Sauron - 4-11-2008 at 21:49

FINALLY the last shipment of my lab equipment has arrived from the warehouse in SF Ca where it was idling. Thai Customs hit me for about $600 and the

customs broker abother $300, freight was prepaid, another $700. But worth it. As usual it came by ocean cargo. A few weeks on the water and a week in

Customs.

My Parr 4521 1 liter heated & stirred pressure reactor and 4843 Controller

And Parr 4833 temperature controller for the mantle to shaker hydrogenator 3911 already here

and Aldrich Kugelrohr (current model) plus an old model air oven that takes up to 4 liter flasks. I can use this with the motor for the new model.

and Ace Hanovia 450 W power supply for med pressure Hg arc lamp

and Sequoia Turner 340 UV-Vis spectrophotometer

and a bunch of Buchi rotavap hardware, trhree motor heads, a couple water baths, and four or five stands or jackstands. Along with the Buchi spares I

have here I can assemble 2-3 more Model R, R110 and EL-130 sets in addition to the R110 I have on hand.

I will have to take some pics and post them once I get everything situated.

I am going to look into upgrading the Parr to 4522, 2 liter, which just involves changing the mantle, reactor body (heads are same) and a few internal

reactor parts that need to be longer. That would give it a working volume of about 1325 ml. The thing is rated at 1900 psig and 325 C. with the

stainless steel vessel.

The only item still on other side of the pond is a Cole Parmer Masterflex peristaltic pump drive with a PTFE diaphragm pump head suitable for pumping

really corrosive, aggressive liquids and there's damned little it can't handle.

The warehouse is closed down so I have to change the way I deal with US purchases in the future.

[Edited on 5-11-2008 by Sauron]

kclo4 - 4-11-2008 at 21:54

Thats very nice! Please get some pictures up, I'm excited to see how nice they all look!

What are some of the experiments you hope to do with all this new equipment?

Oh yeah, Doesn't hydrogen cause problems with Stainless steal?

[Edited on 4-11-2008 by kclo4]

Sauron - 4-11-2008 at 23:00

Not that I am aware, but if it does, Parr makes vessels out of lots of other alloys, like hastalloy, monel, and refractory metals like titanium and

tantalum. I shudder to think of prices. A new vessel body may well cost more than the $2000 I paid for this whole unit, used. And the more exotic

materials will certainly cost more than SS 316.

The main concern when using an autoclave for more than a single purpose it to avoid using it for anything involving catalytic poisons or it will never

be useful for catalytic hydrogenation again.

Klute - 4-11-2008 at 23:48

Oh you lucky person! I would have liked to witness the reception

Now that my dream of having a rotavap is fullfilled, next one on the list is a Parr!Gonna take a while though...

Well hope to hear you doing some work with all that!

Sauron - 5-11-2008 at 00:06

Major money pit is next stop: fume hood. $7000 including the exhaust scrubber That goes outdoors with vent stack over the roof. It's a big hood (2 m

wide, 90 cm deep, 1 m height, cabinets under.) Should have been installed already but various financial snags ensued.

Maybe I will sell off a few spare rotavaps.

Sauron - 6-11-2008 at 04:53

T spebt 4-5 hours unboxing and sorting out the shipment. Thus far no bad new. The Parr pressure reactor came in sections: the vessel, very heavy, the

base, the heater assy with its three legs, the motor and stirrer overarm, which turns out to mount to the shell of the mantle and couples to the

packed-gland stirrer assy. And the controller, which is modular. This one has the mantle controller unit and a digital tachometer. There;s two more

bays available for a t/c and a transduce to display internal temperature and pressure. There's also an option for PC interface and control. The normal

pressure display is a gauge, the one that came with this is a 0-600 psi but I can change that out to one that goes to 2000 psi.

The new model Kugelrohr came with safety guard, which I was not expecting. That's nice. Looks immaculate. Aldrich sells these now for 7X what I paid

for this one. Plus I got an old model coffee-urn type air bath and an old model air motor of the windshield-wiper type which, unlike the air bath, I

probably will never use.

Pleasant surprises in the assorted Buchi rotavap bits. Three Model R bases with jacks. Two Model R110 jackstands, two RE-111 jackstands. One

freestanding waterbath for Model R, one for R110. Two EL-130 motor heads (the variant of R110 that is for reflux and descending condenser setups

mostly.) One R110 motor head built into a custom plexiglass shell that is airtight, with provision for inert atmosphere or purge, intended for use in

a flammable environment (explosion proof.) Probably out of a refinery lab. One diagonal style Buchi double coil condenser. That one was properly

packed (padding between coils) so intact.

Once I consolidate these with the surplus Buchi stands etc and motors I have already, I may have some rotavaps for sale.

A Kipp + Zonen chart recorder.

And Ace Hanovia 450 W power supply for medium pressure Hg vapor UV lamp.

In a day or two I will take some photos. First lots of boxes to inspect for little bits I may have missed, then trash. Lots pf bubblepack and plastic

peanuts to police up. Must keep busy so as not to dwell on how much this all just cost me for freight, duty, VAT, and broker fees.

Maya - 6-11-2008 at 15:09

Geez, that's alot of heavy duty artillery.

I hope you got a project that is worth it. I don't see any chemistry related projects right now that could possibly give any worthwhile investment

returns.

But then of course I don't see this area being a good hedge right now either except for acquiring distressed inventory.

You may be able to get more cheap(er) items soon as values are still deflating

good luck with the project(s)

Sauron - 6-11-2008 at 15:23

Investment recovery has never been my concern. I just want to have fun doing my chemistry. Not out to make a buck, been there, done that. I have

projects backed up for years that are awaiting the last big acquisition (hood).

This little shipment is nothing comapred to what I have ties up in HPLC kit (Waters). A lot of other big ticket purchases were made for now defunct

liquor project, like 20 liter Buchi rotavap w/glass, and a pair of 72 liter Glas Col TM mantles and four matchine flasks. Bought the mantles and two

of the flasks new, other two used. Someday I'll find a use for these.

Here's a photo of Sequoia Turner 340 UV-Vis spectrophotometer, this is off the net but exactly the one I have. I need a manual for this thing. If

anyone has one to scan or knows where I can get one, scan, xerox, anything, I'll be grateful.

[Edited on 7-11-2008 by Sauron]

Buchi Rotavapors Galore!

Sauron - 7-11-2008 at 00:47

After consolidating the old pile of Buchi bits with the new pile of Buchi bits here is what shakes out:

1 R110 w/waterbath and glass - my workhorse.

1 more R110 with custom gas-tight containment for motor head

2 EL-130 (rotating seal) version of R110, 1 w/ bath

1 RE-111 series jackstand only plus a second that needs a little work and a spare stripped baseplate

3 Model R on V-style jackstands, 1 water bath matching

3 alt style stands for built in bath, adjustable track for upright,, no motor heads or baths

1 spare V stand w/jack

That's seven working rotavaps w/jackstands, and I recon I can sell off the 3 Model R's while keeping the 2 R110s and 2 EL130s. Photos shortly.

The nice thing about the R and EL, R110 and EL130 is that they are dead simple, no electronics apart from the capacitor for motor. They last a long

LONG time. Whereas the later models all have pcbs supporting digital displays and once Buchi stops supporting spares for those models, the user is

s.o.l.

[Edited on 8-11-2008 by Sauron]

Sauron - 7-11-2008 at 18:51

What's holding up the pics is that the auto focus on my video camera is on the fritz. I have tom sort this out.

Very annoying.

Well, I took the pics with an unfamiliar Sony digital, and now am having trouble getting XP to recognize the USB card reader that is supposed to move

the jpgs from the SD-card to the hard disk. Grrrrr.

One damned thing after another!

[Edited on 8-11-2008 by Sauron]

Sauron - 9-11-2008 at 08:14

AT LONG LAST

Photos of Recent Shipment from USA

Parr 4521 Pressure reactor Stainless Steel 316, 1 liter, rated 1900 psi @325 C, w/bottom drain. The 4843 controller is also shown.

[Edited on 9-11-2008 by Sauron]

Sauron - 9-11-2008 at 08:19

Just the vessel w/head and assorted kit atop

[Edited on 9-11-2008 by Sauron]

Sauron - 9-11-2008 at 08:23

Another view The two units alongside are Buchi EL-130 Rotavaps which resemble one armed bandits with their jack handles in a Hitler salute.

[Edited on 9-11-2008 by Sauron]

[Edited on 9-11-2008 by Sauron]

vulture - 9-11-2008 at 08:25

Nice equipment. Just one thing, has the parr reactor been tested recently? I would hate to see it fail filled with hydrogen gas and some catalyst.

Testing with some compressed air first might be a good idea.

Sauron - 9-11-2008 at 08:31

Three Model R Buchi rotavaps, one with matching waterbath, all on jackstands. The closest two are early models, the third is the transitional variant

just before change to R-110 late 1960s I think. I had one of these in my lab at university mid 70s.

[Edited on 9-11-2008 by Sauron]

Sauron - 9-11-2008 at 08:40

Nestled in a corner of my master bedroom, more of the loot.

L to R and back to front:

Kugelrohr new model motor, air bath, old model air bath

Kipp + Zonel chart recorder, Sequoia Turner 340 UV-Vis spec, Parr 4833 temperature controller for 3911 shaker hydrogenator's mantles; Kugelrohr air

motor for old model, automotive windshield wiper reciprocating type; very nice costly airtight Halliburton type instrument case that Buchi stuff came

in; jackstand for Re-111 Buchi; B-461 waterbath for R-11o/EL-130 Buchis.

The Kugelrohrs deserve better photos. I will do tomorrow.

[Edited on 10-11-2008 by Sauron]

Sauron - 9-11-2008 at 08:44

Ace Hanovia power supply (lamp ballast) for 450 watt Hg medium pressure UV vapor arc lamp - standard photochemical research tool.

[Edited on 9-11-2008 by Sauron]

Sauron - 9-11-2008 at 08:53

R-110 head interchangeable on the jackstands with EL-130. I have two of these, but only one in this interesting airtight enclosure with gasketing and

a threaded vent for I guess positive overpressure. My best guess if petrochem industry use in volatile environments demanding EX-proof equipment. I

doubt that U/L ever saw this one though.

I already found that this rig is incompatible with the standard Buchi diagonal double coil condensers, so I guess it has to be used with a distributor

head and vertical conder, which I like better anyway as they take up less bench space.

[Edited on 10-11-2008 by Sauron]

Sauron - 9-11-2008 at 08:58

From an earlier shipment, Thermolyne 2" x 12" 1100 C tube furnace.

[Edited on 9-11-2008 by Sauron]

Sauron - 9-11-2008 at 09:05

Lastly for tonight, a few items outside my lab equipment storage room door waiting for me to make room.

The drun is 25 Kg TCCA.

Lurking behind the mini-drill press is a Waters 715 Ultra WISP autosampler for HPLC w/controlled temperature carousel. Still on its skid.

In upper RH corner a Waters fraction Collector (first model), a PrepLC 25mm Radial Compression Module for 1,2, or 3 x 100mm prep HPLC column segments.

Most of what is taking up the space in next room is HPLC equipment.

[Edited on 10-11-2008 by Sauron]

[Edited on 10-11-2008 by Sauron]

Sauron - 9-11-2008 at 09:17

Oh, and @eliteforum, how would you like your entree of crow?

Southern fried?

or Tartar?

Cornish game crow?

Or Crow a l'orange?

You've been as much as calling me a liar for about a year, so now, take what is coming to you.

[Edited on 10-11-2008 by Sauron]

Klute - 9-11-2008 at 11:25

Beautifull, very impressive equipement! Chemporn at it's best

Funny, the 2 old Buchis look alot like the model I recently aquired, it is said to be a Buchi KRV 65/45, although the stand isn't the same (it's one

with a integrated place for the water bath). The motor look identical though. I am always lost with all the Buchi models...

I must agree with the comment about how tought they are, the one I got is from the mid 60's,a nd in perfect conditions (motor works fine, it's just

the old electric plugs). The second one another frecnh member aquired, from the same place, also from mid 60's worked perfect also, although it was

very dusty. That last one is indentical to the two first old Buchis you have.. What model type are they?

I guess you are going to have some fun with all that! The Parr is surely going to appear in a dream of mine tonight

[Edited on 9-11-2008 by Klute]

Maja - 9-11-2008 at 11:58

Sauron, are you planning something huge ? ;]

Sauron - 9-11-2008 at 14:59

@Maja: Global domination! (insane tittering, similar to Richard Widmark as Tommy Udo in "Kiss of Death")

Seriously, not one huge project, just lots and lots of smaller ones.

@Klute: Extremisn in the pursuit of chemistry is no vice. (Paraphrase of half of Barry Goldwater's famous 1964 campaign remark.)

I have two of those stabds for the integral bath, with support rod but no jacks or baths, plus another without even support rod or the clamp assy to

mount it. I had one complete a few years ago that I bought on LabX from Oregon State University, but sold it off. These older Buchis seem to last

forever. I think Buchi later got into planned obsolescence.

That long model number sounds like something off the motor plate rather than the Model of the Rotavap proper. I have lots of Buchi brochures and parts

lists extorted from their former Thai agent and they just refer to the models R and EL for the original Rotavaps, R being stationary seal, rotating

vapor duct, EL being rotating seal, stationary vapor duct.

The next were R-110 and EL-130 which were very similar to R and EL in terms of motor head, but the "one armed bandid" jackstand with fat tubular

column was a departure.

After that c.1980 the RE-111 series and EL-131 and variants, the motor head was now mounted not on a rod or column but directly on a spring loaded

housing and elevated when released by gripping the handle - no jack handle. The introduction of electronics and digital displays allowed for control

of variables like RPM and temperature (on some models) but at the expense of complexity and maintenance problems. The bath for these models interfaces

to the base plate and will not stand alone.

In the 1990s the 124/134/144 models were bundles with vacuum systems and their controllers. Most of that stuff was not actually made by Buchi, the

recirculating aspirator pumps were made by Sibata (Japan) for example. Modularity allowed changeover from R to EL seals and glassware configurations.

The present 200-series models were introduced in the early 21st century and feature even more intergarion with vacuum control, remote operation,

solvent trap (secondary condenser) and powered jack Glassware redesigned and some of the nicer variants of glassware eliminated, a development I

disapprove. For example the descending condenser setup is great for foaming and bumping solvents like toluene. I have this setup on my 20 liter

industrial model Buchi R-151.

[Edited on 10-11-2008 by Sauron]

zed - 9-11-2008 at 16:32

Vulture,

Initial testing of a high-pressure vessel, is most safely carried out by hydro-testing.

Fill the vessel with water, purge all gases. Raise the internal pressure by means of an airless sprayer, or pressure washer unit. Many of these

units can produce pressures of several thousand psi.

If the vessel fails at room temperature, under water pressure, it usually merely warps, or at worst, goes....sploosh.

Under hydro-test conditions, distortion of the vessel can be measured mechanically.

Too much distortion, indicates the vessel should no longer be used for high pressure applications.

If a pressure vessel fails under air/gas pressure, rather than water pressure, more spectacular effects may be observed.

Parr reports testing procedures they use, somewhere on their website. Possibly in their on-line manuals. For a price, you can periodically send in

your vessels for factory testing.

Also note. To me, the stirrer unit on the above pictured Parr pressure vessel, appears to be the more expensive magnetically-coupled drive. The

Parr packed-gland drives that I am familiar with, are considerably smaller in size.

[Edited on 9-11-2008 by zed]

[Edited on 9-11-2008 by zed]

Sauron - 9-11-2008 at 17:17

Thanks, zed. Safety first.

chemrox - 9-11-2008 at 18:47

@Klute, I have the same Buchi and it's listed as an R110. I too acquired extra motors and a jackstand for a later Buchi. What haooened was I kepot

buying "Buchi rotovaps" used and got motors but no glass. Finally I got a complete setup for $375. I need more of the bakelite rings and washers. I

got a great deal through Sauron on a Parr with controller. I have no intention of hydrotesting it but running an inert gas through it first to check

for leaks might be prudent. Water is practically incompressible and placing pressure on water inside the equipment seems like asking for trouble.

Over-pressuring with Argon would be a more realistic and relatively benign test. I'll email Parr and ask them what they recommend. Anyway, thanks

again Sauron for tipping me to the Parr and other stuff I got from the dealer. The Mcleod Gauge was also a steal at 75.

Fleaker - 9-11-2008 at 19:07

@Sauron or to any who can help

First off, nice equipment!!

Now my question: You seem to know considerable amounts about the Rotavapor line, so I think you might weigh in on this.

I am thinking of acquiring a Buchi R-215 Professional model. It's practically brand new and in good working condition I've been told. It comes with a

V700 pump, and V850 controller along with the B-491 heating bath. It's $3K. It is a complete system and it's practically new.

I have another option: I know I can pick up a nice Buchi R-124 for about a thousand, but I'd have to buy another Buchi pump (or my preference, a KNF

Neuberger Laboport UN842.3, 34L/min to 1.5 torr) and then there's a controller for it. Even allowing for getting those used, I'll probably still spend

about two thousand dollars on the whole setup.

Is it worth getting this relative new R-215, or should I save myself a thousand dollars and get the R-124?

PS--I found myself Buchi's equivalent of a Kugelrohr for about $500, any thoughts?

Magpie - 9-11-2008 at 20:50

Nice toys, Sauron. I really like your Parr apparatus.

In reference to pressure testing the Parr vessel, since it is used, I think it would be a good idea to hydrostatically test it prior

to putting it into use with gaseous products. Standard procedure is to test to at least 150% of your planned use pressure. If it is going to warp or

rupture it is far better to find out about its defect using an innocuous liquid than reaction gases in use.

Using liquids is standard practice for the reasons well stated by zed. Pneumatic testing is very dangerous and I have never heard of anyone doing

this for anything but very low pressures.

This thread shows some pictures of hydrostatic testing I did on a homemade pressure vessel. Looks like I went up to about 650 psig (44 bar) on the

tester and about 350 psig (24 bar) on the vessel itself.

http://www.sciencemadness.org/talk/viewthread.php?tid=4566&a...

[Edited on 9-11-2008 by Magpie]

Sauron - 10-11-2008 at 02:52

Thanks @Magpie.

@Chemrox, the Parr 3911 you got through me is a glass vessel shaker and does not need testing, it only goes to 4 bar (60 psig) if you follow Parr's

advice. Parr tests every bottle to 150 psig.

But gkass at best is unpredictable.

The Parr that zed and Magpie and vulture are referring to is the stainless steel 1 liter 4521 upthread, rated at 1900 psig @325 C. An accident with

that at pressure would be a major event.

There's photos of the R110 and EL-130 using same jackstand upthread. But the one Klute is talking about is a Model R, like in the photo with 3 of them

on floor. He just has the different baseplate with adjustable track and big round place for integral water bath. I have a few of those stanbds but

nothing on them but the upright rods.

@Fleaker, I think either of those deals will serve you well. The Buchi pumps and controllers are very good, so are the KNF. The controller I have is a

V-801 programmable one.

I never got my hands on either a 124 or one of the current series like 225. The most recent models I actually owned were RE-111 and EL-131.

[Edited on 10-11-2008 by Sauron]

Klute - 10-11-2008 at 06:18

Sauron, are the model references marked anywhere on your equipement? Indeed the number KRV 65/45 was on the motor steel plate with the serial number,

i checked it on the internet and there are a few articles mentionning the use of a "KRV 65/45 Buchi Rotavap", so I just took it for the old name. I

was very surprised to find no info what so ever on theses old models on the Buchi website. I guess they prefer selling the modern electronics and let

evryone forget about these 50 years-lasting models

At work we had these electronic ones (although not Buchis) where you can indeed set RPM and temp, and even configure an automatic "breaking" of vacuum

at a designated time. But we didn't use them that often, so not much maintance.

BTW, does anyone know where one cna buy some seals for the old Buchis, if other brands can fit, or if it has to specificly be a Buchi? I guess they

don't sell these anymore... Any advice?

Sauron - 10-11-2008 at 06:53

@Klute

The Model R110 is prominently identified as such as are the EL-130s. on faceplate of motor head control box (see pics). They all read BUCHI Rotavap

R-110 and so on, Rotavap was a Buchi trademark.

The later RE-111 series were similarly marked.

The very old Model R (and I assume EL) generally say nothing, the transitional R (and EL) might say Model R - I will have to look at mine.

The motor plate stuff is nothing but a part number for the motor perhaps from the OEM because you can take it to the bank that Buchi did not

manufacture the motors, they were outsourced. So anyone on the Net referring to this model by that number is mistaken. All Model R's are referred to

simply as Model R. All stationary seal Buchis are referred to as having R-type seals. That is just to distinguish them from the rotating seal EL type

models. This continued until the entire glassware and seal system was changed in the 200 series still being sold. That only happened around the turn

of the century.

I am not aware of any third paerty source for the seals. Sorry.

[Edited on 10-11-2008 by Sauron]

Aldrich Kugelrohrs Old and New Models

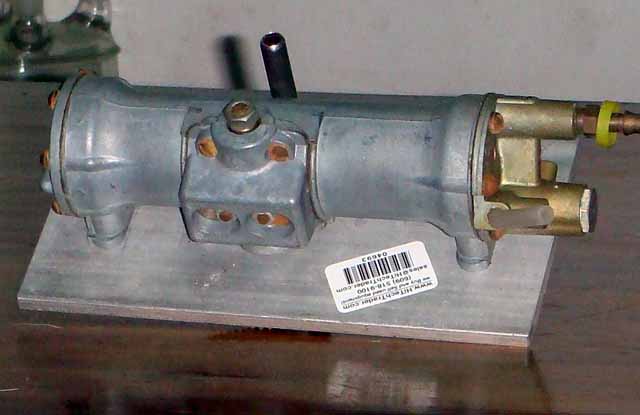

Sauron - 10-11-2008 at 07:20

Also in this shipment were two Kugelrohrs, one old and one new model.

The new model has a shielded stainless steel air oven with thermostat and a sealed heating element. A thermocouple allows temperature control with

good precision and an oven thermometer is also supplied.

The new model motor is electric, heavily geared down for torque, and vacuum takeoff is under the Firestone style valve. The rotation is continuous and

unidirectional. The specimen I have is immaculate.

The old model has an unguarded aluminum alloy air oven without any built in temperature control or t/c but you can add an external controller and a

thermocouple easily enough. There is an oven thermometer. I picture it here with new model motor because that is how I intend to use it, note that the

height is perfectly compatible with the centerline of the oven flask.

The Al shell was not so impervious to chemicals if spilled and the bare heating element was a hazard. Adding a closely fitting SS liner closed at

bottom would correct both deficincies.

In case anyone is wondering this is Aldrich's answer to Buchi's rotavap design.

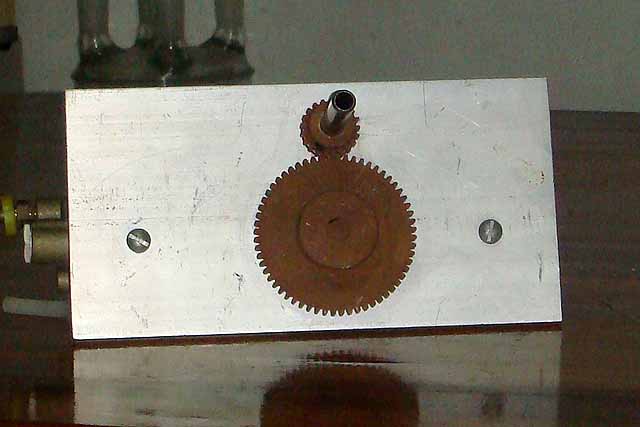

The old model motor is a pneumatic one and reciprocates back and forth, it was originally made as an automotive windshield wiper motor. When Detroit

and Japan changed the design of such things Aldrich was left high and dry. Note the stainless steel tube down the axis of the small gear. That is the

vacuum takeoff. Normally these air motors come in an Aldrich black metal housing intended for ringstand or lattice mounting. And they normally have a

silencer in back because like all pneumatic drives they are noisy.

The new model Kugelrohr was introduced in the late 80s and now sells for almost $5000. Ouch! I was happy to get this one for $700.

The new model Kugelrohr has interchangeable PTFE bearings for oven flask news of 24/40 and 14/20 sizes, so will handle flasks from 50 ml to 2000 ml.

Flasks are filled to 1/3 nominal capacity, because of the horizontal orientation.

The old model oven would handle flasks to 4 liters according to Aldrich, but the old and new ovens look same dimensions to me. Maybe the electric

motor does not have the torque of the air motor? I do not know.If that is the constraint then there is little advantage to the old model unless you

already have compressed air service in the lab.

[Edited on 10-11-2008 by Sauron]

Sauron - 10-11-2008 at 07:24

and old model

[Edited on 10-11-2008 by Sauron]

Sauron - 10-11-2008 at 07:25

And old model motor, back view

[Edited on 10-11-2008 by Sauron]

Sauron - 10-11-2008 at 07:26

and front view

[Edited on 10-11-2008 by Sauron]

Sauron - 10-11-2008 at 07:40

And closing for the nonce, another view of the Parr SS316 1 liter pressure vessel.

[Edited on 10-11-2008 by Sauron]

DJF90 - 15-11-2008 at 17:25

Christmas is also coming early for me too. Although I have no fundamental lab stuff as of yet, I saw a BNIB Buchi M (HB140?) on ebay for just under

£300 after checking labx (I think) and seeing used ones for £650, I decided that I should make a useful aquisition  (especially as organic is what I like best

(especially as organic is what I like best  ). Now for the difficult part...

). Now for the difficult part...

I have sourced (but not yet purchased) a fairly cheap, 2 stage, vacuum pump that pulls to 25 microns (i.e. less than 1torr) and now have a problem...

Having no access to dry ice or LN2, how am I supposed to stop the nasty chemicals from getting into the vacuum pump and destroying it? I assume an

aspirator is no good for a buchi (besides I have no running water (or a lab for that matter... yet.) and would rather not have the hassle of setting

up a recirculating system.

My best thought as of yet is to have a flask (with washbottle head type thing) submersed in the lowest temp salt ice bath I can attain (probably

CaCl2.6H2O => -52C IIRC) and then a column/gas wash bottle filled with activated carbon (granular to minimise effect on flow?) and KOH pellets (if

the vapor is acidic) before letting the vapor reach the vacuum pump. Is this sufficient? Any suggestions are welcome, thanks in advance.

[Edited on 16-11-2008 by DJF90]

Sauron - 15-11-2008 at 17:42

Without any cold trap, and using an oil pump like that, you will quickly contaminate the pump oil and vacuum will go to hell.

For rotavap you do not need a 2-stage pump or 1 torr. An aspirator pump will do fine at 20-30 torr, and a PTFE diaphragm pump like Buchi makes or KNF

Neuberger, even better. Both are impervious to solvents and corrosives and are preferred for rotavap work. Save your 2-stage oil pump for when better

vacuum is needed. But you will always need a cold trap and so dry ice is a necessity. Not a luxury.

DJF90 - 15-11-2008 at 17:51

Thats not the answer I was looking for but I thank your honesty. I may actually be able to aquire dry ice, but only in 10kg loads and for ~£30. I am

fine with the pricing of this, but am unsure if I will be able to make the best use of it before it sublimes... Seems silly to buy 10kg if I can only

manage to use 500g. Could I possibly store it in a thermos flask in an expanded polystyrene box in the freezer? How long could I store it like this

for? Unless you have a better method? I was looking for a ptfe diaphragm pump but it was way too expensive

Sauron - 15-11-2008 at 22:12

That's a ripoff price for dry ice and a ridiculous minimum order.

If you cannot find a better source here is your alternative:

1. Buy an empty new gas cylinder and outfit it with a CO2-rated valve and dip tube. The shop that sells you the cylinder should furnish and install

the valve and dip tube. The dip tube is essential.

Purchase a "Frigimat Jr" (Scienceware, Bel-Art) dry ice snow making tube and cone and poly bags to catch the snow. $100-$150 US. Aldrich, Cole Parmer,

and others distribute this, I do not know who is UK distributor. Check the maker's web site.

Follow the directions for attaching the tube and using the device. Typically it will say Open valve 3/4 of a turn - that is three quarters of 1 turn

NOT three or four turns!

Cryogenic gloves are a good idea.

This way you can make dry ice on demand in finely divided form perfect for acetone slurries. and when you have as much as you need, just close the

valve.

The cylinder and valve with dip tube should cost you less than 10 Kg dry ice.

Getting the cylinder filled with liquid CO2 is very cheap.

Refills same.

At least that is how it is where I am.

I can also order solid blocks of dry ice to my door anytime.

Very cheap.

Liquid N2 is a pain in the ass requiring special dewars ets. Usually not needed unless you need to go below -75 C.

[Edited on 16-11-2008 by Sauron]

Sauron - 16-11-2008 at 00:06

They also make machines to produce cylindrical blocks of dry ice but they are more expensive (2-4X) and the snow is better for lab purposes.

Garage chemist does not like this, saying he got a disappointing amount of dry ice snow from a cylinder of liquid CO2. However, here the CO2 is cheap,

so I could care less about alleged inefficiency. What matters is getting the dry ice when I want it, in the form and quantity I want, and not paying

for solid blocks only to have them sublime off before I can use them!

Klute - 16-11-2008 at 13:44

A aspirator is perfectly suited for a Rotavap. All the ones we had at work used aspirators. A recirculating station is very easy to build and use.

Using a such mechanical pump for a rotavap is a waste IMHO becasue you will never have to use such a vacuum. At best get one of those very though low

vacuum ones. But I would still vouche for an aspirator, honestly.

Sauron - 16-11-2008 at 19:12

Buchi teaches a very simple rule for rotavap use. You want the bath 20 C hotter than the bp of the solvent, you want the cooling water 20 C and you

want the vacuum at a level where the solvent boils at 40 C.

This means 20 C coolant, 40 C bp for solvent and 60 C bath.

They provide a convenient chart of required vacuums for 40 C bp for many solvents in the manual for the V-800 series digital vacuum controller.

At over 60 C water baths become inefficient because of vaporative losses. Oil baths are a mess with rotavaps because of shedding hot oil from spinning

flask.

Low boiling solvents do not require heat at all.

If you pull too much vacuum you will find your condenser will not work very well (unless you switch to dry ice/acetone in a Dewar condenser.)

So follow the 20/40/60 rule and your rotavaping will be happier.

If you can't invest in a digital controller, get a manometer or McLeod gauge and a Cartesian diver type manostat.

DJF90 - 17-11-2008 at 12:09

I guess I had better read up on the threads regarding use of an aspirator. The recent activity regarding use of alternative fluids to create vacuum

seems to be interesting, and it would be superb if such low vacuums (regarding the theory) could be attained using such a simple setup.

The only problem with a recirulator pump is that the water gets contaminated (as it doesnt just go down the drain any more), which may cause pump

damage if care isnt taken to prevent this. What are the solutions everyone else with a recirculating station have come up with? Thanks in advance.

Sauron - 17-11-2008 at 13:17

I would not advise spending too much time on "alt fluids" . Ice water works great and for rotavaps you do not need any better vacuum than c.25 torr

anyway.

The problem of contamination of water is dealt with very simply: change out the water. Do that daily. If you are just stripping solvents, and your

trap is worth a damn, very little will get into the aspirator water. If you are doing a reaction that releases a lot of hydrogen halides,which will

not condense in a cold trap, put a large caustic scrubber in between the cold trap and the pump, or change out the pump water after every run, or

both.

Don't forget to protect your system from suckback.

DJF90 - 17-11-2008 at 14:48

It seems as if I have plenty of time to sort everything out as I do not even have simple glassware yet, I only bought the buchi because it was

(relatively) cheap and I happen to have the money at the moment. It is a small rotovap though, it was hard to tell from the look of the pictures but

the seller described it as being ideal for handling volumes from 30ml to 250ml - perfect for the scale I aim to be working on. What I need now is to

buy a quickfit setup in 19/26 size, as this is ideal for the scale yet again, and most work should be sufficiently done in a 100ml RB flask (with

occasional 250ml use and maybe 500ml for preparing reagents).

I was going to buy a good 0.001g lab balance today but it was based in canada and I didnt fancy having to pay import/export taxes and any other

"hidden" fees  Heating mantles I intend on making myself, possibly a magnetic

stiffer also. ATX power supply needs some components to finish, and some sort of fumehood will be constructed (when I can find somewhere to set up

lab). So much to do and so little time to do it, uni work keeps me busy most of the time. Hopefully I can get ahead during the end of term holidays

Heating mantles I intend on making myself, possibly a magnetic

stiffer also. ATX power supply needs some components to finish, and some sort of fumehood will be constructed (when I can find somewhere to set up

lab). So much to do and so little time to do it, uni work keeps me busy most of the time. Hopefully I can get ahead during the end of term holidays

Sauron - 17-11-2008 at 15:22

The ordinary benchtop Buchi handles flasks from very small to 3 liters. To the best of my knowledge Buchi does not make a smaller rotavap than that,

and why would they need to? In the US the standard vapor duct is 24/40 while in EU it is usually 29/42 and either way adapters can take those down to

14/20 or 19/24 easily. What model number did you say yours is? 144 wasn't it? or 114? That is a 4th generation model from 1990s. The water bath

ought to be about a foot wide and 8-9 inches deep and have an automatic overflow and thermostat.

Plenty of good used Glas Col heating mantles around and cheap. Very little point in DIY there.

Back to rotavap: other companies have made micro-rotavaps in the past but I would shy away from any brand but Buchi. A lot of the glassware is

special. Consumables like seals are essential. Some non standard brand may be long out of business and you will be SOL for spares and support. Whereas

Buchi is still supporting all their old models.

[Edited on 18-11-2008 by Sauron]

DJF90 - 17-11-2008 at 15:34

Not sure about the model, I think its a HB140 though? its quite small, and the description of the waterbath sounds about right. Pictures right here. I

will post my own when I recieve and assemble it

http://cgi.ebay.co.uk/ws/eBayISAPI.dll?ViewItem&ssPageNa...

It'll be more than sufficient for my needs.

[Edited on 17-11-2008 by DJF90]

Sauron - 17-11-2008 at 19:13

I don't think it is a Buchi. Sounds like a Heidolph micro-vap. Made in Germany, more likely outsourced from a German company and built elsewhere, my

guess would be China. I do not know present status, but you might want to check on Web and see if there is an agent in your country and whether or not

you can get glassware and parts/supplies. If the seller represented this as a Buchi and it is not, get your money back.

The eBay listing you linked to is kaput, finito, removed, gone.

[Edited on 18-11-2008 by Sauron]

watson.fawkes - 17-11-2008 at 21:09

This BBS software mangles raw URL (particularly annoying with attachments). Anyway, that eBay auction is still there; just can't click on the

auto-generated link. Use this one:<br>http://cgi.ebay.co.uk/ws/eBayISAPI.dll?ViewItem&ssPageName=STRK:MEWAX:IT&item=370112174805

Sauron - 17-11-2008 at 21:27

As the auction is completed the entry is now only viewable by buyer and seller. Anyway the item description is unequivocal:

BUCHI Rotavapor M with HB140 Waterbath + glassware BNIB

I have what I think is a complete set of Buchi brochures, exploded drawing and parts lists and I have never heard of a Model M nor of a HB140 water

bath. That does not mean that the description is wrong. I am willing to concede that there is a slim possibility that a model has eluded my

attention. I will ask the Buchi agent. That's where I get my old Buchi tech material.

Okay this is a micro Buchi that I never heard of before, and no longer made. However there is a very good chance they will still have spares and

glass, check with the UK agent to be sure.

If the max flask size is 250 ml you need to be aware that you are not to fill the flask fore than 1/3 to 1/2 (ar most) so with this model you are

constrained to 80-125 ml sample sizes. That is 1/10th the capacity of the normal benchtop Buchi that handles 1500 ml in a 3 L flask.

Anyway good luck with your purchase. Older Buchis sans printed circuit boards tend to last forever, short of a major seal failure while stripping

something mega-corrosive.

[Edited on 18-11-2008 by Sauron]

DJF90 - 18-11-2008 at 08:58

As far into the future as I can see it should only be stripping off solvents. If I can get a vapor trap to operate at ~-30 (salt ice bath with

CaCl2.6H2O), then would this be enough to stop the solvent vapors entering the pump? Should just be stuff like Et20, DCM, AcMe, and maybe toluene (so

long as I can get hold of them).

Sauron - 18-11-2008 at 09:37

No, -30 C is not adequate for Et2O and maybe not DCM if youyou are looking to protect your pump oil in a 2-stage pump. Figure out the bp of these at

say 10-20 torr to see why.

That is why a pump impervious to solvent vapors is much preferred for rotavap work. Aspirator or PTFE diaphragm only. Aspirator is cheaper. Then comes

recirculating dual aspirator, then the PTFE diaphragm pumps are costliest in this class.

DJF90 - 18-11-2008 at 10:06

Ok i got it. Bp (Et2O) at 15 torr is -45C ish. But... we never strip of ether at 15 torr in the lab, more likely 450 torr. That way it just about

condenses at room temp (~20C). A SS needle valve could be used to moderate the vacuum to ensure that the ether will condense at room temp under said

vacuum? And then I need to measure the pressure somehow, maybe I can find a gauge that gives absolute pressure in torr.

EDIT: Don't worry, I really should stop clutching at straws. I think I dont really have much choice under my circumstances but to go with the vacuum

aspirator. Plus it'll be better off in the long run. Thanks for you're help Sauron, and thanks for being so patient with me.

[Edited on 18-11-2008 by DJF90]

Sauron - 18-11-2008 at 10:47

The temp of the coolant has to be substantially lower than the bp of the solvent at the vacuum in question, remember. At least 20 C. lower. This is a

hard lesson to learn if you have to rebuild your 2-stage pump or even just do an oil change. I can tell you, even N2 and CO2/acetone traps are not

perfect.

Anyway, you will find out for yourself.

DJF90 - 18-11-2008 at 13:32

I appreciate the input Sauron. I will read up on the relevant threads at the next convenient time. Thanks again

Sauron - 18-11-2008 at 21:53

The problem with using the needle valve/controlled leak technique instead of a real vacuum controller is that you are introducing air into the system,

and in many instances the product neds to be carefully isolated from the air.

So unless your needle valve is hooked up to a N2 or Ar cylinder with a regulator than can tolerate the pressure differential between the compressed

gas on one side and the partial vacuum on the other...

Aside from that, once most of the low boiling solvent is stripped you will have solvent condensed in receiver and when the vacuum is increased it will

start to boil in the receiver. I have seen it happen. This can overload the condenser. Buchi now recommends a secondary condenser to reduce solvent

getting to the aspirator for green purposes.

DJF90 - 19-11-2008 at 05:08

Sorry I didnt mean an air leak. My idea was to just put a SS needle valve in between the vacuum pump and the apparatus, and only open it up enough to

get required vacuum. I suppose now this wont work because if there is some way the apparatus can get evacuated, whether its a regular sized bore or a

tiny little gap in the valve, it will be evacuated to the unltimate vacuum of the pump.

If an air leak is included then surely any air that leaks in will get sucked into the pump (so long as the leak valve is between the apparatus and the

pump, preferably closer to the pump?

Sauron - 18-12-2008 at 00:19

I was not expecting this Cole Parmer item till mid January but they surprised me.

The brass assembly consists of six pipe fittings screwed together:

A CGA320 hex nut and 2 inch long double ended 1/8 MNPT nippe with a sealing washer and a hex nut to retain the CGA nutscrewed into a 45 degree elbow

and a reducer 1/8 NPTM x 3/8 NPTF end, mating to the "nozzle" which appears to be simply a 3/8 NPTM plug which has been drilled with a small hole to

pass the liquid CO2 from cylinder with a dip tube and valve. All off the shelf except for the hole in the "nozzle". Maybe $10 worth of ordinary

hardware.

The nozzle and a few washers retain a plastic cone which is where the PE collector bag attaches via a plastic ring and a very ordinary hose clamp. At

$150 someone is making a killing with this.

The nozzle hole I have not yet measured but I would guess 1/8 to 3/32 inch at most and I doubt this is critical.

I will report back after trying this out next week, time to order a couple cylinders of CO2 with dip tubes.

The fittings are all off the shelf except Swagelok does not seem to have the 45 degree elbows at all. Just 90 degrees.

I am sure other pipe fitting suppliers will have it.

I will see about making a bill of materials in case anyone wants to assemble one of these DIY and save a bundle.

I just ordered (from local supplier for immediate delivery) a 6Q cylinder of CO2 w/valve and dip tube for $175 (I then own the cylinder and valve,

refills are very cheap.)

A 1.5Q same would be $60

[Edited on 19-12-2008 by Sauron]

Sauron - 19-12-2008 at 05:26

I received the first 6 m3 liquid CO2 cylinder (48 liters) with brass CGA320 valve and safety cap today, I purchased the cylinder new (rather than

paying drayage) for $175 filled, locally, including required dip tube. Refills are very cheap, so the cyl and valve and Frigimat are one time costs.

I tested it, it works, well but noisily with a loud industrial shriek.

I am quite pleased and regard this on-demand system of dry ice flakes as far superior to buying slabs of dry ice which never get to slurriable form.

PlasLabs/Scienceware wants too much for this accessory, but I can list all the bits and pieces and anyone can put this together even if not

DIY-inclined. It's all off the shelf with very slight modifications. A welding supply, and any hardware store are all you need and some scrounging for

an appropriate plastic cone.

ou need

Assy 1

-- a CGA320 brass regulator cap and nipple, 1/4"

NPTM A hex nut is flush at one end of regulator nipple and a nylon sealing washer is used between valve outlet and regulator cap.A CGA320 sealing

gasket (washer)

Put those together and you have a nonrotating pipe nipple for CGA 320 valve

Assy 2

A 45 degree brass elbow 1/4 NPTF both faces.

A reducing adapter 1/4 NPTM x 3/8 NPTF brass

A 3/8 NPTM plug brass drilled through 1/8 inch

Put those together and you completed the pipe fittings

Plastic cone

This is a small plastic drinking glass drilled at base to be retained by the brass plug and a flat washer. Another flat washer is on inside. A snapon

ratchet wrench with extension socket will be hady tightening this up.

You will need appropriate bags to contain the dry ice flakes as formed and a hose clamp ortwo to retain them on cone.

The correct valve opening is THREE QUARTERS of A TURN no more no less. Some hapless jerk decided this meant three or four turns and ended up in

hospital with liquid CO2 burns all over him.

When not in use I remove the Frigimat and replace the cylinder cap which protects the valve in case of a fall. A cylinder stand is good idea, buy or

build one.

Photo below is CGA320 regulator cap and nipple including the required hex nut. Nylon washer not shown.

[Edited on 20-12-2008 by Sauron]

Blind Angel - 19-12-2008 at 11:46

I just got my first christmas gift from school today, a beautiful Mettler H54AR 160g d=0.01mg (that's 5 zero after the dot  ). Still need to make it work, it seem to have too much weight in the back part thus

it's always off limit, i'll work on that during the vacation.

). Still need to make it work, it seem to have too much weight in the back part thus

it's always off limit, i'll work on that during the vacation.

Sauron - 21-12-2008 at 21:04

I have the Swagelok part numbers for the reducing fitting, plug, and elbow if anyone wants them. In Thailand the Swagelock agent want 800 baht for

these 3 items all together ($24), Doubtless they are less in USA.

Swagelok does not sell the CGA320 regulator cap and regulator nipple w/hex nut and nylon washer, but these are easy to find from welding suppliers.

In fact I just called my gas shop and they have the correct cap, nipple and nylon washer in stock, price 200 baht (< $6 US).

While Swagelok quality is super, the rest of these fittings (plug, reducer, and elbow) are just hardware store brass gas pipe fittings and without a

doubt cheaper at such places than from Swagelok.

-------------------

This standard CGA320 regulator nut and nipple: nipple turns out to be 3/8 NPTM somewhat longer and beefier than the 1/4" NPTM of the Frigimat Jr. So,

I will replace the 1/4" NPT female elbow with a 3/8" NPT one, and the nozzle (plug with a 1/8" hole drilled through by me) can screw into that

directly, no reducer required. So my DIY "Frigimat Jr" clone will not look exactly same but it will work exactly same as the $150 original.

When I have it all together I will post a pic. It'll be a day or so while I get the Swagelok bits in.

[Edited on 22-12-2008 by Sauron]

[Edited on 22-12-2008 by Sauron]

(especially as organic is what I like best

(especially as organic is what I like best  ). Now for the difficult part...

). Now for the difficult part...

Heating mantles I intend on making myself, possibly a magnetic

stiffer also. ATX power supply needs some components to finish, and some sort of fumehood will be constructed (when I can find somewhere to set up

lab). So much to do and so little time to do it, uni work keeps me busy most of the time. Hopefully I can get ahead during the end of term holidays

Heating mantles I intend on making myself, possibly a magnetic

stiffer also. ATX power supply needs some components to finish, and some sort of fumehood will be constructed (when I can find somewhere to set up

lab). So much to do and so little time to do it, uni work keeps me busy most of the time. Hopefully I can get ahead during the end of term holidays

). Still need to make it work, it seem to have too much weight in the back part thus

it's always off limit, i'll work on that during the vacation.

). Still need to make it work, it seem to have too much weight in the back part thus

it's always off limit, i'll work on that during the vacation.