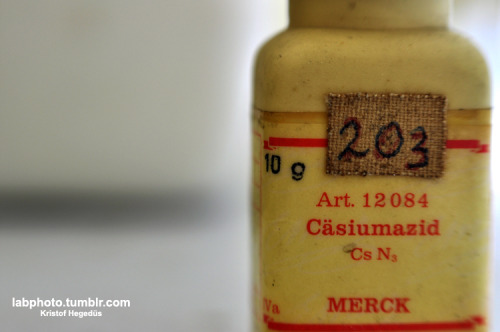

| I have an idea for makeing the caesium and rubidium a bit easier, maybe I could add stochiometric amounts of caesium/rubidium hydroxide to magnesium

in a flask filled with mineral oil ,with a condenser,presure equalizing seperatory funnel and vaccum adapter. I connect it to a vaccum pump, then heat

it to 200c were the caesium/rubidium hydroxide and magnesium would be catalysed by addition of tertiary butanol or tertiary pentanol while in the

inert enviorment of mineral oil, the metal produced would rest on the bottom so that I could coalesce them later, and of course the hydrogen would be

sucked through the presure equalizing seperatory funnel and out of the vaccum adapter. I have a 100ml erlenmyer flask, a 300mm vigruex column, a 25ml

presure equalizing seperatory funnel, and a 90 degree vaccum adapter and a hotplate. Now I just need a vaccum pump. Does this sound like a plausible

method for making rubidium or caesium? |