Fery - 27-3-2022 at 23:10

1,3,5-trithiane = thioformaldehyde trimer

To a 125 ml washing bottle were added these 2 liquids by weight:

0,25 mol 38% formaldehyde CH2O 20,0 g

51 g 35% HCl (should be 43 cm3)

H2S generator was constructed this way:

60 g 35% HCl + 40 g H2O were poured into 500 ml long neck FBF, magnetic stirbar added.

0,50 mol Na2S = 39 g, assuming technical 60% Na2S (approx trihydrate) it is 0,30 mol was dissolved in 300 ml of water and charged into dropping

funnel.

The apparatus was transferred outside of lab. The temperature outside was 0 C (winter time).

The H2S generator was put on magnetic stirrer and connected with a hose with the washing bottle.

Magnetic stirring of HCl was commenced and the solution of Na2S was slowly dropped into diluted HCl. Evolved H2S gas was bubbled into the washing

bottle which lasted 3 hours. At the end the content in washing bottle was semisolid paste (due this I expect the bubbling of H2S was very inefficient

at the end).

Content from washing bottle was washed out with water, gravity filtered, solid product twice suspended in 200 ml H2O and filtered out, final filtrate

only little acidic (univesal pH paper approx pH 3).

Air dried for 1 week close to wood stove at temperatures around 50 C.

3,7 g crude product transferred into extraction thimble, extracted in 100 ml Soxhlet apparatus with 150 ml of benzene.

2,5 g of white crystals in a form of needles obtained = 18 mmol (M=138,27 g/mol), yield 22% (very poor, orgsyn got circa 90 %)

m.p. 217-219 (lit. 215-220 C https://en.wikipedia.org/wiki/1,3,5-Trithiane)

http://orgsyn.org/Content/pdfs/procedures/CV2P0610.pdf

Attachment: CV2P0610.pdf (365kB)

This file has been downloaded 235 times

apparatus

technical Na2S, yellow because of oxidation to polysulfides

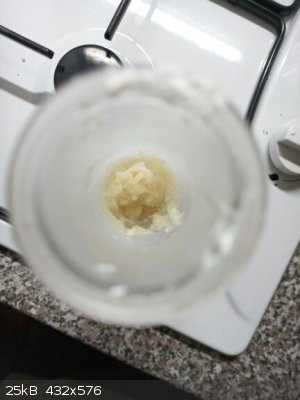

content in washing bottle after transferring it from outside into the lab

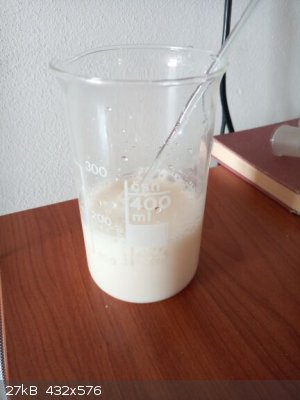

very thick content from washing bottle transferred into a beaker by washing it with water

gravity filtered on filter paper

twice suspended in 200 ml of water and gravity filtered

3,7 g dry crude product extracted in 100 ml Soxhlet apparatus with 150 ml of benzene

2,5 g of white needle form crystals obtained, m.p. 217-219 C

[Edited on 28-3-2022 by Fery]

SplendidAcylation - 28-3-2022 at 14:13

Nice work!

I do love a write-up with photographs

Well done for working with hydrogen sulfide without having the neighbours complain.

I made some FeS for making hydrogen sulfide but I haven't done it yet.

Shame about the lowish yield, hmm, maybe the removal of the solid throughout the process is supposed to push the reaction forward?

This rxn seems to be a nice example of the double-bond rule, thioformaldehyde preferring to trimerize rather than remain with a C=S bond

Do you have any plans for this compound?

[Edited on 28-3-2022 by SplendidAcylation]

Fery - 28-3-2022 at 23:01

Hi SplendidAcylation, orgsyn bubbled H2S for 12-24 hours, me for only 3 hours, that could be the reason. But after 3 hours the content was almost

solid, seems to be some polythioformadehyde polymer with copious volume trapping all the liquid? In orgsyn they filtered it few times and continued

bubbling into the filtrate (that would require sintered glass as cellulose filter paper would not survive concentrated HCl). Moreover during my

experiment there was 0 C outside which is not desirable for formaldehyde (it should be stored above 6 C) - maybe it also polymerized at some degree?

Worth to try during warmer period. On the other side solubility of H2S in H2O is higher at lower temperature... Most of H2S did not react, maybe it

would be worth using much taller and narrower cylinder or connect few cylinders in parallel?

The cheapest H2S generator is paraffin + S + heat. Paraffin could be cost-free from remainder from almost burned off candles.

In the extraction thimble there stayed approx 1 gram of unknown white compound, perhaps some polymer.

I do not have any planes with trithiane yet, this was my first step into organosulfur compounds. Well I did some sulfonations (toluene, naphthalene)

which almost does not counts into organosulfur chemistry as it is almost as nitration. My dream is trimer of thioacetone but I'm not yet brave enough.

Neighbors were already in homes luckily and no passersby on the street.

Another notes: use the oldest glass you have and the oldest glass tube (I used inner diameter 4 mm which was OK and it did not clog). It is very hard

to clean the glass. I approximate solubility of trithiane in boiling benzene approximately 1 g of trithiane in 100 ml and this is perhaps the best

solvent? Perhaps the higher polymers are even worse to clean from glass? Perhaps I produced also some polyformaldehyde due to very low temperature?

Avoid messing sintered glass if you can as I can't imagine how to clean it mechanically. Even if you clean with piranha solution you won't see whether

it is really clear as the color of trithiane is white.

For cleaning I used acetone at room temperature and mechanical force (bottle brush and pipette brush). Very hard to clean. Maybe using wet sand

shaking the glass would be the way to go?

Odor of trithiane is very very very weak, much weaker than mineral waters containing a little of H2S which are common in my country.

Metacelsus - 29-3-2022 at 03:01

Nice work. For the extraction, is benzene necessary or could you use another solvent such as toluene?

Fery - 29-3-2022 at 03:31

Hi Metacelsus, perhaps toluene could be used too. Maybe the trithiane could be even better soluble due to higher b.p. of toluene. M.p. of trithiane is

quite high (above 200 C). Maybe xylene could be tried too (even higher b.p.) ? The solubility in benzene is quite low, only aprroximately 1 g

trithiane in 100 ml of benzene.

mayko - 29-3-2022 at 09:05

This is a really cool compound and well documented reaction. I would be extra careful around formaldehyde/HCl mixtures; bischloromethylether gives me

the willies!

wg48temp9 - 30-3-2022 at 01:11

Great write up Fery for this interesting compound.

I was curious about the compound but did not find much info on it. I did find a patent that describes a method of converting it to carbon disulphide

by heating with sulphur and a catalytic amount of alkali/alkali earth hydroxide. Not the simplest method of making CS2.

Sorry I cannot find the reference at the moment. I will search again later.

I found it: Attachment: CS2-syn-US3404961.pdf (248kB)

This file has been downloaded 232 times

Oops that was the wrong patent. This one only requires a temperature of about 200C

Attachment: CS2-bestsyn-US3397960.pdf (512kB)

This file has been downloaded 260 times

[Edited on 3/30/2022 by wg48temp9]

Fery - 30-3-2022 at 10:42

In the orgsyn epilogue there is a synthesis where they drop solution of sulfide instead of bubbling H2S gas. But my Na2S was technical quality, old

and a lot of S2- oxidized into polysulfides so I discarded that idea of dropping into formaldehyde thus introducing contamination with elementary S.

There was a lot of elementary sulfur in the generator at the end as polysulfides react with HCl into H2S and elementary S. Maybe preparing fresh

solution by bubbling H2S into solution of NaOH and then delivering this solution very slowly to the bottom of formaldehyd+HCl using long tube

submerged just over the bottom of the reacting flask? In my experiment most of H2S was just gone and did not dissolve / react. Bubbling into NaOH

would bind most of it and no such high loses of H2S. But then the problem of delivering the fresh Na2S or even NaHS to the bottom of reactor (dripping

to the top of reactor = most of H2S would escape...).