Magpie - 19-7-2006 at 14:34

As I have mentioned before I have a strange fascination with this chemical. It started in my undergraduate organic class when I first found it on the

reagent shelf and took a cautious whiff. In later years I learned of the high reactivity of the allylic structure which just added to its mystique.

In doing some reading of MSDSs I find that this simple compound is nothing to take lightly. Although it is not listed as carcinogenic, it is highly

toxic, with one MSDS listing the IDLH as 2 ppm! It is also lachrymatory and highly flammable. But as the moth is drawn to the flame I want to

synthesise a little allyl alcohol.

The Norris procedure (our library) calls for the heating together of glycerol and oxalic acid. Formic acid is generated but no equations are provided

for the formation of allylic alcohol.

Rhodium also provides a procedure using glycerol and oxalic acid. He references "Organic Syntheses." Organic

Syntheses much prefers the use of formic acid over oxalic acid, saying foaming is less, acrolein generation is less, and the yield is better.

One equation is provided which shows the allyl alcohol being produced from the decomposition of glycerol monoformate (I think).

So I'm asking the forum members: What is your experience and recommendations for the synthesis of allyl alcohol? Thanks in advance.

chromium - 19-7-2006 at 14:52

No experience so far but also hope to make it some day. I have quite detailed description of this preparation starting from formic acid and glycerine.

This is probably the same on which rhodium article is based. Organic Syntheses vol 1 1921 pp15-19

[Edited on 19-7-2006 by chromium]

Attachment: OrgSyn-01-1921.pdf (185kB)

This file has been downloaded 984 times

leu - 19-7-2006 at 17:50

This old post from a thread started by hellman that took many hours to type should be helpful if there's a shortage of formic acid:

lugh

(Moderator)

09-07-02 20:11

No 354014

Rhodium's Page

(Rated as: excellent)

The only formic acid synth we have, is the one on rhodiums site(god bless) which is a little fucking scarce on the detail, - no offence

intended Rhodium

Obviously Rhodium's page wasn't thoroughly read before this thread was posted, his page has a very clear synthesis of formic acid from oxalic acid and

glycerol on his page, see

https://www.rhodium.ws/chemistry/formic.acid.html

There's also this old account by Coffey and Ward, which goes into much more detail about the chemistry

The well-known process of Tollens for the production of allyl alcohol (Annalen, 1870, 156, 129) is open to very serious objections and is probably

based on a false conception of the reaction. À very large excess of glycerol is used and the amount of oxalic acid lost as carbon monoxide is also

very large, consequently the yield is very poor. Chattaway (T., 1914, 105, 151; 1915, 107, 407) demonstrated that it was essentially by the

decomposition of a dioxalin that allyl alcohol was produced.

The oxalins are initially formed in varying proportions according to the conditions of the experiment. At higher temperatures (110°) the hydrogen

oxalins give carbon dioxide and formins. Dioxalin and monoformin dioxalin, at higher temperatures still (220-225°), decompose into carbon dioxide and

allyl alcohol and allyl formate respectively, whilst at still higher temperatures (24á°) monoformin gives glycerol and carbon monoxide. Formic acid

is produced by the action of an excess of oxalic acid on the formins and distils during the second stage of the reaction. From this it is apparent

that a relatively large amount of oxalic acid must be used in the preparation of allyl alcohol.

Chattaway (loc. cit.) drew these conclusions partly from a study of the action of ammonia and aniline on the products of the reaction and partly from

the properties of the ethyl oxalates; the results of comparative experiments given below completely confirm the above scheme in every detail.

The experiments also clearly demonstrated the four consecutive reactions, and it was possible to convert nearly the whole of the glycerol in one

operation into allyl alcohol and to account for more than 90 per cent of the oxalic acid as free and combined formic acid, carbon dioxide, and water.

The net loss, therefore, is negligible.

From the point of view of the student the usual methods of preparing formic acid and allyl alcohol are very uninteresting and unsatisfactory with

regard to yield, time, and manipulation. Also the simple equation given in the text-books gives no clue as to where the loss occurs.

The method given below would seem to be far superior to the old method as à laboratory experiment. In the course of one day the student could, in one

operation, obtain about 40 grams of formic acid as an approximately 50 per cent solution, and 100 grams of pure allyl alcohol and at the same time

follow the whole reaction and account for all his materials.

Allyl chloride is by far the cheapest allyl haloid, but the methods of preparing it leave much to be desired. Eltekow's method (J. Russ. Phys. Chem.

Soc., 1882, 14, 394) is long and gives only a 60 per cent yield, whilst the action of phosphorus trichloride on the alcohol gives mainly phosphorous

esters and only 10-20 per cent. of allyl chloride. More recently, Bruylant (Rec. Trav. Chim., . 1909, 28, 247) has improved the preparation by heating

allyl alcohol and hydrogen chloride under pressure, but he gives no details of yield. Aschan (Finska. Chem. Med., 1918, 3 pp.) finds that allyl

chloride is obtained in good yield from allyl formate and hydrogen chloride in the presence of anhydrous zinc chloride. The authors' experiments show

that, in the presence of condensing agents, the time of interaction of hydrogen chloride and allyl alcohol may be considerably shortened, but as à

rule the yield of allyl chloride is very little better than that, given bó the older methods. The only condensing agent which is of any practical use

is zinc chloride.

EXPERIMENTAL.

Preparation of Allyl Alcohol, Allyl Formate, and Formic Acid.

Pure, hydrated, finely divided oxalic acid (500 grams) and anhydrous glycerol (250 grams) are mixed in a litre flask which is connected with a

condenser and receiver. The latter is connected with a water-pump and exhausted to about 120-100 mm. The flask is then gently warmed. At about 60°

(thermometer in the liquid) the mixture boils vigorously, becomes homogeneous, and water (more than 100 grains) distils. This is the first stage of

the reaction, the formation of the oxalins, and usually takes one hour. The pressure then rapidly rises to 480 mm and the thermometer remains

stationary at 105-110° for some time. The vigorous ebullition ceases, a rapid effervescence of carbon dioxide sets in, and formic acid distils over

with more water. There is no frothing if pure materials are used and the, pressure is maintained below 500 mm. After one to one and a half hours, the

pressure in the apparatus slowly falls to about 120 mm; this indicates the end of the second stage, namely, the production of formins from the oxalins

by loss of carbon dioxide and their subsequent decomposition into oxalins and formic acid by excess of oxalic acid. The temperature also rises to

190°, when distillation and evolution of gas almost cease. Quite suddenly, at 195-200°, the pressure increases rapidly. The receiver is then changed

and the distillation carried on at the ordinary pressure. Carbon dioxide is again rapidly evolved, contaminated with some carbon monoxide and à

negligible quantity of allyl formate. Allyl alcohol and allyl formate distil over together and the temperature remains stationary at 226° until

distillation ceases, showing the end of the third stage of the reaction. The temperature then rises to 240°, when there is a rapid evolution of

almost pure carbon monoxide. The last reaction ceases abruptly after about five minutes, and the colourless residue (80 grains) consists of glycerol.

During the last two stages of the reaction the apparratus should be connected with a wash-bottle containing water, and the gases led into; in

efficient draught-chamber. If the rate of decomposition is allowed to become too rapid, a large amount of glycerol is liable to distil over. It will

be seen from the above description that the changes on the manometer and the thermometer are accurate criteria of the transitions between the various

stages of the reaction.

To obtain pure allyl alcohol, the crude allyl alcohol-formate mixture (160 grams) is boiled under reflux with 750 c.c. of 10 per cent sodium hydroxide

solution for one hour and fractionated through à long column. All the allyl alcohol passes over below 98° and the distillate is dried with small

quantities of anhydrous potassium carbonate. It is then distilled and should give 100 grams of pure allyl alcohol, b. p. 95-97°.

To obtain allyl formate, the crude allyl alcohol formate mixture is washed several times with small quantities (20 c.c.) of water to remove allyl

alcohol, and the insoluble ester dried over anhydrous calcium chloride. This on distillation gives à yield of pure ester, b. p. 82-83°,

corresponding with 70 per cent of the crude alcohol-formate mixture. The washings may be worked up for allyl alcohol in the usual manner.

Allyl formate may also be obtained by fractionating the crude product several times, but in this case only a 50 per cent yield can be obtained. The

formic acid in the first aqueous distillate (stages I and II) may be recovered either as a formate or as formic acid in the usual manner.

Thus, in one operation, 40 grams of formic acid and 100 grams of pure allyl formate, or about 100 grams of allyl alcohol, can be obtained from 250

grams of glycerol and 500 grams of hydrated oxalic acid. The residue of glycerol (80 grams) is quite suitable for further use.

The experiments were performed exactly as described with different initial concentrations of glycerol and oxalic acid. It can be seen that these

results are in complete accord with those required by the above reaction scheme, and may be summarised as follows.

1. The yield of allyl alcohol calculated on the glycerol actually used is always nearly theoretical.

2. As the amount of oxalic acid increases, the yield of allyl formate in comparison with allyl alcohol also increases. This is to be expected, because

the larger amounts of oxalic acid are favourable to the production of dioxalin hydrogen oxalate, às is readily shown by à comparison of the amount

of the alcohol-formate mixture with the yield of allyl formate. This was actually proved by isolating the allyl formate.

3. With increase of oxalic acid, the amount of free formic acid increases.

4. With increase of oxalic acid, the amount lost as carbon monoxide is diminished. This passes through a minimum in experiment 4, as in experiment 5

the loss increase; again. 1n this experiment the amount of oxalic acid is relatively very large, and no doubt di- and tri-hydrogen oxalins would he

produced in appreciable quantities, giving the corresponding formins and ultimately glycerol and carbon monoxide. There is no necessity to use

anhydrous oxalic acid in the above preparation (see Chattaway, loc. ca.), as all the water of crystallisation distils over during stages I and II.

This effects a saving of several hours in the duration of the experiment.

The amount of carbon monoxide was relatively much larger with smaller amounts of oxalic acid. The quantitative results are not given, but it may be

stated that in experiment 3 the ratio CO : CO2, rapidly exceeded unity, whilst in experiment 4 this ratio was not reached until all the allyl alcohol

had distilled. In experiment 5 the amount of carbon monoxide was larger for the reason already given.

Preparation of Allyl Chloride.

The best results were obtained as follows

Allyl alcohol (46 grams) and anhydrous zinc chloride (20 grams) were mixed in a distillation flask immersed in a water-bath at 75-82°, and hydrogen

chloride was passed into the mixture. The gas was rapidly absorbed and a fluid distilled. The end of the reaction was indicated by hydrogen chloride

issuing from the end of the condenser. The crude distillate gave on fractionation: allyl chloride (35 grams) corresponding with à 60 per cent yield,

and 10 grams of diallyl ether, b. p. 90-95°. The experiment required only half an hour. With aluminium chloride (anhydrous) alone, allyl alcohol

reacts very vigorously, giving very little allyl chloride and a large tar-like residue.

When calcium chloride and allyl alcohol are mixed, an additive compound is obtained, which, when heated at 80-90° in a stream of hydrogen chloride,

gives a product boiling at 30-32°. This is probably diallyl ether, and contains only à trace of chloride.

Aschan's method (loc. cit.) for the formation of allyl chloride was tried, but although the yield on the ester actually used is 80 per cent, the

reaction is extremely slow, and it is advantageous to prepare the alcohol and then use gíven method given first in this paper. An experiment was made

by saturating allyl alcohol in the cold with hydrogen chloride in the presence of zinc chloride. The yield was not improved, however, and the reaction

required a long period for completion.

This synthesis was originally published in J Chem Soc 119 1301 (1921)

[Edited on 20-7-2006 by leu]

[Edited on 20-7-2006 by leu]

[Edited on 20-7-2006 by leu]

Vitus_Verdegast - 20-7-2006 at 02:20

A couple of years ago I've made allyl alcohol from glycerol and oxalic acid following the procedure posted on Rhodium's. The vacuum connector of the

distillation apparatus was connected to plastic tubing which was lead outside in case any acrolein should have formed. It is pretty straightforward,

but I remember the yield being a tad low.

I don't think it is that poisonous. The Merck Index doesn't mention anything other than it being lachrymatory. LD50 orally in rats is 65mg/kg.

I also am fond of its piquante smell. It has an onion-like quality.

btw Onions contain allyl propyl disulphide in its volatile oil, and allyl isothiocyanate is the chemical compound responsible for the pungent taste of

mustard, horseradish and wasabi.

Magpie - 20-7-2006 at 14:07

Thanks for your replies. It is interesting to compare the various procedures, some are simple and some not. The reactant ratios vary considerably

also, i.e., for gylcerol/oxalic acid:

Norris......................................4:1

Coffey & Ward (via lugh) .......0.5:1

Rhodium..................................1:1

To my surprise OTC glycerol is expensive at $16/lb. Since I have no formic acid I will likely try the Rhodium procedure as it is relatively glycerol

efficient and straightforward.

[Edited on 21-7-2006 by Magpie]

evil_lurker - 20-7-2006 at 15:30

Glycerol is dirt cheap if you know where to look:

http://www.chemistrystore.com/glycerin.htm

$17.75 per gallon

Oxalic acid is pretty cheap too...

http://www.chemistrystore.com/oxalic_acid.htm

Magpie - 30-7-2006 at 15:14

Now that the hot weather has provided a reprieve I hurried into the lab for some quality time. I decided to do my planned synthesis of allyl

alcohol. I ended up choosing the Norris procedure even though it is very old (1924) and perhaps inefficient. I chose it because it is

straightforward, uses no vacuum, and provides regular temperature markers throughout.

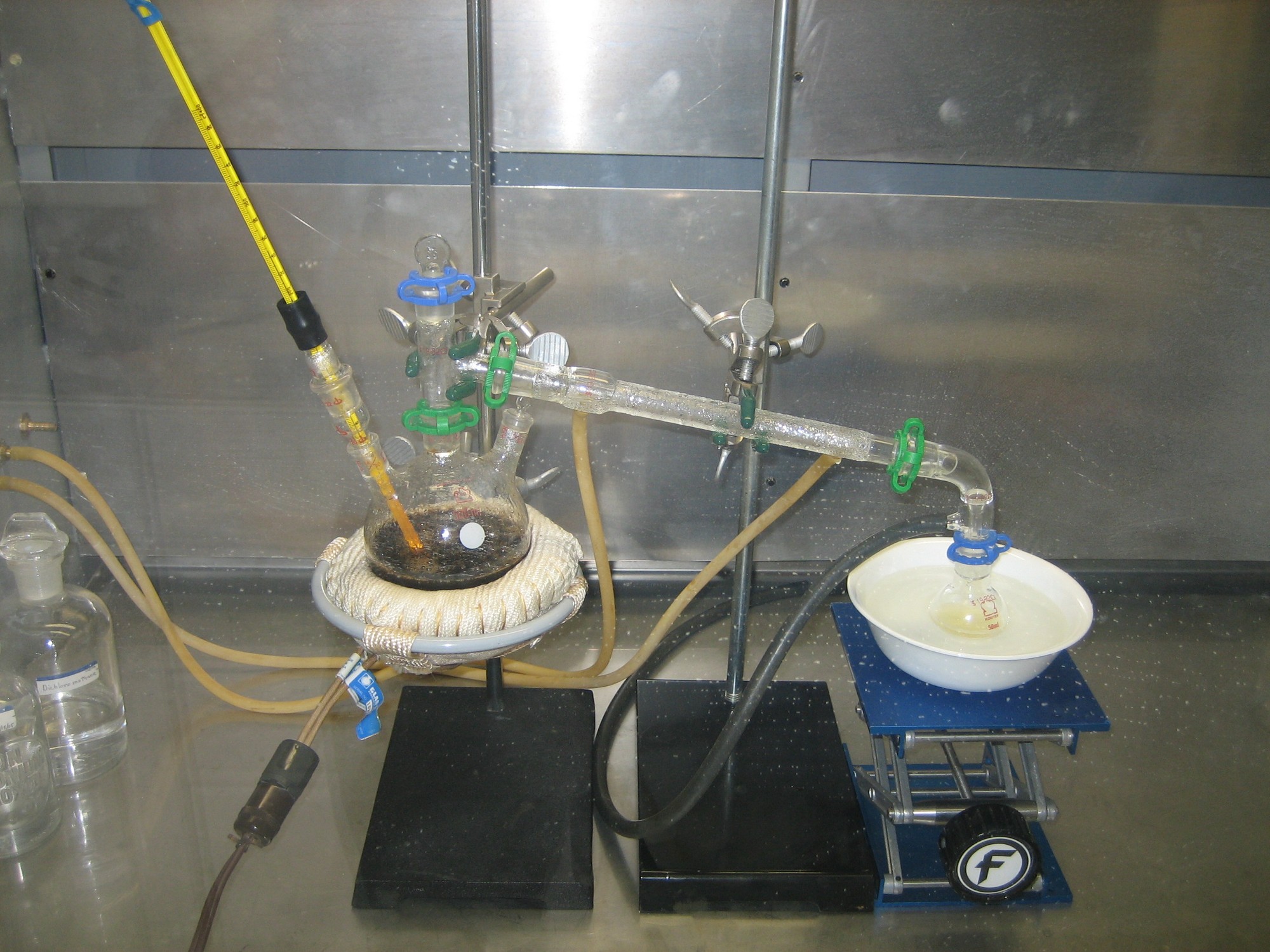

I set up for simple distillation (see attached photo). As did Vitus I ran a piece of rubber tubing from the vacuum adapter to a suction location in

the back of my hood to make sure I didn't breathe any acrolein (if generated). It is an interesting synthesis in that CO2 production starts early

(55C) and just continues on strongly to the end. I ran the reaction for 3 hours to go from 130C to 260C. Per procedure I changed the receiver at

195C. 195C is used as the cutoff between the formic acid/water condensate and the allyl alcohol/water condensate. As you will note the pot liquid

(gycerol) is a very dark brown. The color change started about 225C and got darker as the temperature went up. I presume this is due to

carbonization of the glycerol. I ended up with about 50mL of crude distillate and will report the yield when available.

Don't ask me why I used a 3-neck RBF for a pot. And yes, I probably did ruin my new green Keck clamps as I don't think they are good for 260C.

glycerol and triethylorthoformate

jack-sparrow - 31-7-2006 at 10:48

Hi, I recently discovered ( in the litterature), a new route to allyl alcohol. I tried it 3 times and it is reproductible. I tried the

glycerol/oxalic acid route and one gets a lot of variation in yields and purity. This one is much cleaner. You react glycerol with

triethylorthoformate.

Here is the protocol:

250 ml RBF, dean-stark and condenser, put glycerol (46 g) and triethylorthoformate (74 g) and heat to 120 degC over an iol bath with vigorous

stirring. Distill out ethanol until you get about 60 ml. Raise heating gradually to 140 degC for 3 hours, add a catalysis of acetic acid (1ml) and

heat to 220 degC, Distill out allyl alcohol and ethanol.

Distill crude over glass helices column and you should get allyl alcohol pure in yields of 50% which is much greater than with the oxalic acid route

(typically 10-30 %).

This is tried and true and much less sloppy than glycerol/oxalic acid route.

[Edited on 31-7-2006 by studur]

Magpie - 31-7-2006 at 17:53

Studur that looks like a good procedure. I especially like the fact you don't have to take the temperature above 220C as I think that is about when

the glycerol starts to char. And with charring I believe you get acrolein, which is truly nasty stuff.

I believe I have some acrolein in my allyl alcohol. Either that or I have forgoten how pungent and lachrymatory allyl alcohol is. I haven't done my

workup yet so can't report on yield but suspect your estimate is correct.

BTW what is triethylorthoformate and can it be obtained OTC?

Vitus_Verdegast - 31-7-2006 at 18:44

Triethylorthoformate, a.k.a. triethoxymethane or "aethon" can be made by treating a mixture of chloroform and ethanol with sodium metal.

It is a liquid with a sweeting odor resembling that of pine needles.

bp = 146°C

It starts to decompose on contact with water.

references for its preparation:

CHCl3 and NaOEt:

J. Chem. Soc. 119 (1921) 1228

CHCl3 + EtOH + Na

J. Chem. Soc. Ind. London 42 (1923) 431

Chem. Zentralbl. 95, (1924) 418

CHCl3 + EtOH + Na in ether:

Chem. Ber. 12 (1879) 117

(available for free from gallica.fr)

CHCl3 + EtOH + Li

Chem. Ber. 59 (1926) 500

[Edited on 1-8-2006 by Vitus_Verdegast]

Magpie - 2-8-2006 at 13:09

I tested the crude product from my allyl alcohol synthesis today with Tollen's reagent (silver mirror test). It gave a weak postive using either 1

drop or 3 drops. As a control I tested some fresh Durkee's imitation almond flavoring which I presume contains benzaldehyde. This gave a strong

positve. Based on this testing I conclude that my distillate does indeed contain some small amount of acrolein (an aldehyde).

The allyl alcohol/water azeotrope bp is 87-88C and that for pure allyl alcohol is 97.1C. The bp for acrolein is 52.5C. I'm planning on doing a

fractional distillation in an effort to remove the acrolein from the allyl alcohol. Of course this will be done in my hood with fan ON.

I would appreciate any comments and recommendations regarding this plan. Thanks in advance.

IPN - 2-8-2006 at 14:36

Washing the allyl alcohol with a NaHSO3 solution should remove the acrolein nicely. Then a simple distillation should be enough.

Magpie - 2-8-2006 at 15:53

Thank you IPN. That sounds simple enough.

Some internet research indicates that acrolein reacts well with protein. This made me think that a wash with albumin (egg white) would neutralize it.

I'm not sure how the alcohol would then be separated from the albumin, however.

neutrino - 2-8-2006 at 18:21

Stir some egg white into your solution, let it settle out, decant, and redistill. It doesn't seem that complicated, unless I'm missng some

side-reaction.

chemoleo - 3-8-2006 at 14:18

I'm not sure eggwhite (protein) is such a good idea, it contains too many reactive groups like hydroxyls, amines, etc... which could do all sorts of

reactions with the unsaturated keto-enol tautomeric forms of allyl alcohol.

I'd rather use straight amine, even ammonia, or something like lysine (free amine) from vitamin supplies.

Or, add NaOH and do a Cannizarro - you'll get proprionate and allyalcohol...but do check on base stability of allyalc, it may well polymerise in the

presence of it.

Magpie - 3-8-2006 at 14:27

My old textbook describes the use of NaHSO3 to separate out aldehydes from alcohols, spending a whole page on its use, including equations. My old

lab manual uses it as a test for the presence of an aldehyde. My modern lab manual and text don't say a damn thing about it.

I added sodium metabisulfite in 2.7g increments to my ~50mL of crude allyl alcohol distillate. After each addition I tested with Tollen's reagent to

see if any aldehyde was present. The test results were progressively weaker positive. When the solution was saturated with salt (13.5g added) the

Tollen's result was very weak with just a trace of black precipitate forming - no mirror, even with heating. So I think that the acrolein should now

be tied up as the following salt:

CH2=CH-CHO + NaHSO3 <---> CH2=CH-CHOHNaSO3

I plan to distill this product "as is" to obtain the allyl alcohol/water azeotrope.

not_important - 3-8-2006 at 15:41

As an alpha,beta unsaturated carbonyl compound, it may add the bisulfite across the double bounds.

http://www.asbcnet.org/journal/pdfs/1999/0204-04R.pdf

It still does the job, though.

Magpie - 3-8-2006 at 16:56

not_important,

Yes I was worried that the NaHSO3 would add to the double bond of the allyl alcohol and thereby ruin my product. But in my limited research I saw no

indication of this. When I get this alcohol isolated and its identity verified I will calculate a yield. This may indicate whether it suffered much

damage.

Thanks for posting that interesting paper. I noted that humans can detect even 20 ppb of 2-nonenal in beer. This may be a family trait of the

acrolein analogs.

not_important - 3-8-2006 at 17:22

The unsaturated alcohol should be safe from addition without added catalysts, take that double bonded oxygen to liven it up.

I picked the beer one out of several, it is could be said to have a human interest aspect. Lets you pontificate next time you hoist one.

Nicodem - 4-8-2006 at 00:55

The bisulfite adds to both the double bond and the carbonyl of acrolein forming (-)O3S-CH2CH2CH(OH)-SO3(-). It is a known reaction but don't ask me to

provide a reference as I saw it in a book.

This is however irrelevant in the bisulphite as a way to remove acrolein. Allyl alcohol obviously can't add the bisulfite in a 1,4-addition maner (aka

Michael addition) simply because it has no electrophilic conjugated sistem.

Magpie - 6-8-2006 at 13:21

Nicodem,

Acrolein is an aldehyde with a double bond at the alpha, beta position, as you know. I understand how acrolein can undergo a Michael

addition. What I don't understand is how the designation 1, 4 applies. Please explain.

Progress report:

The crude distillate was saturated with sodium metabisultfite. It was then distilled, with liquid coming off from 80-100C. This 2nd distillate was

then saturated with K2CO3, salting out the allylic alcohol to an upper layer. It has a not unpleasant smell of onions to me. My wife says garlic,

my son says bagels. It was interesting that the crude crude distillate was acidic and initial amounts of added K2CO3 resulted in the evolution of

CO2. I will decant off the organic and distill it one more time.

The NaHSO3 took care of the acrolein nicely.

[Edited on 6-8-2006 by Magpie]

not_important - 6-8-2006 at 14:22

H2C=CH-CH=O

__4_3__2___1

Addition happens at atoms 1 and 4

Ordinary bisulfite to aldehyde carbonyl is 1,2, across the C=O double bond.

exaples

http://www.organic-chemistry.org/frames.htm?http://www.organ...

Magpie - 6-8-2006 at 16:43

Thank you not_important. I'm still hazy on what is meant by a 1,4 addition. What would be the product of a 1,4 addition of bisulfite to acrolein?

I think I may see it now. The SO3-- adds at 4 position and the H+ at 1 position creating an enol which reverts to the saturated aldehyde? Is this

right?

[Edited on 7-8-2006 by Magpie]

Magpie - 7-8-2006 at 20:16

The final product, taking the condensate at 87-97C, amounted to only 9.3mL. Assuming that this is an allyl alcohol/water azeotrope at 72.5 wt%

alcohol (Gmehling, Azeotropic Data, p. 510) the yield is only 18.7% based on the limiting reactant, oxalic acid.

Based on the low yield and the acrolein by-product I cannot recommend the Norris procedure. It was an adventure, however.

jack-sparrow - 8-8-2006 at 07:30

20 % is not surprising for this method. You lose a lot of oxalic acid by side-reactions and decomposition.

I was wondering if anhydrous or hydrated oxalic would make a difference but I did not end up with evidences after trying both methods. The cleanest

method is the triethylorthoformate route.