| Pages:

1

2

3 |

digga

Harmless

Posts: 43

Registered: 11-6-2018

Member Is Offline

|

|

A useful link for relating the percentage of Nitric Acid by weight from density and temperature:

http://www.handymath.com/cgi-bin/nitrictble2.cgi?submit=Entr...

|

|

|

Fulmen

International Hazard

Posts: 1719

Registered: 24-9-2005

Member Is Offline

Mood: Bored

|

|

I'm trying to make a bit of silver nitrate and have run into some odd behavior. The nitric acid was made from dilute H2SO4 (appr 10%) and an excess of

Ca(NO3)2, added in portions until no more CaSO4 precipitated. But when I add the 925 silver I get more white ppt. I filtered off the ppt and added

more Ca(NO3)2, no reaction. Added the silver again, and again I get more precipitate. What's happening?

We're not banging rocks together here. We know how to put a man back together.

|

|

|

fusso

International Hazard

Posts: 1922

Registered: 23-6-2017

Location: 4 ∥ universes ahead of you

Member Is Offline

|

|

Quote: Originally posted by Fulmen  | I'm trying to make a bit of silver nitrate and have run into some odd behavior. The nitric acid was made from dilute H2SO4 (appr 10%) and an excess of

Ca(NO3)2, added in portions until no more CaSO4 precipitated. But when I add the 925 silver I get more white ppt. I filtered off the ppt and added

more Ca(NO3)2, no reaction. Added the silver again, and again I get more precipitate. What's happening?

|

Is both H2SO4 and CN pure?

|

|

|

Fulmen

International Hazard

Posts: 1719

Registered: 24-9-2005

Member Is Offline

Mood: Bored

|

|

Battery acid and recrystallized fertilizer grade. So, not really but it shouldn't be THAT bad. The second/third batch of precipitate did discolor in

sunlight, but this disappeared after a wash with NH3.

We're not banging rocks together here. We know how to put a man back together.

|

|

|

Fulmen

International Hazard

Posts: 1719

Registered: 24-9-2005

Member Is Offline

Mood: Bored

|

|

I have to assume it's coming from the silver alloy somehow. Although the amount has subsided there is still some precipitate forming. It's a light,

white, almost waxy suspension that collects at the top layer. The main alloying component seems to be copper (blue-green tint that turns blue with

ammonia), but there could be other elements there as well.

We're not banging rocks together here. We know how to put a man back together.

|

|

|

Sulaiman

International Hazard

Posts: 3703

Registered: 8-2-2015

Location: 3rd rock from the sun

Member Is Offline

|

|

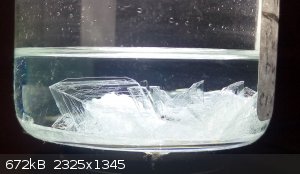

Sorry to make this thread even longer but I could not resist the temptation

I have a small batch of silver nitrate crystalising from nitric acid at the moment that has quite nice crystals growing that I want to show off

Scale: The liquid is 15mm deep

The large-looking crystal centre-left is only a fraction of a millimetre thick,

it has grown to look like like a feather.

During the writing of this the feathery crystal has 'melted' a little

presumably due to the heat of the led torch illuminating from below.

This batch is I think the third re-crystalisation of the same silver nitrate over a few years,

the original Ag surce was a 99.9% Silver Eagle,

I've been trying to eliminate the 0.1%

My current level of understanding is that photo-sensitivity is most commonly caused by organic contaminants,

so I'm going for purity and 'cleanliness'.

The 100ml beaker has a 90mm dia. filter paper covering it, sealed to the wall with tape.

This keeps out dust and slows down the evaporation rate.

CAUTION : Hobby Chemist, not Professional or even Amateur

|

|

|

j_sum1

|

Thread Pruned

22-12-2018 at 13:31 |

j_sum1

|

Thread Pruned

1-1-2019 at 12:56 |

clearly_not_atara

International Hazard

Posts: 2791

Registered: 3-11-2013

Member Is Offline

Mood: Big

|

|

silver pyroglutamate and succinimide

There continues to be no easily accessible alternative to nitric acid for the dissolution of silver. Oxamate is tedious to prepare and isolate;

lactate is too easily oxidized; sulfamate is rather disappointing; trifluoroacetate is not available; fluoride is dangerous; and alkanesulfonates

require a multi-step preparation via the alkyl halides.

Silver pyroglutamate, C5H6NO3Ag, forms white crystals which melt at 176-180, and are slowly colored by exposure to light; it is soluble in dilute

alcohol and in boiling water, but only sparingly soluble in cold water.

https://books.google.com/books?id=hes1AQAAMAAJ&pg=PA642&...

Amides are generally resistant to oxidation, but may be attacked by halogens. Pyroglutamate is sold as the magnesium salt or by itself as a dietary

supplement, or it may be prepared in good yield by heating glutamic acid to 180.

Silver pyroglutamate is also oxidized to succinimide by persulfate, but this depends on persulfate oxidizing Ag+ to Ag2+, which then undergoes a

Hunsdiecker-like reaction. In fact, the oxidation is catalytic in silver and provides excellent yields of succinimide from glutamate by aqueous

reaction, making it one of the better methods available for the preparation of succinimide:

https://pubs.rsc.org/en/Content/ArticleLanding/2014/RA/C4RA0...

|

|

|

halogenstruck1

Harmless

Posts: 10

Registered: 21-12-2018

Member Is Offline

|

|

you can buy silver nitrate AgNO3 at any amount from

www.givanchemi.com 30$ for 25g and 58$ for 50g

he sells to individuals and not only companies.

he sends from Canada to all countries and good quality. he also sells on Ebay with givan-chem profile. I bought and quality was perfect as also

mentioned on ebay reviews for his sales.

[Edited on 25-4-2019 by halogenstruck1]

|

|

|

Herr Haber

International Hazard

Posts: 1236

Registered: 29-1-2016

Member Is Offline

Mood: No Mood

|

|

After heating my reactor to get rid of most HNO3 (excess silver) I extracted part of the solution to drop out the silver.

Somehow in the process I slightly forgot about this thing called a solubility curve

So I got a big mass of silver nitrate. It was very tempting to filter it...

The spirit of adventure was upon me. Having nitric acid and copper, I had only to learn what the words 'act upon' meant. - Ira Remsen

|

|

|

morganbw

National Hazard

Posts: 561

Registered: 23-11-2014

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Herr Haber  | After heating my reactor to get rid of most HNO3 (excess silver) I extracted part of the solution to drop out the silver.

Somehow in the process I slightly forgot about this thing called a solubility curve

So I got a big mass of silver nitrate. It was very tempting to filter it...

|

Just a touch of what I consider beautiful, thank you sir.

|

|

|

YoctoByte

Harmless

Posts: 8

Registered: 8-9-2017

Member Is Offline

Mood: No Mood

|

|

I have some silver plated flatware from which I want to remove the silver metal. Using nitric acid works perfectly but I need a lot of it since it

also dissolves most of the base metal.

Nitric acid in high concentrations is not available where I live so I have to make it myself which takes a lot of time. Instead, I want to use

ammonium nitrate which is more easily available for me;

Ag + 2 NH4NO3 -> [Ag(NH3)2]NO3 + NO2 + H2O

Some catalytic nitric acid or maybe even sulfuric acid (is diamminesilver(I) sulfate soluble?) is needed to get the reaction going.

The diamminesilver(I) complex is stable under basic conditions (see Tollens' reagent) but is it also stable under acidic conditions? If it is not than

the acid would be neutralised during the reaction;

[Ag(NH3)2]NO3 + 2 HNO3 -> AgNO3 + 2 NH4NO3

I would try this right now if I could but I'm not at home this week..

|

|

|

Herr Haber

International Hazard

Posts: 1236

Registered: 29-1-2016

Member Is Offline

Mood: No Mood

|

|

For plated silver HNO3 is very very wasteful.

You're better off with electrolysis and scraping / flaking as much of the silver as possible. Then you can process the mess at the bottom of your cell

in the way you want.

The spirit of adventure was upon me. Having nitric acid and copper, I had only to learn what the words 'act upon' meant. - Ira Remsen

|

|

|

clearly_not_atara

International Hazard

Posts: 2791

Registered: 3-11-2013

Member Is Offline

Mood: Big

|

|

I would hope you don't try it at all, it might not work or it might make a loud noise and get broken glass everywhere.

|

|

|

YoctoByte

Harmless

Posts: 8

Registered: 8-9-2017

Member Is Offline

Mood: No Mood

|

|

Thanks! I'll try electrolysis then.

Another method I just thought of is to dissolve most of the silver layer with nitric acid until some of the base metal is exposed. In my experience

about 70-80 percent of the silver is recoverable this way. And then dissolve the base metal in hydrochloric or sulfuric acid to collect the remaining

silver. These acids are a lot easier to buy than nitric acid.

To answer my previous question (Is the diamminesilver complex stable under acidic conditions) source (woelen.homescience.net):

| Quote: | | "Never allow alkaline solutions of silver (I) compounds with ammonia to stand for more than one hour. If there is some silver waste in the form of

such solutions, add excess acid to them, in order to neutralize the ammonia. With ammonium ion, such complexes are not formed."

|

So I guess ammonium nitrate is useless.

I would immediately add copper scrap to reduce the silver ions back to silver metal after the silver is dissolved. That way there is no time to form

explosive silver compounds, right?

|

|

|

clearly_not_atara

International Hazard

Posts: 2791

Registered: 3-11-2013

Member Is Offline

Mood: Big

|

|

My suggestion would just be to cut the silverware in half, dissolve the whole mess in hydrochloric acid and filter off the unreacted silver.

Do not attempt to use ammonium nitrate to corrode transition metals, period. Concentrated solutions of ammonium nitrate can explode, and transition

metals catalyze the reaction. See:

https://pubs.acs.org/doi/pdf/10.1021/ja01040a011

There's just no good reason for there to be a risk of explosion here. There are plenty of non-blowy-uppy ways of doing this.

|

|

|

Herr Haber

International Hazard

Posts: 1236

Registered: 29-1-2016

Member Is Offline

Mood: No Mood

|

|

I tried that.

Lots of HCL & big volumes of waste for very little silver in the end.

The truth is that most cases the silver layer is so thin you'll get mud with silver in it. Rarely will you be able to scrape off shards of silver.

In any case, I dont recommend dissolving all the base metals.

You just have to admit it'll be a wasteful process and decide if you can let go of a little silver or use lots of acid and time to separate

everything.

I have 8 or 9 kilograms of plated crap in a box. I'll have to get rid of it someday in one of those gold & silver places because there's simply no

way I'll be processing this. Too messy.

The spirit of adventure was upon me. Having nitric acid and copper, I had only to learn what the words 'act upon' meant. - Ira Remsen

|

|

|

YoctoByte

Harmless

Posts: 8

Registered: 8-9-2017

Member Is Offline

Mood: No Mood

|

|

Coincidentally I found an interesting procedure for selectively removing silver plate in a book about electroplating this week.

Add 19 parts by volume concentrated sulfuric acid to 1 part 68% nitric acid and heat up to 80 °C. Then add the silver plated objects. The silver is

removed within minutes and the copper alloy base metal is not attacked at all. When the nitric acid is almost depleted you can add some more.

The solution becomes slightly yellow/green and the produced silver salt almost completely dissolves. Some traces of white powder (probably silver

sulfate) still coat the base metal so you can wash the metal objects in a beak of water. Then add sodium chloride to the water collect the silver

chloride.

By far the most silver seems to collect in the sulfuric acid though. You can precipitate this by adding some hydrochloric acid DROPWISE! (I wouldn't

want to use NaCl because that contaminates the acid with sodium ions). A violent reaction happens and hydrogen chloride gas is evolved and a white

precipitate is formed (AgCl). The sulfuric acid is very viscous so wait at least a day to let the silver chloride sink to the bottom. The sulfuric

acid is decanted and is still a bit cloudy and could probably be used for a next run. The silver chloride at the bottom is washed with water and

collected.

This procedure is probably only useful if you have concentrated sulfuric acid to spare and a lot of silver to process but hopefully someone finds it

useful!

|

|

|

clearly_not_atara

International Hazard

Posts: 2791

Registered: 3-11-2013

Member Is Offline

Mood: Big

|

|

Quote: Originally posted by Herr Haber  |

I have 8 or 9 kilograms of plated crap in a box. I'll have to get rid of it someday in one of those gold & silver places because there's simply no

way I'll be processing this. Too messy.

|

Suppose you had methanesulfonic or trifluoroacetic or pyroglutamic or other silver-dissolving redox-stable (not perchloric/nitric) acid. (I don't know

about HF, but we're all afraid of it, anyway.)

Digest your silver-plated stuff with aqueous acid+H2O2, continuing just until all of the silver coating is removed. The base metals probably

react faster than the silver but the silver should still react, I think?

Then you can just apply a small voltage which should selectively reduce Ag+ over any other ion. Ideally (although no guarantee) most of the base metal

remains untouched and is removed mechanically.

Took me a long time, but saving that silver seems like an interesting problem.

|

|

|

Monoamine

Hazard to Others

Posts: 168

Registered: 25-5-2021

Location: Sweden(ish)

Member Is Offline

Mood: +7

|

|

Guess what happens when you spill silver nitrate on your hand?

This:

(An effect already discovered by Albertus Magnus in the 13th century).

But it also makes lovely crystals and is very easily crystallized from water:

[Edited on 16-12-2021 by Monoamine]

|

|

|

Sulaiman

International Hazard

Posts: 3703

Registered: 8-2-2015

Location: 3rd rock from the sun

Member Is Offline

|

|

or more specifically, when you spill silver nitrate on your hand

then expose it to sunlight before washing with sodium thiosulphate solution, or similar.

CAUTION : Hobby Chemist, not Professional or even Amateur

|

|

|

Monoamine

Hazard to Others

Posts: 168

Registered: 25-5-2021

Location: Sweden(ish)

Member Is Offline

Mood: +7

|

|

or more specifically, when you spill silver nitrate on your hand

then expose it to sunlight before washing with sodium thiosulphate solution, or similar.[/rquote]

Yes, I only notice a few hours later... And thanks for the sodium thiosulfate tip! (Although I hope I won't need it XD)

|

|

|

yobbo II

National Hazard

Posts: 764

Registered: 28-3-2016

Member Is Offline

Mood: No Mood

|

|

Patent on making Nitric acid from AN and sulphuric. GB129305A

The secret is to pull some vacuum on the set up to stop decomposition. About 25mm is recommended.

Attachment: ocr-description.html (9kB)

This file has been downloaded 471 times

|

|

|

Colleen Ortiz

Harmless

Posts: 19

Registered: 16-12-2021

Member Is Offline

|

|

Re: Nitric Acid and Silver Nitrate

Hello,

Preparing Silver nitrate using nitric acid is extremely easy.

Many tests, such as halide detection, halogen precipitation, mirror silvering, and metal displacement, need silver nitrate. Purchasing silver nitrate

might be costly, but you can produce your own for a fraction of the cost by dissolving silver in nitric acid at home. Because the reaction produces

toxic vapors, you must proceed with caution and use the appropriate safety equipment. The chemicals used in this procedure are extremely dangerous

and, if not handled appropriately, can result in harm. To stay safe, you'll need eye protection, gloves, and a lab coat. To prevent floor spills, wear

long trousers and closed-toe shoes, preferably without mesh. The fumes generated during the production of silver nitrate are exceedingly poisonous and

can be fatal if inhaled directly. Working under a chemical fume hood is preferable, but if you don't have one, operate outside in a well-ventilated

environment. If you're working in your garage, make sure the door and all windows are open. The resulting crystals are pure silver nitrate and should

be kept away from light in an airtight container.

|

|

|

| Pages:

1

2

3 |