MMendoza14

Harmless

Posts: 2

Registered: 26-6-2012

Location: State College, PA

Member Is Offline

Mood: Excited!

|

|

Iron (III) Sulfate (ferric sulfate) synthesis

Hey everyone! I'm having troubles producing iron sulfate... I must start with ferric oxide and use sulfuric acid to produce iron sulfate but ive been

having some problems... Ive tried using 0.1 M and 1 M sulfuric acid and I'm thinking about making the jump up to 5 M in hope of getting better

results. So far I've produced some tannish colored solid on top of unused hematite, even when I'm using proper stoichiometry given the sulfuric acid

concentrations. I've tried ranges of starting material from 0.5 g all the way to 2 grams without much success... After I react the two together I put

the solutions into the oven at 120 C for however long it takes for the liquid water to be removed. Whenever I test the pH of the supernatant I find

that its always very low, implying to me that the sulfuric acid has not reacted very much. There's also the problem of ferric sulfate being soluble in

water which makes removal of the acid kind of difficult... I hope one of you guys can help!! Thank you!!

|

|

|

Hexavalent

International Hazard

Posts: 1564

Registered: 29-12-2011

Location: Wales, UK

Member Is Offline

Mood: Pericyclic

|

|

'I must start with ferric oxide' - is this a school project, or an amateur thing? How flexible are the rules?

Do you stir well when you add? How pure is the iron (III) oxide? What form is it in - granules, powder etc.?

Have you tried adding it to hot sulfuric acid?

[Edited on 26-6-2012 by Hexavalent]

"Success is going from failure to failure without loss of enthusiasm." Winston Churchill

|

|

|

kristofvagyok

National Hazard

Posts: 659

Registered: 6-4-2012

Location: Europe

Member Is Offline

Mood: No Mood

|

|

Use a bit more concentrated sulfuric acid, 1M acid is not even good for washing my hands if it get's dirty in the lab....

5-8M acid will do it, esperially if you heat it. Or just add some H2O2, it will do the rest(:

[Edited on 26-6-2012 by kristofvagyok]

I have a blog where I post my pictures from my work: http://labphoto.tumblr.com/

-Pictures from chemistry, check it out(:

"You can’t become a chemist and expect to live forever." |

|

|

Poppy

Hazard to Others

Posts: 294

Registered: 3-11-2011

Member Is Offline

Mood: † chemical zombie

|

|

Thats explains a lot why! Iron III is such a very insoluble thing to work with!

|

|

|

Waffles SS

Fighter

Posts: 998

Registered: 7-12-2009

Member Is Offline

|

|

I have experience about Iron Components, Iron(III)Oxide is really stable and Nitric acid and Sulfuric cant dissolve it(just Hot Hcl can do it)

(see below topic about Ferric Nitrate)

http://www.sciencemadness.org/talk/viewthread.php?tid=17161#...

You can easily react Iron wool or Powder with warm %50 Sulfuric acid (this make Iron(II)Sulfate) and then add Hydrogen Peroxide(or nitric acid or even

chlorine gas) for oxidation Fe2+ to Fe3+

Fe + H2SO4 → FeSO4 + H2

6 FeSO4 + 3 H2SO4 + 2 HNO3 → 3 Fe2(SO4)3 + 4 H2O + 2 NO(beware of mother fu...ker NO and NO2 gas)

or

6 FeSO4 + 3 Cl2 → 2 Fe2(SO4)3 + 2 FeCl3

or

12 FeSO4 + 3 O2 → 4 Fe2(SO4)3 + 2 Fe2O3

I advise first reaction because by Hydrogen peroxide or air oxygen as oxidation agent you will get Iron(III)Oxide too and this is hard to get rid of

it.

[Edited on 27-6-2012 by Waffles SS]

|

|

|

woelen

Super Administrator

Posts: 8016

Registered: 20-8-2005

Location: Netherlands

Member Is Offline

Mood: interested

|

|

Commercially available red/brown ferric oxide (Fe2O3) is amazingly inert and the same is true for the black oxide Fe3O4. I have both oxides from a

pottery supplier and they do not dissolve appreciably, not even in hot 50% H2SO4 or boiling HNO3. It does dissolve in hot concentrated HCl, but only

very slowly and a very large excess amount of acid is needed to get all of it dissolved. The solution in HCl becomes bright yellow, due to formation

of the FeCl4(-) complex.

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by woelen  | | Commercially available red/brown ferric oxide (Fe2O3) is amazingly inert and the same is true for the black oxide Fe3O4. I have both oxides from a

pottery supplier and they do not dissolve appreciably, not even in hot 50% H2SO4 or boiling HNO3. It does dissolve in hot concentrated HCl, but only

very slowly and a very large excess amount of acid is needed to get all of it dissolved. The solution in HCl becomes bright yellow, due to formation

of the FeCl4(-) complex. |

Yep. My experience too. Try fusing with Na or K bisulphate...

|

|

|

MMendoza14

Harmless

Posts: 2

Registered: 26-6-2012

Location: State College, PA

Member Is Offline

Mood: Excited!

|

|

Quote: Originally posted by Hexavalent  | 'I must start with ferric oxide' - is this a school project, or an amateur thing? How flexible are the rules?

Do you stir well when you add? How pure is the iron (III) oxide? What form is it in - granules, powder etc.?

Have you tried adding it to hot sulfuric acid?

[Edited on 26-6-2012 by Hexavalent] |

I suppose I should have been more specific with my intentions... I'm attempting to model the process of sulfur species as a pollutant and then

ultimately sulfuric acid and their effects on mineral dust in the atmosphere. Ferric Oxide (hematite) is a common mineral dust particle. I am using

99% pure hematite powder. Due to the attempt to model actual atmospheric conditions I'm already stretching a little bit using 1M as the pH never

really reaches that low with a minimum usually around 3-4. Many of my experiments have shown that hematite does seem to be inert, but a reaction seems

to occur after I put the solutions in the oven to dissolve the excess water. Before the oven there's the same red color and clear acid and after the

oven theres a brownish solid leftover implying heat may cause the reaction to proceed but the product is unidentifable using ATR and XRD so far.

|

|

|

RU_KLO

Hazard to Others

Posts: 216

Registered: 12-10-2022

Location: Argentina

Member Is Offline

|

|

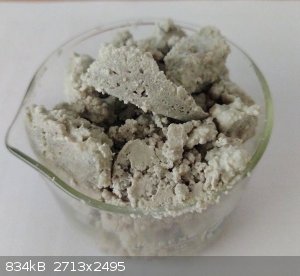

As I got some FeSO4 which was turning orange, decided to transform it to Fe2(SO4)3.

So I dissolved it in H2SO4 (35%), aprox 100ml, filtered the excess FeSO4 (some cristals did not dissolved - not much, I would say less than 5% from

staring material) heated and added 30% H2O2 by drops.

The upper part became orange. Once I added aprox 50 ml H2O2, reomoved from heating. Solution became almost black and some yellow precipitate appeared

(very small quantity) - I think this is Fe2(SO4)3 - filtered it and left the solution one day. No more precipitate.

Next day added 100 ml more of H2SO4 (35%) and heated to reduce the volume of solution (from 250ml to 100ml). during the evaporation, I added 30ml more

of 30% H2O2 by drops. One each drop, yellow bubbles appeared, and some tiny drops (mist), which deposited on the hotplate became yellow.

(on cleanning with a damped cloth, it became rust orange)

Once it cooled, all became a gray mass - NO YELLOW.....

So is this Fe2(SO4)3 or something else..... Thanks

Go SAFE, because stupidity and bad Luck exist.

|

|

|

RU_KLO

Hazard to Others

Posts: 216

Registered: 12-10-2022

Location: Argentina

Member Is Offline

|

|

on this webpage it shows that Ferric Sulfate is light gray, not yellow

(https://www.chemkits.eu/salts/143-ironiii-sulfate-hydrate-fe...)

So which color is right for ferric sulfate? (maybe anhydrous is yellow and xH2O is gray....)

Go SAFE, because stupidity and bad Luck exist.

|

|

|

RU_KLO

Hazard to Others

Posts: 216

Registered: 12-10-2022

Location: Argentina

Member Is Offline

|

|

sorry for 3 post in a row, but this is mine:

Go SAFE, because stupidity and bad Luck exist.

|

|

|

Bedlasky

International Hazard

Posts: 1240

Registered: 15-4-2019

Location: Period 5, group 6

Member Is Offline

Mood: Volatile

|

|

It's still probably contaminated with Fe(II). I made some ammonium ferric sulfate from old FeSO4, H2SO4 and H2O2 years ago. When concentration of

Fe(III) got high, it catalyticaly decomposed H2O2 pretty quickly, I added it slowly with stirring, but when I crystallize the product, ammonium

ferrous sulfate start to crystallize first. Good thing is, that ammonium ferric sulfate is very soluble, while ammonium ferrous sulfate have low

solubility. So I separated them by fractional crystallization. There wasn't very much of ammonium ferrous sulfate, but I still got few grams of this

salt. So my recommendation is, make ammonium ferric sulfate from your ferric sulfate. It crystallize nicely (you can make big beautiful violet

octahedral crystals if you want) and can be easily separated from any ferrous contamination.

|

|

|

Admagistr

Hazard to Others

Posts: 365

Registered: 4-11-2021

Location: Central Europe

Member Is Offline

Mood: The dreaming alchemist

|

|

I would not use Fe2O3 as a starting material for the preparation of Fe salts from aqueous acid solutions, it has a corundum structure. And corundum is

insoluble in acids! Melting with KHSO4 is effective for corundum, so this would also be true for converting Fe2O3 to an aqueous solution. You can

prepare KFe(SO4)2.12H2O this way and use it in aqueous chemistry as an Fe3+ salt without any problem.

|

|

|

RU_KLO

Hazard to Others

Posts: 216

Registered: 12-10-2022

Location: Argentina

Member Is Offline

|

|

Quote: Originally posted by Bedlasky  | | It's still probably contaminated with Fe(II). I made some ammonium ferric sulfate from old FeSO4, H2SO4 and H2O2 years ago. When concentration of

Fe(III) got high, it catalyticaly decomposed H2O2 pretty quickly, I added it slowly with stirring, but when I crystallize the product, ammonium

ferrous sulfate start to crystallize first. Good thing is, that ammonium ferric sulfate is very soluble, while ammonium ferrous sulfate have low

solubility. So I separated them by fractional crystallization. There wasn't very much of ammonium ferrous sulfate, but I still got few grams of this

salt. So my recommendation is, make ammonium ferric sulfate from your ferric sulfate. It crystallize nicely (you can make big beautiful violet

octahedral crystals if you want) and can be easily separated from any ferrous contamination. |

How do you make it? add ammonia? ( from web : A solution of Iron (III) sulfate reacts with ammonia (NH3) gas and water to form Iron (III) hydroxide

and ammonium sulfate. - not ammonium ferric sulfate.

Go SAFE, because stupidity and bad Luck exist.

|

|

|

Bedlasky

International Hazard

Posts: 1240

Registered: 15-4-2019

Location: Period 5, group 6

Member Is Offline

Mood: Volatile

|

|

Just add ammonium sulfate. Or equivalent amount of sulfuric acid and ammonia.

|

|

|

KoiosPhoebus

Hazard to Self

Posts: 53

Registered: 23-1-2023

Member Is Offline

|

|

Quote: Originally posted by woelen  | | Commercially available red/brown ferric oxide (Fe2O3) is amazingly inert and the same is true for the black oxide Fe3O4. I have both oxides from a

pottery supplier and they do not dissolve appreciably, not even in hot 50% H2SO4 or boiling HNO3. It does dissolve in hot concentrated HCl, but only

very slowly and a very large excess amount of acid is needed to get all of it dissolved. The solution in HCl becomes bright yellow, due to formation

of the FeCl4(-) complex. |

The kind of ferric oxide sold commercially tends to be calcined to remove any

water. As I understand it, calcination also alters the morphology of the oxide and makes it difficult to react with most compounds. Which makes me

wonder if yellow iron oxide (sometimes called ferric hydroxide, though it would more accurately described as hydrated ferric oxide) would react with

acids? I've never bought any myself as the stuff at my local suppliers is described as being "natural" which probably means there's a pile of junk in

there.

Quote: Originally posted by MMendoza14  | | I suppose I should have been more specific with my intentions... I'm attempting to model the process of sulfur species as a pollutant and then

ultimately sulfuric acid and their effects on mineral dust in the atmosphere. Ferric Oxide (hematite) is a common mineral dust particle. I am using

99% pure hematite powder. Due to the attempt to model actual atmospheric conditions I'm already stretching a little bit using 1M as the pH never

really reaches that low with a minimum usually around 3-4. Many of my experiments have shown that hematite does seem to be inert, but a reaction seems

to occur after I put the solutions in the oven to dissolve the excess water. Before the oven there's the same red color and clear acid and after the

oven theres a brownish solid leftover implying heat may cause the reaction to proceed but the product is unidentifable using ATR and XRD so far.

|

The problem is that I'm not sure if the laboratory grade hematite (or most

commercially-available hematite) is a good model for naturally-occurring hematite dust. Wikipedia lists four different crystal structures for ferric

oxide (rhombohedral, cubic bixbyite, cubic spinel, orthorhombic) and it may well be that one of these structures is more reactive to acids than the

others, similar to how crystalline silica does not react with aqueous alkali hydroxide solutions but amorphous silica is moderately reactive.

The brown colour can be due to a variety of things. Personally, I've found that the iron(III) oxide I try making tends to cycle between being black at

very high temperatures and red at room temperature, similar to NurdRage's video (https://www.youtube.com/watch?v=8ZQ67POLiqg). I have no idea why this occurs, but depending on the temperature in your oven, it might be the case

that it's somewhere between those two states. Alternatively, it could also indicate the formation of some form of hydrated iron(III) oxide such as

iron(III) oxide-hydroxide, which can be brown in certain polymorphs such as the beta form. Iron(III) oxides have many differing degrees of hydration

and polymorphs, so it's difficult to be sure that what you have is the result of a reaction between the iron(III) oxide and the sulphuric acid.

I'd suggest placing the brownish sample into water and stir it to see if you can dissolve anything, then filter it off. If there was any sort of

reaction, you'd get a clear orange-ish solution in the filtrate; otherwise it'd be practically colourless. Note, if your solution is cloudy or

otherwise unclear, some particles have gotten through the filter and you need to use a finer filter. Alternatively, you can centrifuge a sample of the

solution (or just leave it out to settle) to see if the supernatant is coloured or colourless.

In the environment you're trying to model, I wonder if there's also any effect from microbiology? As I understand it, there are several

sulphur-oxidising bacteria which utilise the reduced sulphur species as a food source and can form sulphuric acid as their end-product. Such microbes

would be able to live on hematite dust particles and would probably have developed strategies for mining iron out of such minerals (the

strongest-known iron chelator, enterobactin, is a siderophore secreted by Gram-negative bacteria to acquire iron), or to otherwise alter their

environment. Microbial activity could ostensibly increase the surface area of the hematite particles and increase their dissolution by sulphuric acid.

Regarding the synthesis of iron(III) sulphate in general: in my experience

oxidation with hydrogen peroxide will often be incomplete even if you add an excess of H2O2. Sometimes this is because the

hydrogen peroxide is not as concentrated as stated on the label, but more often, the H2O2 decomposes to H2O and

O2 before it oxidises the iron (observable as effervescence upon addition of the hydrogen peroxide).

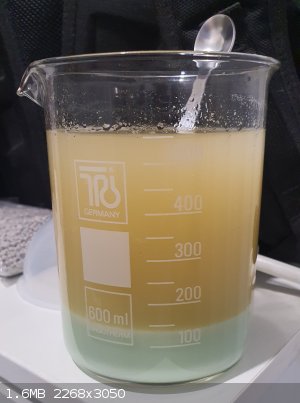

Interestingly, hydrated ferric sulphate is actually somewhat soluble in ethanol while ferrous sulphate is practically impossible. I've been exploiting

this property to purify my samples of impure ferrous sulphate by dissolving it into a solution acidified with a small amount of HCl, filtering off

undissolved ferric oxides and basic ferric sulphate (Fe(OH)SO4), and then adding about 1.2x the volume of ethanol to precipitate the

ferrous sulphate (e.g. if I had a 200mL solution, I'd add ~240mL ethanol).

Any iron oxides which react with the hydrochloric acid would form either ferrous or ferric chloride, both of which are highly soluble in ethanol.

Ferric sulphate nonahydrate has a solubility of 12.7g/100g ethanol and 440g/100g water, so it can remain quite soluble in the aqueous ethanol solution. Ferrous sulphate

heptahydrate has practically no solubility in ethanol solutions and precipitates out as a blue-green mass:

The ferrous sulphate can then be filtered off and washed with ethanol and dried. The reason I bring this up is because the aqueous ethanol filtrate

presumably contains ferric sulphate with some oxide/hydroxide contamination, which could later be removed by recrystallising from water. Usually, I

neutralise the filtrate and dispose of it, but it might be possible to use the same method to isolate iron(III) sulphate specifically from a mixture

of partially-oxidised ferrous/ferric sulphate (although I think you'd need to swap out the HCl for sulphuric acid so you don't get ferric chloride

contamination). Methanol might also be a good alternative to ethanol as ferric sulphate is presumably even more soluble in aqueous methanol, although

I don't know how much ferrous sulphate might remain dissolved in such a mixture.

|

|

|