Mateo_swe - 15-6-2020 at 10:20

Im interested in extracting the oil from different fruits, seeds and plants.

I looked up the oil from avocado seeds and it contains about 48.7% Linoleic acid and some other stuff.

If i were to fractional distill the oil the boiling point of Linoleic acid is 229 °C (446 °F) at 16 mmHg according to wikipedia.

I have bought an vacuum gage but it only shows inHg and Bar.

It goes from 0 to -30 inHg.

Now as Linoleic acid boils at 229 °C @ 16 mmHg, how would i know when i have 16 mmHg using my vaccum gage?

16 mmHg would be about 0.63 inHg according to a converter i found.

But 1 inHg is just 1 small tic on the vacuum gage, have i bought the wrong gage?

I have seen other SM members use same vacuum gage i have bought but i dont really understand how i could see 16mmHg on this vacuum gage.

Is anyone good at these things and care to explain?

Have i bought wrong gauge, i have a aspirator as vacuum source.

monolithic - 15-6-2020 at 10:56

Those types of gauges aren't very accurate especially when you're trying to resolve a few mm Hg. You want something like this, filled with mercury. https://www.eiscolabs.com/products/ph0205

dawt - 15-6-2020 at 11:02

16 mmHg = 0.63 inHg, which corresponds to around -29.3 inHg on your manometer, as it displays the pressure relative to atmospheric pressure (which is

negative in a vacuum) rather than the absolute pressure. You're right in assuming you won't be able to accurately measure 0.63 inHg, but it doesn't

really matter, since you'll likely be working at whatever pressure your vacuum pump provides. If you're using a water aspirator you're looking at

anywhere between 10 and 30 mmHg depending on the temperature of the water, if your system is properly sealed.

Here's a few things to consider: Fats and oils actually contain very little of the free fatty acids, most of them are bound in triglycerides which

you'll have to saponificate first (by boiling in an alkaline solution, followed by acidifying and extracting with a non-polar solvent). Generally it's

a smart idea to turn your free fatty acids into their methyl esters (FAME) for distillation (by boiling your oil in an excess of methanol with a

catalytic amount of sulfuric acid), but that probably won't reduce the boiling point of linoleic acid all that much. It's worth a shot though, if

you're having trouble distilling the free acid.

Tsjerk - 15-6-2020 at 11:37

You can do a transesterfication with methanol directly on the triglycerides!

SWIM - 15-6-2020 at 14:51

Mechanical manometers tend to either be inaccurate or expensive.

The cheap ones are good for a rough indication of vacuum, but relatively few will give you readings accurate to less then 4 Torr.

In the US, they're often rated by some standard where % accuracy means that percent of the total range to the gauge, so accurate to 1% only means

accurate to 8 Torr or so.

Mercury manometers are very accurate, and there are electronic ones that are great too.

I haven't done too much shopping for old fashioned gauge type manometers, but from what I've seen one accurate to 1/2% (3.5 Torr) is almost as

expensive as getting one of those modern electronic ones or a mercury lab manometer.

There are also vacuum control modules that give you the pressure you want, but good ones are not cheap.

Or at least the cheap ones aren't common enough that I've found one.

If you're distilling fats and esters like those you'll probably need all the vacuum you can get unless you've got a very low vacuum pump like

diffusion etc.

The right still could probably help too:https://adamschittenden.com/images/uploads/3297.jpg

I think these were invented for distilling some fatty acids or esters of a delicate nature.

And Kugelrohrs are supposed to be pretty good too for not burning your product.

Mateo_swe - 15-6-2020 at 23:05

OK, thaks for all good answers.

It would be nice to have one of those old type U-tube, glass manometers with mercury.

Is it possible to buy the glass U-tube and then fill it with mercury?

I guess it would need calibration and the mercury needs to be cleaned by distillation first.

What i would guess is a problem is that some vacuum distillations might produce vapors that are reaching both the manometer and the vacuum pump.

If using an aspirator that would be a minor problem but for the manometer its more problematic.

If i would buy an expensive electronic manometer i dont want it to break after a while.

Maybe one could bubble the vapours through some liquid to try remove most bad stuff.

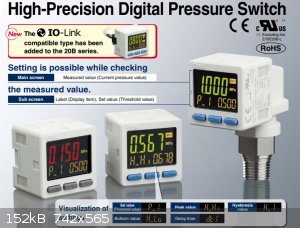

One more thing, I have this vacuum meters that are used in the industry.

Can these be used for a chemistry application?

They measure 0-101kPa vacuum and thats 0-757 mmHg.

They are made for vacuum used in machines.

There are both vacuum meters and vacuum switches and i have a few in a box somewhere, thats why i ask.

Refinery - 15-6-2020 at 23:12

https://www.ebay.com/itm/VMV-1-High-Precision-Digital-Vacuum...

https://www.ebay.com/itm/Cps-Products-VG200-Vacuumeter-Vacuu...

You would wanna add the meter after a cold trap to reduce fumes corroding it.

[Edited on 16-6-2020 by Refinery]

Mateo_swe - 16-6-2020 at 03:22

If i buy one of those i wouldnt want it to break after a while.

Does an ice chilled trap work for catching the fumes or do i need very cold temps?

And the industrial ones in the pic above doesnt work?

Refinery - 16-6-2020 at 04:29

It depends on what you're distilling. Trap can also save solvents and/or reagents from loss, and if you use pump, it protects it. I use CaCl2 -35C but

for serious trapping, dry ice acetone is the usual choice.

I would use the gauge only in where it is necessary to carefully monitor or analyze temps, or calibrating equipment. If you're stripping sulfuric

acid, just use aspirator, it doesn't really need to come over at exactly at 32.64mbar.

I don't actually know if it would be possible to use thin PE foil between the sensor and the vacuum space. This would protect it from any fumes, but

probably give serious off readings.

ThoughtsIControl - 17-6-2020 at 07:37

"If you're using a water aspirator you're looking at anywhere between 10 and 30 mmHg depending on the temperature of the water, if your system is

properly sealed."

Unless you have a barometer in your lab space, assume that the atmospheric pressure is 1. Once your water aspirator is set up, you can test it out

with water to see what it will boil at. Then you'll know how powerful your aspirator is.

Refinery - 17-6-2020 at 08:05

Barometric pressure is a significant factor. I used to check my local weather station to correct my calculations when I realized my still did hit

azeo, but it was the pressure that made the meter give off readings and it was right on spot after calculating the difference. An overpressure of

1010mbar will cause ethanol azeotrope to go much higher (~79.2C) which would give significant error from ABV calculation. Your altitude must also be

deducted, unless you have on spot reading.

Just so that when a single degree can matter, even insignificant looking things become a factor.

ThoughtsIControl - 17-6-2020 at 08:31

"Barometric pressure is a significant factor. I used to check my local weather station to correct my calculations"

You're absolutely right. As an amateur chemist, I haven't had much experience in working with azeotropes quite yet so the pressure hasn't played a big

role in my experiments. However, I didn't know that the barometric pressure is on weather channels  Lol! That's good to know

Lol! That's good to know

Mateo_swe - 19-6-2020 at 02:07

I think i will try use the mechanical vacuum gauge shown in the first post.

It will tell me if i am in the right area at least and is cheap to replace if it breaks.

Hopefully it will not have too many fractions as i only have a 3 flask cow adapter.

I can always divide the distillate up in 3 different temp ranges with a first distillation.

Then fractionally vacuum distillate each of the 3 temp range distillates in to max 3 fractions.

Little complicated and much work but it will be fun and informative, i learn a lot however it turns out.

Lol! That's good to know

Lol! That's good to know