Magpie - 19-8-2015 at 13:01

1. Introduction

This procedure follows the method of garage chemist (ref 1) with the exception that white P (2g) is used instead of red P (10g). The key feature of

this method is the use of chloroform, CHCl3, as a solvent, to facilitate heat removal due to the large heat of reaction. The reaction is as follows:

P + 5/2Cl2 --> PCl5

(ΔH° = -398.9 KJ/mol) (g) (ref 2)

As a side reaction some of the chloroform is chlorinated to carbon tetrachloride as follows:

CHCl3 + Cl2 --> CCl4 + HCl

CCl4 would seemingly be the ideal solvent for this reaction.

Theoretical yield: 13.4g; actual yield: 9.1g (67.7%)

2. Some Properties of P, PCl5, and solvents

Solubility of white P in CHCl3: 1g/40 ml

solubility of white P in benzene: 1g/35 ml

bp of CHCl3: 61.2° C; ρ = 1.39 @60°C

bp of benzene: 80.1° C; ρ = 0.87

bp of carbon tetrachloride: 76.7° C; ρ = 1.59

white P: mp= 44°C ρ = 1.82 @ rt

PCl5: mp = 166.8°C; sublimation point = 160.5°C

3. Reagents

100 ml CHCl3

2g white P (0.0645 moles)

Cl2 (0.1623 moles) – stoichiometric requirement - made from the TCCA

25.8g TCCA (0.111 moles, 2x stoichiometric requirement)

43 ml of muriatic acid (31.45%)

30 ml H2O

400 ml 10% NaOH

Krytox grease

Con H2SO4

P2O5

acetone

Caution!

Chlorine is toxic and hazardous to the environment.

Chloroform is harmful to health.

Phosphorus pentoxide and sulfuric acid are corrosive.

White Phosphorus is highly flammable.

Phosphorus pentachloride is very toxic and corrosive.

This synthesis is to be performed in a hood or outside.

4. Equipment

Gas dryer w/fritted tube

250 ml 2-neck RBF, 19/22

reflux condenser, 19/22, w/CaCl2 guard tube w/hose adaptor

Cl2 sparge tube, OD 6mm, length 8”

3/32” ss welding wire rod or Cu wire #12 AWG, 20” long,

glass 3-way T-connector with hose barb ends, OD 10mm

rubber septum, 19/22

6 ft of PVC tubing, 3/16” x 5/16” (disposable)

100 ml RBF,19/22

Claisen adapter, 19/22

100 ml p-e addition funnel, 19/22

Magnetic stirrer

Female connector w/hose barb, 19/22

Thermometer adapter, 19/22

3” glass funnel

600 ml beaker for HCl absorption trap

250 ml separatory funnel

250 ml RBF w/glass stopper, 19/22

250 ml Erlenmeyer flask w/cork

50ml Erlenmeyer flask w/cork

4 ring stands

2 1/2 feet of ¼” rubber hose

10” of Viton tubing, soft, ¼” ID x 3/8” OD, cut to small lengths as required

5 ea PVDF tubing adapters, ¼” x 3/16” tubing IDs

5. Drying the Glassware

Dry the following glassware in the drying oven at 150°C for at least 1 hour:

1. Sparge tube

2. 2-neck 250 ml RBF

3. Reflux condenser

4. 250 ml separatory funnel

5. 250 ml RBF w/glass stopper

6. 250 ml Erlenmeyer flask

6. Drying the Phosphorus

White phosphorus is stored under water. Any entrained water must be removed prior to the time of use.

1. Place ~ 25ml of acetone in a 50ml Erlenmeyer flask.

2. Add ~1g of P2O5. Cork and swirl.

3. Pre-weigh the Erlenmeyer flask with the acetone, P2O5, and cork.

4. Cool the phosphorus in water to 5-10°C.

5. Remove ~2g of phosphorus, pat it dry on a paper towel, and place it in the Erlenmeyer flask with the acetone.

6. Reweigh the flask and record the weight of phosphorus added out to 2 decimal places.

7. Swirl the flask and set aside for an hour with occasional swirling.

7. Purification of the chloroform

1. Shake the 100 ml of chloroform with 50 ml of con H2SO4 in the dried separatory funnel. Shake several times, letting it sit between shakings.

2. Very carefully separate the chloroform from the H2SO4l. The chloroform is the upper layer.

3. Pour the chloroform into the dried 250 ml Erlenmeyer flask, add some P2O5, cork, and shake. Continue this treatment until the P2O5 flows freely.

Let stand for a few hours, with occasional shaking.

4. Decant the chloroform into a dried 250 ml RBF. Mix in some fresh P2O5 and distil the chloroform into a dried 2-neck 250 ml RBF receiving flask

with plugged the side neck. Use a CaCl2 guard tube leading to the vacuum adapter.

8. Equipment Set-Up

Note: All tapered glass joints that will be exposed to Cl2 are to be lubricated with Krytox grease. This will prevent the formation of the hard,

sticky white residue that forms when silicone grease is used.

a. Cl2 Gas Generator and Dryer

1. Set up a ring stand with a 100 ml RBF w/Claisen adapter.

2. Place a 100 ml p-e funnel in the short neck of the Claisen.

3. Using a 2nd ring stand set-up a Cl2 gas dryer with H2SO4 to receive Cl2 from the long neck of the Claisen. Use 3/16” x 5/16” PVC tubing with

PVDF/Viton tubing connectors.

4. Install a safety trap downstream from the dryer.

b. Reaction Flask

1. Set up a 3rd ring stand with mag stirrer and the 2-neck 250 ml RBF with chloroform.

2. Prepare a CaCl2 guard tube with 19/22 end and tubing adaptor.

3. Install the reflux condenser with guard tube in the center neck of the RBF with the chloroform.

4. Connect the T-shaped 3-way glass adapter with hose barbs to the sparge tube using one of the straight run barbs and PVC tubing.

5. Place an inverted rubber septum on the other straight-run barb and insert the 3/32” weld rod in the straight-run, piercing the septum.

6. Connect the branch leg of the T-connector to the dried Cl2 supply.

7. Using a 4th ring stand install the sparge tube in the side neck of the reaction flask complete with T-shaped 3-way adapter, inverted septum, and

3/32” ss cleaning rod..

c. HCl Gas Absorbtion Trap

1. Prepare 400 ml of 10% NaOH in a 600 ml beaker.

2. Connect the reflux condenser guard tube via ¼”rubber hose to an inverted funnel in the beaker of 10% NaOH.

9. Procedure

Purge the entire gas train and reaction vessel with an inert gas.

1. Charge the 100 ml RBF with the 25.8g of powdered TCCA.

2. Makeup 20% HCl by adding 30 ml of water to 43 ml of muriatic acid. Pour this into the p-e funnel (valve closed!).

3. Place the 2g of dried phosphorus in the RBF with the chloroform, along with a magnet stir bar. Turn the stirrer on high to dissolve the

phosphorus.

4. Turn on the cooling water to the reflux condenser.

5. Begin the slow introduction of Cl2 into the reaction vessel using the sparge tube.

6. Closely monitor the reaction to maintain a steady boil. Monitor the outlet of the sparge tube to assure that it is not being plugged with PCl5

solids. Use the ss cleaning rod as necessary to push any solids out of the tube.

7. Continue the gassing with Cl2 until the product solution has turned yellow, indicating that all the P has reacted and the Cl2 is now dissolving in

the chloroform.

PCl5 apparatus

PCl5 in chloroform

From Stefan’s(garage chemist) report (ref 1), translated from German:

Despite working at the boiling point the inlet tube clogged several times with PCl5 particularly towards the end of the reaction. This is very

dangerous because pressure then builds up and any part of the equipment, usually the wash bottle head or the dropping funnel stopper, can be ejected.

You have to keep this in mind and often move the inlet tube out slightly (but leave in the adapter! so no humidity enters!) to see if it is still

open. A sudden drop in the gas introduction rate, seen in the bubbler, is an alarm signal, and immediately the hose must be cleared at the gas outlet.

This is done by pushing a rigid ptfe rod into the inlet tube and poking out the blockage.The introduction of chlorine lasted three hours (for 10g of

P), and the chloroform continuously boiled under reflux! This shows the enormous amount of heat released by the reaction. Without the solvent there is

nothing to remove the heat, at least not at this rather large scale.

Note: Inorganic Syntheses, volume II, p. 145 provides a procedure for making PCl3 from P4 and Cl2. Both the gas inlet tube

and the condenser are specified as 2.5cm (1”) ID to prevent plugging by PCl5.

10. Distilling off the Chloroform/Carbon Tetrachloride from the PCl5 solids

1. Prepare the reaction flask for distillation. Heating is to be done with a hot water or hot oil bath.

2. Distill until nothing more passes over. Note how much higher boiling CCl4 comes over (bp = 76.7°C).

3. Stefan then opened the flask briefly (atmospheric humidity) and crushed the PCl5 solids with a spatula. Then the solids were heated some more to

bring over more solvent.

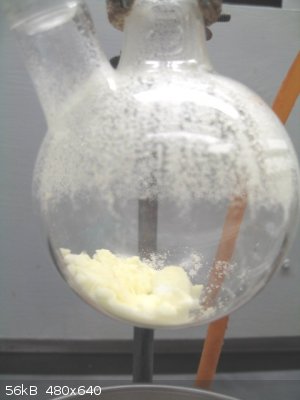

Solvent removal from PCl5

PCl5 precipitating during solvent removal

PCl5 (w/stirbar) nearly dried

11. Vacuum Distillation

Stefan’s report: Then vacuum was applied and the whole mass of the water bath warmed up. Some solvent escaped again,

recognizable by the smell at the water aspirator. It was heated for some time, up to almost 100° C, until the last remnant of the solvent was removed

and the PCl5 began to sublime. Then the heating bath was removed, the vacuum taken away, and the mass crushed after cooling with a spatula. It was

then immediately placed into a pre-weighed, empty, sealable glass bottle with Teflon seal.

1. Place the solids under vacuum using an aspirator with guard flask.

2. Evacuate at almost 100°C (with water bath) or 110°C with oil bath until the PCl5 begins to sublime. Use an absolute pressure of 150-180 mmHg.

3. Remove the vacuum and let the solids cool.

4. Then immediately transfer the solids to a pre-weighed storage bottle with a ptfe seal.

PCl5 vacuum dried

Note: PCl5 is notoriously difficult to store due to the ingress of water vapor from the air. Consider sealing the storage bottle lid

by dipping it in melted paraffin wax. Or place the PCl5 in a glass ampule.

12. Solvent recovery

From Stefan’s report:The distilled solvent is thoroughly washed with aqueous Na2CO3 solution* (still contains a little

phosphorus compounds such as POCl3 and PCl5) and then dried (eg with CaCl2 or sulfuric acid) and distilled (watch to see how much is in the boiling

range of CCl4.) *Be aware that PCl5 + Na2CO3 --> phosgene !

1% ethanol is added for stabilization and it is recycled as chloroform (containing carbon tetrachloride) labeled, and stored. But keep separate from

the main chloroform supply bottle.

13. Use

From Stefan: Phosphorus pentachloride is a most powerful chlorinating agent and can generally convert almost all acids into acid

chlorides. Even the chlorination of sulfuric acid to chlorosulfonic acid is possible! This can not be done with PCl3 or SOCl2. However, only one

chlorine atom is used. The byproduct is always phosphorus oxychloride, POCl3. H2SO4 + PCl5 ---> ClSO3H + POCl3 + HCl. Also from the salts of

oxy-acids can be prepared by the action of PCl5 directly on the acid chlorides. Example is the preparation of phosgene from sodium carbonate: Na2CO3

+ 2 PCl5 ---> COCl2 + 2 POCl3 + 2 NaCl

One can use PCl5 also to produce PCl3 by dry mixing it with an excess of red phosphorus and heating. The mixture liquefies, and then you can distill

off the PCl3.

14. References

1. Stefan’s (garage chemist) post at versuchschemie.de: http://www.versuchschemie.de/ptopic,124916,2d7537946855c29dc...

2. http://nshs-science.net/chemistry/common/pdf/R-standard_enth...

Suggested reading: http://www.sciencemadness.org/talk/viewthread.php?tid=22359

Questions, suggestions, and comments are welcomed.

[Edited on 19-8-2015 by Magpie]

[Edited on 19-8-2015 by Magpie]

[Edited on 19-8-2015 by Magpie]

[Edited on 19-8-2015 by Magpie]

[Edited on 19-8-2015 by Magpie]

[Edited on 19-8-2015 by Magpie]

[Edited on 20-8-2015 by Magpie]

[Edited on 2-9-2015 by Magpie]

gdflp - 19-8-2015 at 16:30

Very nice writeup for quite a useful reagent. I have a question though. Is the theoretical yield higher than it should be due to the phosphorus

being (unavoidably)weighed along with any entrapped water, thus artificially inflating the weight?

Magpie - 19-8-2015 at 17:09

Thanks. No, the phosphorus was dry. But I didn't weigh it all that carefully.

PCl5 is indeed a useful reagent. Too bad the phosphorus is so hard to come by in the US.

[Edited on 20-8-2015 by Magpie]

Magpie - 19-8-2015 at 19:08

Versuchschemie.de seems to be down right now. Since I had saved Stefan's report in a word file, I checked his yield and I quote:

"The bottle is then weighed to determine the amount of product. I got 65g, an almost 100% yield. This must be achieved, otherwise you had sloppy

working conditions, ie, exposure to humidity."

During my first try with the ptfe rod I did struggle to unclog the sparge tube, eventually having to give up. Perhaps air humidity ingress at that

time was more significant than I thought. However, Stefan was also struggling with clearing the PCl5 out of his sparge tube.

His 5X scale factor no doubt reduced the effect of mechanical losses.

At any rate, Stefan's report indicates that much better yields than what I achieved with my small scale experiment should be expected.

Magpie - 1-9-2015 at 17:42

Refering back to my original post and my 67.7% yield:

For 2g of P this means 0.65g of P was lost or unaccounted for.

Some experimentation I conducted today in burning P in Cl2 showed dramatically how the air (20 mole% O2) in the Cl2 gas train can burn up some of the

P to, I presume, P2O5.

If I had 1 liter (very close to my estimate) of air in this train at the beginning this must be pushed though the train to the reaction vessel before

the Cl2 becomes available. So taking 1 liter of air at 25°C as a basis:

moles O2 = (0.2)(1 L) (273°K/298°K)(1 mole/22.4 L) = 0.0082

2P + 5/2O2 --> P2O5

Therefore the moles of P consumed by this O2:

moles P = [(2)/(5/2)] (0.0082) = 0.0065

wt P consumed = 0.0065moles (31g/mole) = 0.2g

It looks like it would pay to push all that air out of the train with a little argon before starting the Cl2 generation.

[Edited on 2-9-2015 by Magpie]

Magpie - 3-10-2015 at 16:53

Today I finished the conversion of my meager supply of phosphorus to PCl5. 6.3g of P was charged. I used 200 ml of chloroform as solvent in a 500 ml

rbf reaction vessel. Yield was 92%. I attribute the losses to: impure P, reaction of dissolved P with O2 in the vapor space, and mechanical losses.

Here's a picture of the PCl5 precipitating as chloroform is being removed by distillation:

precipitating PCl5

I've had my PCl5 from the 1st batch stored in a widemouth 100ml Quorpak bottle with a ptfe liner in a cabinet. Apparently it has reacted some with

ambient humidity and the resulting HCl has corroded the ss hinges as shown here:

corroded hinge

For comparison here is a non-corroded hinge in my main chemical storage closet:

non-corroded hinge

--------------------------------------------------------------

I know - woelen warned me.  I just finished triple dipping the bottle top in

melted paraffin wax. I hope that seals it.

I just finished triple dipping the bottle top in

melted paraffin wax. I hope that seals it.

[Edited on 4-10-2015 by Magpie]

mayko - 31-12-2017 at 19:24

A hobbyist I follow on twitter reported success with a simpler arrangement (no gas dying, no chlorinated solvent to suspend the phosphorus, etc):

https://lab.whitequark.org/notes/2018-01-01/synthesizing-pho...

Sigmatropic - 1-1-2018 at 02:54

It is widely believed (sciencemadness, prepchem.com) that preparation of PCl5 is a complicated affair requiring drying of

Cl2, starting with white phosphorus (lol no), reflux distillation… Turns out all of that is untrue, and a very simple setup works just as well.

Mumbles something about a large amount of hydrolysis...

I just finished triple dipping the bottle top in

melted paraffin wax. I hope that seals it.

I just finished triple dipping the bottle top in

melted paraffin wax. I hope that seals it.