4-Stroke

Hazard to Self

Posts: 60

Registered: 20-4-2024

Location: Canada

Member Is Offline

Mood: Often Wrong, Never Unsure

|

|

Continuous Powder Feeder

Hello everyone. I was wondering how one could make a system that constantly inputs a powder into a reaction flask. Let's assume that one already has a

system (an auger/conveyor) that can move a powder at a defined rate. But, how can the powder be put inside the flask? Can something like this (https://www.directindustry.com/prod/lambda-laboratory-instru...) be improvised?

Because if there is just simply a funnel connected in one of the flask inputs, the fumes of whatever is being distilled will escape out that exit

instead of going in the condenser. The powder could also clump up and get stuck and just overflow out of the funnel.

The funnel could be put on tup of a separate condenser to remove the fumes that escape, but this would create a reflux (which can decompose some

compounds) and the condenser can still clog up and the powder would still overflow and spill.

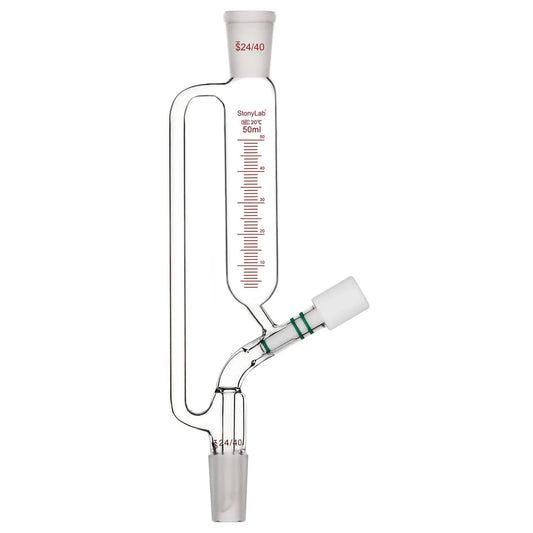

Something like this would be perfect, IF it could be made automatic (electric) instead of having to be spun manually.

Any ideas?

|

|

|

Rainwater

National Hazard

Posts: 987

Registered: 22-12-2021

Member Is Offline

Mood: Break'n glass & kick'n a's

|

|

Short answer - A bigger hole, which the powder will not contact anything but the solution/solvent.

If vapor/gases are an issue, purging them before opening the reactor.

Usually an automated system will be on a much larger scale.

My perfered method is to create a solution of known concentration and deliver that. Its much easier to measure and transport.

If it must be a powder, the exact specifications need to be properly defined in order to design a low maintenance system. For example, baking bread.

We have to mix an explosive powder, with a corrosive powder, then into a parashable solvent.

It is undesirable to simply dump the correct amounts into a mixer and start stirring. The results will not be the well mixed recipe required.

But instead measure out and shift together, in roughly the correct proportions, then add to the solution.

"You can't do that" - challenge accepted

|

|

|

Sulaiman

International Hazard

Posts: 3779

Registered: 8-2-2015

Member Is Offline

|

|

There are a few threads here on SM with similar questions and some discussions,

at least one member made a working prototype,

but the consensus seems to be that it is not a trivial task.

Adding a liquid/solution is the preferred approach.

For most of us a batch method starting with solids in the rbf and adding liquid slowly is the norm.

What sort of scale / addition rate are you considering?

CAUTION : Hobby Chemist, not Professional or even Amateur

|

|

|

Lambda-Eyde

National Hazard

Posts: 860

Registered: 20-11-2008

Location: Norway

Member Is Offline

Mood: Cleaved

|

|

What's stopping you from getting one of these: https://us.vwr.com/store/product/11717091/24-40-powder-dispe...

...and slapping a motor with an axle and a suitable controller on it? Apart from these things being terribly expensive and rare to find used.

This just in: 95,5 % of the world population lives outside the USA

Please drop by our IRC channel: #sciencemadness @ irc.efnet.org

|

|

|

BromicAcid

International Hazard

Posts: 3266

Registered: 13-7-2003

Location: Wisconsin

Member Is Offline

Mood: Rock n' Roll

|

|

Powder funnels can be useful. I hardly use them though in practice, so often the solids are somewhat soluble in the case of adding a reactant and

become dewy and clumpy - or just the refluxing solvent works its way up there and makes them clumpy even when they don't dissolve at all. They can be

pretty slick though when they do work.

|

|

|

4-Stroke

Hazard to Self

Posts: 60

Registered: 20-4-2024

Location: Canada

Member Is Offline

Mood: Often Wrong, Never Unsure

|

|

Air isn't an issue, I meant the vapors that escape out the hole if a distillation is taking place simultaneously.

Quote: Originally posted by Rainwater  | Usually an automated system will be on a much larger scale.

My perfered method is to create a solution of known concentration and deliver that. Its much easier to measure and transport. |

Yes, but the problem is that some powders are insoluble (or very poorly soluble) in any solvents, or the solvents can react with whatever the powder

is being added to.

Quote: Originally posted by Sulaiman  | There are a few threads here on SM with similar questions and some discussions,

at least one member made a working prototype |

I searched for everything related I could find, but I didn't see anyone making a working prototype. Do you mind sharing it?

Yes, but that is not always possible.

Yeah, that's why I usually do as well. But I am just trying to make a fully automatic continuous reactor, so that's why this is the problem for me

now. Adding liquids is easy (e.g. pump), but solids are much harder.

No idea yet, but let's say approximately 10kg/h.

It's that they're terribly expensive and rare to find used

And also, as Bromic Acid said, they don't actually always work like they are supposed to. Also I don't think that they can be used with granulated

powders.

Ukrainium

|

|

|

VincenzoTheGreat

Harmless

Posts: 6

Registered: 4-3-2019

Member Is Offline

|

|

did you try Alibaba?

https://www.alibaba.com/product-detail/Tiandi-Lab-250ml-Boro...

min. order of 5 @ $80USD a piece though

edit: I just bought a single unit (as a sample) for $110 USD. I'll let you know if they're any good or not.

As for handling the mass quantities you describe the unit has a ground glass inlet at the top which could accomodate a larger vessel containing the

bulk powder you wish to add. Maybe one of those column chromatography reservoirs would be ideal.

Regarding automation, I think the main challenge is fitting a DC motor to the PTFE auger and making sure it's flush. Controlling the motor is a

trivial exercise and documented ad nauseum elsewhere. I'm similarly motivated to you so the DC motor/automation angle is something I'd like to

investigate.

A much cheaper proof-of-concept could be rigged up with an overhead stirrer, 24/40 glass addition funnel, and a plastic screw that sits flush with the

walls of the funnel bottom. The design would mimic a regular industrial auger filler. I think that would be much more economical for us amateurs to

rig up something like that because all the parts are readily available.

And one more thing regarding addition. I saw wetting mentioned in a flow chemistry article about powder addition. The powder in question was wetted

10%, making a slurry, allowing for more even and controlled addition. Depending on the wetting solvent in question this might also act as a protective

barrier against solvent vapour which may react with the powder being added e.g. NaBH4 wetted by toluene entering a vigorously stirred solution of

MeOH.

[Edited on 13-11-2024 by VincenzoTheGreat]

|

|

|

4-Stroke

Hazard to Self

Posts: 60

Registered: 20-4-2024

Location: Canada

Member Is Offline

Mood: Often Wrong, Never Unsure

|

|

Yeah, I saw that before. Sometimes you might even be able to get free samples (or even if not free, you at least don't have to order 5 pieces). The

shipping is expensive though. I am trying to order a 1kg sample of something, and the shipping for it is over $100!  . And they apparently cannot ship it by sea because it is a "white powder"! Like is

it so hard to tell apart from cocaine? I think that they ship the bulk orders by sea, so why can't my sample also be shipped by sea? . And they apparently cannot ship it by sea because it is a "white powder"! Like is

it so hard to tell apart from cocaine? I think that they ship the bulk orders by sea, so why can't my sample also be shipped by sea?

Ukrainium

|

|

|

VincenzoTheGreat

Harmless

Posts: 6

Registered: 4-3-2019

Member Is Offline

|

|

without derailing the original topic, is it viable to make a slurry and continuously feed that into the system via a peristaltic pump?

|

|

|

4-Stroke

Hazard to Self

Posts: 60

Registered: 20-4-2024

Location: Canada

Member Is Offline

Mood: Often Wrong, Never Unsure

|

|

Ah, that's nice. Yeah when it arrives, let me know how well it works. How much did the shipping cost?

Quote: Originally posted by VincenzoTheGreat  | | As for handling the mass quantities you describe the unit has a ground glass inlet at the top which could accomodate a larger vessel containing the

bulk powder you wish to add. Maybe one of those column chromatography reservoirs would be ideal. |

Yeah, most likely. If the powder is dry and granulated (not finely ground) make just a very big funnel could be used and filled with the powder which

would ensure that the addition funnel is constantly full. The funnel would probably have to be supported, however, as it's probably going to be very

heavy.

Quote: Originally posted by VincenzoTheGreat  | | Regarding automation, I think the main challenge is fitting a DC motor to the PTFE auger and making sure it's flush. Controlling the motor is a

trivial exercise and documented ad nauseum elsewhere. I'm similarly motivated to you so the DC motor/automation angle is something I'd like to

investigate. |

I've got a 3D printed, so maybe it could be somehow attached to a 3D printed bracket that would be glued or clamped (with screws) around the funnel.

But connecting it to the PTFE is probably going to be harder, as it's virtually impossible to glue anything to it. But that might not even be

necessary if the shape is correct so that it could just be "inserted" into another 3D printed part.

An ESP32 is ~$6 on AliExpress, and that's pretty much the only thing needed to automate the motor. It could probably all be done for under $10. But

automation might not even be necessary if the powder is just added at the correct predefined constant rate.

Quote: Originally posted by VincenzoTheGreat  | | A much cheaper proof-of-concept could be rigged up with an overhead stirrer, 24/40 glass addition funnel, and a plastic screw that sits flush with the

walls of the funnel bottom. The design would mimic a regular industrial auger filler. I think that would be much more economical for us amateurs to

rig up something like that because all the parts are readily available. |

That's a very good idea actually. But the screw would have to be pretty small (and also spin pretty slow but also have good torque). Usually overhead

stirrers are rated for higher speed, but here, I think ~100rmp is best. The overhead stirrers also cost a lot

Quote: Originally posted by VincenzoTheGreat  | | And one more thing regarding addition. I saw wetting mentioned in a flow chemistry article about powder addition. The powder in question was wetted

10%, making a slurry, allowing for more even and controlled addition. Depending on the wetting solvent in question this might also act as a protective

barrier against solvent vapour which may react with the powder being added e.g. NaBH4 wetted by toluene entering a vigorously stirred solution of

MeOH. |

Yes, for example sulfur could be wetted with some S2Cl2. But I don't think that a slurry would be easier to add than a

granulated powder. Maybe even the opposite. The powder could clump, stick, and now move properly to and with the PTFE screw.

Ukrainium

|

|

|

4-Stroke

Hazard to Self

Posts: 60

Registered: 20-4-2024

Location: Canada

Member Is Offline

Mood: Often Wrong, Never Unsure

|

|

Wow that's a lot better then putting the slurry in a powder addition funnel. Those pumps don't cost that much, are unreactive (if PTFE tubing is

used), can move a relatively large volume, are easy to improvise, and are just overall perfect for this task. The slurry would have to be stirred

constantly to avoid the powder settling down to the bottom and clogging the pump, but that's nothing a 5 gallon bucket with a cement mixer cannot fix

Ukrainium

|

|

|

VincenzoTheGreat

Harmless

Posts: 6

Registered: 4-3-2019

Member Is Offline

|

|

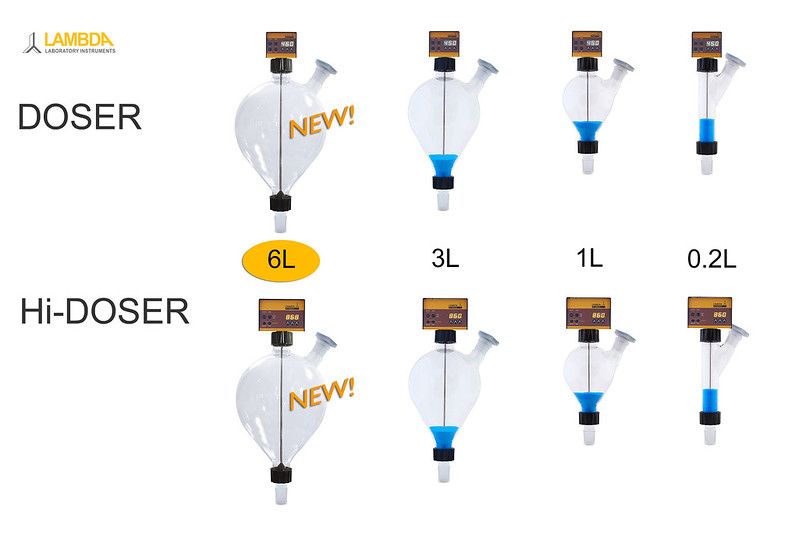

check out these powder dosers from https://www.lambda-instruments.com/powder-doser/ for inspiration:

pretty neat idea! much more elegant design than the auger-style addition funnels.

|

|

|

4-Stroke

Hazard to Self

Posts: 60

Registered: 20-4-2024

Location: Canada

Member Is Offline

Mood: Often Wrong, Never Unsure

|

|

It sure is a neat idea, but the price isn't

But really, it seems very similar to the idea you suggested, just 100x more expensive. It's pretty much just a container (funnel) with a rotating

screw at the bottom.

[Edited on 13-11-2024 by 4-Stroke]

[Edited on 13-11-2024 by 4-Stroke]

Ukrainium

|

|

|