Looks like that the way by NaOH are always exotherm and will require a precise calculation by weight to the NaOH solution. Well known are any content of NaOH in the result can pumping out moisture from the and the result will melt away.

| Quote: |

I have

more good ideas than time for experiments , and I love it when you fellows check it out

I have

more good ideas than time for experiments , and I love it when you fellows check it out And for when I'm wrong ....

And for when I'm wrong .... ,

,

I have yet to do a reduction with actual measuring.

I have yet to do a reduction with actual measuring.

| Quote: |

, ravaged by hordes of

, ravaged by hordes of

| Quote: |

are adding a large access of CCl4 to the mix and this will prepricate the picrate, adding HCl to neutralizing the salt and the picramic

acid will prepricate or the mix will than diluted with H2O and this is cooled to 0 gegree celsius.

are adding a large access of CCl4 to the mix and this will prepricate the picrate, adding HCl to neutralizing the salt and the picramic

acid will prepricate or the mix will than diluted with H2O and this is cooled to 0 gegree celsius. | Quote: |

including the

link posted near the end of the first page , concerning Mr. Anonymous " dry method " for making

including the

link posted near the end of the first page , concerning Mr. Anonymous " dry method " for making

| Quote: |

| Quote: |

always.

always.| Quote: |

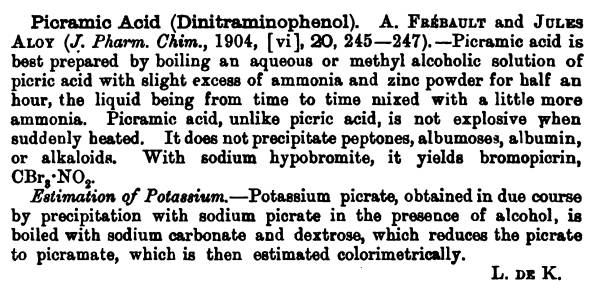

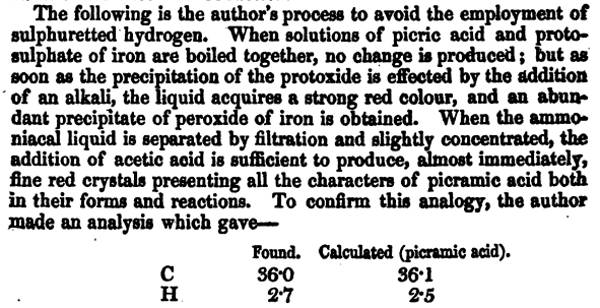

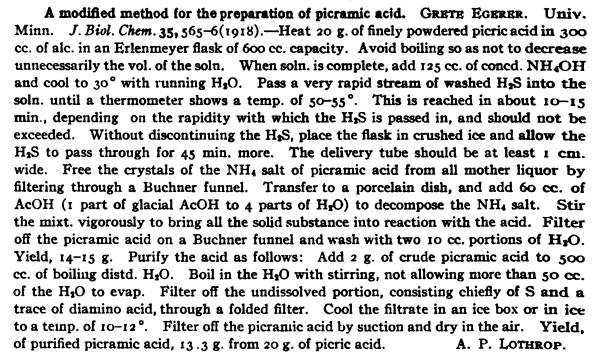

reducing agent for "alkaline picrate" (sodium picrate) forming picramic acid

directly as a major byproduct.

reducing agent for "alkaline picrate" (sodium picrate) forming picramic acid

directly as a major byproduct. I wonder what

the yield of picramic acid would be compared to the other products of the reaction? I'm still trying to interperet the reactions described in this

absract, I guess a few tests to see what we get couldn't hurt.

I wonder what

the yield of picramic acid would be compared to the other products of the reaction? I'm still trying to interperet the reactions described in this

absract, I guess a few tests to see what we get couldn't hurt.| Quote: |

| Quote: |

| Quote: |

| Quote: |

| Quote: |

| Quote: |

Quote: Originally posted by prometheus1970  |