Fery - 26-3-2020 at 07:24

Catalyst was prepared by inserting 99,8 % W electrode (TIG) into a test tube with 30% H2O2 for 1 week, then from the pale yellow clear solution a

precipitate started to form due to very likely H2O2 reactant consumption and its creation from soluble peroxytungstic acid into insoluble tungstic

acid (heavy, sediment)

initialy the W weighed 105,1 g and finally 102,5 g so 2,6 g W dissolved, molar mass 183,85 g/mol = the amount of H2WO4 obtained 0,014142 mol

the test tube was shaken vigorously and 1/3 of the volume was used as a catalyst (4,7 mmol)

Oleic acid was prepared from SOHO (sunflower oil high oleic)

114,7 g SOHO, glyceryl trioleate molar mass 885,4 g/mol which means 0,1295 mol of trioleate thus 0,389 mol of oleic acid

+

28,7 g 85% KOH = 24,4 g 100% KOH M=56.1 g/mol = 0,435 mol (100% KOH)

+

100 ml 95% ethanol

rfx for 3 h

added 300 ml of water and more than 23 g 96% H2SO4 added very slowly and dropwise required to neutralize KOH and to adjust pH to 2 (controlled by

universal indicator paper)

transferred into separator funnel and shaken vigorously (no alkaline allowed to stay as it would later decompose H2O2)

washed with 300 ml of water (warm)

washed again with 300 ml of warm water for the last time

pH of last washing (bottom water phase) neutral to universal pH paper

all alkalinity must be removed (H2O2 decomposes in alkaline environment)

the oleic acid was allowed to settle in a beaker for 2 days, beaker wrapped into plastic foil to prevent possible oxidation by O2 from the air

some water separated and settled at the bottom of beaked from which it was removed using a pipette

yield 96,3 g of crude oleic acid (0,34 mol)

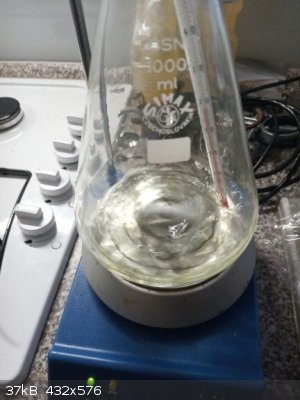

To 1 L Erlenmayer flask was poured the H2WO4 catalyst (0,0047 mol) + 90 ml of 30% H2O2 and magnetically stirred, the catalyst dissolved quickly and

then 96,3 g of oleic acid was added (0,34 mol). Thermometer inserted and the content heated to 100 C while rapid stirring (the faster stirring the

better as oleic acid and H2O2/H2O are immiscible). After 2 hours 90 ml H2O2 added, after 4 hours from the beginnig 90 ml added, after 6 hours from the

beginning 90 ml added and after 8 hours from the beginning the reaction was done, stirring stopped and the flask allowed to cool down to room

temperature.

It is important to keep T always below 102 C, when reaching 103 C the H2O2 starts to decompose and T increases to boiling point (30 % H2O2 b.p. 108

C). When such situation imminent, simple few blows of air from mouth proven sufficient to cool the flask by condensing the vapor on the walls of

flask, if not enough, few drops of cold distilled H2O helped to keep the T at 100 C.

So totally 360 ml 30% H2O2 used. If the H2O2 is stabilized I suggest to use more catalyst to prevent catalyst poisoning (who knows, maybe H3PO4 widely

used as H2O2 stabilizer could bind H2WO4 into phosphotungstic acid which could be less effective catalyst?). Theoretically 0,01 mol of catalyst should

be enough for 1 mol of oleic acid and 1 mol of oleic acid should practically require 8 mols of 100% H2O2 (theoretically only 4 mols of H2O2 but some

of it always decomposes). I used slightly more of H2O2 (molarity of 30% H2O2 is 9,8 M as it has density 1,11 g/ml so I used 3,53 mol of H2O2 for 0,34

mol of oleic acid). Adding more catalyst (e.g. 1/50 compared with oleic acid instead of 1/100 does not cause H2O2 decomposition and perhaps may speed

up the main reaction but anyway there are 2 immiscible phases). There is a race between main reaction and H2O2 decomposition but at 100 C the

decomposition is still acceptably slow. At 70 C the reaction proceeds only upto 9,10-dihydroxystearic acid, but cleaving C-C requires 100 C. Some

authors used rfx temperature but I strongly discourage such temperature as then H2O2 just decomposes so fast that there is no H2O2 left for the main

reaction.

Then the content was let to stay for 2 days at room temperature to allow remaining H2O2 to decompose (very slow evolution of O2 bubbles).

Then it was cooled down to 4 C, filtered. From the filtrate it should be possible to recover the catalyst, but I did not try that (maybe the

recovering is not so easy, H2WO4 is not soluble in water, but pertungstic acid is soluble so perhaps not allowing to stay for 2 days but immediately

filtering while there is still some H2O2 present, otherwise when no H2O2 present the soluble pertungstic acid decomposes into insoluble tungstic

acid). The oxidized mass was transferred into 1 L Erlenmayer flask and was 5 times extracted by 400 ml of boiling water, then always let to cool down

slowly overnight to 4 C in a fridge, the next day water with azelaic acid decanted from the block of solidified fatty acids + nonanoic acid, water

with azelaic acid filtered, filtrate reused for the next extraction and loses of H2O on filter and wet azelaic acid compensated with fresh H2O. After

the 5th washing there was only little of azelaic acid on the filter paper.

The block of solidified monocarboxylic acids + incomplete oxidation products of oleic acid was transferred into 2 L flask, 1400 ml of distilled water

added together with a lot of boiling chips and performed steam distillation (simple distillation) which carried out nonanoic acid. After collecting

1200 ml of distillate and separating the nonanoic using separatory funnel the 1200 ml of water was returned back to the flask to continue steam

distillation. After 4 distillations (so totally 4,8 L of distillate) I collected all nonanoic acid in a separatory funnel (the yield in last fifth

step was already quite low).

The wet azelaic acid from filter papers was put into 2 L distillation flask with 1200 ml of water and 10 boiling stones (tendency to form overheated

liquid and sudden bumping, use more boiling stones as usually) and performed steam distillation (the azelaic acid still contains a little of nonanoic

acid and fatty acids). Collected 800 ml of distillate from which nonanoic acid separated and the water was returned back into the distillation flask

and steam distillation repeated for the second time. Totally 1,6 L of distillate collected when the distillate did not contain oily drops of nonanoic

acid anymore. This small amount of nonanoic acid (approx 2 ml) was added to the main fraction of the nonanoic acid. The volume in distillation flask

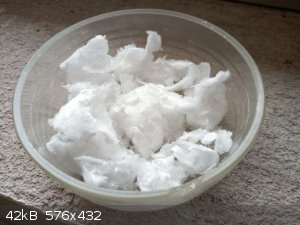

was adjusted to 800 ml, heated to boil and filtered. Cooled down to 4 C and let to stay overnight in a fridge at 4 C. Crystals of azelaic acid were

vacuum filtered and recrystallized from 700 ml of water (well, less of water possible but from very concentrated solution it separates as very small

crystals which dry out to a dust which is hard to handle (highly electrostatic beast), from larger volume of water there are nice 1-2 mm crystals

which are easier to handle without risk of electrostatic force to blow them away while handling, solubility is only 2,1 g in 1 L of water at 20 C and

even much less at 4 C).

Yields:

19,3 g azelaic acid (very pure, recrystallized, loses during 2 crystallizations not more than approximately 2 g)

14,0 g nonanoic acid (crude, unpurified, not dried)

41,4 g of fatty acid mixture (various oxidation states like 9,10-dihydroxystearic acid + saturated fatty acids from the SOHO sunflower oil like

palmitic + stearic acids)

attached a pdf where researchers used this H2O2/H2WO4 method with oleic acid

H2O2 : oleic acid : H2WO4 ratio 800 : 100 : 1 gave them best yield

just their yields were much better than mine, well they used 60% H2O2 and me only 30%, but keeping the flask open (without condenser) allows some

water evaporation and partial H2O2 concentration

Attachment: benessere2015.pdf (521kB)

This file has been downloaded 567 times

photos will follow

[Edited on 26-3-2020 by Fery]

Fery - 26-3-2020 at 08:42

4,7 mmol of H2WO4 in a little of water in 1 L Erlenmeyer flask

after adding 90 ml of 30% H2O2 the H2WO4 catalyst quickly dissolved forming pertungstic acid (aka hydrated tungsten peroxide)

adding 96,3 g of oleic acid (0,34 mol)

temperature increased to 100 C and stirred vigorously (not visible due to thermal insulation), the flask is open (without condenser) which allows

partial concentration of the H2O2 by H2O evaporation (I had only 30% H2O2 at hand, but researchers used 60%)

keeping T at 100 C prevents H2O2 decomposition (especially when there is no alkalinity thanks to careful preparation of oleic acid) - these small

bubbles are mostly from rapid stirring instead of from H2O2 decomposition

if the T raises to 102 C simply few blows of air from mouth to uncovered walls of flask kick T back to 100 C, if not few drops of cold distilled water

always do that, never allow T to raise to 103 C as then H2O2 starts to decompose exothermically which raises T to boil (b.p. of 30% H2O2 is 108 C), in

this case few ml of cold distilled water revert T back to 100 C

here details of bubbles, most of them are created by rapid stirring (which is necessary as H2O2/H2O are immiscible with oleic acid) and only very

little of them are from H2O2 decomposition (assuming you manage to keep T at 100 C and there is no alkalinity coming from oleic acid), here stirring

stopped for a moment to observe bubbles

separation of the oxidated mixture by washing with 400 ml of boiling water and vigorously stirring, then allowed to stay hot so monocarboxylic acids

separate as the upper layer and azelaic acid in bottom water layer

after cooling down the azelaic acid in bottom water layer starts to crystallize while the monocarboxylic acids stay in the upper layer which slowly

solidifies into one block

at the end the density of water decreases as the azelaic acid crystallizes out and the density of upper layer increases as it solidifies so if you

move the flask and a little of water covers the block of upper layer the block sinks to the bottom too

the water with azelaic acid crystals is decanted from the solidified block of monocarboxylic acids (on the left in the flask there is the solidified

block which was formerly the upper layer) and water+azelaic acid is filtered through filter paper (on the right), the water is then returned back to

the flask and fresh water added to cover loses of water (loses are on filter paper + on wet crystals of azelaic acid), so totally 5 times the oxidized

mass was extracted always with 400 ml of water

steam distillation of the solidified block was performed 4 times, always 1,2 L

of distillate collected (4,8 L totally) to obtain main portion of nonanoic acid and steam distillation was also performed with azelaic acid when 2

times 800 ml of distillate collected so 1,6 L totally (removing azelaic acid contamination by nonanoic acid till the distillate does not contain oily

drops of nonanoic acid anymore)

azelaic acid after 2 crystallizations and nonanoic acid obtained by steam distillation

[Edited on 26-3-2020 by Fery]

clearly_not_atara - 26-3-2020 at 10:27

[applause]

I think your prep of the peroxotungstic acid catalyst is very clever. When I posted about this reaction earlier I wasn't sure how the reaction

depended on a solution of insoluble tungstic acid. You seem to have figured out how it should work. Nicely done.

j_sum1 - 27-3-2020 at 02:10

What a lovely piece of work. And great to read. You, sir, are inspiring.

Cou - 28-3-2020 at 19:28

epicness x)

Waffles SS - 1-4-2020 at 11:38

Well done,

Excellent reaction and workup.

I want to suggest to purify your oleic acid to more than 90% by Urea/Methanol method.(i did it before many times with different vegetable oils)

This will be interesting to find out what will happen for Linoleic acid that exist in Sunflower or most of vegetable oils.

[Edited on 1-4-2020 by Waffles SS]

Fery - 2-4-2020 at 00:01

Hi Waffles SS, the urea/methanol purification method is my dream to try in the future. I've only read about it but never tried yet. I've also read

about methylester + vacuum distillation. Also about fractional crystallization from acetone at very low temperatures. For 18:1 acid (oleic) the most

efficient is the method you wrote about (urea/methanol).

Linoleic acid is oxidized to azelaic acid too, just requires more H2O2 due to more double bounds.

My oil was SOHO (Sunflower Oil High Oleic acid) from this shop and they claimed upto 95% oleic acid (but there is no info about the minimal limit of oleic acid, so who knows...).

I believe olive oil should work too (high concentration of oleic acid).

Here a link comparing various purification methods of oleic acid

Waffles SS - 2-4-2020 at 13:45

Sure Azelaic acid is one of the major product but not all product.I am so interested to test another product.Hexanoic acid?Malonic acid?

Fery - 2-4-2020 at 22:26

Yes sure hexanoic acid from linoleic acid. Malonic acid too if it won't decompose.

Safflower oil and grape seed oil are high in linoleic acid and sunflower oil too, the third one quite cheap source and content quite good (65%) -

common oil, not SOHO which I used. Then certainly the purification method you posted prior the oxidation.

Waffles SS - 2-4-2020 at 23:26

I read this article 3-4 months ago:

https://grdc.com.au/resources-and-publications/grdc-update-p...

That is about super high oleic in safflower that contain 93%min oleic acid.I even sent email for them to get or buy this seed but they didnt reply at

all(maybe you be lucky and can get it)

Alkaline cleavage of fatty acid is interesting too and i got Octanol ,Sebacic acid...( i suggest to try that)

[Edited on 3-4-2020 by Waffles SS]