nannah

Hazard to Others

Posts: 136

Registered: 20-12-2013

Member Is Offline

Mood: No Mood

|

|

Homemade fume extractor design.

Hi i have been thinking for a long time to make a fume hood myself out of plywood, but today i came to think about making a fume extractor that you

can just hover over the apoaratus, and then put away.

Im thinking some sort of arm, with a funnel type thing that sucks the fumes. Or maybe you can use pulleys to hold up the ventilation.

Any ideas?

Thanks in advance.

|

|

|

chemrox

International Hazard

Posts: 2961

Registered: 18-1-2007

Location: UTM

Member Is Offline

Mood: LaGrangian

|

|

Like a restaurant hood? I can see the attraction to have something minimallist that you could swing out of the way. Please allow me to suggest a

thought experiment: you wish to synthesize an aldehyde or perhaps you want to make a heterocyclic compound via the Strecker method. You have KCN and

mineral acids in close proximity... is the minimallist approach still the way you want to go?

"When you let the dumbasses vote you end up with populism followed by autocracy and getting back is a bitch." Plato (sort of)

|

|

|

bob800

Hazard to Others

Posts: 240

Registered: 28-7-2010

Member Is Offline

Mood: No Mood

|

|

It would likely work if the funnel were fixed directly on top of the beaker emitting fumes... yet anything requiring pouring of liquids, removal of

stoppers or glass joints, would require the funnel to be "raised" well above the containers to allow easy manipulation.

In the latter case you will catch only a fraction of emitted fumes, and if halogens/NOx were involved, the "fume extractor" will do nothing to prevent

potentially serious harm. If you are going to invest some time/money in a fume removal system, I would definitely recommend building an actual

fumehood instead.

At best the fume extractor will be severely limiting (won't work for anything other than a beaker fixed in place); at worst it will provide a false

sense of security if you think it can function as a real fumehood.

|

|

|

nannah

Hazard to Others

Posts: 136

Registered: 20-12-2013

Member Is Offline

Mood: No Mood

|

|

I was thinking about if you maybe could tie up the fan itself and adjust the height, up and down. And this fan sucks fumes directly through a home

made carbon scrubber before it exits my ventilation system. I dont know if this is a good idea, it was just a thought.

Im going to make fume hood but the plexi glass is so damn expensive. Can someone give an alternative?

|

|

|

careysub

International Hazard

Posts: 1339

Registered: 4-8-2014

Location: Coastal Sage Scrub Biome

Member Is Offline

Mood: Lowest quantum state

|

|

Quote: Originally posted by nannah  | I was thinking about if you maybe could tie up the fan itself and adjust the height, up and down. And this fan sucks fumes directly through a home

made carbon scrubber before it exits my ventilation system. I dont know if this is a good idea, it was just a thought.

Im going to make fume hood but the plexi glass is so damn expensive. Can someone give an alternative? |

Are you using the plexiglass (acrylic) just for the see-through front section above the work entrance? This would require just one piece roughly 3 ft

x 2 ft. I can get such a sheet locally (36 in. x 30 in. x .093 in. Acrylic Sheet) for $23.50. You blower will run much more than that (you want one

that delivers a 1-1.5 ft/sec in-draft through the work entrance). 0.093" acrylic is pretty thin and would require a sash-frame board across the bottom

for stiffness.

All the surfaces can be made of cheap board materials: plywood, hardboard, particle board, actual wood, or my favorite for cheap light-weight

construction - thin plywood glued to sheet insulating foam for a cheap stiff composite.

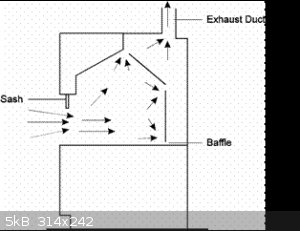

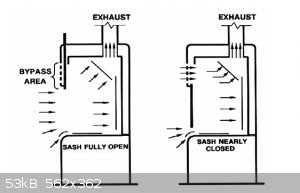

Here are a couple of images showing the preferred draft pattern in a fume hood. You can exhaust out the top or back, but you should have a back-baffle

sheet to force the air to go under and over. You don't really need a lot of clearance behind the baffle, a couple of inches - perhaps even less.

It might be possible to cleverly rig a fume hood that could be pulled up the rafters (if in a garage) with a pulley.

[Edited on 14-11-2014 by careysub]

|

|

|

nannah

Hazard to Others

Posts: 136

Registered: 20-12-2013

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by careysub  | Quote: Originally posted by nannah  | I was thinking about if you maybe could tie up the fan itself and adjust the height, up and down. And this fan sucks fumes directly through a home

made carbon scrubber before it exits my ventilation system. I dont know if this is a good idea, it was just a thought.

Im going to make fume hood but the plexi glass is so damn expensive. Can someone give an alternative? |

Are you using the plexiglass (acrylic) just for the see-through front section above the work entrance? This would require just one piece roughly 3 ft

x 2 ft. I can get such a sheet locally (36 in. x 30 in. x .093 in. Acrylic Sheet) for $23.50. You blower will run much more than that (you want one

that delivers a 1-1.5 ft/sec in-draft through the work entrance). 0.093" acrylic is pretty thin and would require a sash-frame board across the bottom

for stiffness.

All the surfaces can be made of cheap board materials: plywood, hardboard, particle board, actual wood, or my favorite for cheap light-weight

construction - thin plywood glued to sheet insulating foam for a cheap stiff composite.

Here are a couple of images showing the preferred draft pattern in a fume hood. You can exhaust out the top or back, but you should have a back-baffle

sheet to force the air to go under and over. You don't really need a lot of clearance behind the baffle, a couple of inches - perhaps even less.

It might be possible to cleverly rig a fume hood that could be pulled up the rafters (if in a garage) with a pulley.

[Edited on 14-11-2014 by careysub] |

Im going to check that out. I have been so hesitant buying plexiglass becouse i thought i would find it somewhere else for cheaper.

If i would go with a plywood fume hood, i am going for the dimentions 80-100 cm wide by 80 cm high, and about 2 foot depth.

The reason to why i havent built the hood yet is becouse that the plexi is so damn expensive.

|

|

|

Little_Ghost_again

National Hazard

Posts: 985

Registered: 16-9-2014

Member Is Offline

Mood: Baffled

|

|

How well will plywood put up with say conc sulphuric acid? Asking as I am interested, I stayed away from organic materials in the end and went for

glass/plexi glass, it cost much more but that depends how you add up the figures, if things go seriously nasty then it dosnt look so cheap to use

cheaper materials.

For example keep in mind so far I havnt played with much you would consider nasty.........

My front sash is double glazed, the front panel that is in effect the front inside the cupboard is glass, its glass because worst case scenario

something goes tits up and gets on it, then in theory at least little reacts with it, the panel behind that is the panel nearest me and is made of

plexi glass, so if something goes bang and the front glass breaks then hopefully the rear plexi glass will stop the glass shards getting to me.

Does it work?

NO IDEA! I decided not to actually test it yet, but its likely it will be tested at some point with my track record  . .

My dad gave some good advice a few months ago when I started, treat safety equipment like condoms, dont be cheap and always use them. one day you will

be pleased you did.

I still have trouble breathing with a condom on my head though

[Edited on 16-11-2014 by Little_Ghost_again]

|

|

|

Fulmen

International Hazard

Posts: 1718

Registered: 24-9-2005

Member Is Offline

Mood: Bored

|

|

The bench top should be made from a resilient material, the rest of the enclosure is less critical. Epoxy paint should provide some protection, and

it's easy to reapply if you get stains or holes. Maybe not the best or best looking solution, but "good enough" is usually far simpler and cheaper

than "perfect".

|

|

|

Metacelsus

International Hazard

Posts: 2539

Registered: 26-12-2012

Location: Boston, MA

Member Is Offline

Mood: Double, double, toil and trouble

|

|

Doesn't plywood use glue to hold the layers together? I think organic solvents would be bad for plywood.

|

|

|

Little_Ghost_again

National Hazard

Posts: 985

Registered: 16-9-2014

Member Is Offline

Mood: Baffled

|

|

I guess it all depends, if you know what your doing then accidents are limited, if your new or stupid (I belong to both groups) Then plywood probably

not the best idea.

I think thats why I am trying to make mine idiot proof. The thing is I am turning out to be a very clever idiot! Not the greatest combination

Dont ask me, I only know enough to be dangerous

|

|

|

careysub

International Hazard

Posts: 1339

Registered: 4-8-2014

Location: Coastal Sage Scrub Biome

Member Is Offline

Mood: Lowest quantum state

|

|

My suggestions for making a fume hood rely on the assumption that it is bottomless, and is placed on your actual work surface, which should be covered

with something like polyethylene.

For myself I am looking at 2 ft x 4 ft folding tables that have polymer top surfaces, many are available. Laboratories often use epoxy work surfaces.

I agree that epoxy paint is a good choice for plywood.

Breakdown of plywood adhesives should not be a concern, since there is no reasonable scenario in which the sides or roof of a hood gets significant

solvent exposure through its painted surface. It isn't being exposed to liquids, just to air-diluted fumes.

If you are doing regular org syn type experiments indoors then you should have a fume hood. Any (reasonably designed) fume hood is far better than

none. A rough-and-ready set up with cheap materials can do the job. You can consider it a prototype for a fancier future set-up.

If you are doing pyro type energetic material work, well, your needs are different and not addressed by a regular fume hood.

|

|

|

aga

Forum Drunkard

Posts: 7030

Registered: 25-3-2014

Member Is Offline

|

|

I made a glass work surface with a 10mm glass 'fence' all round it sealed with silicone bathroom sealant, and Hardboard (4mm) for the sides.

The hardboard is now stained, yet not dissolved in any way, despite a few explosive 'accidents' involving strong acids and bases.

The glass worktop and 'fence' form a tray in which all sorts of things have been spilled, and were contained perfectly well.

Nothing lasts forever, so it's a balance between Budget, Aesthetics, and effectiveness for your needs.

|

|

|

nannah

Hazard to Others

Posts: 136

Registered: 20-12-2013

Member Is Offline

Mood: No Mood

|

|

I am planning on lining the inside with stainless steel sheet metal.

I am thinking that it could be a good solution for me, becouse of its resistance, and that it is available to me.

Yes, sort of a prototype is what im planning to do now with this one.

But you guys advice me to go with a regular fume hood, and not a extractor.

I am just beginning with basic experiments, and simple reactions. So i wont do any grignards any time soon.

I am also thinking about making a lab stand, and i am thinking that i can use rebar vertically, and then lay rebar on top of the first, and attach

with wire, or maybe solder.

I think you guys have a good idea of what im picturing in my mind.

|

|

|

Praxichys

International Hazard

Posts: 1063

Registered: 31-7-2013

Location: Detroit, Michigan, USA

Member Is Offline

Mood: Coprecipitated

|

|

If you want a fume hood on the cheap, you can make a temporary one for like $15.

Make a frame from a 1/2" PVC pipe and stretch a heavy duty plastic painting tarp over it, secured with clear packaging tape. The pipe is like $5 for a

10-foot stick, the clear polyethylene sheeting is a few dollars, and the pipe fittings are 10 or 15 cents each.

Put a vacuum cleaner outside the house and run an appropriately-sized flex hose in through a window or something. Secure the hose somewhere inside the

hood.

It's far from permanent, but for basic stuff like ammonia, chlorine, chlorinated solvents, hydrazine, and smelly stuff, it will work just fine. Don't

use with flammable stuff unless you are sure the blower in your vacuum is out of the airstream. Also, if your blower motor IS in the airstream, make

sure you use a junk vacuum cleaner from a garage sale or something. I had an electric leaf blower/shredder on a dimmer that did a great job. It was

noisy though.

|

|

|