Junk_Enginerd

Hazard to Others

Posts: 251

Registered: 26-5-2019

Location: Sweden

Member Is Offline

|

|

Help understanding DIY discharge tube emission spectrums

So I've been having a blast DIYing discharge tubes since I got a 5 Pa vacuum pump. I'd have preferred a little harder vacuum, but the price jump was a

little steep...

Anyway, I started making some basic discharge tubes with just air and sure enough looks like a nitrogen discharge color. All is well so far.

Now, one of the reasons I'm doing this is to experiment with other substances not typically used in discharge tubes. There's plenty of info on what

neon, xenon, argon etc looks like but what about other gasses? Other elements? More complex compounds? Sulfur? I dunno, diesel fuel?

So I tried with CO2 and ok yeah there's a slight color shift there, a little whiter. A little disappointing though, because it mostly looked the same

as air.

Okay how about something radically different... maaaybeee HCl? And nothing. Sulfur? Maybe a little paler? Tried a bunch of different things and they

look like a nitrogen discharge. I kept trying different stuff and basically everything is just typical electric purple like nitrogen.

It crossed my mind that there might in fact just be a lot of nitrogen left, but I feel like putting a liquid in there and letting it boil off in the

vacuum should very much drive out all the air.

I don't get it. I do most of the driving with a ~30 kHz, 20 kV and maybe 5 mA supply.

So what am I missing here? Are in fact most substances purpleish in their emission? Am I not reaching the right kind of excitation? Too little

current? Too high pressure?

|

|

|

DraconicAcid

International Hazard

Posts: 4332

Registered: 1-2-2013

Location: The tiniest college campus ever....

Member Is Online

Mood: Semi-victorious.

|

|

Have you looked at the light through a spectrometer?

Please remember: "Filtrate" is not a verb.

Write up your lab reports the way your instructor wants them, not the way your ex-instructor wants them.

|

|

|

Metallophile

Hazard to Self

Posts: 87

Registered: 23-3-2018

Member Is Offline

Mood: No Mood

|

|

Are you running the pump to maintain vacuum, or do you have a valve to close? I'm guessing any small leak could quickly flush all of your desired gas

out of the tube with air. How did you make the tube? I was actually thinking of trying this kind of thing myself. Can you post some pictures?

|

|

|

wg48temp9

National Hazard

Posts: 784

Registered: 30-12-2018

Location: not so United Kingdom

Member Is Offline

|

|

Assuming no leak in your discharge tube or the connections to your pump, the gas in the discharge tube eventually will be water vapor and pump oil

vapour.

Unless you heat the sulfur its vapoyr pressure will much less than 5 Pa. So you need to try substances with significant vapour presser for example

iodine, copper chloride/bromide/iodide for example, though those will probably be corrosive to your pump

The color of the discharge tends to white at higher pressures and at higher power density.

Because your powering the discharge from AC it will be difficult to see the structure and different colours of the discharge as seen in the following

pics

From: http://www.sciencemadness.org/talk/viewthread.php?tid=156334...

I am wg48 but not on my usual pc hence the temp handle.

Thank goodness for Fleming and the fungi.

Old codger' lives matters, wear a mask and help save them.

Be aware of demagoguery, keep your frontal lobes fully engaged.

I don't know who invented mRNA vaccines but they should get a fancy medal and I hope they made a shed load of money from it.

|

|

|

Junk_Enginerd

Hazard to Others

Posts: 251

Registered: 26-5-2019

Location: Sweden

Member Is Offline

|

|

Nope. Don't have one, but I was hoping that the spectrums would vary enough to be obvious by eye by color.

Quote: Originally posted by Metallophile  | Are you running the pump to maintain vacuum, or do you have a valve to close? I'm guessing any small leak could quickly flush all of your desired gas

out of the tube with air. How did you make the tube? I was actually thinking of trying this kind of thing myself. Can you post some pictures?

|

I've done a bit of both. I don't think leaks are an issue. 4/5 tubes I've made so far have held their vacuum for several days at least. It's very

obvious in the arcs behaviour if the vacuum starts failing.

First tubes I made were a simple 6 mm glass tube. First I made a hole roughly in the middle by heating and blowing. Then copper wires as electrodes

inserted in each end, heated and clamped shut to seal. I then attached another glass tube to previously mentioned hole in a T-joint fashion, and also

drew out a thin section of said tube to use when sealing. Connected the tube to the vacuum pump. Once a vacuum was reached I (sometimes) tested the

seals by applying some water to relevant places to see if anything made its way inside. Once satisfied, heating the thin portion of the tube makes it

collapse and it's sealed.

Problem is I'm not very skilled in glasswork, so the T-joint was a source of frustration. Sometimes leaky, sometimes it broke. Also I discovered that

getting a good metal-glass seal with copper is far from trivial, and it failed often.

So I came up with a much easier solution. Not as pretty, but functional and very quick and easy to run tests with. I stick one electrode in one end of

the tube, and then pump in hot glue. Definitive and simple seal. Then I blow a small hole roughly 2/3's the length of the tube away from the

electrode. Typically it's enough to just plug the end of the tube, heat it, and let the heat build up enough pressure to automatically burst the

bubble. In this small hole goes electrode #2, and liberal amounts of hot glue on top of it. Sealed and done. Now I have a free 1/3 length of the tube

to use for vacuum. I do the same thing; draw out a thin section of it, pull vacuum, seal with heat. Takes me about 5 minutes to make such a tube..

Quote: Originally posted by wg48temp9  | Assuming no leak in your discharge tube or the connections to your pump, the gas in the discharge tube eventually will be water vapor and pump oil

vapour.

Unless you heat the sulfur its vapoyr pressure will much less than 5 Pa. So you need to try substances with significant vapour presser for example

iodine, copper chloride/bromide/iodide for example, though those will probably be corrosive to your pump

The color of the discharge tends to white at higher pressures and at higher power density.

Because your powering the discharge from AC it will be difficult to see the structure and different colours of the discharge as seen in the following

pics

From: http://www.sciencemadness.org/talk/viewthread.php?tid=156334... |

Why eventually water vapor?

I did heat the tube during both vacuum pulling and operation to see that the sulfur evaporated, and also hoping that the boiling sulfur would flush

out air. It made a clear difference when heated, but mostly in intensity, no dramatic color shift other than perhaps a whiter purple.

I think any halogens are non-applicable. I don't have a ton of knowledge about this, but I recall reading something about halogens being "quenchers"

which effectively suppress electric discharge. Corrosiveness is probably no big deal. The pump is pretty big and my tubes are pretty small, so it

probably ends up being an insignificant amount.

It's not a pure AC as it is generated by a flyback transformer, which makes it pretty asymmetrical with a heavy DC offset, although it still is

technically AC. The offset is certainly large enough that I can observe an obvious polarity in the tube and make out some typical anode vs cathode

patterns. I'll see if I can get some photos uploaded...

|

|

|

Junk_Enginerd

Hazard to Others

Posts: 251

Registered: 26-5-2019

Location: Sweden

Member Is Offline

|

|

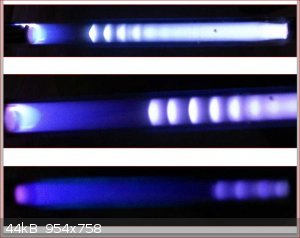

Allright let's see about those photos then. Both of these are with normal air, Getting the sulfur one going needs a bit of setup so I'll get back to

that.

Edit: and lastly one with freshly heated sulfur.

[Edited on 13-1-2021 by Junk_Enginerd]

|

|

|

wg48temp9

National Hazard

Posts: 784

Registered: 30-12-2018

Location: not so United Kingdom

Member Is Offline

|

|

Glass tubes and plastic hoses are covered by a layer of water one to several molecules thick. The components of and the oil of the pump will also

be contaminated by water. That water tends to be a problem at a round 5Pa and below. However i doubt that was your problem. Judging from the

appearance your discharge I estimate the pressure in your jube is a lot higher perhaps 100 Pa to 1000 Pa.

Your discharge tube appears to be sealed with silicon rubber which typically releases acetic acid or methanol as it sets. That will contaminate your

vacuum unless you baked the discharge tube in an oven at say 120C for say ten or more minutes before evacuating it.

If your flyback transformer is operating in flyback mode its output is almost completely pulsed DC with a on off ration approximately determined by

the ratio of the power supply voltage to the transformer to that of the output HT voltage which could be 1 to 100-1000.

In short the relatively high pressure (relative to 5 Pa) and high peak power of your discharge produces a broad emission spectrum (whitish) from the

gas. If you want to see the colors the discharge should be so weak it is almost invisible under normal room light levels.

Apparently argon and a little iodine produces interesting streams. Copper halogen compounds particularly under pulse conditions produce strongly

colored discharges. Of cause iodine and halogen compounds will react with the electrodes.

Apparently epoxy resins like Araldite can be used for sealing. You can get wider tubes from old florescent tubes though removing the fluorescent

coating is tedious. Microwave oven transformers can be used to build a HT supply but unless you have suitable knowledge they can be very dangerous.

Have fun with your discharge experiments and do post the pics.

PS: I see you used a hot glue gun for sealing. That probably has less out gassing than silicon rubber but probably it will not stick to the glass so

well or at least mine does not.

Yes its tricky trying to seal even thin copper wires to glass. There are a few youtube videos on that subject. Wiki suggests tungsten is a good match

for borosilicate glass and thin tungsten wire is available on ebay.

[Edited on 1/14/2021 by wg48temp9]

I am wg48 but not on my usual pc hence the temp handle.

Thank goodness for Fleming and the fungi.

Old codger' lives matters, wear a mask and help save them.

Be aware of demagoguery, keep your frontal lobes fully engaged.

I don't know who invented mRNA vaccines but they should get a fancy medal and I hope they made a shed load of money from it.

|

|

|

DraconicAcid

International Hazard

Posts: 4332

Registered: 1-2-2013

Location: The tiniest college campus ever....

Member Is Online

Mood: Semi-victorious.

|

|

A pocket spectroscope can be easily made from an old CD. It's not great, but it's worth the effort.

Please remember: "Filtrate" is not a verb.

Write up your lab reports the way your instructor wants them, not the way your ex-instructor wants them.

|

|

|

Twospoons

International Hazard

Posts: 1324

Registered: 26-7-2004

Location: Middle Earth

Member Is Offline

Mood: A trace of hope...

|

|

Also note that silicone is quite permeable to gasses.

Helicopter: "helico" -> spiral, "pter" -> with wings

|

|

|

Junk_Enginerd

Hazard to Others

Posts: 251

Registered: 26-5-2019

Location: Sweden

Member Is Offline

|

|

Quote: Originally posted by wg48temp9  | Glass tubes and plastic hoses are covered by a layer of water one to several molecules thick. The components of and the oil of the pump will also

be contaminated by water. That water tends to be a problem at a round 5Pa and below. However i doubt that was your problem. Judging from the

appearance your discharge I estimate the pressure in your jube is a lot higher perhaps 100 Pa to 1000 Pa.

Your discharge tube appears to be sealed with silicon rubber which typically releases acetic acid or methanol as it sets. That will contaminate your

vacuum unless you baked the discharge tube in an oven at say 120C for say ten or more minutes before evacuating it.

If your flyback transformer is operating in flyback mode its output is almost completely pulsed DC with a on off ration approximately determined by

the ratio of the power supply voltage to the transformer to that of the output HT voltage which could be 1 to 100-1000.

In short the relatively high pressure (relative to 5 Pa) and high peak power of your discharge produces a broad emission spectrum (whitish) from the

gas. If you want to see the colors the discharge should be so weak it is almost invisible under normal room light levels.

Apparently argon and a little iodine produces interesting streams. Copper halogen compounds particularly under pulse conditions produce strongly

colored discharges. Of cause iodine and halogen compounds will react with the electrodes.

Apparently epoxy resins like Araldite can be used for sealing. You can get wider tubes from old florescent tubes though removing the fluorescent

coating is tedious. Microwave oven transformers can be used to build a HT supply but unless you have suitable knowledge they can be very dangerous.

Have fun with your discharge experiments and do post the pics.

PS: I see you used a hot glue gun for sealing. That probably has less out gassing than silicon rubber but probably it will not stick to the glass so

well or at least mine does not.

Yes its tricky trying to seal even thin copper wires to glass. There are a few youtube videos on that subject. Wiki suggests tungsten is a good match

for borosilicate glass and thin tungsten wire is available on ebay.

[Edited on 1/14/2021 by wg48temp9] |

Ah, interesting. Is this water layer stubborn enough to remain even after heating past 100°C?

Oh, what difference would you expect with 5 Pa instead of whatever it may be now? The spec on the pump is a "chinese spec" so I can't say I really

expect it to reach 5 Pa. Edit: Though keep in mind that my photos don't exactly reflect reality. The discharge itself is quite overexposed, it's not

as bright and saturated as the photo would have you believe.

No, not silicone, it's hot glue. Ethylene-vinyl acetate, I'd expect.

Yeah, I suppose it could almost be called pulsed DC. But only almost, there is at least a small polarity inversion.

Really? It needs to be that weak? That's no fun at all. Why is this not the case with for example neon lighting? They are quite luminous. Surely there

must be some way to reach a higher intensity than that?

Well okay then, consider me convinced. I'll give some halogens a go. Reaction with electrodes isn't important at this point. If they work for a few

minutes I'm happy with that. Something longer lasting is a later project. I've noticed that I can reach pretty decent ionization just by applying the

voltage through the glass, with no metal present in the tube. That should solve any corrosion issues.

Hot glue seems to wet and bond pretty well to the glass as far as I can tell. Trick is to have a glue gun that runs really hot or preheat the glass a

little. Plus, weak bonding can be fixed by adding more glue.

Yep, I've had much better success with tungsten, but I have a whooole lot more copper wire than I have tungsten... Maybe I'll use tungsten if and when

I find a design I like and want to build to last.

Yeah that makes sense, with their "rainbowey" look. I'll certainly look into that.

No silicone involved, I use hot glue and sometimes cyanoacrylate. The effective seal thickness of the glue is also >5 mm, so I doubt any

significant amount of gas will permeate through that.

[Edited on 14-1-2021 by Junk_Enginerd]

|

|

|