wish i had a kraken!!!

Hazard to Others

Posts: 157

Registered: 22-3-2012

Member Is Offline

Mood: No Mood

|

|

any Cool Ideas are welcomed

Dear friends I Know this post might be a little irrelevant to chemistry (yet it is not completely irrelevant ) ,But I have to mention that I made a

sputter coater Machine (it is not totally home built though) and I need any cool Idea of yours , to make it real with my machine .

U can see the machine here :

https://www.youtube.com/watch?v=AGiX8Rh-GGI

You can also have a look at this paper ,I think it will help you to come up with cool Ideas :-)

Attachment: Materials Letters Volume 128 issue 2014 [doi 10.1016_j.matlet.2014.04.056] Subramanian, B.; Anu Priya, K.; Thanka Rajan, (1.7MB)

This file has been downloaded 846 times

[Edited on 8-3-2015 by wish i had a kraken!!!]

|

|

|

Zombie

Forum Hillbilly

Posts: 1700

Registered: 13-1-2015

Location: Florida PanHandle

Member Is Offline

Mood: I just don't know...

|

|

How about a cool pair of sunglasses?

Very cool machine by the way!

[Edited on 3-8-2015 by Zombie]

They tried to have me "put to sleep" so I came back to return the favor.

Zom.

|

|

|

wish i had a kraken!!!

Hazard to Others

Posts: 157

Registered: 22-3-2012

Member Is Offline

Mood: No Mood

|

|

Thanks :-) ,

sunglasses sound cool But I prefer some other Ideas like this one that I came up with : "tiles coated with nano layer of Cu hopping its antibacterial

properties would make these tiles a good choice for being used in hospitals ! " I figured these tiles won't be applicable cuz coated layer could be

easily removed !

So if U have better ideas I would be happy to share them with me :-)

Many thanks

[Edited on 8-3-2015 by wish i had a kraken!!!]

|

|

|

Sulaiman

International Hazard

Posts: 3692

Registered: 8-2-2015

Location: 3rd rock from the sun

Member Is Offline

|

|

I couldn't read the paper so please excuse me if these were covered

maybe not super cool but,

I'm sure that an advert in your local astronomy forum would have a lot of amateur astronomers interested if you can do multi-coating for lenses

or even better, mirror coating or re-coating for reflectors.

Amateur physicists may want dielectric coatings for home made lasers,

sputter coatings for amateur electron microscopy samples/targets

simply announcing the availability of a cheap sputtering facility would probably interest amateur scientists with requirements that we may not think

of.

Specifically for this forum I imagine platinum or other inert coatings for electrolysis electrodes, or catalytic coatings.

|

|

|

IrC

International Hazard

Posts: 2710

Registered: 7-3-2005

Location: Eureka

Member Is Offline

Mood: Discovering

|

|

Just rename the file adding .pdf at the end, as example I renamed it to Materials Letters Volume 128 issue 2014.pdf, it then opens properly.

"Science is the belief in the ignorance of the experts" Richard Feynman

|

|

|

Sulaiman

International Hazard

Posts: 3692

Registered: 8-2-2015

Location: 3rd rock from the sun

Member Is Offline

|

|

ok, that worked, thanks.

I'd be more inclined to use silver/silver oxide than copper/copper oxide

because I think that;

.silver is a better anti-microbial agent than copper

.there are some health concerns with copper particulates inhalation

|

|

|

Steam

Hazard to Others

Posts: 238

Registered: 25-3-2014

Location: Minnesota

Member Is Offline

Mood: Triple Point

|

|

What about a really cool hat?

DISCLAIMER: The information in this post is provided for general informational purposes only and may not reflect the current law in your jurisdiction.

No information contained in this post should be construed as legal advice from the individual author, nor is it intended to be a substitute for legal

counsel on any subject matter. No reader of this post should act or refrain from acting on the basis of any information included in, or accessible

through, this post without seeking the appropriate legal or other professional advice on the particular facts and circumstances at issue from a lawyer

licensed in the recipient’s state, country or other appropriate licensing jurisdiction.

|

|

|

j_sum1

Administrator

Posts: 6320

Registered: 4-10-2014

Location: At home

Member Is Offline

Mood: Most of the ducks are in a row

|

|

I guess one of the questions is how uniform are your coatings. For optics they would need to be very uniform.

|

|

|

wish i had a kraken!!!

Hazard to Others

Posts: 157

Registered: 22-3-2012

Member Is Offline

Mood: No Mood

|

|

What U mean Plz explain more :-)

|

|

|

wish i had a kraken!!!

Hazard to Others

Posts: 157

Registered: 22-3-2012

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by j_sum1  | | I guess one of the questions is how uniform are your coatings. For optics they would need to be very uniform. |

By the moment of writing this reply I don't think my coatings are good for optics , but I am working on it ! Do U have any Ideas in the field of

optics ? I'd be happy if U share them with me :-)

|

|

|

j_sum1

Administrator

Posts: 6320

Registered: 4-10-2014

Location: At home

Member Is Offline

Mood: Most of the ducks are in a row

|

|

Unfortunately no expertise. I think the simplest method might be to keep your sputtering target in motion.

And measuring the uniformity might be a trick too.

However, I love what you have done. I agree with Sulaiman where he says there might be a large number of people interested in Pt electrodes or

catalysts.

|

|

|

wish i had a kraken!!!

Hazard to Others

Posts: 157

Registered: 22-3-2012

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by j_sum1  | Unfortunately no expertise. I think the simplest method might be to keep your sputtering target in motion.

And measuring the uniformity might be a trick too.

However, I love what you have done. I agree with Sulaiman where he says there might be a large number of people interested in Pt electrodes or

catalysts. |

I am trying to keep my target in motion :-) but I have to solve some engineering problems , first .

Could U explain more about "Pt electrodes or catalysts" , what type of catalysts ? or maybe you can guide me to some scientific references :-)

|

|

|

wish i had a kraken!!!

Hazard to Others

Posts: 157

Registered: 22-3-2012

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by j_sum1  | Unfortunately no expertise. I think the simplest method might be to keep your sputtering target in motion.

And measuring the uniformity might be a trick too.

However, I love what you have done. I agree with Sulaiman where he says there might be a large number of people interested in Pt electrodes or

catalysts. |

I am trying to keep my target in motion :-) but I have to solve some engineering problems , first .

Could U explain more about "Pt electrodes or catalysts" , what type of catalysts ? or maybe you can guide me to some scientific references :-)

|

|

|

j_sum1

Administrator

Posts: 6320

Registered: 4-10-2014

Location: At home

Member Is Offline

Mood: Most of the ducks are in a row

|

|

Sure. I am no expert an I have no need for one at the moment.

Pt is extremely usefil as an electrode because it does not react. the problem is that it is freakisly expensive. One solution is to coat a thin layer

of Pt over a conducting substrate and then you have a functional substitute. This only works if coverage is complete. Bare patches or scratches

exposing the substrate will render the ekectrode useless.

Someone else will be along to tell you the best choice for substrate.

Likewise, Pt is peobably the mist versitile metallic catalyst there is. The normal goal is to have as high a surface area as possible. I can see

sputtering a thin layer as a very practical solution. Again, someone with actual experience wiil give guidance as to geometry and substrate

requirements.

|

|

|

battoussai114

Hazard to Others

Posts: 235

Registered: 18-2-2015

Member Is Offline

Mood: Not bad.... Not bad.

|

|

What I can think of:

-Transparent conductive layers... Although sol-gel deposition is probably a cheaper way to get it done.

-Deposition of Beryllium coatings for (near)IR mirrors.

-Dielectric Mirror/lenses/thingies .

-Deposition of catalytic layers (only ever heard of transition metal oxides). For instance TiO2 can be deposited by reactive sputtering of Ti metal in

a oxidizing atmosphere and and it has got some cool photocatalitic properties. Other works that come in mind are the Ni-Fe thin film catalysts for

water splitting and the Manganese Oxide catalysts for oxidation of organic compounds.

|

|

|

wish i had a kraken!!!

Hazard to Others

Posts: 157

Registered: 22-3-2012

Member Is Offline

Mood: No Mood

|

|

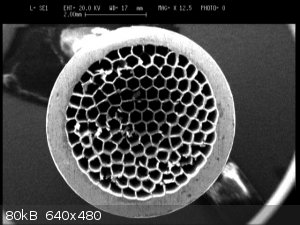

Dear j_sum1 , I have Ideas for Using Pd , Pt , etc .... I also tried to make a porous sample with the most possible surface area U can see it here :

but I don't think sputtering is good choice some conventional methods like electroplating works fine :-) , yet if U have deeper knowledge in this

field and know something that I am not aware of , I'd be happy if U share it with me (I mean maybe some metals cannot be electroplated and one has to

use another method ).

[Edited on 9-3-2015 by wish i had a kraken!!!]

|

|

|

j_sum1

Administrator

Posts: 6320

Registered: 4-10-2014

Location: At home

Member Is Offline

Mood: Most of the ducks are in a row

|

|

Again, I have no specialist knowledge of these things. But at the level I am working at, if I needed a catalyst and wasn't sure what would be an

appropriate choice then I would love to have some Pt sputtered onto a microscope slide.

Actually, that would be good for the element collection too.

|

|

|

TheIdeanator

Harmless

Posts: 29

Registered: 8-11-2015

Member Is Offline

Mood: No Mood

|

|

- Pt/Pd catalysts from vehicle catalytic converters is able to oxidize plenty of hydrocarbon compounds as well as hydrogen (that is pretty much the

extent of my awareness on the subject).

- First surface mirrors for lasers, telescopes, and other optics. Unless it is application critical, I doubt uniform thickness will matter

significantly.

- Coating organic or other specimens so it can go into an electron microscope

- Those "aura" type quartz crystals

- Surface preparation for electroplating

If you have enough equipment, particularly atmosphere control:

- Capacitors

- Novel batteries

- Rudimentary solar cells

- Chemical vapor deposition

- Make graphene and carbon nanotubes

- Vacuum/hydrogen brazing

- Custom ICs

I don't have any experience with any of this so I can't attest to the efficacy of any of these at the small scale. I do want to build a decent chamber

one day to do all of these things, but it will be a lot of work and expense. I already have a roughing pump and I have plenty of stuff to make an ion

pump with, now all I need is the rest of it.

Oh, and the "porous" nature of that catalyst you posted is more of a 'honeycomb' where the holes go straight through rather than something like an

open cell foam. It is that way for high flow rate applications like engine exhaust.

[Edited on 21-11-2015 by TheIdeanator]

|

|

|

Texium

|

Thread Moved

22-11-2023 at 19:55 |