Heptylene

Hazard to Others

Posts: 319

Registered: 22-10-2016

Member Is Offline

Mood: No Mood

|

|

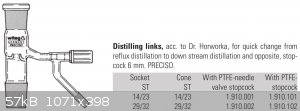

"Horworka" distillation link

Has anyone ever seen a piece of glassware like this? A distilling link according to Horworka, whoever that may be...

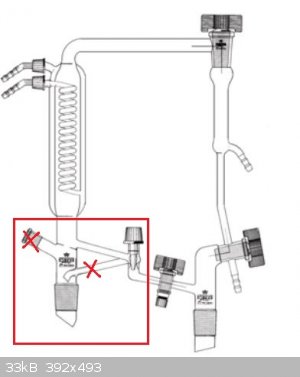

It looks like part of a distillation head with variable reflux, but without the condenser on top. Like the red part in this "Antlinger" distillation

head:

I'm asking because I'm looking at distillation heads with variable reflux ratio, and they all seem to cost about $500-1000, whereas this "Horworka"

link costs about $100. I'm thinking it could be used as an improvised variable reflux head provided a condenser is attached on the top joint... There

would be some dead volume in the horizontal tube unfortunately.

Thoughts? Suggestion on where to find a cheaper distillation head?

|

|

|

SWIM

National Hazard

Posts: 970

Registered: 3-9-2017

Member Is Offline

|

|

This looks pretty good to me.

I don't think the dead space is much different than the various vertical cold finger type PTO heads I've seen.

That thing also will probably arrive intact, too.

I've had terrible luck with damage in shipping on more elaborate PTO heads.

The bigger they are, the more likely to break before you get them.

Used PTO heads in 14/20 sometimes show up on ebay for under $100 (USD), but you may have to wait a while to find one, and the larger sizes are always

more expensive.

I don't see anything like that on there now.

If you want to minimize the dead volume in that fitting you might be able to just load some glass spheres into it before use. The downward angle ought

to keep them in place.

|

|

|

DavidJR

National Hazard

Posts: 908

Registered: 1-1-2018

Location: Scotland

Member Is Offline

Mood: Tired

|

|

Ooooh, that looks pretty neat... Where can I get one?

|

|

|

markx

National Hazard

Posts: 646

Registered: 7-8-2003

Location: Northern kingdom

Member Is Offline

Mood: Very Jolly

|

|

Well you could make one....like thusly:

Exact science is a figment of imagination.......

|

|

|

Heptylene

Hazard to Others

Posts: 319

Registered: 22-10-2016

Member Is Offline

Mood: No Mood

|

|

I'll keep looking on ebay for distillation heads, though I'd like it in 29/32 (or 29/42) which is an uncommon joint size on ebay. Good suggestion with

the glass spheres! I SWIM what do you mean by "PTO"?

DavidJR, I found this in the catalog from Witeg (german glassware/lab equipment supplier)

markx is this part of an ethanol still? It looks pretty neat. Did you weld it yourself? In my case I'm looking to distill nitric acid so stainless

steel won't work. I want to make azeotropic HNO3 from very dilute acid in a single distillation step. I'll get a 700 mm glass packed column at some

point, which will be used in two ways: as an NOx absorption tower to produce the dilute nitric acid, and then as a distillation column to distill it.

I figure if I'm buying a nice column it woud be a shame not to have a nice distillation head too. Besides I just love nice glassware...

|

|

|

SWIM

National Hazard

Posts: 970

Registered: 3-9-2017

Member Is Offline

|

|

PTO is short for partial take off.

Sometimes this term is used for heads with variable reflux.

EDIT: There are also those magnetic variable reflux heads that use a timer and magnet to set the reflux ratio.

They're usually a few hundred used, but sometimes you find ones going cheap on ebay because of low demand, or even the seller not knowing what they

are.

I saw two go for under $50 USD each this month at auction, but they had 55/50 size joints. 29/42 ones do turn up occasionally though.

(I was going to buy them myself, but I overslept and missed the end of the auction.

They went very cheap because they were listed as 'labglass' with no other description so nobody who wanted one could find them. )

[Edited on 30-9-2019 by SWIM]

|

|

|

markx

National Hazard

Posts: 646

Registered: 7-8-2003

Location: Northern kingdom

Member Is Offline

Mood: Very Jolly

|

|

Quote: Originally posted by Heptylene  | I'll keep

markx is this part of an ethanol still? It looks pretty neat. Did you weld it yourself? In my case I'm looking to distill nitric acid so stainless

steel won't work. I want to make azeotropic HNO3 from very dilute acid in a single distillation step. I'll get a 700 mm glass packed column at some

point, which will be used in two ways: as an NOx absorption tower to produce the dilute nitric acid, and then as a distillation column to distill it.

I figure if I'm buying a nice column it woud be a shame not to have a nice distillation head too. Besides I just love nice glassware...

|

Yes, it has been machined and welded by me from ancient stainless material that we dug out from the back yard of my friends house.

For nitric distillations I guess it would make sense to fabricate the PTO part out of PTFE round stock. One can also incorporate the takeoff valve in

that part. Conical mating surfaces for cooler in the upper part and to the column in the lower. Should be pretty doable with a mediocre mini lathe and

some imagination

Exact science is a figment of imagination.......

|

|

|

Heptylene

Hazard to Others

Posts: 319

Registered: 22-10-2016

Member Is Offline

Mood: No Mood

|

|

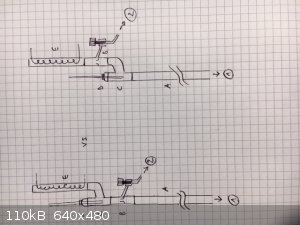

Improvised column head

So I've thought about this a bit more. What this distillation link is lacking is a thermometer inlet and a condenser.

I think I could use a 3-way adapter to connect said thermometer and condenser.

The key points are:

- the thermometer should only come in contact with the vapor, no liquid condensate.

- The condensate should run on the walls of the apparatus such that it is caught by the Horworka link and then divided (i.e. it should not fall in the

hole at the center).

So I see two ways to accomplish this (see picture)

Legend:

A = packed column

B = Horworka link

C = 3-way adapter

D = thermometer adapter

E = condenser

Inlet number ① connected to still pot.

Outlet number ② connected to another condenser followed by receiver.

Which option do you think would work best? Am I missing something about how column heads are supposed to work?

Btw I'm thinking about this because I sadly don't have the capabilities to machine PTFE or blow glass. I have a drill press and that's about it.

However there might be a way to fashion a crude reflux splitter from glass valves and PTFE tubing.

[Edited on 6-10-2019 by Heptylene]

|

|

|

markx

National Hazard

Posts: 646

Registered: 7-8-2003

Location: Northern kingdom

Member Is Offline

Mood: Very Jolly

|

|

Both options shall work for practical purposes. But you also need a "breather channel" for the head....an opening to equalize the column internals

with ambient atmospheric pressure. Trust me, it is not a good idea to design a closed reflux column where the only opening to surrounding atmosphere

is through the takeoff valve. That is if it happens to be open.

Since your intent is the fractional distillation of nitric acid, I would suggest to design the setup in such a way as to minimize possible leaks. That

means proper couplings, sealed valves and an overall well matching fit between components. "Spit and bending wire" type of operations are just asking

for trouble. With alcohol or other solvents a minor leak of a few drips is not the end of the world, but concentrated nitric is another animal

altogether.

As for the head design I am more of a fan of inline configurations....the condenser and pto portion being inline with the main column axis. Much

neater and more compact than the designs which offset the condenser and pto section. But one does make do with the options that are at hand

Since you currently lack any capability to machine materials, I strongly suggest to at least contemplate on investing in said capability. Even a bare

minimum of being able to turn something into a nice fitting size shall ease the pain of building such setups by many orders of magnitude. Otherwise

you are stuck at using commercial parts and fittings....and these do tend to cost dearly if intended for agressive environments.

Exact science is a figment of imagination.......

|

|

|

Heptylene

Hazard to Others

Posts: 319

Registered: 22-10-2016

Member Is Offline

Mood: No Mood

|

|

By breather channel do you mean an opening at the top of the condenser? This is definitely planned, otherwise overpressure would force the distillate

into the sidearm or even break something. If you mean something else please clarify.

Regarding machining, I've been wanting to get a lathe for a long time but I cannot justify the investment for now. And there's all the additional

cutting and other tools you need after that...

As for leaks, ground glass joints will be fitted with PTFE sleeves. These should be gas tight. I also found some PTFE tubing on ebay and it fits glass

hose barbs very well so this might be used in some parts. I don't think there will be any leaks in the setup, I'll invest in some quality glass so

that it might be used for other projects too.

[Edited on 6-10-2019 by Heptylene]

|

|

|

markx

National Hazard

Posts: 646

Registered: 7-8-2003

Location: Northern kingdom

Member Is Offline

Mood: Very Jolly

|

|

Quote: Originally posted by Heptylene  | By breather channel do you mean an opening at the top of the condenser? This is definitely planned, otherwise overpressure would force the distillate

into the sidearm or even break something. If you mean something else please clarify.

Regarding machining, I've been wanting to get a lathe for a long time but I cannot justify the investment for now. And there's all the additional

cutting and other tools you need after that...

As for leaks, ground glass joints will be fitted with PTFE sleeves. These should be gas tight. I also found some PTFE tubing on ebay and it fits glass

hose barbs very well so this might be used in some parts. I don't think there will be any leaks in the setup, I'll invest in some quality glass so

that it might be used for other projects too.

[Edited on 6-10-2019 by Heptylene] |

Yes, the vent channel at the top of head is what I meant.....this be something that is easily overlooked and can cause a lot of grief. It was not

shown on the drawings, so thought it might be worth to mention....

If you have actual physical space for machinery, then you already have all of the justification needed to acquire it  And you do not need to buy all of the accessories at once. Many of these can be

made on the lathe itself from scrap pieces of metal(cutting tool holders, jigs, dead centers, lathe dogs, etc). What you should buy are a decent live

center, tailstock chuck, some cutters to get started and a diamond wheel or plate to sharpen the cutters (400 and 600 grit are fine enough for

reviving carbide inserts or HSS). And you do not need to buy all of the accessories at once. Many of these can be

made on the lathe itself from scrap pieces of metal(cutting tool holders, jigs, dead centers, lathe dogs, etc). What you should buy are a decent live

center, tailstock chuck, some cutters to get started and a diamond wheel or plate to sharpen the cutters (400 and 600 grit are fine enough for

reviving carbide inserts or HSS).

But really, for the life of me I can not understand how I got by without machining capability for all these years. It opens up a whole new universe of

possibilities.

As for working with the PTFE tubing...it tends to be really rigid so do not attempt to just slide it over glass fittings. Very likely that is going to

end sadly for the glass. Heat up the tube end with a heat gun until it becomes transparent and swells up, then make the connection. It will be soft,

mouldable and upon cooling it shrinks into place to make a tight permanent seat. It usually can not be removed unless carefully cut off from the

glass, so try to get it right with the first try.

Exact science is a figment of imagination.......

|

|

|