weilawei - 3-2-2018 at 22:49

I repurposed an old water cooler from work as a chiller for condensers. I've been using a bucket and aquarium pump setup for years, but the ritual of

making the ice and swapping out cooling water during long distillations was getting old. Casual hunting for chillers revealed that they're pretty

expensive. Then, a water cooler at work failed, and they were going to throw it out, so I asked nicely, and they let me cart it off.

It was getting tossed because the heater failed. There's an old recall on this model, but I disconnected the heater (fewer sparks that way/lower power

draw). I also pulled out the filtration system to reduce the needed pressure to run it. It's intended to be supplied from a permanent water line, not

a bottle. I also disconnected the seemingly burnt out UV lamp. Then, I only needed a pump.

As luck had it, I'd asked a guy at work on his opinion about continuous duty pumps. A few weeks later, he offered me a coolant pump (effectively a

centrifugal pump on a long shaft) and reservoir he wasn't using anymore. So, I thanked him profusely, applied some elbow grease to make it

presentable, wired on a new power cord (scavenged from an old husk of a motor speed controller), and plumbed it up. The reservoir had a crack, so I

sealed it with some silicone gasket maker. Good as new.

The pump pulls water out of the reservoir and pushes it into the chiller via a port on the back. It runs through the cold water tank and out the

outlet, which has a hose barb swapped for the old aerator. The hose from the chiller's output flows back into the reservoir. In the reservoir, a

submersible aquarium pump circulates water to a condenser which drains back to the reservoir.

I've only run the compressor for about 20 minutes at a time, and it's gone down to 11.8 C in the reservoir. I need to look up the preferred duty cycle

for that style compressor and put it on a timer. The temperature should go down to around 3 or 4 C (lowest setpoint on the chiller is 37 F) with more

cooling cycles. There are also a couple extremely slow leaks (drops per hour) which will take some fiddling to fix. Note also the highly sophisticated

cellulose and PET mechanism for opening the outlet. That should probably be replaced by something a bit less kludgy. I'm also filling the hot water

tank right now--that will shortly get cut off with a piece of tubing and a hose clamp (like up around the electrical to cut off a line with no easy

way to plumb it's output into the hose barb).

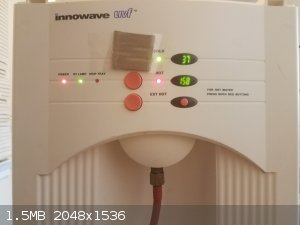

Chiller frontside, set points, hose barb, sophisticated outlet triggering

device

Chiller backside, reservoir, pump motor, thermometer

Inside the reservoir, with a very low level

The impeller, holes to inlet and outlet

Other half of pump chamber

Rear connection to chiller

Bottom two levels of the chiller, compressor and tank/plumbing stages

Electrical for the chiller and outlet plumbing

[Edited on 4-2-2018 by weilawei]

Ubya - 4-2-2018 at 03:27

i was hoping to build something like that, but for me there are a few problems, i don't know anyone with a water chiller, and even if i have, i can't

really use it as it is (i really don't have space, i would like to build it under the fumehood i'm actually finishing). i see yours is quite empty

inside, gutting it and making it more compact would be preferred. at the end anything that uses a compressor cooling or heating cycle can be

reporpused, luck (or bad luck) wants me only to find fridges on the streets near the trash, good for compressors but useless for the coils.

anyeay, good work on that chiller, in my opinion it could be made smaller ( requiring lots of work of course...)

weilawei - 4-2-2018 at 09:14

Yeah, my original plan was to mount a pump directly inside where the filters used to be, but this reservoir and pump are too large to fit. I could rip

out all the parts and put it into a new frame to be more compact, but that's a lot of work for right now. Mounting hose barbs to the reservoir for the

inlets and outlet is probably the next thing to. Here's a slightly more cleaned up picture.

I hope you post pictures of your build process for your fumehood. I'd love to see how you put it together.

[Edited on 4-2-2018 by weilawei]

LD5050 - 4-2-2018 at 10:21

Awesome idea I'm going to try to make one of these myself. Good job,

Melgar - 4-2-2018 at 13:33

I'd probably see about one discarded water cooler a week on the curb in Manhattan. The trouble with making them fit in a smaller space is that

usually the radiator takes up the entire backside of it. So somehow you'd need to replace the radiator with a more compact one, and then probably

recharge the system with refrigerant. Too much work, really.

I ended up setting up a system with thermoelectric coolers. They typically run at 12 volts, and I set up a 360W 12V power supply to power a bunch of

DC electronic devices that I used in my lab area. It was initially LED lights, and a vacuum pump, but mostly I intended the power supply for the

thermoelectric coolers. 60W coolers are the most efficient. They make more powerful ones, but if you can, it's definitely in your interests to just

use more 60W ones rather than use higher-power ones:

https://www.ebay.com/itm/182754836519

Aluminum cooling blocks are quite cheap:

https://www.ebay.com/itm/222411564775

But I'd recommend getting copper cooling blocks if you can afford them:

https://www.ebay.com/itm/272885813509

Search for "cooling block" to see more results, in eBay. They're typically used for cooling CPUs. They don't get the fluid quite as cold as a water

cooler would, but can drop the temperature to about 10-15˚C easily enough. For cooling the fluid, you can get some really high-end copper CPU

heatsinks with fans, if you find them on eBay that are designed to fit obsolete CPUs. I built a rig out of a piece of a 2x4 with some screws in it,

then cut a groove in it for the heatsinks, and drove some screws into the board to attach the fan to. I'll post some pictures when I can, but the

system really works quite well for a closed-loop cooling system.