Doktor Klawonn

Harmless

Posts: 29

Registered: 20-11-2010

Location: Europe

Member Is Offline

Mood: No Mood

|

|

reaction of iron wool and sulfur (whistle!)

Introduction

The reaction of iron and sulfur is a basic experiment in school chemistry. The common way is to react stoichiometric amounts of iron powder and sulfur

powder. This variant allows for a better observation of energy conversion and of the reaction product. And it bears a surprise!

Chemicals and apparatus

- test tube

- wooden clamp

- burner

- sulfur

- iron wool (steel wool)

Warning

In this experiment, sulfur vapors may escape and ignite.

Experimental

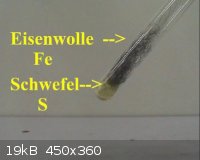

A test tube is filled with sulfur and iron wool.

The lower end of the test tube is heated untill the reaction starts. As soon as the sulfur vapors reach the iron wool a loud whistling noise is

produced.[1]

The test tube is allowed to cool and the reaction product is then poured onto the table.[2]

The product is brittle and can easily be crushed into a glistening powder.[3]

Reaction is

Fe + S --> FeS

Remarks

[1] I chose this variant because the iron powder in stock wouldn't react in the standard experiment. The sudden whistle surprised everybody around.

[2] Don't pour the test tube while still hot! It may break and the sulfur vapors may ignite.

[3] This is iron(II)sulphide, FeS. The balls indicate that the product did actually melt during the reaction. Melting point of FeS is ~ 1200 °C. This

shows the exothermic character of the reaction quite well. (Compare the reaction of copper and sulfur: the resultant Cu<sub>2</sub>S, mp. 1130 °C, doesn't melt).

Links

- This experiment in a video

- The corresponding reaction of copper and sulfur:

[Edited on 6-2-2011 by Doktor Klawonn]

|

|

|

Steve_hi

Hazard to Others

Posts: 196

Registered: 4-12-2010

Member Is Offline

Mood: No Mood

|

|

Thanks for this post and the links.

i just tired an experiment like this 4 times and testing with a magnet my product was totaly attracted to it. Í'm going to try it as you have done

inside a test tube rather than a tin can lid. I also will use steel wool as I used Iron filings befor. I did test my product with HCl and got the

distinct hydrogen sulfide smell but obviouosly the reaction was not complete, as proven by the residule ferromagnetisim so I'm going to give this a

try again thanks. Nice post.

|

|

|

bbartlog

International Hazard

Posts: 1139

Registered: 27-8-2009

Location: Unmoored in time

Member Is Offline

Mood: No Mood

|

|

Interesting. So what causes the whistle? It can't be escaping gases (a la the barking dog); rather there must be some phenomenon that causes pressure

changes in the right range of frequencies for the resonant frequency of the gas column in the test tube to come into play.

|

|

|

Doktor Klawonn

Harmless

Posts: 29

Registered: 20-11-2010

Location: Europe

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Steve_hi  | Thanks for this post and the links.

i just tired an experiment like this 4 times and testing with a magnet my product was totaly attracted to it. |

Yes the product was ferromagnetic in any experiment I've done too. In school lessons I use therefore the brittleness of the FeS as a criterion that a

new compound has been formed.

@bbartlog

The whistle is a physical phenomenon. It is called a thermoacoustic engine or a Rijke tube. When a metal screen inside an open tube is heated, then

the whistle is produced by ascending air inside the tube.

A user of the german forum www.versuchschemie.de gave this link for demonstration (at 07:08 exp. 5 ): http://www.chymiatrie.de/index.php/component/content/article/236-video-75

|

|

|

smuv

National Hazard

Posts: 842

Registered: 2-5-2007

Member Is Offline

Mood: Jingoistic

|

|

I haven been doing some experiments, trying to make FeS on a prep scale from steel wool and sulfur (for H2S generation). So far things are going OK,

but I have to initiate by a Mg/S flash powder and I have to use large amount of sulfur (releasing a lot of SO2) in order to get a reaction that is

self sustaining and is able to consume most of the steel wool (it is very fast and energetic, and always melts/burns the container).

Has anyone done this, any tips to make the process more efficient.

Here is what I am doing now, I uncoil the steel wool, and sprinkle in some Mg turnings, then I wrap the steel wool tightly, and I stuff it tightly

into a steel can, I sprinkle in a layer of sulfur and tap it around to get things as homogeneous as possible. I repeat this for each layer,

until the can is tightly packed. At the top I put a little bit of extra sulfur mixed with a pile of Mg turnings.

To initiate I light the Mg turnings at the top, because they are coarse, the initiation is nice and slow. At first the Mg just burns in air (this

gives me some time to back up), after a couple of seconds, the Mg flash powder goes, which initiates the Fe/S reaction. 255mL can of the stuff burns

in like 4seconds, after the Mg Flash.

Its Ok, but...It produces a lot of SO2, and I want to take down the reaction speed a little, while still maintaining complete consumption of Fe.

I'd like to hear what other people have done. As I am sure its obvious, I have no pyro experience, and this reaction is essentially pyrotechnics.

Thanks.

"Titanium tetrachloride…You sly temptress." --Walter Bishop

|

|

|

smuv

National Hazard

Posts: 842

Registered: 2-5-2007

Member Is Offline

Mood: Jingoistic

|

|

Quick Iron Sulfide (FeS)

Wow, I must be getting pretty annoying with all my double posting lately.  I

changed my approach from making ferrous sulfide to just making a sulfide rich product. Therefore I started liberally using Mg, to keep the reaction

fast and self sustaining with steel wool. The MgS impurity is of no consequence for H2S production. I

changed my approach from making ferrous sulfide to just making a sulfide rich product. Therefore I started liberally using Mg, to keep the reaction

fast and self sustaining with steel wool. The MgS impurity is of no consequence for H2S production.

Reagents + Method

~65g Steel Wool 5x13g Sponges

~120g Sulfur

Mg Turnings

The steel wool was uncoiled and layed out. It was sprinkled with Mg. The amount wasn't quantified, see picture for approx. amount.

Steel wool, unrolled and sprinkled with coarse Mg turnings

The pieces of steel wool were stacked upon eachother, such that the layers alternated: wool|Mg|wool... The sulfur was sprinkled onto the wool/Mg.

Care was taken to handle the wool gently to avoid allowing too much sulfur to fall through.

Steel wool, Mg, S8

The whole mass was gently rolled to make a cylinder. Again, this cylinder maintained the Steel|Mg|Steel|etc. layering. The bulk of the sulfur which

fell out while rolling was sprinkled back onto the cylinder. A mound of sulfur was made on the top and some Mg turnings were placed there.

Warning: Mixtures of Mg/Sulfur can be very unstable, in this case, with coarse Mg turnings, the

mixture is very insensitive. The same CANNOT be said about Mg powder and Sulfur, this is VERY unstable.

Ready to burn

The mound of sulfur/Mg was placed in a thick walled container and lighted with a tourch (careful, sometimes there is not much delay before this

reaction takes off). As soon as the Mg/Sulfur flash began to rapidly burn, the torch was removed and the vessel was covered.

Left: Mg/Sulfur flash just went I am about to cover Right: Container just after reaction (a few seconds after left pic)

The reaction proceeded in a ca. 3-7 seconds, with little production of SO2 (a nicely fitting lid helps reduce SO2 production). The vessel was allowed

to stand undisturbed (covered) until it stopped smoking (allow ~5 min; if the cover is removed too soon, the the sulfur vapor in the vessel

instantaneously ignites).

Next, the vessel was opened and the large pieces of solidified mass were removed. The pot was filled with another load of Fe/S/Mg and the whole

process was repeated...

After a few runs, all the large solidified masses which were removed were broken into pieces by hand, any large clumpes of melted-in steel wool were

removed by hand. The pieces were crushed with a mortar in pestle. These pieces are ready for H2S production.

After all these runs a lot of smaller pieces accumulated in the vessel (faster reactions tended to produce many small pieces as opposed to a large

mass). Larger pieces of wool were removed by hand. Smaller pieces of steel wool were removed by a magnet (nearly everything here is weakly magnetic,

but steel is so much more magnetic that by holding the magnet ~2cm above, the steel wool could be selectively removed). These pieces are now ready

for H2S production, but contain more contaminants than what was collected from the solidified masses).

Left:Ground Large pieces; Right: Purified residue from pot, this has more trash in it; Middle/Front: Removed Steel wool

Conclusion

So, this is my method. It works reasonably well and is rapid. Of course iron filings and sulfur react without any help from magnesium; but I had no

great amount of Fe filings on hand. The mixed in magnesium is absolutely necessary to allow the reaction to self-sustain with steel wool. The MgS

contaminates that the Mg produces are not an issue for H2S production. The only real problem is that any Fe/Mg that is not removed from the mixed

pyrite produced will of course reduce water and contaminate the H2S with H2; for my purposes this is not a significant issue (but still...an

annoyance).

[Edited on 5-7-2011 by smuv]

"Titanium tetrachloride…You sly temptress." --Walter Bishop

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Nice write up. Residual metals would be an issue (H2) if good purity H2S is needed.

I prefer Al2S3 as a source of H2S. The reaction between Al and S is self-sustaining and the Al2S3 doesn't even need acid to generate H2S (water does

ithe trick), thus avoiding any hydrogen being formed.

|

|

|

smuv

National Hazard

Posts: 842

Registered: 2-5-2007

Member Is Offline

Mood: Jingoistic

|

|

Yes, I have pondered making Al2S3 for these reasons. In what form is the aluminum (foil powder...etc) to get a self sustaining reaction?

An interesting thing I have noticed, as on keeping some of the powder (right pile in photo above) exposed to air, a lot of fluffy white mounds formed

in it; indicating that the MgS present has reacted with water forming magnesia and H2S.

At any rate, the H2S has been more than suitable for my purposes (precipitating metal salts).

"Titanium tetrachloride…You sly temptress." --Walter Bishop

|

|

|

annaandherdad

Hazard to Others

Posts: 387

Registered: 17-9-2011

Member Is Offline

Mood: No Mood

|

|

Sorry to revive this old thread, but I've been making FeS lately, too. I found that 40 mesh Fe filings didn't work very well, so I ordered some 300

mesh Fe powder from Amazon (it didn't cost much) and it works much better. I just mix with stoichiometric amounts of sulfur plus a few percent to

account for sulfur boil-off, and heat in a test tube until ignition. Indeed the product is magnetic, suggesting that the conversion to FeS was only

partial, but I have a sample of FeS purchased from a chemical supplier, and it is magnetic, too. Is it possible that pure FeS is magnetic? Some

compounds of iron are certainly magnetic, eg Fe3O4.

It is a little hard to be quantitative in this process since I don't know the purity of my iron, but the indications are that I got 90% or more of my

iron to convert to FeS.

Any other SF Bay chemists?

|

|

|

elementcollector1

International Hazard

Posts: 2684

Registered: 28-12-2011

Location: The Known Universe

Member Is Offline

Mood: Molten

|

|

Did it ever mention what the 'grade' was? Technical, reagent and (more rarely) ACS grade are common sights, and one can usually have a rough estimate

of the (claimed) purity from there.

Other good ways would be to measure density of a piece (for volume, drop into a graduated cylinder of oil and measure the difference of volume before

and after), and compare to the listed density of iron (II) sulfide - Wiki says 4.84 g/mL (switched cm^3 to mL to help with the conversions a bit -

they're both the same thing anyway).

Elements Collected:52/87

Latest Acquired: Cl

Next in Line: Nd

|

|

|

DraconicAcid

International Hazard

Posts: 4334

Registered: 1-2-2013

Location: The tiniest college campus ever....

Member Is Offline

Mood: Semi-victorious.

|

|

I missed this thread. We are supposed to do the reaction of iron and sulphur in one of our labs, but the iron powder has never, ever reacted for me.

I've often thought that I should try it with steel wool...I guess now, I definitely will.

Please remember: "Filtrate" is not a verb.

Write up your lab reports the way your instructor wants them, not the way your ex-instructor wants them.

|

|

|