Fery - 21-11-2022 at 11:35

There are a lot of posts producing chloroform from acetone but only few posts focused in the other product of this reaction.

Benzylideneacetone reacts with sodium hypochlorite into cinnamic acid and chloroform.

Calculations:

1,46 benzylideneacetone = 10 mmol (M=146.19 g/mol)

0,20 g NaOH in 1 ml H2O

2,23 g = 30 mmol NaOCl (74,44 g/mol) = 17,8 g 12,5 %, but 25 ml used (excess)

Procedure:

Into 25 ml Erlenmeyer flask was put fine crystalline benzylideneacetone 1,46 g (10 mmol), 1 ml of 20% NaOH, 25 ml of 12,5% NaOCl (+4 C cold from

fridge) and stir bar. The flask was closed with a plastic foil, cooled in water-snow bath and magnetically stirred at high RPM for 15 minutes. Then

cooling bath removed and stirring continued for 1 day at room temperature. Sometimes the pieces of solid had to be crushed using glass rod.

The content was transferred into 100 ml flask, pleasant scent of chloroform observed. There was added 2 ml of acetone to destroy excess of

hypochlorite. After 2 hours 20 ml of water was added and the content was heated to boil for few minutes to evaporate chloroform and dissolve sodium

cinnamate. Then it was quickly filtered through heated funnel with filter paper, slightly cooled, 10 ml of 35% HCl added (excess), cooled, crystals

gravity filtered.

Product was recrystallized from 100 ml of water, here during filtration colorless filtrate obtained and impurities stayed on filter paper. Cooled to

+4 C in fridge and filtered on Buchner funnel.

Air dried until constant weight.

Yield 0,36 g, very poor. Better to synthesize it by benzaldehyde + acetic anhydride + anhydrous sodium acetate as I did here. Or maybe bigger scale could give better yield?

Thoughts and speculations:

The reaction was heterogenous, the smaller crystals the better, the more rapid stirring, the better. Chloroform formed during the reaction seemed to

clump small crystals into sticky blobs which was disadvantageous but unavoidable.

From time to time it was necessary to crush the formed blobs into small pieces using a glass rod. According the very poor yield most of the reactant

did not react, but I do not know how to dissolve it to proceed the reaction better.

References:

https://www.youtube.com/watch?v=DV7OjgmghxY&t=15s

http://www.sciencemadness.org/talk/viewthread.php?tid=152030

https://sci-hub.wf/10.1002/jccs.195600011

Attachment: jccs.195600011.pdf (209kB)

This file has been downloaded 327 times

reactants: benzilideneacetone in the Erlenmeyer flask, solution of NaOH in the beaker, solution of NaOCl in the syringe

the reaction was magnetically stirred for 15 minutes while cooling in snow-water bath

then it was stirred for 1 day at room temperature

then it was transferred into bigger flask, excess of hypochlorite destroyed by acetone and the content was heated to boil out the chloroform and

dissolve sodium cinnamate

then it was filtered hot, partially cooled, acidified with HCl, cooled, crystals filtered

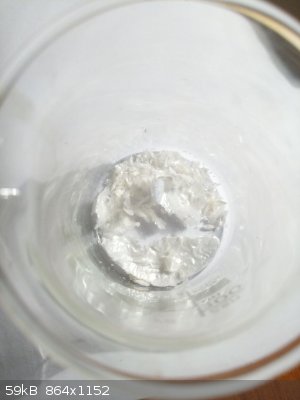

recrystallized from boiling water, filtrate colorless, impurities insoluble and captured on filter paper

cooled, crystals filtered on Buchner funnel, air dried

Bedlasky - 25-11-2022 at 12:24

Nice work as always, Fery! Nice to see different use of haloform reaction. Usually haloform is the desired product. Btw isn't possible that bleach

oxidize double bond?

Fery - 25-11-2022 at 21:23

I added a little of NaOH to be sure not to attack double bond and prevent halohydrin reaction (no free Cl2 either HOCl). For cleaving double bond I

had success with ricinoleic acid + KMnO4 and oleic acid + H2O2 + H2WO4. Both required high temperatures, do not occur in cold. KMnO4 somewhat like

70-80 C but not higher to prevent KMnO4 decomposition. H2O2 required temperatures around 100 C (above 100 C it seemed H2O2 started to decompose -

raising temperature exothermically and bubbling = evolution of O2, H2WO4 was only a catalyst). I do not have O3 generator, that would also work

(ozonolysis).

Pumukli - 26-11-2022 at 08:29

Nice work. I always wanted to see a haloform used for other products not only for chloroform. (I have this triacetyl-benzene sample which failed as

uber-super amino acid decarboxylation catalyst. I wonder if I fed it into hypochlorite I may get trimesic acid.)

How concentrated was your hypochlorite solution? Did you check its strength before use? I understand it was not necessary because you used a fair

excess but I have the feeling that it is not the same to run a reaction with 1% NaOCl or 5% NaOCl solution.

For an amateur's point of view your synthesis route may still be more tempting because for us, amateurs, acetic anhydride is not always easy to

acquire.

Maybe a little regular, old-school soap, the alkali-stearate/palmitate type could have been used to emulgeate those clumps. Then in the end the soap

could have been precipitated as Ca/Mg-salt, then filtered... I know it is a hellish, waxy precipitate that sticks to everything but maybe filtering

after a few hours standing and then decantation would not had been so terrible... Ca/Mg-soaps once formed would not redissolve even after

acidification (at least according to my knowledge  ) so maybe extraction could

have been tried too.

) so maybe extraction could

have been tried too.

Fery - 26-11-2022 at 08:45

Hi Pumukli, it was 12,5% NaOCl... the chinese method had best yield when using 1,0 M concentration so approx 7,5%. I did not check its concentration.

Immediately after buying it I placed it into fridge and it is stored in +4 C cold and dark.

In the video link, they increased solubility of the reagent with methanol... I'm not sure whether it is good idea or not... I didn't use any solvent,

I did everything similarly to the chinese method, just mixing the organic reactant (very poorly soluble in water) with water solution of hypochlorite.

I used something approx 50% excess of hypochlorite.

I did not heat the mixture (that would maybe help by melting the reactant) as that could decompose hypochlorite into chlorate.

I do not know how to perform this reaction of very poorly soluble reactant to achieve better yield... the chinese method looked so nice according the

yield... my practical yield was quite low, I do not know why... maybe also some loses as I recrystallized twice...

Pumukli - 26-11-2022 at 08:54

On second thought, that MeOH as cosolvent is not a bad idea at all. Methanol should not react with hypochlorite if memory serves me well.

Maybe it would worth a shot if you want to try it again.

Bedlasky - 26-11-2022 at 10:56

Wouldn't hypochlorite oxidize MeOH to formaldehyde-->formic acid-->CO2?

Fery - 26-11-2022 at 11:13

Bedlasky that's good point. The guy from the video link got some product. Maybe haloform reaction proceeds faster than the oxidation of alcohol?

Pumukli - 26-11-2022 at 12:56

A quick search brought up a few hits regarding methanol and sodium hypochlorite incompatibility.

It seems that although methanol doesn't go through the haloform reaction it can yield methyl-hypochlorite which is toxic and explosive. The formation

of this compound is pH dependent, and adding some excess NaOH (hence diminishing the available hypochlorous acid in the system) may reduce this

problem.

The possibility of this (side)reaction surely warrants a deeper research of the literature if one wants to walk this path.

kmno4 - 26-11-2022 at 14:31

I did cinnamic acid by this method few times, with yields around 70-80%, close to the yields in the given article

(10.1002/jccs.195600011).

[Edited on 26-11-2022 by kmno4]

Pumukli - 26-11-2022 at 22:46

So you say, kmno4, that basically stronger stirring (to prevent clumping) should provide a good yield? Or what do you think, what went wrong in Fery's

synthesis?

Fery - 27-11-2022 at 05:03

Yes, my yield was something like only 20%... but I did twice recrystallization as from the first one the product was not pure enough... also I did the

synthesis only at small scale... maybe bigger scale = better yield...

Boffis - 27-11-2022 at 12:10

Hi Fery et al. While I haven't tried this reaction on benzalacetone type substrates I have recently used this reaction on substituted acetophenones,

namely 4-methoxyacetophenone, to prepare 4-methoxybenzoic acid. I am away at present and don't have my note books with me but as far as I can recall I

mixed the acetophenone in warm water and stirred it vigorously without a co-solvent and then ran in an excess of rather old (12months) 14-15% sodium

hypochlorite with some extra NaOH to ensure that the reaction mixture remained alkaline while taking the formed acid into solution. The idea being

that even if the reaction only occurs at the surface of the immiscible ketone its continuous solution would drive the reaction forwards. It worked

well but require a considerable excess of sodium hypochlorite and an elevated temperature. I tried to distil the chloroform out of the mixture as it

formed, this gives you an idea of the temperature but this was a total failure! In actual fact the excess required may not need to be that large as I

kept adding more hypochlorite because some brown oily droplets remained in the solution but I eventually found that this material was not residual

acetophenone. I presume that it is either an impurity in the original methoxyacetophenone or more likely, a side product. The overall yield was

reasonable >70% of the benzoic acid if I recall correctly. I ran the reaction twice at about the 20g scale.

So in your case maybe try it without the methanol and warm it up while adding the hypochlorite. On e advantage of methoxyacetophenone is its low

melting point so its fairly easy to emulsify it once molten, benzalacetone should work similarly.

Fery - 25-11-2024 at 11:54

The key to obtain higher yield is that the reaction temperature should be around 75 C. Also solid reactant should be dissolved in small amount of

methanol and then hypochlorite added.

Here chloroform reactions with various substituted acetophenones:

https://sci-hub.se/10.1021/ja01359a506

Attachment: vanarendonk1931.pdf (183kB)

This file has been downloaded 64 times

here also another practical experiment with acetophenone:

https://www.studocu.com/en-us/document/colorado-state-univer...

[Edited on 25-11-2024 by Fery]

) so maybe extraction could

have been tried too.

) so maybe extraction could

have been tried too.