Fery - 9-1-2020 at 09:44

Hydrogenchloride gas generator:

Put 100 ml of 96% H2SO4 into 250 ml flask, attach 100 ml dropping funnel with pressure-equalizing system filled with 50 ml of 35% HCl (0,55 mol).

Connect to 100 ml washing bottle containing 40 ml of 96% H2SO4.

Reactor:

Put 68,1 g of pinene (0,5 mol) into 250 ml washing bottle and dilute with equal volume of hexane (I used medicinal hexane with boiling point range

60-65 C composing from aprox 50% of hexane and 50% of isomers of hexane). Connect its input to the gas generator and output to long hose with inverted

filtration funnel submersed into 1 cm water layer in a beaker (to catch possible HCl gas flowing out of reactor) - I did not use alkaline solution -

using water revealed as the right way at the end of experiment.

Submerse the reactor into ice - NaCl mixture (-10 C = 263 K).

Turn on magnetic strirring of the generator flask at high RPM and allow HCl (aq) to drop very very very slowly into conc. H2SO4. The 50 ml of HCl from

dropping funnel should be used up during approx 5 hours.

Note the stirring is essential for the gas generator as without stirring the HCl (aq) could stay floating as upper layer (lower density) above bottom

layer of conc. H2SO4 (higher density) and evolution of HCl (g) could be irregular and sudden !!!

Note the washing tube with 40 ml of 96% H2SO4 is essential as the gas must be absolutely dry to prevent side reactions (fenchyl chloride) and also for

watching gas evolution (the content in reactor may not be well visible due to ice-NaCl mixture and also HCl (g) could be absorbed very quickly so the

bubbles in reactor are always smaller and sometimes also less of bubbles especially if the HCl gas evolution is very slow so its absorption too and in

that case you may even do not observe any bubbles in reactor at all as HCl is absorbed at the boundary without visible bubbling).

Drain out water from cooling solution using hose and add fresh ice and fine salt when temperature of cooling mixture raises to -8 C = 265 K (about

every half an hour, depends on thermal isolation, plastic bucket isolates better than metal, use some old shred / newspaper / polystyrene box etc),

keep T in range from -10 C to -8 C (from 263 to 265 K). I used about 5 kg of ice and 0,5 kg of NaCl in total during 5 hours (so have 10 kg of ice and

1 kg of NaCl in stock to be sure). A salt with fine crystals is better than big crystals, snow (if you have it) is better than crushed ice.

At the beginning every drop of HCl causes sudden evolution of HCl gas, at the end the evolution is a bit more smooth and continuous. When all HCl (aq)

consumed the evolution of HCl gas ceases in few minutes, especially on stopping stirring it terminates immediately.

Wash the reaction mixture in separatory funnel with warm water thoroughly (but this step is maybe unnecessary? as there is no acid inside, not sure

whether it could remove some of side-reaction contaminants of product?)

Transfer the reaction mixture into 1 L flask, add 650 ml of water and perform steam distillation. Be careful not to clog the condenser (use warm water

when clog imminent).

At first hexane distills with a little of water.

When the ratio of water : organic changes to about 1:1 start to collect second fraction of the distillate separately into a new beaker (do not discard

the first fraction, it contains a little of product too). Then separate the terpenes phase of the second fraction from water in separatory funnel

(primary crop of product).

Separate hexane fraction from water in separatory funnel, dry with anh. Na2SO4, transfer into 100ml flask and distill off hexane, when T suddenly

raises from 65 C to 155 C (b.p. of alfa pinene) stop the distillation and add the content from distillation flask (small second crop) into terpenes

fraction.

Terpene product (both crops put together) is not willing to crystallize due to significant amount of alfa pinene. Cool it to -18 C in freezer and it

solidifies into jelly-like substance finally. The substance contains a lot of alfa pinene. The advantage of excess of pinene (unreacted) is in fact

that it prevents condenser clog during steam distillation and disadvantage in separation difficulty from the product.

Possible way to separate alfa pinene from bornylchloride is by rapid vacuum filtration at -18 C but that could be done only outside during strong

chilly winter. Inside this is a way to go: Touch the jelly surface with an edge of filtration paper and put quickly into freezer again. Do not allow

it to warm up. Replace filter paper soaked with pinene or even better replace paper tissues which only touch this filter paper (function of filter

paper is similar to candle wick and replace only cheap paper tissues / old newspapers etc). After a lot of replacements during few weeks when the

paper does not absorb alfa pinene anymore you can consider alfa pinene separated from bornyl chloride (well, small amount still persists but it does

not hurt and is going to be thoroughly separated using different purification technique).

Recrystall twice from isopropanol:H2O 3:1 (75% w/w IPA), dissolve in boiling solvent, rapid vacuum filtration using preheated fritte, crystallize at

freezing temperature -18 C, rapid vacuum filtration using precooled fritte (-18 C, the fritte in plastic bag was put into freezer before filtration)

yield 15,0 g (0,087 mol, 17%)

m.p. 132 C

Discussion: I overestimated the amount of HCl gas generated. The dead volume of my apparatus was about 0,5 L (cca 22 mmol of HCl). I think that from

0,55 mol HCl (aq) only hardly half of it converted into gas. Pity that I did not weigh the reactor before and after HCl gas addition to alfa pinene to

determine the exact weight of HCl absorbed. The water in which was inverted funnel submersed (everything escaping via outlet tube of reactor) showed

no acidic reaction to indicator paper so all the HCl gas entered the reactor was used up and nothing passed further. Using abundance of HCl is bad

idea as then the excess of HCl splits bornyl ring and dipentene dichloride is formed.

Bornyl chloride readily sublimes at room temperature on drying it, that decreased yield too (which has also such advantage that no need to wash out

fritte with organic solvent, just let the bornyl chloride for few days to sublimate out of the fritte).

I'm not sure whether such low T as -10 C is necessary for the addition but I read about low T in few sources and in only one source the T was above

zero. Addition of HCl gas to alfa pinene is exothermic reaction also.

Excess of alfa pinene (or less of HCl gas generated that expected and estimated) avoided dipentene dichloride formation, allowed full absorption of

HCl gas in reactor (no HCl passed further), allowed smooth steam distillation (my condenser clogged up only very little, but be careful and watch it

for the whole time !!!) but as a disadvantage it made separation of bornyl chloride from alfa pinene tricky (candle wick method of soaking was OK but

terrible slow, second method of filtering outside in strong freeze was unavailable as minimal T outside was only -5 C and bornyl chloride crystallizes

from alfa pinene only at lower temperatures, common freezer temperature -18 C revealed as sufficient and m.p. of alfa pinene is -55 C).

Someone uses chloroform instead of hexane as a diluent of alfa pinene in reactor. Solubility of HCl in hexane is much lower which makes further

processing easier and more safe.

Finding a solvent to produce bigger crystals would be very advantageous because on drying bornyl chloride the smaller crystals the faster it

sublimates out (e.g. my fritte lost signs of the product on its glass walls in 3 hours and the smell disappeared completely after 6 hours). Do not dry

the product between 2 recrystallizations as that would only decrease yield (I did it, just to determine whether not too much of product lost in

solvent so to know whether the solvent was suitable), the 2nd recrystallization should follow the 1st ASAP.

[Edited on 9-1-2020 by Fery]

Fery - 9-1-2020 at 09:53

videos:

beginning of the HCl addition to alfa pinene

somewhere in the middle

near the end of reaction

pics

Fery - 9-1-2020 at 11:18

beginning of the addition

beginning of the addition

beginning of the addition, captured fast evolution of HCl gas on drop of 35% HCl into 96% H2SO4

cooling reactor in -10 C ice - NaCl mixture

siphoning out brine via a hose when T raised to -8 C to have space to add fresh ice - NaCl to maintain T in range from -10 C to -8 C, it was necessary

to do it about every half an hour (depends on thermal isolation, how fast the exothermic reaction proceeds etc)

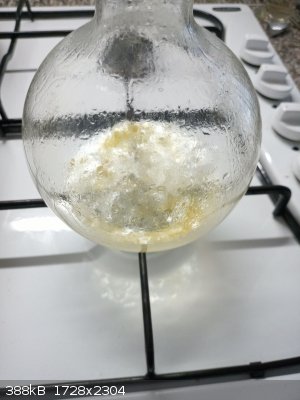

HCl gas addition to alfa pinene done (there is a magnetic stirbar at the bottom of the reactor, but it was NOT necessary to stir the reactor by

magnetic stirrer, bubbling itself revealed as efficient enough to mix the reactor content), there is a little of heavier dark red-brown byproduct at

bottom, hehehe it is NOT bromine :-D

washing the product with water thoroughly to remove traces of HCl (well, there was no unreacted extra HCl present, but I did not know that the moment

yet)

prepared to steam distillation

started heating of distillation flask

water started to boil, so it's the right time to reduce the flame

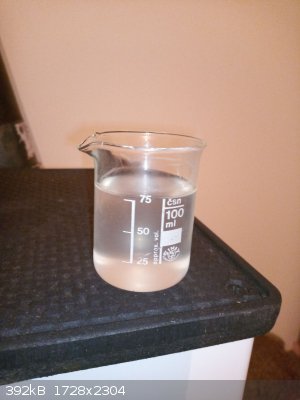

mixture of bornyl chloride with abundant alfa pinene had almost the same density as water which created such beautiful phenomena, this is the primary

first crop of product = the second fraction collected during distillation (the first fraction collected during distillation containing almost hexane

with very small amount of terpenes is on the right side)

side view of the unusual beautiful phenomena, quite big drops of terpene floating near the water surface lacking tendency of merging together (primary

first crop of product, second fraction collected), on the right side there is a beaker with hexane fraction with a small amount of terpenes too

(initially there was only very little of H2O in the hexane fraction but I continued steam distillation slighly longer to certainly eliminate all the

hexane from the primary crop of product as it would cause problems on crystallizing out bornyl chloride if hexane present)

imminent clogging of condenser, first sign that I certainly have some solid product of bornyl chloride and not only liquid alfa pinene

imminent clogging of condenser, must be watched carefully the whole time and if necessary, hot water must be circulated into cooling part of condenser

or at least stopping cooling water circulation to allow the solid mass to liquifer and drain off the condenser

detail of imminent clogging from other side of condenser, do not use any adapter with narrow part to collect the distillate flowing out of condenser

remainings in distillation flask near the end of steam distillation, this now yellow substance was very likely the dark red-brow sideproduct of the

reaction which was sitting at the bottom of reactor

the remainings in distillation flask which do not distill by steam, only water flows out of condenser now without any terpene, it's the right time to

turn the flame off

after freezing the liquid mixture of terpenes in freezer at -18 C it solidified to jelly-like mixture, there was still some alfa pinene present, the

method of removing liquid alfa pinene (m.p. -55 C) without warming the jelly substance (bornyl chloride solubility in alfa pinene is low only at

freezing temperatures)

second recrystallization of bornyl chloride from 75% w/w isopropanol

vacuum filtration of the shiny white product after crystallization at freezing temperature -18 C (filtration done very very very quickly, as quickly

as possible to avoid warming and dissolution of the precious bornyl chloride)

air-drying the product in petri dish at room temperature, it sublimates quite quickly which reduces yield significantly, when it loses the scent of

alcohol the experiment is successfully almost finished, it is just necessary to weigh the product and determine its m.p.

[Edited on 9-1-2020 by Fery]

Fery - 10-1-2020 at 00:11

Mother liquor left after the second recrystallization was concentrated by partial evaporation to about 1/3 of its original volume (so mostly IPA

evaporated with only little of water), put into freezer at -18 C, vacuum filtered. Yield 0,4 g of impure low grade quality bornyl chloride. Definitely

the solvent used for recrystallization proven to be good.

Metacelsus - 10-1-2020 at 10:06

Very cool! Can you try making some borneol or camphor?

Boffis - 11-1-2020 at 08:21

Really nice preparation and a good write-up, well done. What was your source of alpha-pinene and does it matter which enantiomer it is?

Fery - 11-1-2020 at 11:34

Hi Metacelsus, I already tried this:

0,5 g anhydrous Na acetate + 2 ml of glacial acetic acid, completely dissolved in testing tube on heating. On cooling the salt crystallized out

significantly (just wanted to determine the minimal volume of acid to dissolve salt). Then into cold tube I added 0,6 g of impure bornyl chloride

recovered from mother liquors, inserted cold finger (another test tube with smaller diameter used as a simple condenser filled with cold water) and

heated, everything was dissolved well. Then poured into cold water containing NaCl (just to facilitate floating on the surface) where some terpene

solidified. Washed with water and transferred into pure water in a small beaker and heated to water boil but it did not liquify and was sunk at the

bottom (did not float), so I assume it was unreacted bornyl chloride because camphene m.p. is 51-52 C. I wanted to prepare bornyl acetate from

camphene by reacting with glacial acetic acid + catalytic amount of H2SO4 as I love chemicals with nice scent. Then very probably borneol too, but not

camphor as I have 250 g of fresh racemic camphor in stock and 25g from since my beginnings in childhood. I would try methol -> menthone rather than

borneol -> camphor.

If you have some laboratory praparation method to eliminate HCl from bornyl chloride pls let me know otherwise I will have to develop it. Maybe easier

to produce camphene from alfa pinene directly by isomerisation (e.g. TiO2 activated with H2SO4 which I have in stock).

Reacting bornyl chloride with something alkaline should eliminate HCl and produce camphene. Then reacting camphene with acetic acid catalyzed by H2SO4

should produce bornyl acetate.

Boffis I've bought 2x5L canisters of alfa pinene at price 65 CZK per 1 L (24 EUR per 10 L) from a supplier who is unavailable for already last 1 month

(I wanted to buy also other chemicals from him), one of his mailbox returns error message that it is full, second mailbox accepts emails but the man

do not answer, when calling his mobile phone automatic answer the number you are calling is not available, pls call later, calling to number of his

fixed line telephone / fax automatic answer the number does not exist anymore. Inspecting business registry his name still exists. Very strange -

lockup / hospital / heaven ? Pity, I was buying from him regularly every month coz he had very good prices.

I planed to buy a polarimeter, I found one sold at ebay by a seller from my country but it was incomplete (glass cell missing) and very old model

without a chance of finding suitable glass cell so I did not buy it at the end.

Assuming the alfa pinene origin is in my country it should be (1S,5S)- or (-)-alfa-pinene (common isomer in Europe, in America it is (+)-alfa pinene)

but that is only my guessing.

The preparation is not yet good enough and should be improved due to low yield which was caused by much less HCl produced from the generator than I

assumed (reactor should be weighed before and after addition of HCl gas and eventually second batch of HCl gas bubbled into it where amounts of acids

for the second addition of HCl could be easy to calculate), but excess of alfa pinene made steam distillation smooth by preventing condenser clogging

and this method of separation seems to by superior for impurities / byproducts with are oily and have high b.p. I lost also a lot of the product by

drying out on air and only then realized how fast does it sublime, no surprise its name is artificial camphor. I was also afraid of

overhydrochlorinating it as then dipentene dihydrochloride should be produces. I still do not know whether such low temp is necessary as in 1 source I

found temp range 0-30 C preferrably 20 C which is room temp but other aprox 5 sources everywhere T below 0 C.

Quite rare chemical today, not in acros organics database, neither sigmaaldritch, the old way of producing camphor from alfa pinene via bornylchloride

was abandoned long ago.

Fery - 11-1-2020 at 12:23

GDOSB I found the method, it was sitting in my disk for few months already... When you have a lot of info it is hard to remember / find.

So I had to use higher temp 200 C.

I kept the solution for 5 hours at only b.p. of acetic acid which was probably only very slightly elevated by the presence of Na acetate (I did not

use thermometer).

Also the book suggest to recrystal bornyl chloride from ethanol - I think it is too much soluble (I found 1 source where they used 70% ethanol and I

used 75% isopropanol which was suitable too, but I wouldn't try concentrated ethanol).