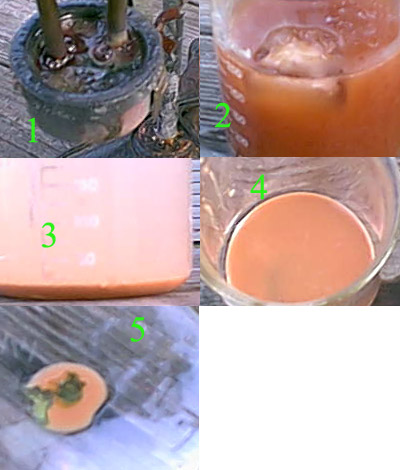

Concentrated solution of potassium hydroxide being electrolyzed in a steel crucible with iron electrodes at 12V and 10A. When the electrolysis was first commenced a definate purple color came from the anode but as the solution heated up and it progressed the whole solution became black.

Added the mess still boiling hot to iced water, the water was distilled but the ice was not

Regardless, some solid iron fell to the bottom of the beaker and from there I filtered it twice while still ice cold.

Regardless, some solid iron fell to the bottom of the beaker and from there I filtered it twice while still ice cold.Added conc BaCl2 solution and after 10 minutes this is the precipitate that settled.

Picture of precipitate after decanting the water, looks darker almost chocolate.

Put some of the precipitate into the middle of a watch glass and put a drop of HCl on the edge. It bubbled like neutralizing a carbonate but nothing of the sort was present in the solution. After adding a few drops more I was left with a green solution with a precipitate of BaCl2 on the bottom. I do not believe I had Ba(OH)2 because that would not have given an efforvesence however I believe if I had indeed made the ferrate it would have caused chlorine evolution from oxidizing the chlorine anion in the HCl. So I'm not really sure what I eneded up with.

) into cold water.

) into cold water.