Introduction

1,1,3-triphenylprop-2-yn-1-ol is a chemical which can be converted to rubrene that is a chemical that can be used as a dye used for glow sticks. In

this experiment 1,1,3-triphenylprop-2-yn-1-ol was prepared by a Grignard reaction. Ethyl magnesium bromide was generated to which phenylacetylene was

added. This depronated the phenylacetylene. The phenylacetylene anion is a strong nucleophile and a strong base. The electrophile in this case was

benzophenone. The resulting alcohol from the reaction was produced on the workup. A brief mechanism for the reaction can be found here: http://www.wikipremed.com/03_organicmechanisms.php?mch_code=...

A full synthetic scheme as well as some pictures can be found here

http://www.versuchschemie.de/topic,10433.html

Warning!

This experiment uses very flammable liquids and toxic compounds! This is not to be attempted unless you have the equipment, knowledge and experience

to do so safely. It is advantageous to run this reaction under nitrogen but it is not a necessity.

Reaction Notes

It is essential to use absolutely dry and pure reagents and dry equipment in this reaction. This reaction does not work with a small amount of

moisture present and if it does work with a small amount of moisture present then it will make purification a living hell. The yellow oil obtained at

the end of the workup can be extraordinarily hard to get to crystallize if a poor job was done in the reaction. If a proper job is done in the

reaction then the yellow oil will begin to crystallize on it’s own, usually within an hour to a day. It is possible that the oil may not crystallize

which happened to me the first time I attempted this synthesis. I found that vacuum distillation like vogel recommends does not work very well to

purify the oil. I found that chromatography also didn’t work very well, but I didn’t put a large amount of effort into it. After 6 months of

letting the oil sit on the shelf it finally began to crystallize. After collecting the crystals and recrystalizing them I obtained a 3% yield. The

second time I attempted this reaction I managed to get spontaneous crystallization after the workup. The product is practically insoluble in hexanes,

ligroin and pet, ether. It is fairly soluble in toluene and much more soluble in hot toluene. It is also soluble in ether and acetone. The ethyl

bromide was prepared as per the video that myst32yt posted on youtube. The benzophenone was prepared by the Freidel Crafts acylation of benzene with

benzoyl chloride. It was recrysallized from a methanol water solution to yield large crystals. The procedure was adapted from Vogel 3rd editon for the

benzophenone synthesis. The phenylacetylene was prepared as per UC235’s procedure from styrene. This procedure was adapted from Vogels 5th Edition.

Experimental

Table of Reagents

9.5mL ethyl bromide

12.75g phenylacetylene

22.75g benzophenone

3.0g magnesium turnings

Spec of iodine

Diethyl Ether

27.5g Ammonium Chloride

Reagent Preparation

The ethyl bromide was kept over 4A molecular sieves and distilled the day prior to use and was stored in a well sealed dried bottle. The

phenylacetylene was stored over 4A molecular sieves and fractionally distilled at atmospheric pressure the day before use. The benzophenone was kept

in a dessicator under vacuum over calcium chloride for a week before use and the magnesium turnings were used as it. The diethyl ether was stored over

3A, 4A molecular sieves and activated alumina and was distilled immediately before use. The ethyl bromide, phenylacetylene and benzophenone were all

home made and were well purified after synthesis. The M.P and B.P. ranges of the compounds were 38-40C (lit. range of 38-40C) for the ethyl bromide,

141-144C (lit range of 142-144C) for the phenylacetylene and the benzophenone had a M.P. of 47.3-48.6C (lit. range of 48.5C. The diethyl ether was

obtained commercially which was HPLC grade. The ether tested negative to peroxides before it was distilled.

Equipment Preperation

All of the glassware used in this experiment was oven dried before use. The glassware was dried at 105C for 1 hour before the experiment. When pieces

were ready to be used they were immediately removed from the oven, greased and assembled in the fumehood. A vacuum was applied to the apparatus until

it cooled to room temperature then the apparatus was flushed 3x with dry nitrogen.

Part 1. Ethylmagnesium Bromide Synthesis

An apparatus was assembled from hot glassware that was freshly greased. It consisted of a 250mL 2-neck round bottomed flask with a stir bar, a spec

of iodine and the magnesium in it with a reflux condenser, and an addition funnel in the two necks. It was clamped in two places, one on a neck and

the other on a condenser for support and suspended over a hotplate magnetic stirrer. A rubber septum was applied to the top of the addition funnel and

a vacuum adapter was added to the top of the condenser. The whole apparatus was then evacuated of air until it was cool. Once the apparatus was cooled

it was flushed 3x with nitrogen and kept under a positive pressure of nitrogen. By using a glass syringe and needle, 9.5mL of ethyl bromide and 25mL

of anhydrous ether was added into the addition funnel through the septum. The solution in the addition funnel was then slowly dripped onto the

magnesium bits and an immediate reaction was evident. The solution was dripped in as to maintain reflux. Once all of the solution was added the

reaction was refluxed for 15 more minutes. Once the reflux had finished the reaction mixture was cooled down slightly. The solution was a light green

colour and translucent.

Part 2. Addition of Phenylacetylene

A solution of 12.75g of phenylacetylene in 15mL of anhydrous ether was added into the addition funnel by a syringe. The solution was then added

fairly rapidly as the reaction was not violent. After the phenylacetylene solution was added the mixture was refluxed for two hours. After two hours

of reflux it was found that the solution had become quite viscous and creamy. At first the phenylacetylene solution did not mix with the

ethylmagnesium bromide solution but with good stirring and reflux the two layers mixed just fine. Once the reflux had completed the mixture was cooled

down to room temperature

Part 3. Addition of Benzophenone

A benzophenone solution was made by first adding the benzophenone to oven dried schlenk flask and adding a rubber septum. A vacuum was applied until

the flask cooled and then it was flushed 3x with dry nitrogen. Through the septum 25mL of anhydrous ether was added. The solution required a small

amount of heating to drive all of the benzophenone into solution.A solution of benzophenone was made by dissolving 22.75g of benzophenone in 25mL of

anhydrous ether. The solution needed some heating to get all of the benzophenone to dissolve. While the reaction apparatus was under nitrogen the

addition funnel was replaced by a rubber septum. The benzophenone solution was then added slowly under nitrogen by cannula transfer from the schlenk

flask. The reaction was quite violent so an ice bath was kept on hand to cool the reaction mixture as to stop it from boiling too vigorously. The

reaction mixture was too thick to stir so it was simply let to sit without stirring for 1.5 hours. The rubber septum was then replaced with a glass

stopper and the reaction was then refluxed for 1 hour. The mixture was then allowed to cool to room temperature. The condenser and stopper were then

removed and the flask allowed to be exposed to the atmosphere.

Part 4. Work-up

A saturated aqueous solution of ammonium chloride was prepared by adding 27.5g of ammonium chloride to 75mL of distilled water, heating helped to

drive the salt into solution. The solution was then added to the reaction mixture which was a solid cake. The cake was broken up and then allowed to

stir until all of the solid pieces dissolved. The reaction mixture was then added to a separatory funnel and the upper ether layer was separated. The

lower aqueous layer was then extracted twice more with peroxide free ether. The combined ether extracts were then dried using anhydrous magnesium

sulfate and filtered into a 200mL round bottomed flask. The ether was then removed by distillation on a water bath, and the final residual ether was

removed under reduced pressure. This yielded a thick yellow oil

Part 5. Purification and Recrystallization

Situation A, The oil crystallized on it’s own

The crystallized oil was taken and 25mL of hexanes was added. The clumps were broken up to yield a yellow paste. The paste was then vacuum filtered

and washed with hexanes which removed some of the yellow impurity. Suction was applied for 15 more minutes. A small seed crystal was then taken out.

The resulting solid was added to a 200mL Erlenmeyer flask with a boiling stone and the solid was then covered with hexanes and heated to boiling.

Toluene was slowly added to the boiling solution while it was swirled to mix the contents. The toluene was added just until the crystals dissolved.

The flask was then removed from the heat. The flask was slowly allowed to cool and a seed crystal was added. The flask was cooled as slowly as

possible. The solution was heated when oiling out occurred which looked like a fine while precipitate forming on the sides of the flask. The heating

drove the oil back into solution but did not dissolve the seed crystal which was growing in size. The solution was carefully cooled to prevent oiling

out from occurring. The resulting room temperature solution had beautiful needle like crystals that crystallized in the shape of clouds. The solution

was then cooled in an ice bath. The contents of the flask were then broken up and it was vacuum filtered. The solid was washed with a large amount of

hexanes. The resulting crystals were then allowed to dry. The M.P. of the crystals was 80.3-82.1C. The lit. melting point for the crystals was 80-82C.

The total obtained yield was 15.90g which was 44% of the theoretical yield. This was fairly close to the literature yield of 49%.

Situation B, The oil did not crystallize on it’s own.

It is very tricky to get the oil to crystallize if it is not willing. I could not get vacuum distillation to work as Vogel stated but maybe someone

else can. Silica chromatography may be a good was to purify it. If all else fails just let it sit for a while, it may spontaneously crystallize after

days, weeks or even years. If all else fails, buy a small amount of this compound to use as a seed crystal or repeat the experiment. I found that the

crystal structure greatly resembled that of sodium acetate so it might be possible to initiate crystallization using sodium acetate.

References

(1) Furniss, B., Hannaford, A., Smith, P., Tatchell, A.: Aliphatic Alcohols. Textbook of Practical Organic Chemistry; 5th Ed.; No Editors, Eds; John

Wiley and Sons, 1989, pp 539.

(2)1,1,3-triphenyl-2-propyn-1-ol;MSDS[Online];Sigma-Aldrich: Oakville, ON. http://www.sigmaaldrich.com/MSDS/MSDS/DisplayMSDSPage.do (accessed Jan 21 2013)

Here are a few pictures of the finished product

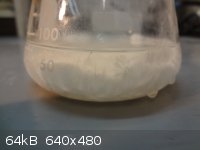

Crystals in solution after cooling in an ice bath

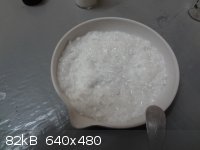

Some pictures of the dried crystals

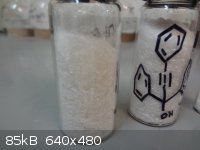

The crystals were packed into vials

[Edited on 22-1-2013 by Mercedesbenzene]