Fery - 21-12-2022 at 06:11

I followed this method:

Attachment: ed054p383.pdf (2.2MB)

This file has been downloaded 246 times

To 50 ml RBF was added:

1,6 g 1,2,3,4-tetrahydrocarbazole (I used the second grade product recovered from mother liquors, not the main pure crop).

0,32 g 10% Pd/C catalyst recovered from 1 of my synthesis and air dried

14,0 g freshly distilled cumene, b.p. 150-152 C (I weighed it, I did not measure its volume, d = 0,862 g/ml that should be 16,2 ml).

No boiling stones added as the catalyst is enough to cause smooth boiling (but later things did not go smoothly).

Air condenser attached (luckily with wide inner diameter circa 25-30 mm).

Refluxed for 9 hours (maybe 2-4 hours could be enough but my catalyst was from sales and certainly older than fresher and produced for unknown purpose

for uknown lab / industrial usage). From the beginning nice small bubbles (H2 ?) but soon bumping started and went progressively worse in time.

Luckily 50 ml RBF with less than 20 ml content was used and wide tube air back condenser. I can only speculate what caused the bumping but it was very

likely H2O by oxidation of H2 ? There were 2 immiscible liquids visible in air condenser, suspected H2O on top part, but some drops flowed down, maybe

moisture from not absolutely dry 1,2,3,4 tetrahydrocarbazole?, Pd/C used in this experiment was recovered from 4-phenyl-butan-2-one experiment and air

dried. Or maybe cumene hydroperoxide formed? Luckily I at least distilled it before the experiment. Cumene hydroperoxide could help in dehydrogenation

reaction as would quickly remove H2 from Pd.

Bumping was about every 5-10 seconds !!! and with time it hit upper and upper parts of the condenser and reached also its top...

I wanted to reflux for 12 hours but let it be after 9 hours. Because I used solvent with lover b.p. than in the reference link (the best solvent I had

at hand was cumene) so the reaction needed more time due reduced speed at lower temperature.

The bumping itself was not the worse fact, the worse fact was that water presence reduced dramatically boiling point and thus reflux temperature and

thus reaction rate.

Filling flask to not more than 20-25% is recommended and using wide tube condenser. Better if I used 100 ml than 50 ml RBF.

You can also put a small glass funnel on top of condenser to prevent spattering out of the top of the condenser or use longer condenser (mine was only

30 cm long).

I do not know how to simply remove very likely few drops of water from the reaction (maybe drying tube on top of condenser???)

At the end it seemed like circa 5 ml of solvent was lost during reflux??? But I did not measure the difference.

Cooled below b.p. of ethyl acetate and added 25 ml ethyl acetate through top of the condenser drop by drop on walls of condenser which dissolved

product and catalyst adhering on walls of condenser so they returned back down into the flask.

Mixture heated to dissolve product which meanwhile crystallized on cooling. Twice gravity filtered hot through hard dense filter paper (after first

filtration there was still a little of catalyst in the filtrate).

Ethyl acetate evaporated until product started to crystallize and mixture cooled down to temperature of b.p. of petrolether (60 C). Some product

crystallized so a little of boiling ethyl acetate added to dissolve it - if no suspect loses of cumene during bumping, the additional ethyl acetate

very likely unnecessary?

Slowly added 15 ml of boiling petrolether (b.p. 60-65 C = isohexanes) and cooled to 0 C (winter temperature outside).

Vacuum filtered on sinter, washed with 5 ml of cold petrolether (0 C) and dried by sucking air through sinter for 15 minutes.

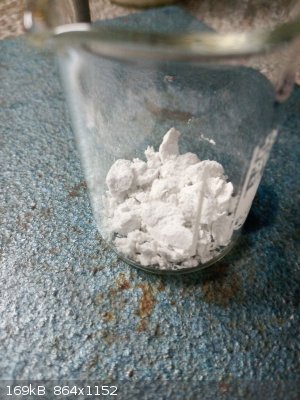

1,3 g of overnight air dried product next day.

Prepared 30 ml 85%vol solution of methanol with water by mixing 25,5 ml methanol + 4,5 ml H2O.

Product magnetically stirred with 25 ml 85%vol methanol in a beaker for 1 hour (to dissolve unreacted 1,2,3,4 tetrahydrocarbazole).

Vacuum filtered on sinter, washed with remaining 5 ml of 85% methanol on sinter, sucked on sinter for 15 minutes, air dried for half a day on a warm

place (40 C) until stable weight not decreasing anymore.

1,1 g carbazole obtained, m.p. 245-246 C.

If someone knows how to remove small amounts of water from high boiling organic solvent on the fly, please post here your ideas!

reagents

apparatus

beginning of reflux, nice small bubbles (solvent or maybe H2)

some very likely water (oxidation of H2 with O2 from air?) above condensed cumene - whole condenser on photo

top, middle and bottom part of air condenser with suspected water present

bumping carried a little of reaction mixture into condenser - here dark Pd/C visible

with time progression the bumping was getting worse, here top of condenser at the end of reflux, the condenser inner diameter was cca 25-30 mm and

length 300 mm, I used this "cap" to reduce spattering from the top of condenser (you can also use small glass funnel inserted into the top joint)

filtration of hot dissolved product after addition of ethyl acetate, this is second filtration as a little of catalyst passed through filter paper

during first filtration

ethyl acetate evaporated and solution cooled to b.p. of petrolether, some product crystallized so a little of boiling ethyl acetate was added to

redissolve it, then boiling petrol ether (b.p. 60-65 C, colorless in smaller beaker on right side) was added into the mixture (bigger beaker on left

side with yellowish solution)

the addition of petrol ether caused quick crystallization of the product, mixture was further cooled down to 0 C

vacuum filtered on sintered glass funnel

after drying overnight 1,3 g of crude product obtained which was magnetically stirred for 1 hour with 25 ml of 85%vol methanol

product vacuum filtered on sinter

and transferred into a beaker for air drying

Johnny Windchimes - 21-12-2022 at 06:46

Always a treat to read your synth lab notes; a picture's worth 1000 words~!

[Edited on 21-12-2022 by Johnny Windchimes]