BelCha

Harmless

Posts: 6

Registered: 28-10-2019

Member Is Offline

|

|

Venturi Water Aspirator - Bad design? Not achieving a good vacuum

I have designed a water aspirator pump but I have been unable to achieve a good consistent vacuum and I am starting to think there is a fundamental

flaw in my design. I am trying to achieve the maximum vacuum possible inspired by NurdRage (https://www.youtube.com/watch?v=tYLlkTDstmo)

This is the issue I am having with my current setup

- https://imgur.com/Tb5hWiV

I am using a 12V 70W 6L/Min High Pressure Micro Diaphragm Water Pump 130Psi and in the video above (see link), I am using a metal water aspirator. I

am only able to achieve a weak vacuum before backflow seems to stop any further vacuum. I have also tried a glass vacuum aspirator and the vacuum was

even worse. In both cases, it seems that a vacuum is being drawn before water backflows and stops any further vacuum.

Link for the metal water aspirator used.

https://www.ebay.com.au/itm/VACUUM-HYDRO-ASPIRATOR-FILTER-PU...

Link for the water aspirator used (video not shown)

https://www.ebay.com.au/itm/Glass-Water-Aspirator-Pump-Humbo...

Any ideas on what is the problem and how to overcome this? My current thought is that the water aspirator might work better positioned horizontally

rather than vertically or that the PSI rating for the pump I am using is too high.

|

|

|

draculic acid69

International Hazard

Posts: 1371

Registered: 2-8-2018

Member Is Offline

|

|

The aspirator i used gave like -8psi at room temperature.never tried cooling it though but that was the best vac achievable.

|

|

|

XeonTheMGPony

International Hazard

Posts: 1640

Registered: 5-1-2016

Member Is Offline

Mood: No Mood

|

|

try adding an accumulator to the pressure side of the pump, you can make one simply by gluing end caps on a length of 4 inch pvc then adding a nipple

on it.

The air acts as a buffer to smooth out the pulsations and should give a better vacuum (Smoother)

Aspirators rely on water velocity, ie pressure, those little pumps have neither, but good enough for crude stuff.

All so looks like you're getting air ingestion at the intake of the pump, need better baffling or larger volume.

[Edited on 13-1-2020 by XeonTheMGPony]

|

|

|

Assured Fish

Hazard to Others

Posts: 319

Registered: 31-8-2015

Location: Noo Z Land

Member Is Offline

Mood: Misanthropic

|

|

How long is the tube your using for the water outlet on the aspirator, the one thats going down that we cant see the end of.

This water outlet tube needs to be minimum 200mm long in order to get the aspirator to work properly.

Sufficiently advanced science is indistinguishable from madness.

|

|

|

egret

Harmless

Posts: 20

Registered: 22-2-2018

Member Is Offline

Mood: No Mood

|

|

I bought exactly the same type of diaphragm pump some time ago. The maximal flow was 4.5 liter per minute instead of 6 l/min. May be it is a reason of

poor vacuum.

|

|

|

Dr.Bob

International Hazard

Posts: 2734

Registered: 26-1-2011

Location: USA - NC

Member Is Offline

Mood: No Mood

|

|

For most aspirators to provide a good vacuum, you need a water pressure from 60-100 psi at a flow rate of 3-6 gallon per minutes. Most small pumps

just cannot do that. It would make more sense to buy a small vacuum pump than to use a water pump to try to run an aspirator. Each step in the

process will lose energy.

[Edited on 15-1-2020 by Dr.Bob]

|

|

|

S.C. Wack

bibliomaster

Posts: 2419

Registered: 7-5-2004

Location: Cornworld, Central USA

Member Is Offline

Mood: Enhanced

|

|

I suspect that the problem is your expectations for cheap Chinese garbage.

|

|

|

XeonTheMGPony

International Hazard

Posts: 1640

Registered: 5-1-2016

Member Is Offline

Mood: No Mood

|

|

The aspirators are fine quality, and so is the pump for its intended function, the two together how ever, for any serious usage is a dismal failure.

I use a pump twice that size and power and it does a steady 20inches, To get better I would need to use a gear pump with a pressure bypass system to

regulate it to desired PSI, Now we're talking about a 1/4Hp motor, regulator valves and noise.

So I use it to help with solvent distillations, nitric acid distillations, for any thing that needs real vacuum I use my 2 stage rotary vane vacuum

pump!

|

|

|

BelCha

Harmless

Posts: 6

Registered: 28-10-2019

Member Is Offline

|

|

Thanks for all the replies. I think I am starting to come to the conclusion that my pump is underrated and insufficient - despite NurdRage's video

showing otherwise :/

I connected the metal aspirator to my garden hose and it pulled -26 inHg! (opposed to 12V my pump which was ~ -10 inHg. I think I will bite the bullet

and buy a different pump.

Any thoughts on the pump below? 12V, 17A 18.9LPM 60PSI

https://www.ebay.com.au/itm/18-9LPM-Diaphragm-Water-Pump-Hig...

Many thanks in advance

|

|

|

XeonTheMGPony

International Hazard

Posts: 1640

Registered: 5-1-2016

Member Is Offline

Mood: No Mood

|

|

Point one: You will need to specify a by pass valve and not a switch

Point two: You will need to specify cont duty, other wise the brush guides will melt and you will have a dead pump

|

|

|

wg48temp9

National Hazard

Posts: 784

Registered: 30-12-2018

Location: not so United Kingdom

Member Is Offline

|

|

Quote: Originally posted by BelCha  | Thanks for all the replies. I think I am starting to come to the conclusion that my pump is underrated and insufficient - despite NurdRage's video

showing otherwise :/

I connected the metal aspirator to my garden hose and it pulled -26 inHg! (opposed to 12V my pump which was ~ -10 inHg. I think I will bite the bullet

and buy a different pump.

Any thoughts on the pump below? 12V, 17A 18.9LPM 60PSI

https://www.ebay.com.au/itm/18-9LPM-Diaphragm-Water-Pump-Hig...

Many thanks in advance

|

Ok now you can measure the flow rate when its connected to the garden hose and its creating a vaccum of -26inHg. You could also reduce the flow

until it only creating a vacuum of -10inHg and measure the flow with perhaps a few other flow levels.

Ii would also be useful if you could measure the hose pressure at the same time. The data would be useful in selecting a new pump for both yourself

and others.

I am wg48 but not on my usual pc hence the temp handle.

Thank goodness for Fleming and the fungi.

Old codger' lives matters, wear a mask and help save them.

Be aware of demagoguery, keep your frontal lobes fully engaged.

I don't know who invented mRNA vaccines but they should get a fancy medal and I hope they made a shed load of money from it.

|

|

|

BelCha

Harmless

Posts: 6

Registered: 28-10-2019

Member Is Offline

|

|

I tested my current pump (12V 70W 6L/Min) and despite being rated at 6 L per minute, it actually only achieved 3.5 L per minute! As S.C. Wack said,

cheap Chinese garbage.

Comparatively, my garden hose had a flow rate of approximately 14 L per minute. Unfortunately, no information on pressure.

The pump I am considering to purchase is https://www.ebay.com.au/itm/18-9LPM-Diaphragm-Water-Pump-Hig... which has a builtin bypass and does not require an accumulator.

XeonTheMGPony - I am not sure about cont duty and brush guides potentially melting. Can you elaborate for a newb like myself?

Many thanks in advance!

|

|

|

BelCha

Harmless

Posts: 6

Registered: 28-10-2019

Member Is Offline

|

|

Also another

https://www.ebay.com.au/itm/High-Pressure-12V-Water-Pump-20L...

|

|

|

XeonTheMGPony

International Hazard

Posts: 1640

Registered: 5-1-2016

Member Is Offline

Mood: No Mood

|

|

cyclic duty (Such as most those pumps) use a pressure switch and are designed to be run under moderate to low stress, showers, taps, spray nozzles,

and when a set back pressure is met they simply turn off.

Due to the low working most use fiber re-enforced polymer to guide the carbon brushes that supply the motor with energy, these can melt if you by pass

the switch and force the pump to work hard.

Continuous duty motors use heavier brushes and guides meant to take and dissipate the heat, and instead of a switch they use a spring relief that can

be set to the desired pressure, so if a valve where to be turned off the water will simply be allowed to circulate against the set spring pressure

(usually adjustable between 20 to 60psi)

https://www.altestore.com/store/solar-water-pumps/surface-so...

You can make a by pass system as well by disabling the switch and putting in an external bypass valve

https://www.amazon.com/Watts-0371271-Poppet-Adjustable-Relie... just as an example, a relief is not the same as a bypass / unloader valve.

To smooth out the pulsations caused by a positive displacement pump you use what is called a pressure accumulator / pressure tank:

https://www.amazon.com/Seaflo-Pre-Pressurized-Accumulator-Ta...

[Edited on 17-1-2020 by XeonTheMGPony]

|

|

|

wg48temp9

National Hazard

Posts: 784

Registered: 30-12-2018

Location: not so United Kingdom

Member Is Offline

|

|

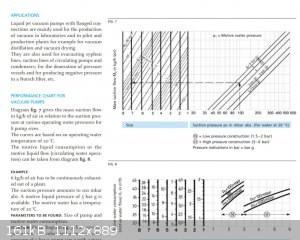

Below are graphs of performance of a venturi pump/s. It gives an indication of how the vacuum changes with water pressure. Its for an industrial pump

and not a typical lab type but its probably very similar differing only in the flow rates. Its all I could find.

From Attachment: ejectors-jet-pumps-heaters-mixer-vacuum-pumps-gea_tcm11-34890.pdf (7.7MB)

This file has been downloaded 824 times

I am wg48 but not on my usual pc hence the temp handle.

Thank goodness for Fleming and the fungi.

Old codger' lives matters, wear a mask and help save them.

Be aware of demagoguery, keep your frontal lobes fully engaged.

I don't know who invented mRNA vaccines but they should get a fancy medal and I hope they made a shed load of money from it.

|

|

|