itm/PTFE-Magnetic-Stirrer-Gear-Type-Oc...

http://www.ebay.co.uk/itm/Bel-Art-Products-371520000-Spinbar...

CAUTION : Hobby Chemist, not Professional or even Amateur

|

|

|

VSEPR_VOID

National Hazard

Posts: 719

Registered: 1-9-2017

Member Is Offline

Mood: Fullerenes

|

|

You could always make a controller such as that. With a motor controller, RTC, and an ardiuno you could construct such a device.

Within cells interlinked

Within cells interlinked

Within cells interlinked

|

|

|

Melgar

Anti-Spam Agent

Posts: 2004

Registered: 23-2-2010

Location: Connecticut

Member Is Offline

Mood: Estrified

|

|

Quote: Originally posted by VSEPR_VOID  | | You could always make a controller such as that. With a motor controller, RTC, and an ardiuno you could construct such a device.

|

That was actually the plan. The stirrer on my hotplate is broken, and rather than just use it without a stirrer, I figured I'd replace it with a

custom-made one. I have an H-bridge motor controller, (to switch polarity on the motor) and since the motor only draws about 100-200 mA, the

controller should work fine without any power-boosting circuitry. I mounted the original permanent magnet onto the new motor already, now I just need

to build a mount to hold the motor in place inside the hotplate, hook up the stirrer potentiometer, then write the arduino code. I took apart an old

12V 500 mA AC adapter, and that circuitry should be able to provide the necessary DC power to the system, and can be hooked up internally. But if I'm

going to be putting an Arduino in there, I feel like I should add more functionality too, while I'm at it. Of course, I'd then need to add more

controls somehow, or hook up a bluetooth module and use my phone to control and write control software for my phone or something... but I should

probably just focus on the stirring for now.

The first step in the process of learning something is admitting that you don't know it already.

I'm givin' the spam shields max power at full warp, but they just dinna have the power! We're gonna have to evacuate to new forum software!

|

|

|

CRUSTY

Hazard to Others

Posts: 139

Registered: 5-6-2016

Location: Nearby

Member Is Offline

Mood: High-Order

|

|

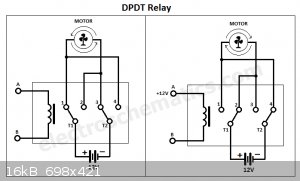

For those who prefer something that doesn't involve Arduino or programming for that matter, you can build the entire controller circuit for $5-15 USD:

You can get the "relay" there (a double-pole double-throw) for less than $5 (usually), and control the relay using a 50% duty-cycle 555 timer circuit,

which costs MAX $4. Probably cheaper. Personally, I'd prefer Arduino though.

EDIT: God dammit, images are such a pain.

[Edited on 29-9-2017 by CRUSTY]

|

|

|

VSEPR_VOID

National Hazard

Posts: 719

Registered: 1-9-2017

Member Is Offline

Mood: Fullerenes

|

|

Quote: Originally posted by Melgar  | Quote: Originally posted by VSEPR_VOID  | | You could always make a controller such as that. With a motor controller, RTC, and an ardiuno you could construct such a device.

|

That was actually the plan. The stirrer on my hotplate is broken, and rather than just use it without a stirrer, I figured I'd replace it with a

custom-made one. I have an H-bridge motor controller, (to switch polarity on the motor) and since the motor only draws about 100-200 mA, the

controller should work fine without any power-boosting circuitry. I mounted the original permanent magnet onto the new motor already, now I just need

to build a mount to hold the motor in place inside the hotplate, hook up the stirrer potentiometer, then write the arduino code. I took apart an old

12V 500 mA AC adapter, and that circuitry should be able to provide the necessary DC power to the system, and can be hooked up internally. But if I'm

going to be putting an Arduino in there, I feel like I should add more functionality too, while I'm at it. Of course, I'd then need to add more

controls somehow, or hook up a bluetooth module and use my phone to control and write control software for my phone or something... but I should

probably just focus on the stirring for now. |

You could design a housing and have it 3d printed from 3dHubs

Within cells interlinked

Within cells interlinked

Within cells interlinked

|

|

|

Melgar

Anti-Spam Agent

Posts: 2004

Registered: 23-2-2010

Location: Connecticut

Member Is Offline

Mood: Estrified

|

|

I actually have the stirrer motor in there now, but hooked up to an adjustable DC power supply that's primarily for things like electrosynthesis and

electroplating. The wires are running out one of the vent slits on the hotplate, and the motor was just mounted with this double-sided foam tape

stuff, to keep it from rattling too much. So far, it's worked okay, but I feel like I'd need a pretty good incentive to finish fixing it.

How much do things like enclosures cost to have made? It'd probably need to be a fairly heat and chemical resistant type of plastic, for a mount

that'd be inside a hotplate.

The first step in the process of learning something is admitting that you don't know it already.

I'm givin' the spam shields max power at full warp, but they just dinna have the power! We're gonna have to evacuate to new forum software!

|

|

|