Fery - 15-5-2020 at 05:06

Kolbe-Schmitt synthesis - carboxylation of phenols (addition of CO2).

Phenol reacts with CO2 at high temperatures and high pressures forming salicylic acid.

In home lab such reaction runs well with more reactive phenols like resorcinol (1,3-benzenediol), phloroglucinol (1,3,5-benzenetriol), it works with

NaHCO3 but KHCO3 should be better (RbHCO3, CsHCO3 too).

reactants in molar ratio 3:1

15,0 g KHCO3 (or 12,5 g NaHCO3) 0,150 mol

5,5 g resorcinol 0,050 mol

45 ml water (should fully dissolve KHCO3 even at 70 C).

5,5 g resorcinol (0,050 mol) + 15 g KHCO3 (0,150 mol) + 45 ml H2O was placed into 100 ml flask (the smaller volume the less of O2 to oxidize

resorcinol) and boiling chips added.

1,5 hours heated in 95 C water bath during which a little of CO2 evolved, then 1 hour at reflux temperature (total reaction time 150 minutes, heating

for longer than 2,5 h leads to product loses and purity degradation due to rearrangement into 2,6-dihydroxybenzoic acid).

Transferred into 250 ml flask while still hot + twice rinsed with little of H2O, cooled down to room temperature, dropwise added 17 ml 35% HCl

(minimal amount for neutralization 0,150 mol 35% HCl = 14 ml) with massive CO2 evolution, acidic pH must be achieved with pH at least 3 (controlled

with universal indicator paper after the whole HCl added).

Put into a fridge to 4 C for few hours, vacuum filtered.

Recrystallized from 20 ml of H2O.

Yield 1,9 g.

m.p. not determined due to allegedly decomposition - m.p. 208-211 C (dec.) (lit.)

maybe less than 45 ml of H2O could be used and a mixture of KHCO3 + NaHCO3 in which NaHCO3 dissolves later as the reaction proceeds ?

maybe different heating scheme could give better yield (maybe rfx temperature, but then HCO3 decomposes faster and may be missing for the reaction ?)

KHCO3 is better than NaHCO3 in industrial production but in home lab in H2O and reflux temperature and atmospheric pressure maybe both Na, K are

similarly effective?

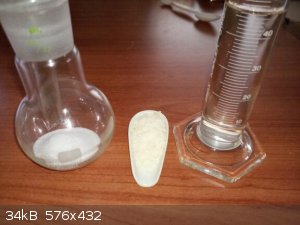

reactants - flask with KHCO3 on left, resorcinol in middle

heating in water bath, little of CO2 evolution

rfx

transferred into larger flask (on left) suitable for following massive CO2 evolution on acidification (HCl on right)

recrystallization

mackolol - 15-5-2020 at 10:43

Interesting procedure, does it have to have two hydroxy groups to react like that with KHCO3?

myr - 15-5-2020 at 14:36

Nice reaction! Never heard of it, but worth trying.

Here's a rather old lit. review:

Lindsey, A. S., & Jeskey, H. (1957). The Kolbe-Schmitt Reaction. Chemical Reviews, 57(4), 583–620. doi:10.1021/cr50016a001

It does not need 2 hydroxy groups, but without the meta dihydroxy more strenuous conditions are needed. Worth noting (on p 587) boric acid increases

the yield for aminophenol, which I'd imagine would generalize for most phenols.

Boffis - 16-5-2020 at 11:06

Nice work and write-up Fery. Good to see some real chemistry being conducted.

This is a very useful method of introducing a carboxylic acid into a phenol (ie salicylic acid is the most common use of this reaction as you say). It

works well with pyrogallol and the naphthols too. Interestingly when the reaction is carried out on b-naphthol it substitutes in the 3-position rather

than the expected 1-postion and with pyrogallol it give 2,3,4-trihydroxybenzoic acid rather than gallic acid. I seem to recall that you can use this

reaction to rearrange gallic acid to the 2,3,4- trihydroxy derivative too.

Fery - 24-5-2020 at 23:20

here a method with somewhat better yield (3,0 g instead of previous 1,9 g)

5,5 g resorcinol

25 g NaHCO3

60 ml H2O

250 ml flat bottom flask

3 boiling chips

a stopper just lightly inserted into the neck of flask to allow escaping CO2 gas

heated in boiling water bath for 2 hours, only very little of NaHCO3 (1-2 g) stayed undissolved at the end

removed from bath, very weak rfx 15 minutes with still the stopper in the neck (not to evaporate too much H2O otherwise later NaCl would crystallize)

cooled down to room temperature at which the whole content of the flask solidified

dropwise acidified with 30 ml 35% HCl (minimal amount 28 ml) with massive evolution of CO2, in the middle of the addition the content liquified, ugly

frothing during the last 5 ml due to fine precipitated product, frothing managed by swirling the flask in hand vigorously,

then the content heated to dissolve the product, acidic pH must be achieved by previous HCl addition, at least pH 3 must be achieved (checked with

universal indicator paper)

cooled down to room temperature very slowly and later put into fridge to 4 C to obtain crystals of the product rather than fine precipitate

vacuum filtered

recrystallized from 25 ml of water (here I didn't filter the hot solution as it was clear)

yield 3,0 g

15 minutes reflux, no need to mess/wet condenser, just do not boil out too much water (a little of evaporation does not matter)

Boffis - 25-5-2020 at 02:12

Hi Fery, nice improvement. Do you think it would help the yield if you could stop the loss of CO2 by placing a balloon over the neck of the flask?

Pumukli - 25-5-2020 at 02:15

Nice synths, Fery!

A melting point determination would be nice too. Doesn't matter, if it decomposes at that temperature. Does the 2,6-dihydroxy compound also decompose?

Maybe a TLC?

By the way you said KHCO3 is better than the sodium salt but you used the later one and still got improved yields. Wondering if potassium would be any

better.

Fery - 25-5-2020 at 05:54

Hi Boffis, using the baloon is great idea. I observed that bubbles of CO2 evolved slowly during the whole reaction for both K/NaHCO3.

Hi Pumukli, the KHCO3 seems to be better at industrial scale in which phenol is melted at 125 C, well not phenol but Na/K phenolate (phenol melts at

40 C) and brutal CO2 pressure 100 atm applied. In home lab we can't achieve these conditions so we are limited to perform the reaction in water

solution and not to use phenol but more reactive resorcinol, phloroglucinol and others suggested by Boffis. Better yield 3,0 g vs. 1,9 g could be

caused by doubling the concentration of HCO3-, not by cation itself, 3,0 g yield was with 25 g NaHCO3 which is 0,30 mol and 1,9 g yield was with 15 g

KHCO3 which is 0,15 mol. Another difference was that whole KHCO3 dissolved at the beginning but NaHCO3 dissolved only partially and during 2 h of

heating it dissolved slowly more and more so it could increase CO2 availability. Also different temperature scheme used for heating. I just wanted to

improve yield as I found that the yield could be upto 50% and my initial experiment (KHCO3) yielded only 1,9 g = 12 mmol of the product from 50 mmol

of resorcinol so the yield was only 24%. 3,0g = 19,4 mmol so the yield 39% which is much better.

Literature claims decomposition at m.p. 208-211 C so I do not know whether it is worth of trying (I have only capillaries and Thiele tubes for that,

nothing more advanced).

According suggested chromatography I have only thin layer aluminium foils with silicagel layer, some of them with UV indicator and others without

indicator so perhaps visualizing 2,4 and 2,6 acids and eventually other isomers could be done by spraying the foil with an acidobasic indicator? I

have plenty of them, maybe 10 with different pH range color change. Foils are somewhat older, I saved them years ago while visiting biochem analysis

lab in hospital which was just right shut down forever, they planed to trash them.

[Edited on 25-5-2020 by Fery]

Pumukli - 25-5-2020 at 06:20

Fery,

I think even a decomposition test would be meaningful (=confirmation of the identity and maybe purity). A capillary/Thiele tube system is great, I

have a similar thing (a Büchi something), which is basically a Thiele tube with electronically controlled heating and digital thermometer

combination.

For TLC visualisation I use almost exclusively a small pickle jar with a few I2 crystals in it. The iodine vapour makes the spots visible. When you

remove the plate from the jar, quickly mark the perimeter of the spots with a sharp pencil otherwise they will disappear within a few hours in the

open air. A hair drier can help accelerate this. :-) This way you can apply another developer (maybe the indicators you suggested) if you fancy them,

but I found iodine satisfactory, non-destructive and safe. (Safer than e.g. spraying with cc. sulfuric acid/vanilline or similar nasties.)

Fery - 31-5-2020 at 10:58

I found this

Comprehensive Practical Organic Chemistry: Preparations And Quantitative Analysis

By V.K. Ahluwalia, R. Aggarwal, V.K. Ahluwalia

Chemi Pharma - 1-6-2020 at 00:37

@Fery, I was just looking for this book since a time ago. Do you have a PDF copy? Could you upload that at the Sciencemadness references section, or

at least indicate any download link? I have opened a new request there at "The New Book Thread (Organic Chemistry)" .

Link: http://www.sciencemadness.org/talk/viewthread.php?tid=11815&...

Thank you.

Fery - 1-6-2020 at 02:55

Hi Chemi Pharma, I have only few pages which google books system allowed me to preview

https://books.google.cz/books?id=mnsKyupepQEC&printsec=f...

If publishing system offers pages randomly maybe few different people are able to put all pages together?

For me these pages were offered to preview (and download using small tricky which I can share, it's not secret)

pages 88-153, page 156

now when I change the domain cz in the link to different country like sk then the system offers me different pages...

Boffis - 1-6-2020 at 07:15

@Chemi Pharma; like I said elsewhere there is not much in that book that isn't in Vogel and thats easy to download: both 3 and 5th editions.

@Fery; I have just spotted this in a paper about the chemistry of Purpurogallin, check out about half way down, 2,3,4-trihydroxybenzoic acid. The rest

of the paper probably isn't of much interest.

Attachment: Temp-2,3,4-trihydroxybenzoic acid.pdf (134kB)

This file has been downloaded 327 times

Fery - 1-6-2020 at 12:06

Hi Boffis, thx for the paper! Right time to buy pyrogallol (from trihydroxybenzenes I have currently only phloroglucinol yet). Very nice yield

achieved in the method described in the paper.

Boffis - 1-6-2020 at 12:32

You're welcome; looking at this paper tends to confirm my belief that if you can over-pressure the solution with CO2 you can improve the yield. I

don't think you need high pressures, rather just enough to minimise the escape of CO2 from the solution. Potassium bicarbonate starts to lose CO2 at

about 40-45 C.