experimental

Harmless

Posts: 21

Registered: 9-7-2017

Member Is Offline

Mood: curious

|

|

Issues with stannous sulfate

Does anyone have a reference for the solubility of stannous sulfate?

Wikipedia says it's 33 g/100mL but when I try to make it by reacting metallic tin with copper sulfate, the resulting solution settles at the bottom of

the beaker despite being just a few grams in 50 mL of water.

Also, if someone has experience working with it, is there an easy way to remove the white stains it leaves to the side of the beaker when heated? They

appear at the water line and seem to be insoluble in either hydrochloric or sulfuric acid.

|

|

|

unionised

International Hazard

Posts: 5126

Registered: 1-11-2003

Location: UK

Member Is Offline

Mood: No Mood

|

|

How are you sopping the air getting to the tin (II) and oxidising it to stannic oxide?

|

|

|

Σldritch

Hazard to Others

Posts: 309

Registered: 22-3-2016

Member Is Offline

Mood: No Mood

|

|

If you are using excess cupric sulfate it will oxidize the tin to stannic oxide.

(Which is soluble in conc. H2SO4 and "normal" NaOH)

|

|

|

experimental

Harmless

Posts: 21

Registered: 9-7-2017

Member Is Offline

Mood: curious

|

|

I didn't know that could be an issue. Acutally the residue left at the sides of the beaker could be stannic oxide, as it adheres to glass quite well.

I only tried cleaning it with dilute sulfuric acid, will try with NaOH and see if it soluble.

That is likely to solve the cleaning issue, but now I have a bigger issue, how to prevent oxygen in the air from getting at my product. Any

suggestions in this regard?

By the way, what I'm trying to do is to use tin sulfate for plating tin on copper. It shouldn't be too hard, I hope.

|

|

|

woelen

Super Administrator

Posts: 8014

Registered: 20-8-2005

Location: Netherlands

Member Is Offline

Mood: interested

|

|

Your main problem is hydrolysis. Sn(2+) ions can hardly exist in water at medium pH. They hydrolyze as follows:

Sn(2+) + H2O ---> [Sn(OH)](+) + H(+)

[Sn(OH)](+) + H2O <--> Sn(OH)2 + H(+)

The latter precipitates as a white solid. Clear solutions of tin(II) salts only are possible at very low pH.

|

|

|

Melgar

Anti-Spam Agent

Posts: 2004

Registered: 23-2-2010

Location: Connecticut

Member Is Offline

Mood: Estrified

|

|

Actually if you want a stannous sulfate solution, your best bet might be tin metal, sulfuric acid, and careful addition of H2O2. Too little and the

sulfate will be reduced to SO2 and tin sulfide. Too much, and you'll have an insoluble oxide. When I did it, I added a little bit every time I

noticed the smell of H2S (from acid hydrolysis of the sulfide).

However, stannous chloride is really easy to plate onto copper, so you probably don't need to go through the trouble. Just use a tin anode to deal

with the chlorine issue, and problem solved. That way your tin ion concentration stays relatively stable too.

[Edited on 8/24/17 by Melgar]

The first step in the process of learning something is admitting that you don't know it already.

I'm givin' the spam shields max power at full warp, but they just dinna have the power! We're gonna have to evacuate to new forum software!

|

|

|

experimental

Harmless

Posts: 21

Registered: 9-7-2017

Member Is Offline

Mood: curious

|

|

Thanks Melgar for the suggestion. I tried on a very small scale given that you mentioned the possible production of H2S.

I started with 1.2 grams of tin metal, 1 ml of water, 1 ml of concentrated sulfuric acid, gentle heating and adding dropwise H2O2 to a total of 1 ml.

I weighted the tin metal at the end of the reaction at 0.7 g, so around 0.5 grams of tin were consumed.

However I must have done something wrong, as the solution turned yellow, which is not the colour of stannous sulfate.

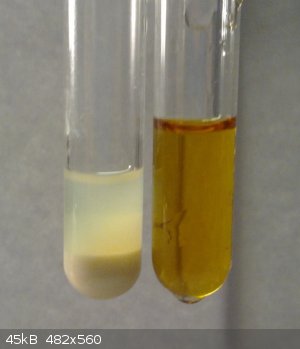

For reference I pictured the resulting yellow solution (right), and the previous attempt of reacting tin metal and copper sulfate (left).

Still no success, I'll just keep experimenting.

|

|

|

aga

Forum Drunkard

Posts: 7030

Registered: 25-3-2014

Member Is Offline

|

|

Bravo !

|

|

|

SWIM

National Hazard

Posts: 970

Registered: 3-9-2017

Member Is Offline

|

|

Could it be lead contamination in your tin causing that yellow?

Is it tech grade?

|

|

|

experimental

Harmless

Posts: 21

Registered: 9-7-2017

Member Is Offline

Mood: curious

|

|

I tried another experiment. Electrolysis of tin in 50 % sulfuric acid. Again, it didn't work as expected. I used tin for both electrodes, and tried

with 12 V, mainly for convenience. Bubbles were evolving from both electrodes, probably water electrolysis. Current was somewhere between 0.3 A and

0.6 A.

After a few hours one of the electrodes (can't remember which) turned black and some black soot-like substance was present in the beaker. I weighted

the electrodes, but no significant weight loss occurred, around 0.1 g, comparable to the resolution of my scale.

Tin may have reacted with the oxygen being produced by the water electrolysis to produce tin oxide.

But also lead dioxide is black. The tin I'm using was bought online, maybe it is a tin lead alloy.

|

|

|

UC235

National Hazard

Posts: 565

Registered: 28-12-2014

Member Is Offline

Mood: No Mood

|

|

Sn(II) is very sensitive to air oxidation, with SnO2 being a very energetically favorable place to stop. Much like in Co(II), I'm quite certain halide

counterions go a long way toward stabilizing it, hence the ubiquity of SnCl2.

Have a look at DOI: 10.1039/JR9600004000

SnSO4 is prepared by reaction of tin metal with copper sulfate in dilute sulfuric acid under nitrogen. The solution is boiled, concentrated under

vacuum and the crystals filtered, rinsed with alcohol, and ether, and dried.

They report that it is stable when dry in contact with air over a period of months. It is better stored under vacuum in the dark.

Solutions are obtainable and remain clear when containing >18.9g SnSO4 per 100ml water. Below this, there is hydrolysis to insoluble basic tin

sulfates.

|

|

|

AJKOER

Radically Dubious

Posts: 3026

Registered: 7-5-2011

Member Is Offline

Mood: No Mood

|

|

My view is that the interactive reactants here are water and oxygen acting in succession.

First, the hydrolysis reaction discussed by Woelen:

Sn[(H2O)6](2+) + H2O = Sn[(H2O)5(OH)]+ + H3O+

Reference: See, for example, for the case with iron at: http://www.geo.utexas.edu/courses/376m/coord_chem.htm

Now the above reaction could be moved to the right with another reaction consuming H+ like the below summary net electrochemical based reaction

involving oxygen and an aqueous stannous salt:

Sn(ll) aq + 2 H+ + 1/2 O2 → Sn(lV) + H2O (see, for the case of iron: http://corrosion-doctors.org/Experiments/rust-chemistry.htm )

The associated half cell reactions I would expect are:

Cathode: 1/2 O2 + 2 H+ + 2 e- ---> H2O

which is based on page 20-13 at http://www.public.asu.edu/~jpbirk/CHM-115_BLB/ClassNotes/chp... , and also my prior comments with respect to iron and copper on SM discussed at:

https://www.sciencemadness.org/whisper/viewthread.php?tid=73... ).

Anode: Sn(ll) ---> Sn(IV) + 2 e-

I would expect agitation of the solution, increasing the amount of dissolved oxygen, and the presence of a very small amount of NaCl, could expedite

the reaction.

[Edited on 12-9-2017 by AJKOER]

|

|

|

experimental

Harmless

Posts: 21

Registered: 9-7-2017

Member Is Offline

Mood: curious

|

|

I finally understood at least one of the reasons why my attempts were producing strange results. The tin I was using contains lead.

To discover it I tried the lead test proposed here https://www.sciencemadness.org/whisper/viewthread.php?tid=13... Since it was the first time I've done this test, I used a sample of leaded and

lead free solder wire for comparison.

On the left there's the leaded solder, on the center the lead free solder, and on the right the supposedly pure tin I was using for the experiment.

It's hard to see, but there's a yellow precipitate indicating the presence of lead.

I guess I'll have to get better tin to make stannous sulfate. Or maybe use the lead free solder?

|

|

|

experimental

Harmless

Posts: 21

Registered: 9-7-2017

Member Is Offline

Mood: curious

|

|

Finally I had success in tin plating. Since my last attempt there was one major breakthrough: NurdRage has posted a video on the subject.

Apparently my mistake was insisting on stannous sulfate while stannous chloride works as well but is much easier to prepare.

That, and using leaded solder without knowing it.

|

|

|